Professional Documents

Culture Documents

Technical Bulletins TB - Quick-Fill Tank Vents

Uploaded by

api-3752216Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Bulletins TB - Quick-Fill Tank Vents

Uploaded by

api-3752216Copyright:

Available Formats

Document Title: Technical Bulletin Revision No: 1

Description: Installation and Inspection Issue Date: 06/01

Guidelines for the AUS25

Quick-Fill Tank Vents

The objective of this technical bulletin is to detail key information on the correct

installation, operation and maintenance of the Banlaw Quick-Fill Tank Vent.

NOTE: Please refer to the dedicated Banlaw Pipeline vent brochure for part

numbers and other specific product information.

1. Key Advantages of the Banlaw Vent

The Banlaw vent has a number of key advantages over equivalent competitors

products i.e. the Wiggins ZV10. The Banlaw vent has:

• A ¾” bore breather tube – the ZV10 has only a ½” bore. This enables

a single Banlaw vent to be used at flowrates up to 800LPM (210GPM)

without appreciable tank pressurisation, whilst flowrates between 800

and 1100LPM require 2 vents per tank

• Splash tube to provide protection against excessive turbulence or

splashing affecting the correct operation and orientation of the float

balls.

• All parts of the vent are manufactured from high quality cast

aluminium, machined aluminium, and zinc plated mild steel – selected

vent models

• All Banlaw vents incorporate o’ring seals, thus providing an extended

and a more reliable service life. Other manufacturers use flat “gasket”

style seals, prone to leakage and premature failure

• Banlaw manufacture a wide range of standard vent models to cater for

most tank designs and applications, including CAT and Komatsu

manual fill necks. Banlaw also offer custom designed vents to suit

unique installations

• Banlaw vents are available with a choice of 2 emergency relief

pressures; 110kPa (16psi) and 49kPa (7psi), to suit a variety of tank

designs. The relief setting of each vent is clearly identified by the

colour of the anodised aluminium vent cap; 49kPa (GREEN) and

110kPa (RED).

• A number of vent accessories are available to ensure the correct

installation of the vent is achieved easily

2. Function of the Quick-Fill Vent

The Quick-Fill tank vent was designed to be installed onto fuel and oil tanks fitted

with Dry-Break (or quick-fill) pressurised refuelling equipment. Its primary

functions are to:

1. exhaust air from the tank during normal filling, whilst creating minimal

back-pressure and thus tank pressurisation during filling

Banlaw Pipeline Technical Bulletin 1

02/01

2. provide an air-tight seal within the tank once the fuel level has reached the

required level, thus creating pressurisation of the tank and upstream

delivery line in order to cause the refuelling nozzle to terminate the flow of

fuel into the tank

3. gradually allow the tank pressure to return to atmospheric pressure, by

passage of air through the 1/16” bleed hole

4. the emergency relief facility provides protection against overpressurisation

of the tank due to excess vapour pressure

NOTE: A Banlaw quick-fill tank vent is designed only as a partial relief device for

the range of flowrates used. It is designed to exhaust excess vapour pressure

from the tank, due to thermal expansion or otherwise. If required to exhaust

liquid fuel, the pressure within the tank will increase substantially . A full relief

device must be installed if comprehensive protection is required i.e. exhausting of

liquid fuel without a substantial rise in tank pressure. The Banlaw vent will begin

to open at the stated relief pressure, and will remain open until the tank pressure

decreases to a level below the vent relief pressure.

Options available with the vent include:

• a ¾” male nipple threaded into the vent exhaust port. This enables a

breather hose to be attached and thus route the discharge of tank

vapour to a safe or more convenient location = see also Section 5.2

• a 2” NPT female socket (or half coupling) which can be welded into the

tank top plate to securely locate the vent

• a vent box, so that the vent can be mounted on the side wall of a tank,

in instances where insufficient space exists on the top surface of the

tank, or when ready access to the vent is required

• a small Ryco air filter cartridge with a serviceable filter element, which

conveniently screws into the vent exhaust port. This filter prevents the

ingress of dust and other contamination into the vent and thus tank

through the otherwise open vent exhaust

3. Components of the Banlaw Vent

Figure 3.1 below details the components and essential features of the vent. Note

the 1/16” breather hole in the top flange of the valve.

