Professional Documents

Culture Documents

ARCH 3126 Concrete & Steel Structures

Uploaded by

Susána SgfOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ARCH 3126 Concrete & Steel Structures

Uploaded by

Susána SgfCopyright:

Available Formats

ARCH 3126 Steel, Timber & Concrete Spring 2005

Monday, March 28

th

Homework #23 is due Today (Chapter 3 Steel). Homework #24 is

due Wednesday, March 30

th

(Chapter 12 - Steel).

The text is written for the ACI 318-95 code. The current edition, ACI

318-02, contains some major revisions and we will cover most of the

difference in the two codes that pertain to homework solutions. The

newest version of the code 318-05 has not been published yet.

Chapter 1 -- Introduction, Materials, and Properties

1.1 -- Reinforced Concrete Structures

The three most common building materials used today from which

structures are built are wood, steel, and concrete (including

prestressed). The three most common structural systems are better

termed timber, structural steel, and reinforced concrete.

The primary reason that reinforced concrete is a logical union of plain

concrete and steel in regards to there strength is due to the high

compressive (but low tensile) strength of concrete and the high tensile

strength of steel reinforcing (Draw a beam showing the location of the

reinforcement in the tension zone). Also they have similar rates of

thermal expansion.

1.2 -- Historical Background

Very interesting, but this is not a history class.

1.3 --Concrete

Plain concrete is made by mixing cement, fine aggregate, coarse

aggregate, water, and frequently admixtures.

1

ARCH 3126 Steel, Timber & Concrete Spring 2005

1.4 -- Cement

The cement has adhesive and cohesive properties, which bond mineral

fragments. Cements used in reinforced concrete construction are called

hydraulic cements, which set and harden in the presence of water (Type

I Portland cement). Strength is normally attained in 28 day (varies with

strength). Table 1.4.1 pp. 6 shows the types of Portland cement as

follows:

Type Properties

I Ordinary construction

II Moderate sulfate resistance

III High early strength

IV Low heat of hydration

V High sulfate resistance

K Expansive

In addition an A indicates that the concrete be air-entrained which

provides durability.

1.5 -- Aggregates

Aggregate occupies about 75% of the total volume of concrete (least

expensive part). Fine aggregate (sand) is material less than 3/16 in. and

coarse aggregate (gravel) large than that. The nominal maximum size

of coarse aggregate from ACI - 3.3.2 is governed by the clearance

between the sides of a form and the adjacent bars as follows:

1. 1/5 the narrowest dimension between sides of forms

2. 1/3 the depth of slabs

3. 3/4 the minimum clear spacing between reinforcing bars

2

ARCH 3126 Steel, Timber & Concrete Spring 2005

Structural lightweight concrete is usually made from kiln dried

aggregates of expanded shale or clay (some are natural). Typical

weights are from 70 to 115 pcf (145 for normal weight). All-

lightweight concrete contains both lightweight fine and coarse

aggregate. Sand-lightweight concrete contains only lightweight coarse

aggregate. Sand replacement is a term used to define concrete with all

or part of the lightweight fine aggregate replaced with natural sand.

See Figure 1.5.1 pp. 7 for some approximate unit weights of

lightweight aggregate concrete.

1.6 -- Admixtures

1. The most widely used admixture in concrete is air-entraining

which provides an increase in durability.

2. Accelerating admixtures will decrease the time required for curing

(best for cold weather placement).

3. Water-reducing and Set-controlling admixtures may be used for

higher strength (less water) and durability (also for hot weather

placement).

4. Admixtures for flowing concrete are used to produce slump rates

of 7 inches or greater and increase workability (commonly

termed plasticizers).

Other admixtures can produce gas, expansion, color, fungus-germ-

insect protection or provide dampproofing, reduced permeability and

aggregate expansion or inhibit corrosion.

1.7 -- Compressive Strength

The strength of concrete is controlled by proportioning of cement,

coarse and fine aggregate, water and admixture. The most important

variable in determining strength is the water to cement (w/c) ratio.

The slump test is the measure of the workability of concrete where a

truncated cone-shaped 12 inch metal mold is filled with fresh concrete

and the lifted off. The distance the top of the wet mass is the slump (3

to 4 inched is normally desired).

3

ARCH 3126 Steel, Timber & Concrete Spring 2005

The strength of concrete is denoted by f'

c

which is the standard 28 day

compressive strength in psi of test cylinder 6 in. in diameter and 12 in.

high. (200-mm cube test in other parts of the world). The maximum

ultimate strain of concrete is 0.003 per ACI - 10.2.3. Strengths of

concrete range from 3000 psi up the 18000 psi (3 to 10 normal for slabs

to high strength columns).

1.8 -- Tensile Strength

The strength of concrete in tension greatly effects the extent and size of

cracking in structures and is measured by the split-cylinder test.

Tensile strength in flexure is known as the modulus of rupture and

is governed by ACI - 11.2 as follows:

f f normal

ct c

6 7 . ' ( )

f f sand lightweight

ct c

5 7 . ' ( )

f f all lightweight

ct c

5 ' ( )

1.9 -- Modulus of Elasticity

The modulus of elasticity of concrete varies primarily with strength, but

also with weight, age and size. The modulus of elasticity per ACI -

8.5.1 is as follows (also in Table 1.9.1 pp. 16 for normal weight):

E w f all

c c c

33

1 5 .

' ( )

E f normal

c c

57000 ' ( )

1.10 -- Creep and Shrinkage

Creep is the property of concrete by which it continues to deform with

time under sustained loads at unit stresses within the elastic range.

Shrinkage is the property of concrete by which it continues to change in

volume with time that is unrelated to load application (both rates will

decrease with time).

4

ARCH 3126 Steel, Timber & Concrete Spring 2005

1.11 -- Concrete Quality Control

The specified compressive strength is deemed adequate when both

of the following are occur (ACI 5.6.3.3):

1. Average of all sets of three consecutive strength test equal or exceed f'

c

2. No individual strength test falls below f'

c

by more than 500 psi when

f'

c

<5000 psi or by more than 0.1 f'

c

when f'

c

>5000 psi.

If these are not met in-place testing may indicate the concrete is

adequate. If not re-analysis may indicate acceptance. If not load

testing may be used for acceptance. If not then it must be strengthened

or removed.

1.12 -- Steel Reinforcement

Steel reinforcement may consist of bars, welded wire fabric, or wires

(usually deformed bars). Sizes are given in Table 1.12.1 pp. 21 (also in

back of your ACI code or ACI 340 SP-7(97) REINFORCEMENT 1,

(make a big copy of this) and types and strengths of steel in Table

1.12.4 pp. 23. Billet steel (ASTM A615/A615M) is newly made and is

sufficiently ductile. Grade 60 is the primary material used (75 is

become more popular), but grade 40 is used for smaller bars to be bent.

The modulus of elasticity of steel is 29,000,000 psi (ACI 8.5.2) and

prestress steel is lower (27,000,000 psi) and more variable, thus it

should be obtained from the manufacturer or by test (ACI 8.5.3).

1.13 -- SI Units

You are the torch bearers for this, Federal government now and others

later. We will do very little in terms of SI units.

5

ARCH 3126 Steel, Timber & Concrete Spring 2005

Tuesday, March 29

th

Chapter 2 -- Design Methods and Requirements

2.1 -- ACI Building Code

The ACI Building Code Requirements for Reinforced Concrete is

based partly on empirical and mostly rational data.

2.2 -- Strength Design and Working Stress Design Methods

The working stress method focuses on conditions at service load and

the strength design method focuses on loads when failure may be

imminent.

2.3 -- Working Stress Method

The working stress method (now referred to as alternate design method,

but not in ACI 318-02) has set limits on the stresses allowed under

service loads (working loads).

allowable

f f

Alternate Design Method ACI App A of old code, not in ACI 318-02.

Some of the obstacles to the working stress method are as follows:

1. No account for different types of loads.

2. Creep and shrinkage are not easily accounted for in elastic

stresses.

3. Stress is not proportional to strain at concrete crushing therefore

the inherent factor of safety is unknown.

2.4 -- Strength Design Method

The strength design method (formerly called ultimate strength method)

has the service loads increased by sufficient factors to obtain the load at

which failure is considered to be imminent. The strength provided

must be greater than the required strength to carry these factored loads.

6

ARCH 3126 Steel, Timber & Concrete Spring 2005

2.5 -- Comments on Design Methods

Although strength design is currently the philosophy employed most

widely, serviceability must be maintained. Working stress is stilled

required to calculate deflections and cracking of structure in service

load conditions.

