Professional Documents

Culture Documents

Egg Powder

Uploaded by

Gisel Ingrid Puma TorrezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Egg Powder

Uploaded by

Gisel Ingrid Puma TorrezCopyright:

Available Formats

EGG POWDER

1.0 INTRODUCTION: The egg is the most nutritious natural product. Eggs are rich in protein, vitamins and minerals. During last three decades, the poultry industry in the country has made remarkable progress and grown into an organized and highly productive industry. Dried egg powder can be stored and transported at room temperatures. It is quite stable and has long shelf life. The manufacture of egg powder is an important segment of egg consumption. There is enough scope of an egg powder manufacturing plant, with a suitable capacity. 2.0 PRODUCT 2.1 Applications Egg powder is one of the most common products in poultry industry in the country. Attempts have been made to prepare egg pudding also but this product has not yet been accepted by the consumers, whereas demand for egg powder is increasing year after year. This project can be set up in UP, WB, Maharashtra and AP. The preferred location is Maharashtra in view of vast market. 2.2 Availibilty of technical know how and compliances

CFTRI, Mysore, can offer the technical know-how. Compliance under the PFA Act is necessary. 3.0 MARKET POTENTIAL 3.1 Demand and Supply Eggs are full of nutrients and minerals and are consumed in different forms since centuries. There was misconception that they are from non-vegetarian food category but now people at large have accepted them as a vegetarian item and their consumption is increasing year after year. Transportation of eggs is difficult as chances of breakage during transportation are

86

higher and it is costly also. Egg powder is comparatively easier to transport and there is no question of any breakage during the transit. 3.2 Marketing Strategy

The major market is defense establishments, various government and non-government nutritional programmes, bakeries and all such areas like hills or forests where transportation is difficult. Before venturing into this project, a proper market assessment and some firm tieup is advisable. 4.0 MANUFACTURING PROCESS Manufacture of dried egg powder starts with breaking of eggs and removing egg-shells. After removal of shells, the mixture is filtered and stored in storage tanks at about 4 C and then it is taken to tubular heater wherein it is dried at about 65 C for 8 to 10 minutes and it is filtered and passed to high pressure spray drier with the help of high pressure pump. The material which comes out of high pressure spray drier is not only in dried form but also in powder form which is then packed in poly-lined boxes. The average yield is around 80%. CFTRI, Mysore, has developed a process and the promoters may like to seek their help. A typical process flow chart would be as under: Breaking of Eggs and removal of shells K Filtration K Storage and Drying K Packing 5.0 CAPITAL INPUTS: 5.1 Land and Buildings

A plot of around 800 sq.mtrs. will be sufficient as the built-up area requirement is not more than 500 sq.mtrs. The built-up area would have main production unit in around 300 sq.mtrs. and balance area will be utilized for storage and packing. Cost of land is expected to Rs.2.40 lacs whereas that of civil work would be Rs.12.50 lacs. 5.2 Plant and Machinery

It is proposed to install dry egg powder making unit with capacity of 240 tons per annum with 16 hours of working per day for 300 working days.

87

The plant and machinery required for the above production capacity may cost about Rs.65.00 lacs. (Rs. in lacs) Particulars Egg Breaker Centrifuge Filter Storage Tank Feed Pump Tubular Heater Balance Tank Feed Pump High Pressure Pump High Pressure Spray Dryer Cyclone with exhaust and fan Packing Unit Electrification and Installation Quantity/ No. 4 2 2 4 2 1 4 2 2 1 1 1 -Total 5.3 Miscellaneous Assets Price 2.00 6.00 2.00 3.00 6.00 8.00 3.00 7.00 8.00 7.50 3.50 5.00 4.00 65.00

Other miscellaneous assets required are fans, weighing balance, tables, chairs, furniture etc which would cost Rs.10.00 lacs. 5.4 litres. 5.5 Raw and Packing Materials Utilities:

The total power required shall be 75 HP whereas per day water requirement would be 2500

The major raw material required is fresh eggs and the daily requirement is 20,000. Prior confirmed arrangements for this quantity are necessary. Packing material like poly-lined paper bags, corrugated boxes, labels etc. shall be needed.