Banlaw Pipeline Technical Bulletin 2

02/01

Figure 3.1: Components of the Banlaw Quick-Fill Vent

The vent is fully assembled and tested at the Banlaw factory prior to sale. As with

all Banlaw products, each vent is covered by a 3 month manufacturers’ warranty

and is manufactured in accordance with Banlaw Pipeline company Quality

Assurance procedures, accredited by Lloyd’s Register of Quality Assurance

Australia (AS/NZS ISO 9001-1994).

4. Application of the Banlaw Vent

The vent is designed to accompany the Banlaw (or equivalent) refuelling nozzle

and the Banlaw (or equivalent) dry-break fuel receiver. The vents primary function

is to support the operation of the quick-fill refuelling system. It is distinct from

traditional “free-to-air vents” and other vent designs, and thus cannot be replaced

with other vent types or used for other purposes outside the scope of this

document without the express permission of Banlaw Pipeline. It can only be

classed as a “free-to-air” vent whilst ever the fuel level and thus float balls remain

at a low level so as to ensure the free passage of air through the vent valve. If the

fuel is at such a level so as to raise the float balls against the o’ring seal at the

base of the vent valve, thus effectively sealing the tank, the only unrestricted

passage of air from or into the tank will pass through the 1/16” bleed hole in the

top flange of the valve. This is to ensure any further filling of the tank is

discouraged by the resistance of air through the vent bleed hole and thus

pressurisation of the tank contents.

If additional fuel is forced into the tank i.e. if the automatic shut-off of the nozzle

is manually over-ridden, the emergency relief facility of the vent may be activated.

Sustained filling of the tank and thus relief of excess vapour will eventually

eliminate the ullage within the tank and hence cause overfilling. Once the ullage

in the vicinity of the vent has been eliminated, the vent will be forced to exhaust

liquid fuel. As mentioned earlier, such a task will increase the pressurisation of

the tank substantially creating the risk of tank rupture or some other catastrophic

failure.

Banlaw Pipeline Technical Bulletin 3

02/01

If in any doubt, contact your nearest authorised Banlaw distributor or Banlaw

Pipeline direct for confirmation of the correct vent application, prior to

installation.

5. Correct Installation Guidelines

The correct installation of the tank vent is crucial to the proper operation of the

Banlaw refuelling system. Incorrect or otherwise poor installation practice will

jeopardise the safety and reliability of the system. The Banlaw Quick-Fill refuelling

system is a “pressurised” system, and thus its inherent safety relies on the

installation being in accordance with the manufacturers’ guidelines.

Following are guidelines on the correct location and installation of the vent within

a tank.

NB: Refer also to Banlaw technical bulletins on multi-compartment tanks and

dual tank configurations for additional vent installation information.

5.1 Positioning the Vent in the Tank

The correct location of the vent can best be determined by considering the factors

affecting the vents operation:

a) Action of float balls: once the fluid level within the tank reaches a level

approximately equal with the second vent float ball (from the top), the

buoyancy force generated by the 3 hollow float balls force the solid ball

upwards onto the o-ring seal at the base of the vent valve. This effectively

seals the vent and thus subsequent flow of fuel into the tank will pressurise

the tanks’ contents. The solid ball remains against the seal whilst ever the

fluid level remains above a level approximately equal to that of the second

ball. Whilst the vent valve is sealed, air or fuel can only bypass the valve in 2

ways:

• Through the 1/16” breather hole

• Activating the emergency relief function of the vent, by overcoming the

force provided by the relief spring and thus lifting the valve flange from

its sealed “home” position. This will occur at any time the pressure

within the tank exceeds the emergency relief pressure of the vent.

b) generation of tank ullage: the tank ullage is the volume within the top of the

tank occupied by air/vapour. Whilst the value does vary, it is generally

required to maintain an ullage of 3-5% of the tank volume to account for

thermal expansion and the difference in time taken to both pressurise the

tank and create sufficient back pressure to close the refuelling nozzle. Due to

the standard range of quick-fill vents available and the vast array of tank

designs, delivery systems, flowrates etc., the proportion of ullage will vary.

