Professional Documents

Culture Documents

APS Drill Press

Uploaded by

VinjkCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APS Drill Press

Uploaded by

VinjkCopyright:

Available Formats

Advanced Photon Source

Drill Press Study Guide P.1

Drill Press (Upright Drilling Machine)

This study guide will cover the major working parts, functions, and machining techniques that can be found/used on most Drill Presses (Upright Drilling Machine) This study guide has been designed to directly represent the questions that will be found on the open book written assessment and as an aid for the hands-on usability assessment. Both assessments will also include questions related to standard machine shop safety and APS internal user safety guidelines. Answering the questions found at the end of the study guide will enable the user to successfully pass the hands-on usability and written assessments. Study guide practice test and answers can be found at the end of the guide. The Drill Press is one of the most frequently used machine tools. They are used mainly for drilling holes but reaming, countersinking, and boring can also be accomplished with the drill press. Most machine shops are equipped with at least one pedestal-type drill press. These machines are used to drill holes in wood, plastic, aluminum, brass, steel, and most other common engineering materials. Injuries on this equipment generally arise from careless operation by users who fail to take the time to clamp their work to the table or who try to hold the drill press vise in one hand while advancing the spindle in the other. Be sure to clamp your work securely before drilling. Another common injury results from broken cutting tools. When a drill begins to emerge from the bottom of the work piece on through-holes, the feed rate needs to be reduced in order to prevent the drill flutes from biting too aggressively into the work. This action sometimes causes cutting tool breakage. Reduce the feed force and let the drill advance slowly.

Machine Guarding required suggest using a magnetic backed safety shield as a minimum. Secure the work piece by clamping it to the table or holding it in a vise. Clear the table of unnecessary clutter. Wear safety glasses. Do not wear gloves while drilling. Constrain long hair (wear a hat). Constrain loose clothing (roll up your sleeves). When the tool is about to break through, ease up on the feed force.. Remove chip fragments only when the machine spindle is stopped. Never remove long stringy chips with your bare hands.

JG 2005

Advanced Photon Source

Drill Press Study Guide P.2

On/Off Switch Power Range

THE CONTROLS POWER/RANGE This switch has three positions, high range, low range and off. Low range is used when larger holes or harder materials need to be machined while high range is useful when small holes and softer materials are being drilled. Some machines may have separate switches for power and range, or only one range, as the second picture shows. SPINDLE SPEED Both the high range and low range spindle speeds are changed using this control. The speeds should only be changed while the motor is running.

JG 2005

Advanced Photon Source

Drill Press Study Guide P. 3 FEED LEVER The Feed Lever is used to raise and lower the spindle.

USING THE DRILL PRESS Parts being machined with the drill press must either be in a vise or clamped to the table. A piece of plywood must be used under parts that are clamped to the table. This prevents drilling into the tabletop. After a part is secured it must be aligned under the spindle. The part should have all lines and points laid out with a scribe or punch before moving onto any machining, this will help align the spindle to the proper locations on the part.

JG 2005

Advanced Photon Source

Drill Press Study Guide P. 4

The following steps can be used as a guideline for drilling a hole in metal or plastic: Step 1: Drill a center drill hole to start the hole. Note: The center drill should leave an opening big enough to give the first drill a place to start cutting. Step 2: As a rule you should always start with a 1/8th" drill and increase the drill size by 1/8th" increments until the required drill size is approached. Step 3: Use the final drill size. Note: If a hole must be an exact size at finish then a reamer must be used. A hole approximately 1/64th" smaller then the size desired should be drilled before finishing the hole with a reamer. If these precautions are used the drills will last longer and there is less of a chance that a mistake will be made. Starting holes with small drills can also help avoid breaking the drill off inside your part or cracking Plexiglas parts. The speed of the drill is also inversely proportional to the size of the drill, so small drills require a high spindle speed and as the size of the drill increases the speed of the drill press should be decreased. Special drilling application: One last note should be made about drilling thin materials, plexi-glass or soft metals. A brand new drill is not always better when cutting plexi-glass or soft metals because it tends to bite into it and may pull it out of the vise. There are special drills that are dulled on the cutting edge in order to avoid this problem.

JG 2005

Advanced Photon Source

Drill Press Study Guide P. 5 Practice Test The following questions have been designed to directly represent the questions that will be found on the individual user written assessments and can be used as an aid for the hands-on usability assessments.