88

6.0

MANPOWER REQUIREMENTS Particulars Machine Operators Skilled Workers Semi-skilled Workers Unskilled Workers Salesmen Clerk No 2 6 4 10 1 1 Monthly Salary (Rs.) 3,500 2,500 1,750 1,250 2,500 2,500 Total Total Monthly Salary (Rs.) 7,000 15,000 7,000 12,500 2,500 2,500 46,500

7.0

TENTATIVE IMPLEMENTATION SCHEDULE Activity Application and sanction of loan Site selection and commencement of civil work Completion of civil work and placement of orders for machinery Erection, installation and trial runs Period (in months) 2 1 4 1

8.0

DETAILS OF THE PROPOSED PROJECT 8.1 Land and Building (Rs. in lacs) Particulars Land Building Area (Sq.Mtrs) 800 500 Total 8.2 Plant and Machinery Cost 2.40 12.50 14.90

The total cost of machinery is estimated to be Rs.65 lacs, as explained earlier. 8.3 earlier. 8.4 Preliminary and Pre-Operative Expenses Miscellaneous Assets

The provision for miscellaneous assets of Rs. 10.00 lacs shall be adequate as explained

The registration charges, establishment expenses, trial run expenses, interest during implementation etc would be around Rs.10 lacs.

89

8.5

Working Capital Requirement (Rs. in lacs)

At 65% utilisation in the first year, the total working capital needs shall be as under:

Particulars Stock of Raw and Packing Materials (except Lime) Stock of Finished Goods Receivables Working Expenses

Period Month Month Month 1 Month

Margin 30% 25% 25% 100% Total

Total 1.80 2.40 3.90 1.25 9.35

Bank 1.25 1.80 2.90 -5.95

Promoters 0.55 0.60 1.00 1.25 3.40

8.6

Cost of the Project and Means of Financing Items Land and Buildings Plant and Machinery Miscellaneous Assets Preliminary and Pre-operative Expenses Contingencies @ 10% on land and building and machinery Working Capital Margin Total Means of Finance Promoter's Contribution Bank Loan/ Financial Institutions Total Debt Equity Ratio Promoters' Contribution

(Rs. in lacs) Amount 14.90 65.00 10.00 10.00 8.00 3.40 111.30

35.30 76.00 111.30 2.15 : 1 31%

Financial assistance in the form of grant is available from the Ministry of Food Processing Industries, Govt. of India, towards expenditure on technical civil works and plant and machinery for eligible projects subject to certain terms and conditions. 9.0 PROFITABILITY CALCULATIONS 9.1 Production Capacity and Build-up The installed production capacity of the proposed unit would be 240 MTA in 300 working days of 16 hours. The capacity utilization of 65% and 80% is envisaged during the first two years.

90

9.2

Sales Revenue at 100% Capacity (Rs. in lacs) Qty. Tonnes 240 Selling Price Per Ton/Rs. 65,000 Value 156.00

Product Egg Powder 9.3

Raw and Packing Materials Required at 100% (Rs. in lacs) Quantity (Nos) 60 Lacs -Rate per No. 1.00 -Total Value 60.00 7.20 67.20

Product Fresh Eggs Cost of Packing Materials @ 3000/Ton

9.4

Utilities

The annual cost of utilities at 100% activity level would be Rs.6.00 lacs. 9.5 Interest

Interest on term loan of Rs. 76 lacs has been calculated @ 14% per annum assuming repayment in 6 years including a moratorium period of 1 year, whereas interest on working capital would be 14% per annum. 9.6 assets. Depreciation

It has been calculated on WDV basis @ 10% on building and 15% on machinery and other