The standard length of vent available does cater for the majority of tank

designs, although end-users must be aware that ullage will vary. Selection of

the correct vent model for an application is important if the required ullage is

to be maintained.

c) ullage and it’s role in the quick-fill system: as mentioned in point (b), the

generation of ullage depends upon the fluid level at which the vent closes, the

Banlaw Pipeline Technical Bulletin 4

02/01

rate at which that level is rising, and the amount of back pressure required to

turn the nozzle off – see Technical Bulletin on Quick-Fill Nozzle Theory. If

these factors are too high, the risk of overfilling the tank is a real threat. Such

a problem leads to leakage from the vent – even after the nozzle has shut-off

– and the rapid overpressurisation of the tank due to the elimination of the

compressible air “cushion” normally within the ullage. The overpressurisation

of the tank is partially compensated for by the release of excess pressure

through the vent’s emergency relief facility, although forcing liquid fuel –

rather than air – through the vent relief requires significantly more force,

which must be provided by the rapid pressurisation of the tank. ELIMINATION

OF ULLAGE CAN CAUSE TANK RUPTURE OR OTHER SIGNIFICANT

DAMAGE. To minimise this risk, a number of key points needs to be

considered:

1. the position of the vent with respect to the highest point of the tank

volume is critical – many examples are shown in the following

drawings. In essence, some ullage must be maintained in the region

surrounding the vent. Allowing the fuel level reach the underside of the

vent body (top of the vent valve) will cause leakage from the vent bleed

hole and perhaps exhausting of fuel from the emergency relief valve.

To minimise this risk, the vent should be installed in the uppermost

section of the tank – see also point 3

2. ensure all manual fill caps, flanges, threaded fittings, and all other

fittings either mounted on the tank or hydraulically linked with the

tank, are air-tight. ANY SUCH LEAKS WILL DELAY THE

PRESSURISATION OF THE TANK AND HENCE DELAY THE SHUT-OFF

OF THE NOZZLE. Such faults will cause overfilling of the tank and

perhaps leakage of fuel from either the vent breather hole or relief

valve. NB: this also includes fuel supply or return lines from the

engine(s) linked to the fuel tank. In extreme circumstances, the engine

fuel circuit may delay the pressurisation of the tank due to fuel

bypassing the diesel pump etc. Low flowrates and high levels of tank

pressurisation further exacerbate this problem. Evidence of this

problem occurring is the engine revving or flooding once the tank

becomes pressurised.

NOTE: Banlaw manufacture a ¾” ball check valve which can be installed in the

fuel return line from the engine. This will prevent the pressurisation of the tank

forcing fuel back through the return line.

3. There is an inherent time delay between the vent closing and the

nozzle turning off. If the rate of fuel level increase surrounding the vent

is high (high ratio of flowrate : fluid surface area), then the level at

which the vent closes relative to the top surface of the tank is critical to

ensure ullage is maintained. Such examples are cylindrical tanks and

tall, narrow tank designs, Also, installing a vent into a manual fill tube

rising from the top of the tank will certainly cause problems. NB: The

vent may be installed in a manual fill tube provided the top of the tube

does not rise above the top of the tank – see Figure 5.6. For

applications such as tall narrow tanks and cylindrical tanks, Banlaw do

manufacture vents with an extended vent valve to ensure the

premature closing of the vent does maintain the correct tank ullage.

Banlaw Pipeline Technical Bulletin 5

02/01

Detailed below are various tank designs. Shown also are the correct and incorrect

locations for the installation of the Banlaw vent.

IMPORTANT: Each Figure is accompanied by text explaining the relationship

between the tank design and corresponding vent placement. The critical factors of

each application are mentioned, in addition to any comments regarding

limitations or restrictions for each case. It is important this text is read

carefully, as minor variations to tank design from that shown in an example

can alter the correct placement of the vent. To confirm the correct installation

of the vent prior to installation, contact your nearest authorised Banlaw

distributor or Banlaw Pipeline direct for assistance.

Figure 5.1: Bi-level Tank (1)

Figure 5.1 shows a tank design commonly used in vehicles where the fuel tank is

located beneath the engine. The scale of the tank may vary, but generally the

correct and incorrect vent locations shown do apply. The only exception to this is

when the width (and hence volume) of the upper region(s) at each side of the tank

are relatively insignificant compared to the width of the lower (central) level. Such

circumstances permit the installation of the vent onto the lower level, provided

the key points of this document are considered. NOTE: If minor spillage is

detected from the vent bleed hole at the completion of refuelling, an extended

series vent may be installed to create earlier vent shut-off and thus a slightly

reduced fuel level within the tank. Again, this will depend upon the relationship

between the volume differential between the upper and lower regions. Comments

on both Figures 5.2 and 5.4 should also be considered.