2.6 -- Safety Provisions--General

The two primary factors used to provide safety in the ultimate strength

method of design are U the overload factors (load factors) in ACI 9.2

(new factors) or ACI C.2 (old factors) and the understrength factors

(strength reduction factors) in ACI 9.3 (new factors) or ACI C.3 (old

factors).

u n

M M

Design Strength<Required Strength

2.7 -- Safety ProvisionsTraditional ACI Code skip details

The structure must be designed for the most severe of any load

combination. The load factors for some basic combinations are as

follows per ACI C.2 (the text pp. 38 is old code):

(C-1)U = 1.4D + 1.7L Dead D & Live - L

(C-2)U = 0.75(1.4D + 1.7L) + (1.6W or 1.0E) Wind W Seismic - E

1.3W w/o direction factor

1.4E if service loads

(C-3)U = 0.9D + (1.3W or 1.0E) Overturning

(C-4)U = 1.4D + 1.7L +1.7H Earth pressure - H

(C-5)U = 0.75(1.4D + 1.7T + 1.7L) Temperature - T

(C-6)U = 1.4D + 1.4T

No account for D+L+(2 others), but old codes use 2/3 of basic factors.

In addition, for intermediate moment frames shear must be check with

seismic load doubled per ACI 21.12(b). Applies to members resisting

seismic loading (frame).

7

ARCH 3126 Steel, Timber & Concrete Spring 2005

The strength reduction factors accounting for adverse variations in

material strength, workmanship, dimensions, control & degree of

supervision, and importance of the member to the building structure are

as follows per ACI C.3 (the text pp. 39 is old code):

= 0.90 Tension controlled sections (

t

> 0.005)

= 0.75 Compression members, spirally reinforced

Compression controlled sections (

t

< 0.002 i.e. balance)

= 0.70 Compression members, others

Compression controlled sections (

t

< 0.002 i.e. balance)

= 0.85 Shear and torsion

= 0.70 Bearing on concrete

= 0.65 Bending in plain concrete

2.8 -- Safety ProvisionsACI Appendix C Load and Strength Reduction

Factors

The structure must be designed for the most severe of any load

combination. These are the factors in the ACI 318-02 code. The load

factors for some basic combinations are as follows per ACI 9.2 (the text

pp. 40 is old appendix (typo 1.5 vs. 15)):

(9-1) U = 1.4(D+F)

Dead D & Fluid - F

(9-2) U = 1.2(D+F+T) + 1.6(L+H) + 0.5(L

r

or S or R)

Live - L

Temperature T

Earth pressure H

Roof Live - L

r

Snow S

Rain - R

(9-3) U = 1.2D + 1.6(L

r

or S or R) + (1.0L or 0.8W)

Wind W

Can use 0.5L (not garages or L>100psf)

(9-4) U = 1.2D + 1.6W + 1.0L + 0.5(L

r

or S or R)

1.3W w/o directionality

(9-5) U = 1.2D + 1.0E + (1.0L or 0.2S)

8

ARCH 3126 Steel, Timber & Concrete Spring 2005

Seismic E

1.4E if service

Can use 0.5L (not garages or L>100psf)

(9-6) U = 0.9D + 1.6W + 1.6H

1.3W w/o directionality

(9-7) U = 0.9D + 1.0E + 1.6H

1.4E if service

The strength reduction factors accounting for adverse variations in

material strength, workmanship, dimensions, control & degree of

supervision, and importance of the member to the building structure are

as follows per the text pp. 41 pr C.3 (ASCE 7-88):

= 0.90 Tension controlled sections

= 0.70 Compression members, spirally reinforced

Compression controlled sections

= 0.65 Compression members, others

Compression controlled sections

= 0.75 Shear and torsion

= 0.65 Bearing on concrete

= 0.55 Bending in plain concrete

2.9 -- Handbooks and Computer Software

Some of the useful books include the following:

1. Strength Design Handbook - ACI 340R-97 SP-17(97)

2. CRSI Handbook

3. PCI Design Handbook

4. ACI Detailing Manual

5. PCA Design Handbook

2.10 -- Dimensions and Tolerances

These are covered in ACI 7.5 called placing reinforcing and the

strength reduction factors are intended to account for this.

9

ARCH 3126 Steel, Timber & Concrete Spring 2005

2.11 -- Accuracy of Computations

Every book has this section (Carry 4 digits in calculations and round

answer to 3 digits).

Chapter 3 -- Strength of Rectangular Sections in Bending

3.1 -- General Introduction

Working stress methods will be covered in Chapter 4 and for now we

will concentrate on the strength design method.

3.2 -- Basis of Nominal Flexural Strength

The modern analytical approach to reinforced concrete beam design

should include a linear strain distribution and a nonlinear stress

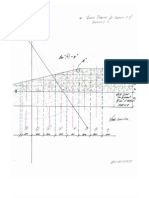

distribution as shown in Figure 3.2.1 pp. 48 (shown below). The

following equations can be derived statically assuming a ductile failure

of steel at yield stress:

k

1

- fraction of stress area to rectangular block

k

2

- fraction of x to centroid

k

3

- fraction of f

c

at maximum stress

C k k f xb

c

1 3

'

10

ARCH 3126 Steel, Timber & Concrete Spring 2005

T A f

s y

F T C

x

0

x

A f

k k f b

s y

c

1 3

'

M M T d k x

c n

( )

2

M A f d

k

k k

A f

f b

n s y

s y

c

_

,

2

1 3

'

It should be noted that only the ratio of k

2

/(k

1

k

3

) need be know and

not the individual constants. Tests indicate that the variation is

between 0.55 and 0.63 as shown in Figure 3.2.3 pp. 50.

3.3 -- Whitney Rectangular Stress Distribution

The computation of flexural strength based on the approximately

parabolic stress may be done, but the designer needs a simpler method

based on static equilibrium. The Whitney rectangular stress block as

shown in Figure 3.3.1 pp. 51 (shown below) is the basis for standard

design. The average stress of 0.85f

c

' is used over a rectangular depth

a=

1

x (ACI 10.2.7.1). The value for

1

should be taken as 0.85 for f

c

'

< 4000 psi, and 0.05 less for each 1000 psi of f

c

' in excess of 4000 psi

(10.2.7.3). The value of

1

need not be less than 0.65 (See ACI SP-

17(97) FLEXURE 1 for this and more). This can be written as follows:

1

085 0 05

4000

1000

0 65

_

,

. .

'

.

f

c

11

ARCH 3126 Steel, Timber & Concrete Spring 2005

The static derivation is as follows:

C f ba

c

0 85 . '

T A f

s y

F T C

x

0

a

A f

f b

s y

c

0 85 . '

M M A f d

a

c n s y

( )

2

M A f d

A f

f b

n s y

s y

c

_

,

059 .

'

It should be noted that the ratio of k

2

/(k

1

k

3

) turn out to be 0.59 which

is right in the middle between 0.55 and 0.63.

12

ARCH 3126 Steel, Timber & Concrete Spring 2005

3.4 Nominal Moment Strength M

n

- Rectangular Sections Having

Tension Reinforcement Only

The above definitions are for sections that are singly reinforced.

Minimum concrete cover around the reinforcing per ACI 7.7 provides a

minimum, but protection from fire may require more. Typical values

for cast-in-place concrete include the following:

3 Cast against and permanently exposed to earth (All)

2 Exposed to weather or earth (#6 & Larger)

1-1/2 Beam & columns not exposed to weather or earth (All)

3/4 Slab walls & joists not exposed to weather or earth

(#11 & smaller)

It should be obvious that all the concrete in tension was ignored and the

effective depth d (distance from tensile steel to compressive face of

concrete) was used in computation.

The ACI Strength Design Method includes the provision for basic load

factors and a strength reduction factor of 0.9 (tension controls) down to

0.65 (tied members). The basic equations for the ultimate moment

caused by the load M

u

and the nominal moment strength of the beam

M

n

is as follows:

M M

n u

The following assumptions apply (ACI 10.2)

1. The strength of members shall satisfy equilibrium and compatibility.

2. Strain in the steel and concrete shall be directly proportional to the

distance from the neutral axis.

3. The maximum usable strain

cu

at the extreme compression fiber shall

be 0.003.

4. The tensile strength of the concrete is neglected

5. The modulus of elasticity of steel is 29000 ksi.

6. Whitney stress block applies as previously defined.

13

ARCH 3126 Steel, Timber & Concrete Spring 2005

The following example is from Fall 1999 and is actually a homework

problem for Fall 1997 and 2001 and Spring 2004 (work either the next

or this example). This example is revised for Unified Design.

Problem 3.3 case 2 - Compute the nominal flexural strength M

n

and the

service moment capacity (M

D

+ M

L

) assuming the total service moment

is 60% live load. Use d=19.5 in, b

w

=12 in, 3-#10 bars, f

c

=3500psi and

f

y

=60,000psi.

