Professional Documents

Culture Documents

Msds PP

Uploaded by

bella_dsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Msds PP

Uploaded by

bella_dsCopyright:

Available Formats

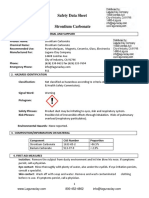

Material Safety Data Sheet Polypropylene

Safripol (Pty) Ltd encourages and expects you to read and understand the entire (M)SDS, as there is important information throughout the document. We expect you to follow the precautions identified in this document unless your use conditions would necessitate other appropriate methods or actions.

1.

Identification of the Substance/Preparation and of the Company/Undertaking

Product Name Polypropylene resin (PP homopolymer) Use of the substance/preparation A polypropylene plastic - for industrial conversion as a raw material for the manufacture of articles or goods. Company Identification Safripol (Pty) Ltd Eugene Houndry Street, Sasolburg Private Bag X 52 Bryanston, 2021 Gauteng, South Africa Customer Information Number: 24-Hour Emergency Contact: +27 (0)11 575 4549 +27 (0)16 970 4000

2.

Composition/Information on Ingredients

Amount

99.0 % 1.0%

Component

1-propene, homopolymer Additives

Classification:

Not classified Not classified

CAS #

9003-07-0 N/A

EC #

Polymer

N/A

3.

Hazards Identification

This product is not classified as dangerous according to EC criteria.

4.

First-aid Measures

Eye Contact: Flush eyes thoroughly with water for several minutes. Remove contact lenses after the initial 1-2 minutes and continue flushing for several additional minutes. If effects occur, consult a physician, preferably an ophthalmologist. Skin Contact: If molten material comes in contact with the skin, do not apply ice but cool under ice water or running stream of water. DO NOT attempt to remove the material from skin. Removal could result in severe tissue damage. Seek medical attention immediately. Inhalation: Move person to fresh air; if effects occur, consult a physician. Ingestion: If swallowed, seek medical attention. May cause gastrointestinal blockage. Do not give laxatives. Do not induce vomiting unless directed to do so by medical personnel.

Date of issue: 1 September 2007 Document No: MSDS-PP-H-5502

Page 1 of 6 Polypropylene

Material Safety Data Sheet Polypropylene

Notes to Physician: If burn is present, treat as any thermal burn, after decontamination. No specific antidote. Treatment of exposure should be directed at the control of symptoms and the clinical condition of the patient.

5.

Fire Fighting Measures

Extinguishing Media: Water fog or fine spray. Dry chemical fire extinguishers. Carbon dioxide fire extinguishers. Foam. Fire Fighting Procedures: Keep people away. Isolate fire and deny unnecessary entry. Soak thoroughly with water to cool and prevent re-ignition. If material is molten, do not apply direct water stream. Use fine water spray or foam. Cool surroundings with water to localize fire zone. Hand held dry chemical or carbon dioxide extinguishers may be used for small fires. Special Protective Equipment for Fire-fighters: Wear positive-pressure self-contained breathing apparatus (SCBA) and protective fire fighting clothing (includes fire fighting helmet, coat, trousers, boots, and gloves). If protective equipment is not available or not used, fight fire from a protected location or safe distance. Unusual Fire and Explosion Hazards: Pneumatic conveying and other mechanical handling operations can generate combustible dust. To reduce the potential for dust explosions, do not permit dust to accumulate. Dense smoke is emitted when burned without sufficient oxygen. Hazardous Combustion Products: During a fire, smoke may contain the original material in addition to combustion products of varying composition which may be toxic and/or irritating. Combustion products may include and are not limited to: Carbon monoxide. Carbon dioxide.

6.

Accidental Release Measures

Steps to be Taken if Material is Released or Spilled: Contain spilled material if possible. Sweep up. Collect in suitable and properly labelled containers. See Section 13, Disposal Considerations, for additional information. Personal Precautions: Spilled material may cause a slipping hazard. Use appropriate safety equipment. For additional information, refer to Section 8, Exposure Controls and Personal Protection. Environmental Precautions: Prevent from entering into soil, ditches, sewers, waterways and/or groundwater. See Section 12, Ecological Information.