The purpose of the hose linking both upper regions of the tank is to equalise the

ullage pressure and thus fluid level between each region during pressurisation of

the tank after the vent has closed. This will become of increasing importance at

high flowrates and high levels of tank pressurisation.

Banlaw Pipeline Technical Bulletin 6

02/01

Figure 5.2: Bi-level Tank (2)

Figure 5.2 illustrates a similar point to that described in Figure 5.1, and

subsequently carries the same precautions. Most importantly, the rate of fuel

level increase surrounding the vent must not be excessively high such that the

rate of tank pressurisation is rapid. Such events will lead to overfilling of the tank

and subsequent spillage of fuel from the vent bleed hole or relief valve if the tank

is overpressurised prior to nozzle shut-off.

Figure 5.3: Cylindrical Tanks

Banlaw manufacture a vent specifically for cylindrical tanks, or other tanks where

the rate of fuel level increase at the vent is high – see also Figure 5.4 below.

Banlaw Pipeline Technical Bulletin 7

02/01

Figure 5.4: Tall Narrow Tank Designs

The purpose of the extended vent is to create an otherwise premature closure of

the vent and hence pressurisation of the tank contents. Such a need exists in

cylindrical tanks (Fig. 5.3), thin narrow tanks (Fig. 5.4), or other applications

where the standard length of vent is insufficient to create the correct tank ullage.

In essence, a rapid rate of fuel level increase in the upper region of the tank – in

which the vent is installed – will reduce the length of time between vent closure

and elimination of tank ullage (overfilling). This time is increased to that required

by extending the length of the vent valve and thus causing the vent to close

earlier. Sufficient ullage is created at the completion of refuelling, which would

otherwise not have been possible.

Figure 5.5: Short / Wide Tanks and the Effect of Gradient

Banlaw Pipeline Technical Bulletin 8

02/01

Figure 5.5 demonstrates an application typically encountered with lighting plants,

drilling rigs, and dewatering pumps. Wide tanks are particularly susceptible to

changes in gradient (slope) adversely affecting the quick-fill system.

Figure 5.5B will cause spillage from the vent, as the vent will close prematurely

and the relatively high percentage of ullage will take a longer period of time to

pressurise. By the time sufficient back pressure has been generated and thus

forced the nozzle into the off position, fuel has already begun to leak from the

vent breather hole.

The success of the situation depicted in Figure 5.5C depends upon the same

considerations given to cylindrical and tall, narrow tanks. The vent will not close

until the fluid level has reached the float balls, which in this situation is after what

would normally be the case with the tank level i.e. Figure 5.5A. Thus the tank will

be overfilled, and spillage may occur from the vent if the ullage is eliminated.

Locating the vent in the middle of the tank may negate the effect of gradient to

some extent, although the objective remains to maintain the tank in a level

position whilst refuelling.

Figure 5.6: Manual Fill Pipes

The installation of a quick-fill vent into the manual fill pipe of a tank is a

convenient option. The function of the vent and thus the quick-fill system will not

be adversely affected provided a simple factor is considered. When installing the

vent into the pipe, care must be taken to ensure the level of the float balls, with

respect to the main volume of the tank, is approximately the same as if the vent

was installed directly into the tank itself. To achieve this Figure 5.6A incorporates

the use of an extended vent valve, whilst Figure 5.6B illustrates a truncated

(shortened) fill pipe and a standard length vent. Either installation will work,

although for the purposes of simplicity, option B is preferred if space permits. NB:

Note the downward facing vent exhaust port to minimise the ingress of dust and

other foreign material into the vent cap.

Banlaw Pipeline Technical Bulletin 9

02/01

5.2 Routing the Discharge of Vent Exhaust

Regardless of where the vent is installed, care must be taken to ensure the

discharge of tank vapour – and liquid fuel in the case of a problem – is directed

away from heat and other ignition sources, and humans. Such a task is made

easier by the attachment of a breather tube onto the exhaust port to allow

routing of the discharge point to a convenient and safe location. Such a location

should also be clearly visible to the refuelling operator to ensure prompt

termination of fuel flow if the discharge of fuel is detected.