91

10.0

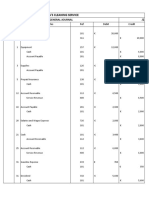

PROJECTED PROFITABILITY (Rs. in lacs) No A Particulars Installed Capacity Capacity Utilisation Sales Realisation B. Cost of Production Raw and Packing Materials Utilities Salaries Stores and Spares Repairs and Maintenance Selling Expenses @ 10% Administrative Expenses Total C. Profit before Interest & Depreciation Interest on Term Loan Interest on Working Capital Depreciation Net Profit Income-tax @ 20% Profit after Tax Cash Accrual Repayment of Term Loan 43.68 3.90 5.58 1.80 2.40 10.14 2.50 70.00 31.40 9.80 0.84 12.50 8.26 1.66 6.60 19.10 -(Rs. in lacs) Amount 101.40 43.68 2.73 3.91 1.80 7.10 1.25 0.84 61.31 40.09 23.17 58% 53.76 4.80 6.25 2.40 3.00 12.48 3.00 85.69 39.11 8.33 1.05 10.69 19.04 3.81 15.23 25.92 14.00 1st Year 65% 101.40 2nd Year 80% 124.80 ---240 MTA ---

11.0

BREAK-EVEN POINT ANALYSIS No. A B Particulars Sales Variable Cost Raw and Packing Materials Utilities (70%) Salaries (70%) Stores and Spares Selling Expenses (70%) Administrative Expenses (50%) Interest on working capital Total C D. E. Contribution Fixed Cost Break Even Point (D C)

92

12.0

[A]

LEVERAGES Financial leverage = EBIT/EBT = 18.90 = 2.29 8.26

Operating Leverage = Contribution / EBT = 40.09 8.26 = 4.85

Degree of Total Leverage = FL/OL = 2.29 4.85 = 0.47

[B]

Debt Service Coverage Ratio (DSCR) (Rs. in lacs)

Particulars Cash Accruals Interest on TL Total [A] Interest on TL Repayment of TL Total [B] DSCR [A] [B] Average DSCR

1st Yr 19.10 9.80 28.90 9.80 -9.80 2.95

2nd Yr 25.92 8.33 34.25 8.33 15.20 23.53 1.45

3rd Yr 28.11 6.37 34.48 6.37 15.20 21.57 1.59

4th Yr 31.01 4.11 35.12 4.11 15.20 19.31 1.82

5th Yr 34.00 2.45 36.45 2.45 15.20 17.65 2.06

6th Yr 37.11 1.38 38.49 1.38 15.20 16.58 2.32

-------------------------------------- 2.03 -------------------------------

93

[C]

Internal Rate of Return (IRR)

Cost of the project is Rs. 111.30 lacs. (Rs. in lacs) Year 1 2 3 4 5 6 7 8 Cash Accruals 19.10 25.92 28.11 31.01 34.00 37.11 39.23 42.01 256.49 The IRR is around 20. Some of the machinery suppliers are 1. 2. 3. 4. Techno Equipments, 31, Parekh street, Girgaum, Mumbai-400004 GR Engg. Works Pvt Ltd, Worli, Mumbai 400 018 and Apurva Engg. Works, Boriwali, Mumbai 400 098 FMC Technologiy, Hong Kong Ltd., 2 Bhubhaneshwar Housing Soc., Pashan Rd., Pune 411008. Tel No. 25893700. Flavourire Foods and Services Pvt. Ltd. 208 Manas Bhavan, 11 RNT Marg, Indore 452008. Tel No. 2527644-5046500 16% 16.46 19.26 18.02 17.12 16.18 15.22 13.89 12.81 128.96 18% 16.18 18.61 17.12 16.00 14.86 13.73 12.32 11.17 119.99 20% 15.91 17.99 16.28 14.95 13.67 12.43 10.95 9.79 111.97 24% 15.39 16.85 14.73 13.12 11.59 10.21 8.71 7.52 98.12

94

You might also like

- Plantain Production Economic Assessment in Rivers StateDocument29 pagesPlantain Production Economic Assessment in Rivers StateThompson Onovughe100% (3)

- Urban Water Partners Group ADocument5 pagesUrban Water Partners Group AAman jhaNo ratings yet

- Maize Processing Unit 1Document4 pagesMaize Processing Unit 1Nikita Arora50% (2)

- Producing Animal FeedDocument28 pagesProducing Animal FeedTed Habtu Mamo Asrat100% (1)