7.

Handling and Storage

Handling

General Handling: No smoking, open flames or sources of ignition in handling and storage area. Good housekeeping and controlling of dusts are necessary for safe handling of product. Avoid breathing process fumes. Use with adequate ventilation. When appropriate, unique handling information for containers can be found on the product label. Workers should be protected from the possibility of contact with molten resin. Do not get molten material in eyes, on skin or clothing. Pneumatic conveying and other mechanical handling operations can generate combustible dust. To reduce the potential for dust explosions, electrically bond and ground equipment and do not permit dust to accumulate. Dust can be ignited by static discharge.

Storage

Store in accordance with good manufacturing practices.

Date of issue: 1 September 2007 Document No: MSDS-PP-H-5502

Page 2 of 6 Polypropylene

Material Safety Data Sheet Polypropylene

8. Exposure Controls / Personal Protection

Exposure Limits

None established

Personal Protection

Eye/Face Protection: Use safety glasses. Safety glasses should be consistent with Directive 89/686/EEC Category 2. If there is a potential for exposure to particles which could cause eye discomfort, wear chemical goggles. Chemical goggles should be consistent with EN 166 or equivalent. If exposure causes eye discomfort, use a full-face respirator. Skin Protection: No precautions other than clean body-covering clothing should be needed. Hand protection: Chemical protective gloves should not be needed when handling this material. Consistent with general hygienic practice for any material, skin contact should be minimized. Use gloves with insulation for thermal protection, when needed. Respiratory Protection: Use an approved air-purifying respirator when vapours are generated at increased temperatures or when dust or mist is present. Use the following CE approved air-purifying respirator: When dust/mist are present use a/an Particulate filter, type P2. When combinations of vapours, acids, or dusts/mists are present use a/an Organic vapour cartridge with a particulate pre-filter, type AP2. Ingestion: Use good personal hygiene. Do not consume or store food in the work area. Wash hands before smoking or eating.

Engineering Controls

Ventilation: Good general ventilation should be sufficient for most conditions. Local exhaust ventilation may be necessary for some operations.

9.

Physical and Chemical Properties

Pellets or granules White Odourless Not applicable Lower: Not applicable Upper: Not applicable No test data available Not applicable Not applicable Not applicable 0.9 Literature Not applicable o 170 176 C Literature Negligible Not applicable Not applicable

Physical State Colour Odour Flash Point - Closed Cup Flammable Limits In Air Autoignition Temperature Vapour Pressure Boiling Point (760 mmHg) Vapour Density (air = 1) Specific Gravity (H2O = 1) Freezing Point Melting Point Solubility in Water (by weight) pH Kinematic Viscosity

Date of issue: 1 September 2007 Document No: MSDS-PP-H-5502

Page 3 of 6 Polypropylene

Material Safety Data Sheet Polypropylene

10. Stability and Reactivity

Stability/Instability

Stable. Conditions to Avoid: Exposure to elevated temperatures can cause product to decompose. Incompatible Materials: None known.

Hazardous Polymerization

Will not occur.

Thermal Decomposition

Decomposition products depend upon temperature, air supply and the presence of other materials. Processing may release fumes and other decomposition products. At temperatures exceeding melt temperatures, polymer fragments can be released. Fumes can be irritating. Decomposition products can include and are not limited to: Aldehydes. Alcohols. Organic acids. Decomposition products can include trace amounts of: Hydrocarbons.

11.

Toxicological Information

Acute Toxicity

Ingestion Very low toxicity if swallowed. Harmful effects not anticipated from swallowing small amounts. May cause choking if swallowed. Estimated LD50, Rat > 5,000 mg/kg Eye Contact Solid or dust may cause irritation or corneal injury due to mechanical action. Vapour may cause eye irritation experienced as mild discomfort and redness. Skin Contact Prolonged contact is essentially non-irritating to skin. Mechanical injury only. Under normal processing conditions, material is heated to elevated temperatures; contact with the material may cause thermal burns. Skin Absorption No adverse effects anticipated by skin absorption. Estimated LD50, Rabbit > 2,000 mg/kg Inhalation No adverse effects are anticipated from single exposure to dust. Vapours/fumes released during thermal processing may cause respiratory irritation.