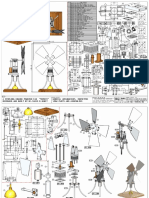

Identify the parts of a Drill Press

1. _____ Power Range switch On/Off switch 2. _____ Table 3. _____ Vice 4. _____ Spindle Speed 5. ______ Feed Lever 6. ______ Depth Gage 7. ______ Spindle 8. ______ Drill Chuck

A B H C

G F E D

9. Always secure the work piece by clamping it to the table or holding it in a vise. True False

10. Maintain constant awareness of activity in surrounding area. True False

11. A drill press is a power-driven machine used to drill, counter-bore and counter-sink holes.

JG 2005

Advanced Photon Source

True

False

Drill Press Study Guide P.6

12. Counter-boring is done to prepare a drilled hole to receive a fillister or socket-head screw. True False

13. Spot facing is machining a surface to permit a nut or bolt head to bear uniformly (flat). True False

14. It is permissible to leave the chuck key in the chuck while drilling a hole. True False

15. When drilling a hole on a drill press it is OK to stop the drill chuck with your hands to make the job go faster. True False

16. Most drill bits have their size stamped or written on the shank of the drill. True False

17. Serious injury can result from a work piece that becomes loose and spins during a drilling operation in a drill press. True False

18. What is the name of the tool used to remove the drill chuck from the spindle of the drill press? A. Chuck Key B. Chisel C. Drift Pin D. You un-screw it 19. The prick punch is used to mark where a hole is to be drilled. True False

20. Too slow a speed will cause the countersink to chatter. True False

21. Use only brushes, vacuums or special tools for machine clean up.

JG 2005

Advanced Photon Source

True

False

Drill Press Study Guide P. 7

22. The work piece should never be held in the hands while drilling. True True False False 23. Always use vices or clamps to hold work pieces while machining. 24. Serious injury can result from a work piece that becomes loose and spins during a drilling operation in a drill press. True True False False 25. It is permissible to leave the chuck key in the chuck while drilling a hole. 26. Be thoroughly familiar with the placement of the machines stop switch or lever. True False

27. A drill with a worn margin will: A. Drill holes oversize B. Drill holes undersize C. Run off center D. Drill an accurate hole 28. . A high-speed drill will never break. True True False False 29. . Brass and aluminum may be drilled faster than steel.

30. While drilling a hole, never hold work piece with your hands. True False 31. To pick up a hole for accurate drilling a center drill should be used first. True False

JG 2005

Advanced Photon Source

Drill Press

Study Guide Answer Sheet

1. H 2. D 3. E 4. A 5. C 6. B 7. G 8. F 9. True 10. True 11. True 12. True 13. True 14. False 15. False

16. True

17. True 18. C 19. True 20. True 21. True 22. True 23. True 24. True 25. False 26. True 27. B 28. False 29. True 30. True 31. True

JG 2005

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Gear Cutting FormulaeDocument30 pagesGear Cutting Formulaeqoolshabi80% (5)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- KCP Parts Catalog 2019Document9 pagesKCP Parts Catalog 2019Jaison McDonaldNo ratings yet

- ITCO Type Releasing SpearDocument20 pagesITCO Type Releasing SpearRazvan Radu80% (5)

- Air Compressor Piping DiagramDocument2 pagesAir Compressor Piping DiagramOrueta ClaudioNo ratings yet

- HSE Risk Assessment for Wire Rope ReplacementDocument4 pagesHSE Risk Assessment for Wire Rope ReplacementMohamed Elnagdy75% (4)

- Machine Design 1000 ProblemsDocument108 pagesMachine Design 1000 Problemsmaria katherine pantoja83% (6)

- NFPA 11 Tank Fire Protection ChartDocument1 pageNFPA 11 Tank Fire Protection ChartTjay NóniiNo ratings yet

- Example 3 - Bisection MethodDocument2 pagesExample 3 - Bisection MethodRyan IrfandiNo ratings yet

- Ready Solution 2018Document104 pagesReady Solution 2018Suthirak SumranNo ratings yet

- Design of Drill JigDocument26 pagesDesign of Drill JigDIPAK VINAYAK SHIRBHATE100% (1)