A length of breather hose or tube may be attached to the vent exhaust port using

either the optional ¾” male hosetail fitting, or directly over the 33mm diameter

“olive” at the end of the port. Ideally 1” hose should be used for longer distances,

and a minimum of ¾” hose for shorter distances. NB: For flowrates in excess of

say 600LPM per vent, a minimum of 1” hose is recommended to minimise the

restriction of air flow from the tank.

The free and unrestricted passage of air through the vent and the vent breather

hose (if attached) is critical to the proper operation of the quick-fill system. Any

excessive or abnormal restriction is analogous to the partial sealing of the vent

and hence partial pressurisation of the tank. Such pressurisation, although

appearing minimal, may be sufficient to cause premature shut-off of the

refuelling nozzle, thus only partial filling of the tank . Such restriction often

comes from dirt and mud built up in the end of the vent exhaust / breather hose,

commonly found on rail locomotives and mining vehicles where the breather hose

terminates behind a bogey or wheel. Other sources include kinks, small diameter

hose, and blocked filters (if fitted).

6. Vent Maintenance

The Banlaw vent is virtually maintenance free. The only regular maintenance an

end-user should perform is the inspection and clearing of the vent exhaust port or

breather hose – see section 5.2, and a general inspection to detect any damage

to the vent. To do this, the vent may be removed from the tank during prescribed

vehicle servicing and inspected for any noticeable defects, in particular damage to

the o’ring seal at the base of the vent valve, and the ingress of liquid fuel into any

of the hollow float balls. If these defects are detected, the vent must be replaced.

Removing the vent for inspection may only be necessary if a refuelling problem

associated with the vent is suspected – see section 7.

Based on market research recently conducted, Banlaw have derived a

“preventative maintenance plan” for its refuelling equipment. For the quick-fill

vent, it is recommended the vent be replaced every 3-4 years for mining use, and

every 5-6 years for railway use. These figures represent the recommended

exchange period, and will obviously vary according to the nature of the operating

environment.

Banlaw Pipeline Technical Bulletin 10

02/01

7. Troubleshooting

This section is designed to assist the end-user in identifying and rectifying

common problems associated with the Banlaw vent – in particular leakage of fuel

from the vent breather.

Most problems associated with quick-fill refuelling are incorrectly attributed to

the nozzle. Such problems as leakage from the vent exhaust are blamed on the

nozzle failing to shut-off at the correct pressure. Although in some cases the

nozzle is at fault, the majority of the time the cause of the problem is tank

related. For example, overfilling of the tank and subsequent leakage from the

vent breather is usually due to either incorrect vent placement or air leaks in the

tank i.e. welds, tank flanges, manual fill caps or threaded fittings, delaying the

pressurisation of the tank and subsequent nozzle shut-off. Such delays in nozzle

shut-off can also lead to rapid overpressurisation of the tank and subsequent

venting of vapour or liquid fuel through the emergency relief valve in the vent.

Performing a few simple checks may resolve the problem of a leaking vent

1. Check for diesel and air leaks in the tank and associated fittings

(particularly manual fill caps) – this is best done during tank

pressurisation prior to nozzle shut-off. Rectify any leaks found.

2. If the vent was installed by someone other than the OEM, an

authorised Banlaw agent or Banlaw Pipeline itself, confirm the vent is

installed in the correct location, as per section 5.1– consult Banlaw

Pipeline or an authorised distributor for assistance

NOTE: Refer also to Banlaw technical bulletins on multi-compartment tanks and

dual tank configurations for further information on those applications.

3. If manufacturing or modifying a tank, confirm the changes with Banlaw

prior to commencing work to ensure the quick-fill system will operate

correctly

4. Confirm the vent does effectively seal the tank prior to nozzle shut-off.

This is best done by placing your hand over the vent exhaust port or

breather and detecting the exhaust air from the tank whilst refuelling.