Since f

c

=3500psi < 4000 psi

85 . 0

1

Else

65 . 0

1000

4000 '

05 . 0 85 . 0

1

,

_

c

f

OR FLEXURE 1

( ) a a ba f C

c

35700 12 3500 85 . 0 ' 85 . 0

( ) 228600 60000 27 . 1 3

y f

f A T

228600 35700 0

a T C C T F

x

( )

( )

403 . 6

12 3500 85 . 0

60000 27 . 1 3

' 85 . 0

b f

f A

a

c

y s

OR

403 . 6

35700

228600

a

( ) ft k in lb

a

d f A M M

y s n c

,

_

5 . 310 3726000

2

403 . 6

5 . 19 60000 27 . 1 3 )

2

(

OR

ft k in lb

a

d C

a

d T M M

n c

,

_

5 . 310 3726000

2

403 . 6

5 . 19 228600 )

2

( )

2

(

OR

( )

( )

( )

ft k in lb

b f

f A

d f A M

c

y s

y s n

,

_

,

_

5 . 310 3726000

12 3500

60000 27 . 1 3

5882 . 0 5 . 19 60000 27 . 1 3

'

5882 . 0

ft k M

n

5 . 310

14

ARCH 3126 Steel, Timber & Concrete Spring 2005

Find what value to use from

t

Since a = 6.403 =

1

x , x = a/

1

x = 6.403/0.85 = 7.533

Find

t

from the strain diagram by geometry as follows:

004766 . 0 003 . 0

533 . 7

533 . 7 5 . 19

533 . 7 5 . 19 533 . 7

003 . 0

cu t

t t cu

x

x d

x d x

Since

t

> 0.004, meets code, but

t

< 0.005, transition zone

t

= 0.005 = 0.9 tension controls

t

= 0.004766 = 0.8805 Our case

t

= 0.002 = 0.65 compression controls (tied)

Since M

L

=0.6M

s

, M

D

=0.4M

s

and M

u

=1.2M

D

+1.6M

L

then:

) 6 . 0 ( 6 . 1 ) 4 . 0 ( 2 . 1 ) 5 . 310 ( 8805 . 0

s s n

M M M +

635 . 1

5 . 310

635 . 1 8805 . 0

44 . 1

5 . 310

n

s

s

n

M

M

M

M

ft k M

s

9 . 189

The following example is from Fall 1997 and 2001 and is actually a

homework problem for Fall 1999 and 2003 and Spring 2005 (work

either the previous or the this example). This example is revised for

Unified Design.

Problem 3.3 case 5 - Compute the nominal flexural strength M

n

and the

service moment capacity (M

D

+ M

L

) assuming the total service moment

is 60% live load. Use d=36.25 in, b

w

=18 in, 8-#11 bars, f

c

=4000psi

and f

y

=60,000psi.

1

0 85 0 05

4000

1000

0 85 0 05

4000 4000

1000

0 85 0 65

_

,

_

,

. .

'

. . . .

f

c

FLEXURE 1

( ) C f ba a a

c

0 85 0 85 4000 18 61200 . ' .

15

ARCH 3126 Steel, Timber & Concrete Spring 2005

( ) T A f

f y

8 156 60000 748800 .

F T C C T a

x

0 6 1 2 0 0 6 4 8 8 0 0

( )

( )

a

A f

f b

s y

c

0 85

8 156 60000

0 85 4000 18

12 24

. '

.

.

.

OR

a

748800

61200

12 24 .

( ) M M A f d

a

ib in k ft

c n s y

_

,

( ) . .

.

2

8 156 60000 36 25

12 24

2

22560000 1880

OR

M M T d

a

C d

a

ib in k ft

c n

_

,

( ) ( ) .

.

2 2

648800 36 25

12 24

2

22560000 1880

OR

( )

( )

( )

M A f d

A f

f b

in lb k ft

n s y

s y

c

_

,

_

,

0 59 8 156 60000 36 25 0 59

8 156 60000

4000 18

22560000 1880 .

'

. . .

.

M k ft

n

1880

Find what value to use from

t

Since a = 12.24 =

1

x , x = a/

1

x = 12.24/0.85 = 14.40

Find

t

from the strain diagram by geometry as follows:

004552 . 0 003 . 0

40 . 14

40 . 14 25 . 36

40 . 14 25 . 35 40 . 14

003 . 0

cu t

t t cu

x

x d

x d x

Since

t

> 0.004, meets code, but

t

< 0.005, transition zone

t

= 0.005 = 0.9 tension controls

t

= 0.004552 = 0.8618 Our case

t

= 0.002 = 0.65 compression controls (tied)

16

ARCH 3126 Steel, Timber & Concrete Spring 2005

Since M

L

=0.6M

s

, M

D

=0.4M

s

and M

u

=1.2M

D

+1.6M

L

then:

) 6 . 0 ( 6 . 1 ) 4 . 0 ( 2 . 1 ) 1880 ( 8618 . 0

s s n

M M M +

671 . 1

1880

671 . 1 8618 . 0

44 . 1

1880

n

s

s

n

M

M

M

M

ft k M

s

1125

17

ARCH 3126 Steel, Timber & Concrete Spring 2005

Wednesday, March 30

th

Homework #24 is Today (Chapter 12 - Steel). Homework #25 is due

Wednesday, April 6

th

(Chapters 1 & 2).

3.5 -- Balanced Strain Condition

At the balanced strain condition the maximum strain

cu

at the extreme

concrete compression fiber just reaches 0.003 simultaneously with the

tension steel reaching

y

= f

y

/E

s

(0.002069 for f

y

= 60 ksi) as shown

below. The amount of steel corresponding to the balanced condition is

A

sb

.

If the actual steel provided was more than A

sb

then a sudden failure

would occur at ultimate loading since the concrete would fail first in a

brittle manner (BAD).

If the actual steel provide was less than A

sb

then a gradual failure

would occur at ultimate loading since the steel would fail first in a

ductile manner (GOOD).

18

ARCH 3126 Steel, Timber & Concrete Spring 2005

Derive Equations 3.5.1 through 3.5.4 on pp. 55 for the balanced strain

condition for a rectangular beam with tension reinforcement only (SKIP

AND SHOW RESULTS) (FLEXURE 1).

A

bd

s

(3.5.1)

x d

b

cu cu y

+

x

d

b cu

cu y

x

d f

b

y

+

0 003

0 003 29000000

.

. /

x

d f

b

y

+

87000

87000

(3.5.2)

C f b x

b c b

0 85

1

. '

T A f bdf

b sb y b y

F T C

x

0

0 85

1

. ' f b x bdf

c b b y

b

c

y

b

f

f

x

d

_

,

085

1

. '

(3.5.3)

b

c

y y

f

f f

_

,

085 87000

87000

1

. '

(3.5.4)

19

ARCH 3126 Steel, Timber & Concrete Spring 2005

3.6 -- Maximum Reinforcement Ratio

In order to assure a ductile failure the ACI limits (ACI 10.3.3) the

amount of tension steel to not more than 75 % of the amount in the

balanced strain condition (max = 0.75

b

). Table 3.6.1 pp. 57 gives

maximum reinforcement ratios, also FLEXURE 1 SP-17(97). This is

all from the 1995 or 1999 ACI code. The 2002 code states in 10.3.5

that if

t

>0.004 to ensure ductility (about 72.4% for grade 60).

A more direct way of controlling ductility is prescribe a maximum

value for the neutral axis distance x at the failure imminent condition

(max x = 0.75 x

b

).

For the 2002 code for flexural tension reinforcement at

t

= 0.004 the

strength reduction factor turns out to be = 0.81667 using

t

= 0.002

for grade 60 steel. Other important strain-phi relationships are as

follows:

t

= 0.005 = 0.9 tension controls

t

= 0.002 = 0.65 compression controls (tied)

t

= 0.002 = 0.70 compression controls (spiral)

t

= 0.004 = 0.81667 maximum for singly reinforced (tied)

t

= 0.003667 = 0.78889 balanced condition (tied)

3.7 -- Minimum Reinforcement Ratio

This is all a very nice derivation of the amount of reinforcement

required to provide the same moment capacity as the cracking moment

of the concrete. This led to ACI 10.5.1 that states:

A

f

f

b d

s

c

y

w ,min

'

3

but not less than

y

f

200

min

OR

d b

f

A

w

y

s

200

min ,

20

ARCH 3126 Steel, Timber & Concrete Spring 2005

For statically determinate T-section with the flange in tension ACI

10.5.2 that states:

A

f

f

b d

s

c

y

w ,min

'

6

(old)

d b b

f

f

A

w E

y

c

s

) 2 , min(

' 3

min ,

(new)

but not less than

A

f

f

b d

s

c

y

E ,min

'

3

(old) none (new)

Looks like the same requirements to me. Is it?

The amount of reinforcing may be less than the minimum per ACI

10.5.3 provided the area provided is one-third more than is required.

For Slab or footings the minimum area is per ACI 7.12 with spacing

not to exceed 3t or 18.