- G&P Rapid Fire II Airsoft AEG Rifle W - QD Barrel Extension (Package - Tan - Evike - Com Receiver - Battery + Charger) - Evike PDFDocument3 pagesG&P Rapid Fire II Airsoft AEG Rifle W - QD Barrel Extension (Package - Tan - Evike - Com Receiver - Battery + Charger) - Evike PDFVinjkNo ratings yet

- A&K Full Metal M16-A4 SPR NS15 Airsoft AEG LiPo ReadyDocument3 pagesA&K Full Metal M16-A4 SPR NS15 Airsoft AEG LiPo ReadyVinjkNo ratings yet

- A&K Full Metal M16-A4 SPR NS15 Airsoft AEG LiPo ReadyDocument3 pagesA&K Full Metal M16-A4 SPR NS15 Airsoft AEG LiPo ReadyVinjkNo ratings yet

- Duas Configurações Sniper NovritschDocument1 pageDuas Configurações Sniper NovritschVinjkNo ratings yet

- Gmail - Failing To Listen To God - in Touch - August 3, 2017Document3 pagesGmail - Failing To Listen To God - in Touch - August 3, 2017VinjkNo ratings yet

- Newton's Interpolation FormulaeDocument7 pagesNewton's Interpolation FormulaeVinjkNo ratings yet

- (Eb) New York Times 14 July 2017 Mandar Nos Grupos Do CanadáDocument1 page(Eb) New York Times 14 July 2017 Mandar Nos Grupos Do CanadáVinjkNo ratings yet

- Exam1sol PDFDocument3 pagesExam1sol PDFVinjkNo ratings yet

- Deriving Simpsons Rule Using Newton InterpolationDocument4 pagesDeriving Simpsons Rule Using Newton InterpolationVinjkNo ratings yet

- Tokyo Marui VSR-10 G-Spec Airsoft Sniper Rifle With Mock Suppressor (Color - OD Green) - EvikeDocument2 pagesTokyo Marui VSR-10 G-Spec Airsoft Sniper Rifle With Mock Suppressor (Color - OD Green) - EvikeVinjkNo ratings yet

- (Eb) New York Times 14 July 2017 Mandar Nos Grupos Do CanadáDocument1 page(Eb) New York Times 14 July 2017 Mandar Nos Grupos Do CanadáVinjkNo ratings yet

- Architectural Acoustics SuperconductivityDocument42 pagesArchitectural Acoustics SuperconductivityVinjkNo ratings yet

- Newton's Forward Difference Formula - From Wolfram MathWorldDocument1 pageNewton's Forward Difference Formula - From Wolfram MathWorldVinjkNo ratings yet

- Electric Field, Line ChargeDocument3 pagesElectric Field, Line ChargeVinjkNo ratings yet

- A&K Full Metal M16 SPR MOD-2 Airsoft AEG Sniper Rifle - EvikeDocument3 pagesA&K Full Metal M16 SPR MOD-2 Airsoft AEG Sniper Rifle - EvikeVinjkNo ratings yet

- Electric Field of Charged Ring: Q λ = Q/2πa dqDocument1 pageElectric Field of Charged Ring: Q λ = Q/2πa dqVinjkNo ratings yet

- Eletric RocketsDocument8 pagesEletric RocketsVinjkNo ratings yet

- Manual RepetidorDocument3 pagesManual RepetidorVinjkNo ratings yet

- PhysicsLAB - Derivation of Bohr's Model For The Hydrogen SpectrumDocument4 pagesPhysicsLAB - Derivation of Bohr's Model For The Hydrogen SpectrumVinjkNo ratings yet

- Bohr ModelDocument36 pagesBohr ModelManu SharmaNo ratings yet

- mapBW 45 2014 11 20Document2 pagesmapBW 45 2014 11 20VinjkNo ratings yet

- 4D Examples 4Document2 pages4D Examples 4VinjkNo ratings yet

- Electric Field, Line ChargeDocument3 pagesElectric Field, Line ChargeVinjkNo ratings yet

- HSE Investigation ReportDocument6 pagesHSE Investigation ReportVinjkNo ratings yet

- HSL ReportDocument24 pagesHSL ReportVinjkNo ratings yet

- HSL ReportDocument24 pagesHSL ReportVinjkNo ratings yet

- IntroductionDocument8 pagesIntroductionThomas ShelbyNo ratings yet

- US Marines Close Quarters Combat Manual FMFM 07Document99 pagesUS Marines Close Quarters Combat Manual FMFM 07lokyle100% (1)