- Detail Project Report of Wheat FDocument27 pagesDetail Project Report of Wheat FYogesh PatilNo ratings yet

- EGG POWDER MANUFACTURING PROCESSDocument8 pagesEGG POWDER MANUFACTURING PROCESSLavanya Damodaran0% (1)

- Alcohol From Yam CassavaDocument15 pagesAlcohol From Yam Cassavadinba123No ratings yet

- Feasibility Study On Cassava Production in NigeriaDocument38 pagesFeasibility Study On Cassava Production in NigeriaAnonymous usfjk94W9100% (2)

- Cold StoreDocument22 pagesCold StoresajidaliyiNo ratings yet

- Christine Sousa BagsDocument8 pagesChristine Sousa BagsKaila Clarisse Cortez100% (5)

- Manufacturing AccountsDocument3 pagesManufacturing AccountsSimba MuhondeNo ratings yet

- SK Budget Forms 2023Document4 pagesSK Budget Forms 2023Djaenzel Ramos0% (1)

- Produce Poultry FeedDocument26 pagesProduce Poultry FeedMOHIT KHATWANINo ratings yet

- Fringe Benefit TaxDocument11 pagesFringe Benefit TaxJonard Godoy75% (4)

- Edible Oil GheeDocument25 pagesEdible Oil GheeLTE00233% (3)

- Vegetable Farm Business DevelopmentDocument16 pagesVegetable Farm Business DevelopmentnewayNo ratings yet

- Dairy Farm Project Report - Crossbred Cow (Large Scale) - Project ReportDocument2 pagesDairy Farm Project Report - Crossbred Cow (Large Scale) - Project Report1stabhishek78% (9)

- On Any Agri Business of Your ChoiceDocument14 pagesOn Any Agri Business of Your Choiceataisi osatNo ratings yet

- Nabard DPR Feed Proccessing PlantDocument31 pagesNabard DPR Feed Proccessing Plantsrscribd1075% (4)

- Cassava Business PlanDocument14 pagesCassava Business PlanMAVERICK MONROENo ratings yet

- 10 Egg Powder Unit PDFDocument20 pages10 Egg Powder Unit PDFAsif Ali100% (3)

- India's Growing Edible Oil Imports and Business OpportunitiesDocument19 pagesIndia's Growing Edible Oil Imports and Business Opportunitiessreeramchellappa100% (1)

- Poultry Farm Business PlanDocument24 pagesPoultry Farm Business PlanAnwar jemal100% (1)

- Baby Food Business PlanDocument1 pageBaby Food Business Planadedoyin123No ratings yet

- Poultry GiftDocument25 pagesPoultry GiftChima KingsleyNo ratings yet

- Barley Flour Mill DPR by NIFTEMDocument28 pagesBarley Flour Mill DPR by NIFTEMManav AggarwalNo ratings yet

- Broiler Farm Project ProfileDocument6 pagesBroiler Farm Project ProfileMd Enamul HaqueNo ratings yet

- Egg Powder PDFDocument6 pagesEgg Powder PDFRamnath R Naiudu100% (1)

- Project Profile - Lyantonde Animal Feed MillDocument67 pagesProject Profile - Lyantonde Animal Feed MillInfiniteKnowledge88% (16)

- q4 Tle Week 1 Day 4Document25 pagesq4 Tle Week 1 Day 4Cheeny De Guzman100% (1)

- Egg Powder Manufacturing Plant Ecom Final Ppt1Document19 pagesEgg Powder Manufacturing Plant Ecom Final Ppt1brickses100% (2)

- Pre-Feasibility Study of Fodder Production and Trading UnitDocument28 pagesPre-Feasibility Study of Fodder Production and Trading UnitimranNo ratings yet

- NABARD Broiler Farming ProjectDocument10 pagesNABARD Broiler Farming ProjectGrowel Agrovet Private Limited.No ratings yet

- Poultry Farm Records MaintenaceDocument4 pagesPoultry Farm Records Maintenaceronalit malintadNo ratings yet