Grade 40 or 50 A

s

= 0.0020*A

g

Grade 60 A

s

= 0.0018*A

g

Grade 40 or 50 A

s

= 0.0018*A

g

(60/f

y

)

3.8 -- Design of Rectangular Sections in Bending Having Tension

Reinforcement Only Under ACI-10.3 and 10.5

The problem is to determine b, d, and As from the required value of M

n

= M

u

/ and the material properties f

c

' and f

y

. Since there are only two

applicable equations of equilibrium, but three unknown, many possible

solutions exist. Assume = 0.9, if required, and check at the end.

If the reinforcement ratio is preset then the following equation can be

derived from the previously solved equilibrium conditions:

,

_

m f

bd

M

R

y

n

n

2

1

1

2

(3.8.4b)

where

21

ARCH 3126 Steel, Timber & Concrete Spring 2005

m

f

f

y

c

0 85 . '

(3.8.4a)

In some situations the values of b and d are preset are the equations

would be:

_

,

1

1 1

2

m

mR

f

n

y

(3.8.5)

The procedure to be used in strength design of rectangular sections with

tension reinforcement only is as follows (Flexure 2.1 - 2.4 from ACI

SP-17(97) typ., cover this NOW):

Design Table for Singly Reinforced Rectangular Beams

ACI 340R-97 SP-17(97)

FLEXURE 2.1 - 2.4 is set up to find A

s

given bd as follows:

F

bd

2

12000

F

M

F

M

K

u

n

n

Enter FLEXURE 2.1 - 2.4 with K

n

and interpolate to find .

A bd

s

It should be noted that if K

n

is above the line then is must be increased

to 1.33 (<

min

). If 1.33 is less than minimum then use it (<

min

).

If 1.33 is more than minimum then use minimum (

min

). Also if K

n

is off the bottom of the chart compression steel is required (>

max

).

FLEXURE 2.1 - 2.4 is also set up to find bd given as follows:

22

ARCH 3126 Steel, Timber & Concrete Spring 2005

Enter FLEXURE 2.1 - 2.4 with and interpolate to find K

n

.

It should be noted that if K

n

is above the line then is must be decreased

to 0.75K

n

(<

min

). Also if K

n

is off the bottom of the chart

compression steel is required (>

max

).

F

M

F

M

K

u

n

n

bd F

2

12000

FLEXURE 2.1 - 2.4 is also set up to find M

n

given A

s

and bd as

follows:

A

bd

s

Enter FLEXURE 2.1 - 2.4 with and interpolate to find K

n

.

It should be noted that if K

n

is above the line then is must be decreased

to 0.75K

n

(<

min

). Also if K

n

is off the bottom of the chart

compression steel is required (>

max

).

F

bd

2

12000

n n

u

FK M

M

The following example is from Fall 1999 and is actually a homework

problem for Fall 1997 and 2001 and Spring 2004, it has been revised

for the newer version of SP-17 without in the tables (work either the

next or this example). This example is revised for Unified Design.

23

ARCH 3126 Steel, Timber & Concrete Spring 2005

Problem #3.8 case 2 - Design a rectangular beam with tension

reinforcing only such that excessive deflections would not be expected

under normal circumstances. Use the following data and include the

actual beam weight (d/b=1-5-2.0[1.75], w

D

=0.8k/ft, w

L

=1.8k/ft, L=30ft,

f

c

=3000psi and f

y

=60,000psi.)

You could assume thebeam weight in lb/ft = 20 lb/ft * span in feet

20 lb/ft * 30 = 600 lb/ft

( ) ( ) ft k w w w

L D u

/ 56 . 4 8 . 1 6 . 1 4 . 1 2 . 1 6 . 1 2 . 1 + +

( )

n

u

u

M ft k

ft ft k l w

M 0 . 513

8

30 / 56 . 4

8

2 2

00835 . 0

pref

@

01 . 0

T

FLEXURE 1 or 2.1

Enter Table 2.1 with to find K

n

and check = 0.9

1 . 451

n

K

and

F

M

F

M

K

u

n

n

and

F

bd

2

12000

12000

75 . 1

12000

264 . 1

1 . 451

9 . 0

513

2

2

d

d

bd

K

M

F

n

u

,

_

( ) 83 . 29

3

26535

3

75 . 1 12000 264 . 1 d

For total height add 2.5 and round up to h=33 (d=30.5) and b=18

ft k

ft in

in

ft in

in

ft k w

beam

/ 6188 . 0

/ 12

33

/ 12

18

/ 15 . 0

3

,

_

,

_

The following revised values include the beam weight

( ) ( ) ft k w w w

L D u

/ 583 . 4 8 . 1 6 . 1 6188 . 0 8 . 0 2 . 1 6 . 1 2 . 1 + + +

( )

n

u

u

M ft k

ft ft k l w

M 6 . 515

8

30 / 605 . 4

8

2 2

24

ARCH 3126 Steel, Timber & Concrete Spring 2005

( )

395 . 1

12000

5 . 30 18

12000

2 2

bd

F

7 . 410

395 . 1

9 . 0

6 . 515

F

M

K

u

n

Enter Table 2.1 with K

n

and interpolate to find and check = 0.9

0.00751

( )

2

123 . 4 5 . 30 18 00751 . 0 in bd A

s

Choose 3-#11 from REINFORCEMENT 14 (b

max

= 23.5 int.)

The following a check

( )

00834 . 0 00844 . 0

5 . 30 18

68 . 4

2

pref

s

in in

in

bd

A

Enter Table 2.1 with to find K

n

and check = 0.9

K

n

=456.0

( )

395 . 1

12000

5 . 30 18

12000

2 2

bd

F

( ) 9 . 572

9 . 0

6 . 515

1 . 636 395 . 1 0 . 456 >

u

n n

M

F K M

There are many answers to this question, but I will use the following

18x33 w/3-#11

The following example is from Fall 1997 and 2000 and is actually a

homework problem for Fall 1999 and 2003 and spring 2005 (work

either the previous or this example). This example is revised for

Unified Design.

25

ARCH 3126 Steel, Timber & Concrete Spring 2005

Problem #3.8 case 4 - Design a rectangular beam with tension

reinforcing only such that excessive deflections would not be expected

under normal circumstances. Use the following data and include the

actual beam weight (d/b=1-5-2.0[1.75], w

D

=1.2k/ft, w

L

=2.5k/ft, L=30ft,

f

c

=4000psi and f

y

=60,000psi.)

( ) ( ) ft k w w w

L D u

/ 44 . 5 5 . 2 6 . 1 2 . 1 2 . 1 6 . 1 2 . 1 + +

( )

n

u

u

M ft

ft ft k l w

M 0 . 612

8

30 / 44 . 5

8

2 2

01112 . 0

pref

@

01 . 0

T

FLEXURE 1 or 2.2

Enter Table 2.2 with to find K

n

check = 0.9

5 . 601

n

K

and

n

u

K

M

F

and

F

bd

2

12000

12000

75 . 1

12000

131 . 1

5 . 601

9 . 0

0 . 612

2

2

d

d

bd

K

M

F

n

u

,

_

( ) 74 . 28

3

23740

3

75 . 1 12000 131 . 1 d

Increase 5% add 2.5 and round up to h=33 (d=30.5) and b=18 inches

ft k

ft in

in

ft in

in

ft k w

beam

/ 6188 . 0

/ 12

33

/ 12

18

/ 15 . 0

3

,

_

,

_

The following revised values include the beam weight

( ) ( ) ft k w w w

L D u

/ 183 . 6 5 . 2 6 . 1 6188 . 0 2 . 1 2 . 1 6 . 1 2 . 1 + + +

( )

n

u

u

M ft k

ft ft k l w

M 5 . 695

8

30 / 183 . 6

8

2 2

26

ARCH 3126 Steel, Timber & Concrete Spring 2005

( )

395 . 1

12000

5 . 30 18

12000

2 2

bd

F

0 . 554

395 . 1

9 . 0

5 . 695

F

M

K

u

n

Enter Table 2.2 with K

n

and interpolate to find and check 0.9

0.01014

( )

2

57 . 5 5 . 30 18 01014 . 0 in bd A

s

Choose 4-#11 from REINFORCEMENT 14

The following a check

( )

01112 . 0 01137 . 0

5 . 30 18

) 56 . 1 ( 4

2

pref

s

in in

in

bd

A

Enter Table 2.2 with to find K

n

andcheck = 0.9

K

n

=613.7

( )

395 . 1

12000

5 . 30 18

12000

2 2

bd

F

( ) 7 . 772

9 . 0

5 . 695

1 . 856 395 . 1 7 . 613 >

u

n n

M

F K M

There are many answers to this question, but I will use the following

18x33 w/4-#11

1. Assume that

min

< <

max

(I like =@

T

=0.01)

2. Determine the required bd

2

(from R

n

)

3. Choose values for b and d (reasonable proportions d/b=1.5 to 2.0)

4. Determine revised (for new b and d)

27

ARCH 3126 Steel, Timber & Concrete Spring 2005

5. Compute A

s

(from )

6. Select reinforcement and calculate strength (M

n

> M

u

)

7. Remember to check = 0.9 an any step

28

ARCH 3126 Steel, Timber & Concrete Spring 2005

Thursday, March 31

st

Exam # 5 Chapter 3, 5, 6, 11 & 12 (Steel)

29

ARCH 3126 Steel, Timber & Concrete Spring 2005

Friday, April 1

st

Seminar #3 Steel

Homework #25 is due Wednesday April 6

th

(Chapters 1 & 2).