Repeated Dose Toxicity

Additives are encapsulated in the product and are not expected to be released under normal processing conditions or foreseeable emergency.

12.

Ecological Information

Chemical fate

Movement & Partitioning No bioconcentration is expected because of the relatively high molecular weight (MW greater than 1000). In the terrestrial environment, material is expected to remain in the soil. In the aquatic environment, material is expected to float.

Date of issue: 1 September 2007 Document No: MSDS-PP-H-5502

Page 4 of 6 Polypropylene

Material Safety Data Sheet Polypropylene

Persistence and Degradability

This water-insoluble polymeric solid is expected to be inert in the environment. Surface photodegradation is expected with exposure to sunlight. No appreciable biodegradation is expected.

Ecotoxicity

Not expected to be acutely toxic, but material in pellet or bead form may mechanically cause adverse effects if ingested by waterfowl or aquatic life.

13.

Disposal Considerations

For uncontaminated material the disposal options include mechanical and chemical recycling or energy recovery. In some countries landfill is also allowed. For contaminated material the options remain the same, although additional evaluation is required. For all countries the disposal methods must be in compliance with national and provincial laws and any municipal or local by-laws. All disposal methods must be in compliance with the EU framework Directives 91/156/EEC, 91/689/EEC and their subsequent adaptations, as implemented in National Laws and Regulations, as well as EU Directives dealing with priority waste streams. Transboundary shipment of wastes must be in compliance with EU Regulation 259/93 and subsequent modifications.

14.

Transport Information

Road & Rail

NOT REGULATED

Ocean

NOT REGULATED

Air

NOT REGULATED

Inland Waterways

NOT REGULATED This information is not intended to convey all specific regulatory or operational requirements/information relating to this product. Additional transportation system information can be obtained through an authorized sales or customer service representative. It is the responsibility of the transporting organization to follow all applicable laws, regulations and rules relating to the transportation of the material.

15.

Regulatory Information

European Inventory of Existing Commercial Chemical Substances (EINECS) This product is a polymer according to the definition in Directive 92/32/EEC (7th Amendment to Directive 67/548/EEC) and all of its starting materials and intentional additives are listed in the European Inventory of Existing Commercial Chemical Substances (EINECS) or in compliance with European (EU) chemical inventory requirements.

Classification and User Label Information

This product is not classified as dangerous according to EC criteria.

Date of issue: 1 September 2007 Document No: MSDS-PP-H-5502

Page 5 of 6 Polypropylene

Material Safety Data Sheet Polypropylene

16. Other Information

Revision

Identification Number: MSDS-PP-H-5502 Issue Date: 01/09/2007 Version: 1 Most recent revision(s) are noted by the bold, double bars in left-hand margin throughout this document.

Legend

N/A W/W OEL STEL TWA ACGIH IHG WEEL HAZ_DES Not available Weight/Weight Occupational Exposure Limit Short Term Exposure Limit Time Weighted Average American Conference of Governmental Industrial Hygienists, Inc. Industrial Hygiene Guideline Workplace Environmental Exposure Level Hazard Designation

Safripol (Pty) Ltd urges each customer or recipient of this (M)SDS to study it carefully and consult appropriate expertise, as necessary or appropriate, to become aware of and understand the data contained in this (M)SDS and any hazards associated with the product. The information herein is provided in good faith and believed to be accurate as of the effective date shown above. However, no warranty, express or implied, is given. Regulatory requirements are subject to change and may differ between various locations. It is the buyer's/user's responsibility to ensure that his activities comply with all federal, state, provincial or local laws. The information presented here pertains only to the product as shipped. Since conditions for use of the product are not under the control of the manufacturer, it is the buyer's/user's duty to determine the conditions necessary for the safe use of this product. Due to the proliferation of sources for information such as manufacturer-specific (M)SDSs, we are not and cannot be responsible for (M)SDSs obtained from any source other than ourselves. If you have obtained an (M)SDS from another source or if you are not sure that the (M)SDS you have is current, please contact us for the most current version.