Once the fuel level has reached the required level, the float balls

should seal the vent thus terminating the flow of exhaust air. Once the

vent has sealed, a slight hissing sound will be heard indicating the

pressurisation of the tank and subsequent discharge of pressurised air

through the 1/16” vent breather hole. The nozzle should shut-off within

approximately 5-10 seconds after the vent has sealed – this value may

vary according to tank volume, flowrate, and the spring setting of the

nozzle. At no stage either prior to or after nozzle shut-off should

any leakage be detected from the vent

NOTE: If the nozzle fails to remain in the open (on) position until the tank is

pressurised by the sealing of the vent valve, check for excessive flow restriction in

the fuel delivery line between the fuel receiver and the tank i.e. partially closed

valve or a recently installed check valve etc. If no cause can be detected, Banlaw

Banlaw Pipeline Technical Bulletin 11

02/01

Pipeline or your nearest authorised Banlaw distributor agent should be informed

promptly and the details of the refuelling application explained.

NOTE: For information on the Banlaw refuelling nozzle, refer to the relevant

technical bulletin

5. Confirm the flowrate of fuel is within the range recommended for the

refuelling nozzle:

• Banlaw 21 and 800 series nozzles: 170-800LPM (45-210GPM)

• Banlaw 22 and 1000 series nozzles: 400-1000LPM (105-265GPM)

6. Confirm the recommended number of vents is installed on the tank:

• 80-200LPM (21-53GPM): single vent recommended

• 200-800LPM (53-210GPM): single vent recommended (4 max.)

• 800-1000LPM (210-265GPM): 2 vents recommended (4 max.)

NOTES: 1. The maximum number quoted in brackets should not be required,

unless either minimal (near zero) tank pressurisation is permitted

during refuelling, or the tank compartments / baffling has been

incorrectly designed – refer to technical bulletin on multi-compartment

tanks

2. These recommendations apply to Banlaw quick-fill vents only

Contact your nearest authorised Banlaw distributor or Banlaw Pipeline direct

should problems persist.

8 The Banlaw FillSafe System

The Banlaw FillSafe System is an electronic level sensing system, used in

applications where zero tank pressure is required. Once installed, FillSafe

becomes the primary system responsible for termination of fuel flow into the tank.

The refuelling equipment used is identical to that used in the standard Banlaw

refuelling system – the FillSafe equipment complements existing refuelling

equipment. In the vent of a failure to the FillSafe system, or if the system is

overridden, the tank will be pressurised thus causing the nozzle to shut-off as

would normally occur.

The FillSafe System has three key components:

• Float switch installed into tank (optic sensor or other switch types are

optional)

• Transmitter unit installed on vehicle

• Receiver unit installed at refuelling depot

To terminate fuel flow, the receiver unit may be connected to an in-line solenoid

valve or the pump control relay.

Additional information is available from the Banlaw Pipeline webpage

(www.banlaw.com) or from Banlaw Pipeline direct.

Banlaw Pipeline Technical Bulletin 12

02/01

Kind Regards

Adam Peattie

Product & Design Engineer

BANLAW PIPELINE Pty Ltd

Email: adam@banlaw.com.au

Disclaimer: The information supplied in this document is meant as a guide only.

Banlaw Pipeline Pty Ltd accepts no liability for any damage or event resulting

from the implementation of any content of this document. To confirm the correct

advice has been received, all details should be checked with an authorised Banlaw

distributor or Banlaw Pipeline direct prior to installation.

Banlaw Pipeline Technical Bulletin 13

02/01

You might also like

- PhoneList (FirstName)Document35 pagesPhoneList (FirstName)api-3752216100% (3)

- Technical Bulletins TB - Nozzle Shut-Off MechanismDocument4 pagesTechnical Bulletins TB - Nozzle Shut-Off Mechanismapi-3752216No ratings yet

- Wiggins Vents Info Wiggins VentsDocument2 pagesWiggins Vents Info Wiggins Ventsapi-3752216No ratings yet

- Technical Bulletins TB - Dual Tanks 0300Document4 pagesTechnical Bulletins TB - Dual Tanks 0300api-3752216No ratings yet

- Technical Bulletins TB - Fluid Theory 0400Document8 pagesTechnical Bulletins TB - Fluid Theory 0400api-3752216No ratings yet

- Technical Bulletins TB - Quick-Fill Tank VentsDocument13 pagesTechnical Bulletins TB - Quick-Fill Tank Ventsapi-3752216No ratings yet

- Technical Bulletins TB - Multi Compartment Tanks 0300Document4 pagesTechnical Bulletins TB - Multi Compartment Tanks 0300api-3752216No ratings yet

- Technical Bulletins TB - 800LPM Installation Advice 0601Document5 pagesTechnical Bulletins TB - 800LPM Installation Advice 0601api-3752216No ratings yet