Homework #26 is due Friday, April 8

th

(Chapter 3).

30

ARCH 3126 Steel, Timber & Concrete Spring 2005

Monday, April 4

th

Homework #25 is due Wednesday April 6

th

(Chapters 1 & 2).

Homework #26 is due Friday, April 8

th

(Chapter 3).

3.9 -- Practical Selection for Beam Sizes, Bar Sizes, and Bar Placement

The choice of the steel reinforcement ratio is dependent on the

limitation on the deflection of the beam. Normally one-half of the

maximum permissible value is adequate ( = 0.5

max

= 0.375

b

).

Numerous table in the text and handbooks have been developed to aid

in the selection of proper reinforcement. Some of the following in the

text (I like to us Reinforcement 14 - ACI - SP17):

Table 3.9.1 pp. 66 Total Area for Various Numbers of Reinforcing Bars

Also in REINFORCEMENT 2

Table 3.9.2 pp. 67 Minimum Beam Width According to ACI Code

Also in REINFORCEMENT 9 & 10

Table 3.9.3 pp. 68 Minimum Beam Width for 2 d

b

clear spacing

Table 3.9.4 pp. 68 Minimum Beam Width for 3 d

b

clear spacing

Table 3.9.5 pp. 69 Standard Types and Sizes of Bar Supports

Table 3.9.6 pp. 76 Area per Foot of Width for Various Bar Spacings

Also in REINFORCEMENT 15

The following are some guidelines for selection of beam size:

1. Use whole inches for overall dimensions (slabs 1/2 inches)

2. Beam stem widths in multiple of 2 or 3 inches

3. Minimum clear cover is to ties and stirrups (d not whole inches)

4. Economical beam depth-to-width ratio of 1.5 to 2.0

5. T-shape beam flanges about 20 % of overall depth

The following are some guidelines for selection of reinforcement:

6. Maintain bar symmetry about plane of loading

7. Use at least 2 bars for flexure (1 in joist sometimes)

8. Use #11 for maximum size beam bar

31

ARCH 3126 Steel, Timber & Concrete Spring 2005

9. No more than 2 bar sizes and no more than two sizes apart (ok

but)

10. Try to use one layer of reinforcement

11. Follow ACI 7.6.1 (clear space horizontally > d

b

or 1) & 7.6.2

(clear space vertically > 1 and directly above bars below) for

distances between bars

12. For layers place largest bar nearest face of beam

3.10 Nominal Moment Strength M

n

of Rectangular Sections Having

Both Tension and Compression Reinforcement (SKIP THIS)

Rectangular section with both tension and compression reinforcement

are called doubly reinforced sections. Compression reinforcement is

used to reduce the size of the cross section and reduce deflections. This

may lead to other problems such as large amounts of shear

reinforcement.

The proportion of tension reinforcement above the maximum allowed

that is equalized by compression reinforcement need not be reduced by

the 0.75 factor.

Let the class work through Examples 3.10.1 & 3.10.2 pp. 78 - 81.

3.11 Design of Beams Having Both Tension and Compression

Reinforcement Under ACI-10.3.3 (SKIP THIS)

The compression steel will yield under the following conditions from

Figure 3.11.1 pp. 83:

s y

'

(3.11.2)

T A f bdf

s y y

C f b x

c c

0 85

1

. '

( ) C f f bd

s y c

085 . ' '

F T C C

x c s

+ 0

32

ARCH 3126 Steel, Timber & Concrete Spring 2005

( ) 085 085

1

. ' . ' ' f b x f f bd bdf

c y c y

+

x

f d

f

f

f

y

c

c

y

_

,

1

]

1

1

085

1

085

1

. '

'

. '

(3.11.3)

( )

s

cu

x

x d ' ' (3.11.4)

Substituting (3.11.4) into (3.11.2) gives

( )

cu

y

x

x d '

( )

87000

x

x d f

y

'

x

d

f

y

87000

87000

'

(3.11.5)

Substituting (3.11.3) into (3.11.5) gives

,

_

,

_

,

_

y y

c

y

c

f d f

d f

f

f

87000

87000 ' '

85 . 0

' 85 . 0

1 '

1

(3.11.1)

An alternate solution is as follows (assume at yield, find x):

x d

cu cu y

'

Find the area of tension steel for this condition (A

sy

). If A

sy

> A

s

then

A

s

' yields and

s

' >

y

. The solution is direct (F find x and M find

M

n

). If A

sy

< A

s

then A

s

' does not yield and

s

' <

y

. The solution

is a quadratic as follows (draw strain diagram):

x d

cu cu s

'

'

or

( )

s

cu

x

x d ' '

T A f

s y

33

ARCH 3126 Steel, Timber & Concrete Spring 2005

C f b x

c c

0 85

1

. '

( ) ( ) C A f f A E f

s s s c s s c

' . ' ' . ' 085 085

( ) C A E

x

x d f

s s

cu

c

_

,

_

,

' ' . '

085

F T C C

x c s

+ 0

T C C

c s

+

This turn out to be a quadratic in x (solve it). Then write the moment

equation as follows:

( ) M M C d

a

C d d

n c s

_

,

+

2

'

34

ARCH 3126 Steel, Timber & Concrete Spring 2005

Tuesday, April 5

th

3.12 -- Design of Sections in BendingACI Appendix B Unified

Procedure (THIS IS WHAT WE ARE DOING)

This will be a major part of the ACI 318-02 code. Let the class work

through Examples 3.12.1 & 3.12.2 pp. 90 - 91.

3.13 -- Non-Rectangular Beams (SKIP THIS)

Whitney stress block applies to these shapes per ACI 10.2.7.

The following procedures need revisions for exclusion of from tables

Design Table for Doubly Reinforced Rectangular Beams

Table A (2.1 - 2.4) is set up to find A

s

and A

s

' given bd as follows:

It is assumed that K

n

is off the bottom (compression steel is required).

Select K

n

at

max

from the bottom of Table A(2.1 - 2.4).

F

bd

2

12000

M FK

n n 1

M

n1

should be less than M

u

.

A bd

s1

max

Calculate the additional tension steel required beyond

max

.

M M M

n u n 2 1

With d'/d enter Table B (3.1 - 3.2) to find a

n

'.

35

ARCH 3126 Steel, Timber & Concrete Spring 2005

A

M

a d

s

n

n

2

2

'

A A A

s s s

+

1 2

Select c/d at

max

from the bottom of Table A (2.1 - 2.4) and together

with d'/d enter Table D (4.1 - 4.4) to find a

n

''. If a

n

'>a

n

'' then

compression steel has not yielded (A

s

'>A

s2

) use a

n

'', otherwise use a

n

'.

A

M

a d

n

n

'

' '

2

To enter Table F (10.1.1 - 10.1.2) with '/ and d'/d to check

max

.

Design Table for Design of Singly Reinforced T-Beams

First assume the neutral axis is in the flange (a<t).

F

b d

E

2

12000

K

M

F

n

u

Table A (2.1 - 2.4) with K

n

find and a/d, if a/d<h

f

/d=t/d

then N.A. is in flange (a<t)

A b d

s E

Case with neutral axis in the web (a/d>h

f

/d=t/d) from above (a>t)

Table C (3.3) with b/b

w

find K

nf

Table B (3.1 - 3.2) with h

f

/d=t/d find j

f

& a

nf

A

k j b h

a

sf

nf f w f

nf

M A a d

n sf nf 2

M M M

nw u n

2

36

ARCH 3126 Steel, Timber & Concrete Spring 2005

K

M

F

n

nw

F

b d

w

2

12000

Table A (2.1 - 2.4) with K

n

find

A b d

sw w

A A A

s sw sf

+

A

b d

s

E

Table E (10.2.1 - 10.2.2) with b/b

w

and h

f

/d=t/d find

max,

check that

<

max

37

ARCH 3126 Steel, Timber & Concrete Spring 2005

Wednesday, April 6

th

Homework #25 is due Today (Chapters 1 & 2). Homework #26 is due

Friday, April 8

th

(Chapter 3). Homework #27 is due Monday, April 11

th

(Chapter 3 & 4).