Date of issue: 1 September 2007 Document No: MSDS-PP-H-5502

Page 6 of 6 Polypropylene

You might also like

- MSDS ABS GF 20% V0 XindaDocument5 pagesMSDS ABS GF 20% V0 Xindaanisa novita sariNo ratings yet

- فوvمDocument6 pagesفوvماحمد المصرىNo ratings yet

- Pfeiffer P3 MSDSDocument7 pagesPfeiffer P3 MSDSPin SantosNo ratings yet

- PP Safety Data SheetDocument9 pagesPP Safety Data SheetTychNo ratings yet

- Gadinia AL30 - MSDSDocument6 pagesGadinia AL30 - MSDSBeryl FernandesNo ratings yet

- Corena S2 P100Document7 pagesCorena S2 P100Beryl FernandesNo ratings yet

- Corena S2 P68Document7 pagesCorena S2 P68Beryl FernandesNo ratings yet

- MSDS - Anionic Polyacrylamide - "Snow": Section 1: Name & Hazard SummaryDocument5 pagesMSDS - Anionic Polyacrylamide - "Snow": Section 1: Name & Hazard SummaryNashruNo ratings yet

- Material Safety Data Sheet Tpe (Lainer)Document7 pagesMaterial Safety Data Sheet Tpe (Lainer)luiscamposdiazNo ratings yet

- MSDS of Methyl Perfluorobutylisobutyl EtherDocument5 pagesMSDS of Methyl Perfluorobutylisobutyl EtherVova TripolskyNo ratings yet

- 671 - Msds-Cassida Fluid GL 460Document8 pages671 - Msds-Cassida Fluid GL 460Alvin LimlengcoNo ratings yet

- Argina X40 - MSDSDocument7 pagesArgina X40 - MSDSBeryl FernandesNo ratings yet

- Melina 30 - MSDSDocument7 pagesMelina 30 - MSDSBeryl FernandesNo ratings yet

- MSDS Yellow MB MaterialDocument3 pagesMSDS Yellow MB Material박종안No ratings yet

- Propylene Glycol USP MSDSDocument6 pagesPropylene Glycol USP MSDSeprastyo_3No ratings yet

- HDAX 5200 Low Ash Gas Engine Oil-MSDSDocument6 pagesHDAX 5200 Low Ash Gas Engine Oil-MSDSAlin AspiryeNo ratings yet

- MSDS - Shell Madrela - Compressor OilDocument7 pagesMSDS - Shell Madrela - Compressor OilAnonymous LfeGI2hMNo ratings yet

- Corena S2 P150Document7 pagesCorena S2 P150Beryl FernandesNo ratings yet

- Sylfat Dp-8 MsdsDocument7 pagesSylfat Dp-8 MsdsmisterpokeNo ratings yet

- Omala S2 G 68Document7 pagesOmala S2 G 68Beryl FernandesNo ratings yet

- PP DC4839F03Document4 pagesPP DC4839F03Imam SitumeangNo ratings yet

- Diala B MsdsDocument6 pagesDiala B MsdsMarco GodoyNo ratings yet

- Morlina S4 B 220Document6 pagesMorlina S4 B 220Beryl FernandesNo ratings yet

- Material Safety Data Sheet: Polyethylene TerephthalateDocument4 pagesMaterial Safety Data Sheet: Polyethylene Terephthalatesaeful anwarNo ratings yet

- Wood Charcoal MSDS Safety SheetDocument5 pagesWood Charcoal MSDS Safety SheetCOKDEHNo ratings yet

- Strontium CarbonateDocument7 pagesStrontium Carbonatetrishala shahiNo ratings yet

- Lockstop Primer Adhesive SDS-GreenstreakDocument11 pagesLockstop Primer Adhesive SDS-Greenstreakrobox514No ratings yet

- 15.20 Bio Clean SafetyDataSheetDocument4 pages15.20 Bio Clean SafetyDataSheetFrancisco GonzalezNo ratings yet

- Alexia Ls - MsdsDocument7 pagesAlexia Ls - MsdsBeryl FernandesNo ratings yet

- Safety Matches PDFDocument4 pagesSafety Matches PDFBorislav MalinovićNo ratings yet