- Project Report On MillDocument13 pagesProject Report On MillAashish KuNo ratings yet

- National Open University of Nigeria Business Plan for Emy Farms Cassava Processing CompanyDocument19 pagesNational Open University of Nigeria Business Plan for Emy Farms Cassava Processing CompanyMAVERICK MONROENo ratings yet

- Business Plan For A Maize and Beans FarmDocument4 pagesBusiness Plan For A Maize and Beans FarmUsman Hena75% (4)

- 20-Project Profile-Meat Processing UnitDocument6 pages20-Project Profile-Meat Processing UnitSyed Ali Zain0% (1)

- Poultry Broiler FarmingDocument20 pagesPoultry Broiler FarmingSanjeev MiglaniNo ratings yet

- Chapter 8 (Edt) Financial Management EventDocument25 pagesChapter 8 (Edt) Financial Management EventplanetrafeeNo ratings yet

- Feasibility Study of Soya ProductDocument21 pagesFeasibility Study of Soya ProductOgochukwuNo ratings yet

- Supplemental Guide: Module 4: Reporting & TroubleshootingDocument75 pagesSupplemental Guide: Module 4: Reporting & TroubleshootingEdward DubeNo ratings yet

- Free Packaged Sachet Pure Water Startup Plan PDFDocument24 pagesFree Packaged Sachet Pure Water Startup Plan PDFAlabi OlanrewajuNo ratings yet

- 8.business Plan of Srinagar Agro FarmDocument9 pages8.business Plan of Srinagar Agro FarmSantosh BhandariNo ratings yet

- 4000 BroilerDocument10 pages4000 BroilerDanish JavedNo ratings yet

- Lekan Poultry Farm Business - PlanDocument29 pagesLekan Poultry Farm Business - PlanMAVERICK MONROENo ratings yet

- Egg Powder 15Document5 pagesEgg Powder 15Amit AggarwalNo ratings yet

- Sem ProjDocument92 pagesSem ProjJiyaul Haque100% (1)

- TS4F01-1 Unit 3 - Master DataDocument59 pagesTS4F01-1 Unit 3 - Master DataLuki1233332100% (1)

- Sunflower Oil Refinery Project ReportDocument6 pagesSunflower Oil Refinery Project ReportMohamed ShuaibNo ratings yet

- Feasibility Study of Concentrate Feed Final ReportDocument45 pagesFeasibility Study of Concentrate Feed Final ReportIjaaraa SabaaNo ratings yet

- EdibleDocument23 pagesEdibleAjay ChoudharyNo ratings yet

- Analysis of Various Brands of Soyabean Refined Oil in The MarketDocument38 pagesAnalysis of Various Brands of Soyabean Refined Oil in The MarketDouglas OrtizNo ratings yet

- Project Profile For Lyantonde Animal Feed Mill - Table of ContentsDocument4 pagesProject Profile For Lyantonde Animal Feed Mill - Table of ContentsInfiniteKnowledge100% (1)

- Project ProposalDocument2 pagesProject ProposalKrishna PaudelNo ratings yet

- MDN Pasta and Macaroni ProductionDocument33 pagesMDN Pasta and Macaroni ProductionElias Keiredin100% (1)

- Broiler Prodution Business PlanDocument8 pagesBroiler Prodution Business PlantichaonaNo ratings yet

- Milk Production Unit and Dairy Farming Project Requirments 1. 2. Pre-Requisite 3. Construction WorkDocument17 pagesMilk Production Unit and Dairy Farming Project Requirments 1. 2. Pre-Requisite 3. Construction WorkVivek TomarNo ratings yet

- Dairy Project For Zaru Last EditedDocument15 pagesDairy Project For Zaru Last Editedgaromsa degaga100% (1)

- Project Profile of Edible OilDocument47 pagesProject Profile of Edible OilManish Bhoyar100% (2)

- Final Drafting PoultryDocument17 pagesFinal Drafting PoultryMoh'd Aminu UsmanNo ratings yet

- Agriculture Jimma DR Final GetachoDocument46 pagesAgriculture Jimma DR Final GetachoTesfaye DegefaNo ratings yet