Chapter 4 -- Rectangular Sections in Bending Under Service Load

Conditions

4.1 -- General Introduction

The 2002 ACI code does not cover the alternate design or working

stress method. We will skip the working stress method, which was

called the alternate design method in Appendix A of the ACI code. In

this chapter all references will be to the old code. Strength is

associated with imminent failure at a multiple of the service load.

Serviceability means satisfactory performance under service load

(working stress) conditions. This performance is based on deflections

and crack control.

The concept of working stress is to allow only a maximum value of

concrete compressive stress (0.45f

c

') and steel tension stress to exist (20

or 24 ksi).

4.2 -- Fundamental Assumptions

There are four basic assumptions used in working stress for flexure:

1. Plane sections before bending remain plane after bending, that is, strain

is linear across the section.

2. Stress is proportional to strain.

3. Concrete does not take tension.

4. No slip occurs between the steel and concrete.

38

ARCH 3126 Steel, Timber & Concrete Spring 2005

4.3 -- Modulus of Elasticity Ratio n

The modular ratio (n) is equal to the modulus of elasticity of the steel

divided by the modulus of elasticity of the concrete. ACI A.5.4 (old

code) say that n may be rounded to the nearest whole number and

should never be less than 6. The text recommends the use of Table

4.3.1 pp. 107 or DEFLECTION 9.

4.4 -- Equilibrium Conditions

Example 4.4.1 pp. 108 - 109 will be used to show the basic concepts of

strain, stress, and equilibrium. The basic formulas are as follows from

the given drawing (we will skip this method):

C f bx

c

1

2

T f A

s s

F T C 0

f A f bx

s s c

1

2

f

f

bx

A

s

c s

2

1

39

ARCH 3126 Steel, Timber & Concrete Spring 2005

s

c

d x

x

f

f

E

E

n n

d x

x

s

c

s s

c c

s

c

2

bx

A

n

d x

x

s

2

1 & 2

x

A n

b

x

A nd

b

s s 2

2 2

0 +

Solutions of the above equations yield the location of the neutral axis

(x).

M M C d

x

T d

x

w

_

,

_

,

3 3

The above equation can be used to find T or C given the moment.

f

C

bx

c

2

f

T

A

s

s

The above two equations should be checked against the allowable

stress.

4.5 -- Method of Transformed Section

In the transformed section method the area of steel is transformed into

an equivalent area of concrete by multiplying by the modular ratio (n).

The static equilibrium and strain compatibility equations still apply

from a sketch as follows (we will do this method):

40

ARCH 3126 Steel, Timber & Concrete Spring 2005

A f A f

s s t t

f

E

f

E

s

s

t

c

These concepts and equations will be shown by example in the

following sections and the moment of inertia of the transformed

cracked section as follows:

( )

bx

nA d x

s

2

2

0

Solve above location for the position of the neutral axis. The

transformed cracked moment of inertia is then as follows:

( ) I

bx

nA d x

cr s

+

3

2

3

The equivalent concrete area and imaginary stress are as follows:

A nA

t s

f

f

n

t

s

41

ARCH 3126 Steel, Timber & Concrete Spring 2005

The actual stress are found form the bending stress theory (My/I) as

follows:

f

Mx

I

c

cr

( )

f n

M d x

I

s

cr

The following example is from Fall 1999 and is actually a homework

problem for Fall 1997 and 2001 and Spring 2004 (work either the next

or this example).

Problem 4.3 case 4 - Calculate the allowable bending moment for the

beam according to the working stress (Alternate Method). Is the

service moment capacity controlled by concrete or steel? Use d=19.5

in, b

w

=14 in, 3-#8 bars, f

c

=4000psi and f

y

=60,000psi.

According to ACI section A.3 (Appendix A of old code) the allowable

stresses are as follows:

( ) psi psi f f

c c

1800 4000 45 . 0 ' 45 . 0

and

) 60 ( 000 , 24 Grade psi f

s

The modular ratio can be calculated or found in DEFLECTION 9

8 044 . 8

000 , 605 , 3

000 , 000 , 29

4000 57000

000 , 000 , 29

' 57000

000 , 000 , 29

c

c

s

f

E

E

n

The location of the neutral axis can be found by either method.

One might notice that the equations are actually identical

x

A n

b

x

A nd

b

s s 2

2 2

0 +

(Equilibrium)

( )

bx

nA d x

s

2

2

0

(Transformed)

42

ARCH 3126 Steel, Timber & Concrete Spring 2005

( ) ( ) 0 5 . 19 79 . 0 3 8

2

14

2

x

x

0 72 . 369 96 . 18 7

2

+ x x

0 817 . 52 709 . 2

2

+ x x

747 . 8 , 038 . 6 x

YOU CAN SKIP THIS METHOD

Assuming that the moment is controlled by concrete (wrong)

( ) ( ) k lb in in psi bx f C

c

08 . 78 080 , 76 038 . 6 14 1800

2

1

2

1

From equilibrium C=T therefore

( )

) Good No ( 24 10 . 32

79 . 0 3

08 . 78

2

ksi ksi

in

k

A

C

f

s

s

>

Assuming that the moment is controlled by steel (right)

( ) ( ) k lb in psi A f T

s s

88 . 56 880 , 56 79 . 0 3 000 , 24

2

From equilibrium C=T therefore

( )

( )

) ( 800 . 1 346 . 1

038 . 6 14

88 . 56 2 2

OK ksi ksi

in in

k

bx

T

f

c

<

ft k in k in k

x

d T M

w

,

_

,

_

89 . 82 7 . 994

3

038 . 6

5 . 19 88 . 56

3

ft k M

w

9 . 82

STEEL CONTROLS

WE WILL USE THIS METHOD

43

ARCH 3126 Steel, Timber & Concrete Spring 2005

Alternatively, according to the working stress method as follows:

Solve above location for the position of the neutral axis.

in x 038 . 6

The transformed cracked moment of inertia is then as follows:

( )

( )

( ) ( )

4 2

3

2

3

4463 038 . 6 5 . 19 79 . 0 3 8

3

038 . 6 14

3

in x d nA

bx

I

s cr

+ +

Assuming the concrete controls and from the bending stress equation

(My/I) as follows (wrong):

( )

ft k in lb

in

in psi

x

I f

M

I

Mx

f

cr c

cr

c

8 . 110 000 , 330 , 1

038 . 6

4463 1800

4

The stress in the steel is as follows:

( ) ( )

( ) Good No 20 09 . 32

4463

038 . 6 5 . 19 1330

8

4

ksi ksi

in

in in k

I

x d M

n f

cr

s

>

Assuming the steel controls and from the bending stress equation

(My/I) as follows:

( )

ft k in lb

in

in psi

x d n

I f

M

I

x d M

f

cr s

cr

s

88 . 82 600 , 994

) 038 . 6 5 . 19 ( 8

4463 000 , 24

) (

) (

4

The stress in the steel is as follows:

( )

( ) OK ksi ksi

in

in in k

I

Mx

f

cr

c

800 . 1 346 . 1

4463

038 . 6 6 . 994

4

<

ft k M

w

9 . 82

STEEL CONTROLS

44

ARCH 3126 Steel, Timber & Concrete Spring 2005

The following example is from Fall 1997 and 2000 and is actually a

homework problem for Fall 1999 and 2003 and Spring 2005 (work

either the previous or this example).

Problem 4.3 case 2 - Calculate the allowable bending moment for the

beam according to the working stress (Alternate Method). Is the

service moment capacity controlled by concrete or steel? Use d=19.5

in, b

w

=12 in, 3-#10 bars, f

c

=3000psi and f

y

=40,000psi.

According to ACI section A.3 (Appendix A) the allowable stresses are

as follows:

( ) f f psi psi

c c

0 0 3000 1350 .45 ' .45

and

f psi Grade

s

20 000 40 , ( )

The modular ration can be calculated or found in DEFLECTION 9

n

E

E f

s

c c

29 000 000

57000

29 000 000

57000 3000

29 000 000

3122 000

9 289 9

, ,

'

, , , ,

, ,

.

The location of the neutral axis can be found by either method.

One might notice that the equations are actually identical

x

A n

b

x

A nd

b

s s 2

2 2

0 +

( )

bx

nA d x

s

2

2

0

( ) ( )

12

2

9 3 127 19 5 0

2

x

x . .

6 34 29 668 655 0

2

x x + . .

x x

2

5 715 111 0 + . .4425

45

ARCH 3126 Steel, Timber & Concrete Spring 2005

x 8 079 13 794 . , .

YOU CAN SKIP THIS METHOD

Assuming that the moment is controlled by concrete

( ) ( ) C f bx psi in in lb k

c

1

2

1

2

1350 12 8 079 65 440 65 . , .44

From equilibrium C=T therefore

( )

f

C

A

k

in

ksi ksi OK

s

s

<

65

3 127

17 18 20

2

.44

.