- Hoja Seguridad SikaboomDocument6 pagesHoja Seguridad SikaboomcristhianNo ratings yet

- Propylene Glycol USP EPDocument12 pagesPropylene Glycol USP EPCaio César RaposoNo ratings yet

- SDS - Jotamastic 87 Standard - Comp. B - Marine - Protective - English (Uk) - SingaporeDocument6 pagesSDS - Jotamastic 87 Standard - Comp. B - Marine - Protective - English (Uk) - SingaporeAmi Terecef Gamboa MirandaNo ratings yet

- Ghs Calcium Glycerophosphate MsdsDocument6 pagesGhs Calcium Glycerophosphate MsdsSRI VYJAYANTHI QANo ratings yet

- Used Oil MsdsDocument7 pagesUsed Oil Msdspequenita34No ratings yet

- SPE RMD v1 Refractory Model DipDocument4 pagesSPE RMD v1 Refractory Model DipPiNo ratings yet

- Safety Data Sheet for Polylactide (PLA) ResinDocument6 pagesSafety Data Sheet for Polylactide (PLA) ResinJimena SuárezNo ratings yet

- Engine Oil MSDSDocument7 pagesEngine Oil MSDSSantos RexNo ratings yet

- G41363046476 Specs SheetDocument4 pagesG41363046476 Specs SheetsercanworkNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument6 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingRavi YadavNo ratings yet

- MSDS Cony WangDocument7 pagesMSDS Cony WangHsalmani1991No ratings yet

- Msds Shell Thermia BDocument7 pagesMsds Shell Thermia BMuhammad Nurul AminNo ratings yet

- SDS - Dipropylene Glycol LODocument10 pagesSDS - Dipropylene Glycol LOMahmud HusainNo ratings yet

- msds masterbatch stobecDocument4 pagesmsds masterbatch stobecemirugaldNo ratings yet

- MSDS-H1D572C-WB Primer White OutdoorDocument3 pagesMSDS-H1D572C-WB Primer White Outdooragung satriaNo ratings yet

- MSDS for Antisol A solvent and resin solutionDocument3 pagesMSDS for Antisol A solvent and resin solutionAbu MaazNo ratings yet

- Identification and hazards of hardener componentDocument5 pagesIdentification and hazards of hardener componentAndres Fitria FarrelNo ratings yet

- Der 332Document9 pagesDer 332bd1972No ratings yet

- Corena S4 P68Document7 pagesCorena S4 P68Beryl FernandesNo ratings yet

- AZG 368 Aluminum - Zirconium Tetrachlorohydrex-Gly, USPDocument6 pagesAZG 368 Aluminum - Zirconium Tetrachlorohydrex-Gly, USPZi LiNo ratings yet

- Hypogear 80W-90 - BP Australia Pty LTDDocument5 pagesHypogear 80W-90 - BP Australia Pty LTDBiju_PottayilNo ratings yet

- MSDS Capilene G 86 EDocument4 pagesMSDS Capilene G 86 Ezubair1951No ratings yet

- Identification and hazards of water-based zinc primer componentsDocument5 pagesIdentification and hazards of water-based zinc primer componentsAndres Fitria FarrelNo ratings yet

- Material Safety Data Sheet Mixed Xylene: 1. Product and Company IdentificationDocument7 pagesMaterial Safety Data Sheet Mixed Xylene: 1. Product and Company IdentificationsahilchemNo ratings yet

- Safety Data Sheet SummaryDocument6 pagesSafety Data Sheet SummaryMASH TLMOSNo ratings yet

- Corena S3 R 46Document7 pagesCorena S3 R 46Beryl FernandesNo ratings yet

- Safety Data Sheet for FSC-7C Leak Sealing CompoundDocument3 pagesSafety Data Sheet for FSC-7C Leak Sealing CompoundSagu LempengNo ratings yet

- Workplace Vocabulary for Esl Students: With Exercises and TestsFrom EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsNo ratings yet