- Oil Sampling Valve Oil Sampling Valve0001Document1 pageOil Sampling Valve Oil Sampling Valve0001api-3752216No ratings yet

- Bam 800 T004 - Nozzle Flow Testing GuidelinesDocument11 pagesBam 800 T004 - Nozzle Flow Testing Guidelinesapi-3752216100% (1)

- Technical Bulletins TB - 800LPM Installation AdviceDocument4 pagesTechnical Bulletins TB - 800LPM Installation Adviceapi-3752216No ratings yet

- Risk Analysis Refueling Nozzles RA Refuelling Nozzles - Generic Rev3Document39 pagesRisk Analysis Refueling Nozzles RA Refuelling Nozzles - Generic Rev3api-3752216100% (1)

- Bam 800 T001 - Air TestDocument2 pagesBam 800 T001 - Air Testapi-3752216No ratings yet

- Technical Bulletins TB - 1000LPM Installation Advice 0601 - 1Document5 pagesTechnical Bulletins TB - 1000LPM Installation Advice 0601 - 1api-3752216No ratings yet

- Technical Bulletins Hydrostatic Pressure & Flow Test Results Rev3Document1 pageTechnical Bulletins Hydrostatic Pressure & Flow Test Results Rev3api-3752216No ratings yet

- Banlaw Sales Brochures Filtered VentDocument2 pagesBanlaw Sales Brochures Filtered Ventapi-3752216No ratings yet

- Scully Systems - Scully Systems Electronic Tank Truck Equipment - Files Banlaw FillSafeTM Electronic Overfill Protection SystemDocument3 pagesScully Systems - Scully Systems Electronic Tank Truck Equipment - Files Banlaw FillSafeTM Electronic Overfill Protection Systemapi-3752216100% (1)

- Installation Guidelines Installation Guidlines On The Installation of 800LPM Refueling SystemDocument1 pageInstallation Guidelines Installation Guidlines On The Installation of 800LPM Refueling Systemapi-3752216No ratings yet

- Fast Fill Couplers LubeCentralhfcouplingsDocument2 pagesFast Fill Couplers LubeCentralhfcouplingsapi-3752216No ratings yet

- Fuel Trial Results Fuel TrialsDocument2 pagesFuel Trial Results Fuel Trialsapi-3752216No ratings yet

- Installation Guidelines Installation and Inspection Guidlines For The AUS 25A Quick Fill VentsDocument1 pageInstallation Guidelines Installation and Inspection Guidlines For The AUS 25A Quick Fill Ventsapi-3752216No ratings yet

- Fast Fill Couplers Flush Face Flyer - PDDocument2 pagesFast Fill Couplers Flush Face Flyer - PDapi-3752216No ratings yet

- Scully Systems - Scully Systems Electronic Tank Truck Equipment - Files Banlaw FillSafeTM Electronic Overfill Protection SystemDocument3 pagesScully Systems - Scully Systems Electronic Tank Truck Equipment - Files Banlaw FillSafeTM Electronic Overfill Protection Systemapi-3752216100% (1)

- Filtered Vents FilteredVentDocument2 pagesFiltered Vents FilteredVentapi-3752216No ratings yet

- Fill Safe General Operating Instructions 08-05Document1 pageFill Safe General Operating Instructions 08-05api-3752216No ratings yet

- Banlaw Sales Brochures FillSafeDocument2 pagesBanlaw Sales Brochures FillSafeapi-3752216No ratings yet

- Fast Fill Couplers NEW FJ Broch PG 12Document1 pageFast Fill Couplers NEW FJ Broch PG 12api-3752216No ratings yet

- Fast Fill Couplers FF Coupling Price List-06Document1 pageFast Fill Couplers FF Coupling Price List-06api-3752216No ratings yet

- Fast Fill Couplers LC Hi-Flow FlyerDocument3 pagesFast Fill Couplers LC Hi-Flow Flyerapi-3752216No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Risk Management Report SummaryDocument61 pagesRisk Management Report SummaryIamCcj100% (1)

- Cement Evaluation CAST-CBL HalliburtonDocument36 pagesCement Evaluation CAST-CBL HalliburtonrezaNo ratings yet

- Vastra Grah .Pvt. LTD: In-House Manufacturing FacaltyDocument2 pagesVastra Grah .Pvt. LTD: In-House Manufacturing FacaltySaurabh JainNo ratings yet