. ( )

M C d

x

k in k in k ft

w

_

,

_

,

3

65 19 5

8 079

3

1 099 8 91 65 .44 .

.

, . .

M k ft

w

91 65 .

CONCRETE CONTROLS

WE WILL USE THIS METHOD

Alternatively, according to the working stress method as follows:

Solve above location for the position of the neutral axis.

x 8 079 .

The transformed cracked moment of inertia is then as follows:

( )

( )

( ) ( ) I

bx

nA d x in

cr s

+ +

3

2

3

2 4

3

12 8 079

3

9 3 127 19 5 8 079 6582

.

. . .

Assuming the concrete controls and from the bending stress equation

(My/I) as follows:

( )

f

M x

I

M

f I

x

p si i n

in

lb i n k ft

c

cr

c cr

1 35 0 6582

8 079

1 0998 51 916 5

4

.

, , .

46

ARCH 3126 Steel, Timber & Concrete Spring 2005

The stress in the steel is as follows:

( ) ( )

( ) f n

M d x

I

k in in

in

ksi ksi OK

s

cr

< 9

1099 8 19 5 8 079

6582

17 18 20

4

. . .

.

4.6 -- Investigation of Rectangular Sections in Bending with Tension

Reinforcement Only

The concept of working stress is to allow only a maximum value of

concrete compressive stress (0.45f

c

') and steel tension stress to exist (20

or 24 ksi).

The condition where both the concrete and steel reach their respective

allowable stresses simultaneously is called the ideal condition (neutral

axis at ideal location or balanced condition). If the steel reaches the

allowable stress first (steel controls) the beam is said to be under-

reinforced (neutral axis closer to compression face than the ideal

location). If the concrete reaches the allowable stress first (concrete

controls) the beam is said to be over-reinforced (neutral axis farther to

compression face than the ideal location). The condition is shown in

the following sketch.

4.7 -- Design of Rectangular Sections in Bending with Tension

Reinforcement Only (SKIP)

This is all very nice, but nobody designs using working stress.

47

ARCH 3126 Steel, Timber & Concrete Spring 2005

Thursday, April 7

th

4.8 -- Serviceability - Deflections

Solve of the moment of inertia of the transformed cracked section as

follows in the sketch:

( ) ( ) ( )

bx

n A x d nA d x

s s

2

2

1 0 + ' '

Solve above location for the position of the neutral axis. The

transformed cracked moment of inertia is then as follows:

( ) ( ) ( ) I

bx

n A x d nA d x

cr s s

+ +

3

2 2

3

1 ' '

The following example is from Fall 1999 and is actually a homework

problem for Fall 2000, 2001, 2002 and 2003 and Spring 2005 (work

next example).

Problem 4.12 For the beam shown in figure for Prob. 4.12, compute

the transformed cracked section moment of inertia I

cr

that would be

needed for a deflection calculation. Use d=36.1 in, d=2.5 in, b

w

=18 in,

h=40 in, 6-#7 bars (top), 10-#11 bars (bot), f

c

=4000psi and

f

y

=60,000psi.

Solve above location for the position of the neutral axis.

48

ARCH 3126 Steel, Timber & Concrete Spring 2005

( ) ( ) ( )

bx

n A x d nA d x

s s

2

2

1 0 + ' '

( ) ( ) ( ) 0 1 . 36 56 . 1 ) 10 ( 8 5 . 2 ) 60 . 0 ( 6 1 8

2

18

2 2

2

+ in x in in x in

x

( ) ( ) 0 1 . 36 8 . 124 5 . 2 2 . 25 9

2

+ x x x

0 28 . 4568 0 . 150 9

2

+ x x

0 59 . 507 67 . 16

2

+ x x

in x 36 . 32 , 67 . 15

The transformed cracked moment of inertia is then as follows:

( ) ( ) ( ) I

bx

n A x d nA d x

cr s s

+ +

3

2 2

3

1 ' '

( )

( ) ( ) ( )

2 2 2 2

3

67 . 15 1 . 36 56 . 1 ) 10 ( 8 5 . 2 67 . 15 ) 60 . 0 ( 6 1 8

3

67 . 15 18

in in in in in in

in in

I

cr

+ +

( )

4 4

79550 52090 4371 23090 in in I

cr

+ +

4

79550 in I

cr

The following example is new for Fall 2000, 2001, 2002 and 2003 and

is actually a homework problem for Fall 1999 and Spring 2004 (work

this example).

Problem 4.11 For the beam of Problem 4.10, compute the

transformed cracked section moment of inertia I

cr

that would be needed

for a deflection calculation. Use d=27.3 in, d=2.5 in, b

w

=16 in, h=30

in, 3-#11 bars (top), 4-#11 bars (bot), f

c

=4000psi and f

y

=60,000psi.

Solve above location for the position of the neutral axis.

( ) ( ) ( )

bx

n A x d nA d x

s s

2

2

1 0 + ' '

49

ARCH 3126 Steel, Timber & Concrete Spring 2005

( )( ) ( ) ( ) 0 3 . 27 56 . 1 ) 4 ( 8 5 . 2 ) 56 . 1 ( 3 1 8

2

16

2 2

2

+ in x in in x in

x

( ) ( ) 0 3 . 27 92 . 49 5 . 2 76 . 32 8

2

+ x x x

0 7 . 1447 68 . 82 8

2

+ x x

0 59 . 180 34 . 10

2

+ x x

in x 56 . 19 , 23 . 9

The transformed cracked moment of inertia is then as follows:

( ) ( ) ( ) I

bx

n A x d nA d x

cr s s

+ +

3

2 2

3

1 ' '

( )

( ) ( ) ( )

2 2 2 2

3

23 . 9 3 . 27 56 . 1 ) 4 ( 8 5 . 2 23 . 9 ) 56 . 1 ( 3 1 8

3

23 . 9 16

in in in in in in

in in

I

cr

+ +

( )

4 4

21998 16300 8 . 1483 8 . 4193 in in I

cr

+ +

4

22000 in I

cr

4.9 -- Serviceability - Flexural Crack Control for Beams and One-Way

Slabs

Go over Figure 4.9.1 pp. 122 and the use of Equation 4.9.2 pp. 122 as

follows in the picture:

50

ARCH 3126 Steel, Timber & Concrete Spring 2005

z f d A

s c

3

Where A=A

e

/number of bars (m=A

s

/A

b

for largest bar), A

e

=area of

concrete surrounding bars and having the same centroid of the bars, and

d

c

=thickness of concrete cover measured form the extreme tension

fiber to the center of the bar located closest to that fiber (largest bar

used).

REINFORCEMENT EXAMPLE 1 (ACI 340R-97 SP-17 (97)) Check

the following beam section for Exterior Crack Control provisions.

d=18 in, b

w

=11 in, c

c

=2 in (main reinforcing), 3-#9 (1L), f

c

=4000 psi,

& f

y

=60,000 psi. WORK ONLY THIS EXAMPLE

z f d A

s c

3

ksi ksi f f

y s

36 ) 60 ( 6 . 0 6 . 0

[ ] in in d c d

b c c

564 . 2 ) 128 . 1 ( 5 . 0 2 ) ( 5 . 0 + +

For single layer of equal size bars

n

A

A

e

( )

2

41 . 56 11 564 . 2 2 2 in in in b d A

w c e

bar

in

in

n

A

A

e

2

2

80 . 18

3

41 . 56

(OK) 145 0 . 131 ) 80 . 18 ( 564 . 2 36

3

2

3

in

kips

in

kips

bar

in

in ksi A d f z

c s

<

If b

w

=15in, then z=145.3 (No good just barely, but rounding to 3 digits

z=145 (Ok) see REIFORCEMENT 14, which is based on 2 inches of

clear cover to main reinforcing. Other tables could have be used

(REINFORMENT 8.1, 8.2 & 11)

SKIP THIS EXAMPLE

51

ARCH 3126 Steel, Timber & Concrete Spring 2005

REINFORCEMENT EXAMPLE 3 (ACI 340R-97 SP-17 (97)) Check

the following beam section for Exterior Crack Control provisions.

d=18 in, b

w

=11 in, c

c

=2 in (main reinforcing), A

s

=2.0in

2

, f

c

=4000 psi,

& f

y

=60,000 psi.