- NDX ZuoDocument28 pagesNDX Zuobella_dsNo ratings yet

- An Interpreters Guide To Understanding and Working With Seismic-Derived Acoustic Impedance DataDocument8 pagesAn Interpreters Guide To Understanding and Working With Seismic-Derived Acoustic Impedance Databella_dsNo ratings yet

- ITB IFP Dual Master 2015 Application - Motivation FormDocument6 pagesITB IFP Dual Master 2015 Application - Motivation Formbella_dsNo ratings yet

- Stratimagic 2015Document6 pagesStratimagic 2015bella_dsNo ratings yet

- Seismic Attributes - A Historical PerspectiveDocument71 pagesSeismic Attributes - A Historical PerspectivePhạm Lê Huy KhánhNo ratings yet

- Academic Transcript (In English)Document2 pagesAcademic Transcript (In English)bella_dsNo ratings yet

- Nautilus Full Course List: Nautilus Is Part of The RPS GroupDocument23 pagesNautilus Full Course List: Nautilus Is Part of The RPS Groupbella_dsNo ratings yet

- Shale Gas Reservoir Characterization WorkflowsDocument5 pagesShale Gas Reservoir Characterization Workflowsbella_dsNo ratings yet

- Presentation A.braathen Sinai Basement ReservoirsDocument27 pagesPresentation A.braathen Sinai Basement Reservoirsbella_dsNo ratings yet

- MATLAB Curve FittingDocument3 pagesMATLAB Curve FittingredpoptartNo ratings yet

- Opendtect Seismic Lab IDocument6 pagesOpendtect Seismic Lab IParth ChauhanNo ratings yet

- Stratimagic 2015Document6 pagesStratimagic 2015bella_dsNo ratings yet

- Chapter 10 - Well CorrelationDocument33 pagesChapter 10 - Well Correlationbella_ds50% (2)

- Aapg08 Chimney PosterDocument6 pagesAapg08 Chimney Posterbella_dsNo ratings yet

- CGGV 0000007821Document4 pagesCGGV 0000007821bella_dsNo ratings yet

- Petrel 2011 - Data ImportDocument41 pagesPetrel 2011 - Data ImportBangsawan Arief100% (1)

- F029Document5 pagesF029bella_dsNo ratings yet

- Create horizons and zones in 3D geological modelingDocument30 pagesCreate horizons and zones in 3D geological modelingbella_dsNo ratings yet

- Chapter 06 - Seismic InterpretationDocument11 pagesChapter 06 - Seismic Interpretationbella_ds0% (1)

- Chapter 11 - Fault ModelingDocument52 pagesChapter 11 - Fault Modelingbella_ds100% (1)

- Chapter 09 - Input Data EditingDocument34 pagesChapter 09 - Input Data Editingbella_dsNo ratings yet

- Chapter 14 - Geometrical Property ModelingDocument5 pagesChapter 14 - Geometrical Property Modelingbella_dsNo ratings yet

- Chapter 08 - IsochoreDocument3 pagesChapter 08 - Isochorebella_ds0% (1)

- Chapter 05 - 3D Seismic DataDocument8 pagesChapter 05 - 3D Seismic Databella_dsNo ratings yet

- Chapter 07 - Fault DataDocument8 pagesChapter 07 - Fault Databella_dsNo ratings yet

- Chapter 02 - Petrel InterfaceDocument12 pagesChapter 02 - Petrel Interfacebella_ds100% (1)

- Chapter 07 - Fault DataDocument8 pagesChapter 07 - Fault Databella_dsNo ratings yet

- Chapter 01 - GeomodelingDocument10 pagesChapter 01 - Geomodelingbella_dsNo ratings yet

- Chapter 03 - Data SetDocument8 pagesChapter 03 - Data Setbella_ds100% (1)

- Chapter 1 PetrelDocument5 pagesChapter 1 PetrelmydealiaNo ratings yet

- Msds Etoposide DP 003Document8 pagesMsds Etoposide DP 003Aat Prayoga MuhtarNo ratings yet

- Minimum Oil Circuit BreakerDocument4 pagesMinimum Oil Circuit BreakergshdavidNo ratings yet

- Comments Resolution SheetDocument16 pagesComments Resolution SheetPurushothaman SeenuNo ratings yet