- Temporomandibular Joint SyndromeDocument11 pagesTemporomandibular Joint SyndromeRahma RahmaNo ratings yet

- Jeffrey Ansloos - Indigenous Peoples and Professional Training in Psychology in CanadaDocument17 pagesJeffrey Ansloos - Indigenous Peoples and Professional Training in Psychology in CanadaleoNo ratings yet

- Recombinant DNA TechnologyDocument14 pagesRecombinant DNA TechnologyAnshika SinghNo ratings yet

- Limetas Maximos ResidualesDocument27 pagesLimetas Maximos ResidualesXjoelx Olaya GonzalesNo ratings yet

- Vacuum Conveyin 5.0Document56 pagesVacuum Conveyin 5.0Mostafa AtwaNo ratings yet

- Plant Cell Culture: Genetic Information and Cellular MachineryDocument18 pagesPlant Cell Culture: Genetic Information and Cellular MachineryYudikaNo ratings yet

- Diploma Pharmacy First Year - Hap - MCQSDocument13 pagesDiploma Pharmacy First Year - Hap - MCQSAnitha Mary Dambale91% (33)

- 670W Bifacial Mono PERC ModuleDocument2 pages670W Bifacial Mono PERC Modulemabrouk adouaneNo ratings yet

- VentilationDocument92 pagesVentilationRobert Nixon100% (1)

- Milovanovic 2017Document47 pagesMilovanovic 2017Ali AloNo ratings yet

- Age Discrimination PDFDocument20 pagesAge Discrimination PDFMd. Rezoan ShoranNo ratings yet

- Guide To Admissions 2024-25Document159 pagesGuide To Admissions 2024-25imayushx.inNo ratings yet

- 4-Week Weight Loss ChallengeDocument6 pages4-Week Weight Loss ChallengeTammy JacksonNo ratings yet

- Chin Cup Therapy An Effective Tool For The Correction of Class III Malocclusion in Mixed and Late Deciduous DentitionsDocument6 pagesChin Cup Therapy An Effective Tool For The Correction of Class III Malocclusion in Mixed and Late Deciduous Dentitionschic organizerNo ratings yet

- Causes of Failure of Earth DamsDocument11 pagesCauses of Failure of Earth DamsThéoneste NSANZIMFURANo ratings yet

- Myofascial Release for Piriformis MyalgiaDocument14 pagesMyofascial Release for Piriformis MyalgiaApoorvNo ratings yet

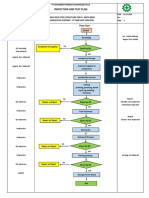

- Inspection and Test Plan: Flow Chart Start IncomingDocument1 pageInspection and Test Plan: Flow Chart Start IncomingSinden AyuNo ratings yet

- Catalogo Unidad Enfriadora Trane R-407C PDFDocument8 pagesCatalogo Unidad Enfriadora Trane R-407C PDFJUAN FRANCISCO AYALANo ratings yet

- D Formation Damage StimCADE FDADocument30 pagesD Formation Damage StimCADE FDAEmmanuel EkwohNo ratings yet

- Human Diseases A Systemic Approach 8th Edition-Páginas-15-26Document12 pagesHuman Diseases A Systemic Approach 8th Edition-Páginas-15-26Karime LopezNo ratings yet

- Kuan Yin 100 Divine Lots InterpretationDocument30 pagesKuan Yin 100 Divine Lots InterpretationEsperanza Theiss100% (2)

- Delta C200 Series AC Drives PDFDocument5 pagesDelta C200 Series AC Drives PDFspNo ratings yet

- Class9. CVD and PVDDocument30 pagesClass9. CVD and PVDiraNo ratings yet

- Bibie Evana OsmanDocument6 pagesBibie Evana OsmanStabat Jaya TrademarkNo ratings yet

- Kloos Community Psychology Book FlyerDocument2 pagesKloos Community Psychology Book FlyerRiska MirantiNo ratings yet

- Heat Transfer Augmentation in Decaying Turbulent Swirl FlowDocument1 pageHeat Transfer Augmentation in Decaying Turbulent Swirl FlowOnkar ChavanNo ratings yet

- 01 01Document232 pages01 01Muhammad Al-MshariNo ratings yet