Just using REINFORCEMENT 14 the following judgements are made:

A

s

Bars Arrange Min b

w

Max b

w

Comment

2.00 2 #9 1L 8.0 10.0 No good

2.37 3 #8 1L 9.5 15.5 OK BEST

2.12 2#6 & 4#5 2L 9.0 21.5 Example

2.20 5 #6 2L 9.0 21.0 Example

Check of 2 #9 bars

z f d A

s c

3

ksi ksi f f

y s

36 ) 60 ( 6 . 0 6 . 0

[ ] in in d c d

b c c

564 . 2 ) 128 . 1 ( 5 . 0 2 ) ( 5 . 0 + +

For single layer of equal size bars

n

A

A

e

( )

2

41 . 56 11 564 . 2 2 2 in in in b d A

w c e

bar

in

in

n

A

A

e

2

2

205 . 28

2

41 . 56

good) (No 145 0 . 150 ) 205 . 28 ( 564 . 2 36

3

2

3

in

kips

in

kips

bar

in

in ksi A d f z

c s

>

Check maximum b

w

for 5 #6 (2L) bars

z f d A

s c

3

52

ARCH 3126 Steel, Timber & Concrete Spring 2005

ksi ksi f f

y s

36 ) 60 ( 6 . 0 6 . 0

[ ] in in d c d

b c c

375 . 2 ) 75 . 0 ( 5 . 0 2 ) ( 5 . 0 + +

For multi-layers of equal size bars find centroid of bars

First find location of top layer of bar

[ ] in in d s d c d

b c b c top

125 . 4 ) 75 . 0 ( 5 . 0 1 75 . 0 2 ) ( 5 . 0 + + + + + +

[ ]

in

in

n

y

A

y A

y 075 . 3

5

) 125 . 4 ( 2 ) 375 . 2 ( 3

n

A

A

e

( )

2

15 . 6 075 . 3 2 2 in b b in y A

w w e

bar

in

b

in b

n

A

A

w

w e

2

2

230 . 1

5

15 . 6

in b

in

kips

bar

in

b in ksi A d f z

w w c s

37 . 22 145 ) 230 . 1 ( 375 . 2 36

3

2

3

in b

w

4 . 22

Note: REINFORCEMENT 14 is incorrect (Example is correct)?

Check maximum b

w

for 2 #6 & 4 #5 (2L) bars

z f d A

s c

3

ksi ksi f f

y s

36 ) 60 ( 6 . 0 6 . 0

[ ] in in d c d

b c c

375 . 2 ) 75 . 0 ( 5 . 0 2 ) ( 5 . 0 + +

For multi-layers of unequal size bars find centroid of bars

53

ARCH 3126 Steel, Timber & Concrete Spring 2005

First find location of top layer of bar

[ ] in in d s d c d

b c b c top

0625 . 4 ) 625 . 0 ( 5 . 0 1 75 . 0 2 ) ( 5 . 0 + + + + + +

( ) ( ) [ ] ( )

( ) ( )

in

in in

in in in in in

A

y A

y 11527 . 3

31 . 0 4 44 . 0 2

0625 . 4 31 . 0 3 375 . 2 31 . 0 44 . 0 2

2

2 2 2

+

+ +

m

A

A

e

( ) ( )

bars

in

in in

m 8181 . 4

44 . 0

31 . 0 4 44 . 0 2

2

2

where A

b

is largest bar

( )

2

23054 . 6 11527 . 3 2 2 in b b in y A

w w e

bar

in

b

in

m

A

A

w

w e

2

2

29313 . 1

8181 . 4

23054 . 6

in b

in

kips

bar

in

b in ksi A d f z

w w c s

28 . 21 145 ) 29313 . 1 ( 375 . 2 36

3

2

3

in b

w

5 . 21

Note: REINFORCEMENT 14 is correct (Example is correct)?

4.10 -- Serviceability - Side Face Crack Control for Large Beams

For deep beams the maximum crack width may occur on the side faces.

Equation 4.10.1 pp. 126 (ACI 10.6.7) is to be used for beams greater

than 3 feet deep as follows:

( ) A d

sk

0 012 30 .

in

2

/ft of height

Spaced at the MIN(d/6,12) as shown in the sketch as follows:

54

ARCH 3126 Steel, Timber & Concrete Spring 2005

55

ARCH 3126 Steel, Timber & Concrete Spring 2005

Friday, April 9

th

Homework #26 is due today (Chapter 3). Homework #27 is due

Monday, April 11

th

(Chapters 3 & 4). Homework #28 is due

Wednesday, April 13

th

(Chapter 5).

Chapter 5 -- Shear Strength and Shear Reinforcement

5.1 -- Introduction

Failures in beams commonly referred to as "shear failures" are actually

tension failures at the inclined cracks as shown below.

5.2 -- The Shear Stress Formula Based on Linear Stress Distribution

(SKIP)

This is a very nice derivation of shear stress that you have seen in

Strength of Materials and Elementary Steel (lets not do it again).

5.3 -- The Combined Stress Formula (SKIP)

This is just another form of the combined stress equation that was

derived in Strength of Materials. Shown below is the cracking

orientation along a simple beam.

56

ARCH 3126 Steel, Timber & Concrete Spring 2005

5.4 -- Behavior of Beams Without Shear Reinforcement

An inclined crack in a beam that was previously uncracked due to

flexure is known as a web-shear crack. An inclined crack forming at

the top of and becoming an extension of an existing flexural crack is

known as a flexure-shear crack. The sketch below illustrate cracking

types near a support.

The transfer of shear in a reinforced concrete member occurs by a

combination of the following mechanisms:

1. Shear resistance of the uncracked concrete, V

cz

.

2. Aggregate interlock force tangent to the shear crack (similar to friction)

due to irregular interlock of the aggregate, Va.

3. Dowel action by the longitudinal reinforcement to transverse force, Vd.

4. Arch action on relatively deep beams

5. Shear reinforcement resistance from stirrups, Vs.

57

ARCH 3126 Steel, Timber & Concrete Spring 2005

There are four general categories of failure may be established and the

corresponding a/d (shear span) ratios as follows (SKIP):

1. a/d<=1, Deep beams that behave like an tied-arch after cracking (many

possible failures in Figure 5.4.5 pp. 143)

2. 1<a/d<=2.5, Short beams with shear strength in excess of the inclined

cracking strength (flexure-shear crack failure)

3. 2.5<a/d<=6, Usual beams of intermediate length that form beam

segments known as teeth due to flexural cracks

4. a/d>6, Long beams normally failing in yielding of the tension steel.

5.5 -- Shear Strength of Beams Without Shear Reinforcement-ACI Code

The (detailed method ACI 11.3.2.1) shear strength of concrete beams

without shear reinforcing is as follows (don't worry about the

derivation):

V f

V d

M

b d f b d

c c

w u

u

w c w

+

_

,

19 2500 35 . ' . '

The quantity V

u

d/M

u

<1.0 in the above equation.

The (simplified method ACI 11.3.1.1) shear strength of concrete beams

without shear reinforcing is as follows:

V f b d

c c w

2 '

The cracking in a continuous beam is somewhat similar to a simple

beam as shown below

58

ARCH 3126 Steel, Timber & Concrete Spring 2005

For lightweight concrete two methods may be used as follows

(substitute the values shown for the square root of f'

c

):

ACI 11.2.1.1

f

f

f

c

ct

c

'

.

'

6 7

Values of V

c

and T

c

ACI 11.2.1.2 f f

c c

' . ' 0 75 Values of V

c

,T

c

, and M

cr

all LW

ACI 11.2.1.2

f f

c c

' . ' 0 85

Values of V

c

,T

c

, and M

cr

Sand LW

Interpolation is allowed for partial sand replacement.

5.6 -- Function of Shear Reinforcement

Shear reinforcement can come in many types as follows:

1. Vertical stirrups (perpendicular to longitudinal reinforcement) are the

most common

2. Welded wire fabric (used in double tees)

3. Inclined stirrups (45

o

or more from the longitudinal reinforcement) is

very effective but labor intensive

4. Longitudinal reinforcement bent toward the compression zone

Figure 5.6.3 pp. 151 shows the effectiveness of the various types of

shear resistance devices. Concrete and stirrups are primary resistance

in uncracked and cracked states respectively. Dowel action and

aggregate interlock are secondary.

59

ARCH 3126 Steel, Timber & Concrete Spring 2005

5.7 -- Truss Model for Reinforced Concrete Beam

The truss analogies shown in Figure 5.6.2 pp. 150 and Figure 5.7.1 pp.

152 show how the requirement that required shear reinforcement be

placed at no more than one-half the effective depth s<=d/2.

5.8 -- Shear Strength of Beams with Shear Reinforcement

The nominal shear strength per ACI 11.1.1 is as follows:

V V V V

u n c s

+

The following is the strength of reinforcement ACI 11.5.6.2 & 11.5.6.3:

V

A f d

s

s

v y

( )

V

A f d

s

s

v y

+ sin cos

The above is with measured from the longitudinal axis.

5.9 -- Lower and Upper Limits for Amounts of Shear Reinforcement

The minimum amount of shear reinforcement per ACI 11.5.5.3 is as

follows (only when required and spaced at not more than d/2 or 24

inches ACI 11.5.4.1) (NEW in 2002 code):

y

w

y

w

c v

f

s b

f