- Cambridge Face2face Upper Intermediate WorkbookDocument85 pagesCambridge Face2face Upper Intermediate WorkbookVinjk0% (1)

- Quick & Effective Miniature Paintning Guide - Craftworld Studio Art PatreonDocument18 pagesQuick & Effective Miniature Paintning Guide - Craftworld Studio Art PatreonSamuel GarciaNo ratings yet

- 5493R4 E6050lm Kit Manual 20180531Document78 pages5493R4 E6050lm Kit Manual 20180531Juan Carlos Benitez MartinezNo ratings yet

- Cectek Gladiator t6 Engine WBC SloveniaDocument43 pagesCectek Gladiator t6 Engine WBC SloveniaEnes KaragićNo ratings yet

- 3PE - Technical CatalogueDocument32 pages3PE - Technical CatalogueFernando MoreiraNo ratings yet

- Meetering Valves S, M, L &31 Series (MS-01-142) R3Document8 pagesMeetering Valves S, M, L &31 Series (MS-01-142) R3herysyam1980No ratings yet

- Extension: Miss A Turn: Add 38 Min, To Your Next Jour-Ney Time Miss A Turn: Add 55 Mins To Your Next Jour - NeyDocument1 pageExtension: Miss A Turn: Add 38 Min, To Your Next Jour-Ney Time Miss A Turn: Add 55 Mins To Your Next Jour - Neymk78_inNo ratings yet

- Pulley Dimensions and Belt Specifications TableDocument1 pagePulley Dimensions and Belt Specifications TableyokelomeNo ratings yet

- Onderdelenlijst Hydro 857 MinDocument66 pagesOnderdelenlijst Hydro 857 MindanielNo ratings yet

- Manual de Partes CX24Document6 pagesManual de Partes CX24Axel BetancourtNo ratings yet

- 627 Series Pressure Reducing RegulatorsDocument36 pages627 Series Pressure Reducing RegulatorsKrisvell ArmentaNo ratings yet

- Pipe Sizing Chart and Flange SpecificationsDocument3 pagesPipe Sizing Chart and Flange SpecificationsPedro Diaz UzcateguiNo ratings yet

- Hand Tool Checklist For All UnitDocument1 pageHand Tool Checklist For All UnitHariomNo ratings yet

- Phase2 Analysis Information Tajeo Esperanza NV 920: Project SummaryDocument5 pagesPhase2 Analysis Information Tajeo Esperanza NV 920: Project SummarysanchezmendozaaNo ratings yet

- United States PatentDocument15 pagesUnited States PatentAlexcel CorporalNo ratings yet

- SPARBSluXUAt Gearbox Parts ListDocument11 pagesSPARBSluXUAt Gearbox Parts ListSergei KurpishNo ratings yet

- General Arrangement, Isometric View Parts and Assemblies A Stirling Engine Powered Fan "Moriya" Designed and Built by DR - James R.SenftDocument2 pagesGeneral Arrangement, Isometric View Parts and Assemblies A Stirling Engine Powered Fan "Moriya" Designed and Built by DR - James R.SenftJuan Esteban CusiNo ratings yet

- Catalogue of Unlocking Plates Suzhou Youbetter Medical Apparatus Co., LTDDocument9 pagesCatalogue of Unlocking Plates Suzhou Youbetter Medical Apparatus Co., LTDazisaaiNo ratings yet

- PT CouplingDocument88 pagesPT CouplingHotnCrispy CrispyNo ratings yet

- Cessna172 Stall CharacteristicsDocument2 pagesCessna172 Stall Characteristicsledeni1983No ratings yet

- DIN 2353 - 2013non-Soldering Compression Fittings With Cylindrical Screw-In Pins Form A or B According To DIN 3852-1, DIN 3852-2Document3 pagesDIN 2353 - 2013non-Soldering Compression Fittings With Cylindrical Screw-In Pins Form A or B According To DIN 3852-1, DIN 3852-2Er.Amritpal SinghNo ratings yet

- Experimental Behavior of Stiffened and Unstiffened End-Plate Connections Under Cyclic LoadingDocument6 pagesExperimental Behavior of Stiffened and Unstiffened End-Plate Connections Under Cyclic LoadingJJ JJNo ratings yet