- Bank Financing Proposal for Brick Factory ExpansionDocument11 pagesBank Financing Proposal for Brick Factory ExpansionSudhakaar ShakyaNo ratings yet

- Brick Making Poverty Alleviation Project Business Plan 2005 Maluti A Phofung Local MunicipalityDocument27 pagesBrick Making Poverty Alleviation Project Business Plan 2005 Maluti A Phofung Local MunicipalitySandeep PaulNo ratings yet

- Milled Maize ProductDocument7 pagesMilled Maize ProductFarhat DurraniNo ratings yet

- Maize FlakesDocument8 pagesMaize FlakesFarhat DurraniNo ratings yet

- Rice FlakesDocument9 pagesRice FlakesAkhil PittyNo ratings yet

- Jowar FlakesDocument8 pagesJowar FlakesAmit JainNo ratings yet

- Coffee Flavoured Milk Market PotentialDocument8 pagesCoffee Flavoured Milk Market Potentialneha0007No ratings yet

- Fruit SquashDocument9 pagesFruit SquashGanesh DarsipudiNo ratings yet

- CIR V. Isabela Cultural accrual accountingDocument2 pagesCIR V. Isabela Cultural accrual accountingMary AnneNo ratings yet

- Golis University: Faculty of Business and Economics Chapter Five Income StatementDocument21 pagesGolis University: Faculty of Business and Economics Chapter Five Income Statementsaed cabdiNo ratings yet

- BADM741 Chapter 4Document29 pagesBADM741 Chapter 4eyob yohannesNo ratings yet

- Company ProfileDocument5 pagesCompany ProfileinvestorsNo ratings yet

- Accounting 12 Summative AdidasDocument57 pagesAccounting 12 Summative AdidasWensen LiNo ratings yet

- CPCS 2021-011 Participation in Conventions, SeminarsDocument3 pagesCPCS 2021-011 Participation in Conventions, SeminarsEdson Jude DonosoNo ratings yet

- Form - X: Plot No 116-117 & 65-66, Part-A, Mie, Bahadurgarh, Distt - Jhajjar (Haryana)Document11 pagesForm - X: Plot No 116-117 & 65-66, Part-A, Mie, Bahadurgarh, Distt - Jhajjar (Haryana)Varun MalhotraNo ratings yet

- Management Accounting - IDocument41 pagesManagement Accounting - Ivicky bindassNo ratings yet

- Anya's Cleaning ServiceDocument22 pagesAnya's Cleaning ServiceArya HerdiansyahNo ratings yet

- Reporting and Interpreting Liabilities ChapterDocument110 pagesReporting and Interpreting Liabilities ChapterShilpee Haldar MishraNo ratings yet

- Borrowing CostsDocument17 pagesBorrowing CostsAngelica PagaduanNo ratings yet

- Tax Comp ExampleDocument115 pagesTax Comp ExampleJayjay FarconNo ratings yet

- Report Arutmin Indonesia September 2011Document56 pagesReport Arutmin Indonesia September 2011Fredy Milson SimbolonNo ratings yet

- ITR3 - 2019 - PR1.1 Example FileDocument208 pagesITR3 - 2019 - PR1.1 Example FilePrateek SharmaNo ratings yet

- Revision Exercise For FCQ 1Document10 pagesRevision Exercise For FCQ 1Dilfaraz KalawatNo ratings yet

- Workout Gym Business PlanDocument25 pagesWorkout Gym Business PlanZUZANI MATHIYANo ratings yet

- Revenue DeficitDocument9 pagesRevenue DeficitroshniNo ratings yet

- f6 Vietnam VNM Specimen Questions Applicable From June 2015Document10 pagesf6 Vietnam VNM Specimen Questions Applicable From June 2015Thị Linh Chi VũNo ratings yet

- Plan Expenditure and NonDocument3 pagesPlan Expenditure and NonkankshNo ratings yet

- Soumen Sen: ResumeDocument3 pagesSoumen Sen: Resumesoumensenrana32No ratings yet