- Safety Data Sheet: Hempadur Avantguard 750Document10 pagesSafety Data Sheet: Hempadur Avantguard 750Gusti NugrahaNo ratings yet

- Safety Data Sheet: Styropor BF - 222Document8 pagesSafety Data Sheet: Styropor BF - 222Desy Arisandi YahjaNo ratings yet

- MSDS Fleetguard ES Complete EG Premix LT16587 ENDocument14 pagesMSDS Fleetguard ES Complete EG Premix LT16587 ENVusal HasanovNo ratings yet

- Northport LBT Manual Guides Safety OperationsDocument11 pagesNorthport LBT Manual Guides Safety OperationsEsewGembulNo ratings yet

- Helizarin ET Liq CDocument12 pagesHelizarin ET Liq CMayank DhawanNo ratings yet

- Manual Standpipes HandoutDocument9 pagesManual Standpipes HandoutjosebolisNo ratings yet

- Msds 1301 RemtecDocument5 pagesMsds 1301 RemtecJeremy KumarNo ratings yet

- SDS Dezcal Descaler GB v5Document7 pagesSDS Dezcal Descaler GB v5jeanyoperNo ratings yet

- Fire Safety Manual (2015Document545 pagesFire Safety Manual (2015anon_49126960085% (13)

- Eni OTE 32 - 2610 MsdsDocument13 pagesEni OTE 32 - 2610 MsdsRajesh BNo ratings yet

- FF Plan Submission Guide-Rev3Document7 pagesFF Plan Submission Guide-Rev3FaseeshNo ratings yet

- EU Safety Data Sheet: KRONES Hydrocare 1902Document10 pagesEU Safety Data Sheet: KRONES Hydrocare 1902A TurkiNo ratings yet

- MSDS UreaDocument15 pagesMSDS UreaKadek Ayang Cendana PrahayuNo ratings yet

- Rubia S Serie MSDS TLCDocument5 pagesRubia S Serie MSDS TLCWong JowoNo ratings yet

- Arcroma Lutexal Additive HVWDocument13 pagesArcroma Lutexal Additive HVWClub classic 350No ratings yet

- SP661E Safety Ver 1.1 GBDocument17 pagesSP661E Safety Ver 1.1 GBDrow RangerNo ratings yet

- Methanol MSDS PDFDocument10 pagesMethanol MSDS PDFPutriErvinaNo ratings yet

- FM Global - Fire Suppression Physics For Sprinkler ProtectionDocument14 pagesFM Global - Fire Suppression Physics For Sprinkler ProtectionChidi Henry100% (1)

- Topic:: Barangay Fire BrigadeDocument10 pagesTopic:: Barangay Fire BrigadeMarvin SantosNo ratings yet

- Draft Aar First Day CompetencyDocument3 pagesDraft Aar First Day CompetencyKeziah Nicole FernandezNo ratings yet

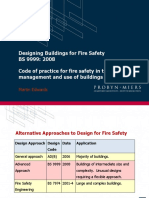

- Designing Buildings For Fire Safety BS 9999: 2008 Code of Practice For Fire Safety in The Design, Management and Use of BuildingsDocument39 pagesDesigning Buildings For Fire Safety BS 9999: 2008 Code of Practice For Fire Safety in The Design, Management and Use of BuildingsSikliNo ratings yet

- Fire Fighting SystemDocument29 pagesFire Fighting SystemAnonymous F3Ekm6HBs50% (2)

- Material Safety Data SheetDocument4 pagesMaterial Safety Data SheetalexandrepondeNo ratings yet

- Comprehensive Safety and Health Program ConstructionDocument15 pagesComprehensive Safety and Health Program ConstructionNina CaliwagNo ratings yet

- Guide Autocad LayersDocument17 pagesGuide Autocad LayersMoe Oo HtunNo ratings yet

- Fire Hose Couplings and Reducers Product GuideDocument18 pagesFire Hose Couplings and Reducers Product GuideMuhammad Ja'far IbrahimNo ratings yet

- Fire Safety Systems ManualDocument21 pagesFire Safety Systems Manualkartikeya RanjanNo ratings yet