Professional Documents

Culture Documents

Untitled

Uploaded by

faizuddin_ghiasiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Untitled

Uploaded by

faizuddin_ghiasiCopyright:

Available Formats

Study on inventory management conducted at reid&taylor(india)ltd - Document Tran script Inventory Management Chapter 1 introduction 1.1.

Introduction Inventory is a lis t of goods and materials, or those goods and materials themselves, held availabl e in stock by a business. Inventory management is primarily about specifying the size and placement of stocked goods. Inventory management is required at differ ent locations within a facility or within multiple locations of a supply network to protect the regular and planned course of production against the random dist urbance of running out of materials or goods. The scope of inventory management also concerns the fine lines between replenishment lead time, carrying costs of inventory, asset management, inventory forecasting, inventory valuation, invento ry visibility, future inventory price forecasting, physical inventory, available physical space for inventory, quality management, replenishment, returns and de fective goods and demand forecasting. Management of the inventories, with the pr imary objective of determining, controlling stock levels within the physical dis tribution function to balance the need for product availability against the need for minimizing stock holding and handling costs. The objectives of materials ma nagement are primarily focused at achieving efficiency in sales and production b y minimizing the investment in inventory without sacrificing quality and continu ity of supply of materials obtained at lowest possible price. Most manufacturing organizations usually divide their "goods for sale" inventory into Raw material s - materials and components scheduled for use in making a product. Work in proc ess, WIP - materials and components that have begun their transformation to fini shed goods. Finished goods - goods ready for sale to customers. Goods for resale - returned goods that are saleable. Spare parts Haranahalli Ramaswamy Institute of Higher Education, Hassan 1 Inventory Management Inventory management is a sub-system of an organisation whi ch in turn has a number of sub- systems. The inter related nature of inventory m anagement function and other organizational functions such as finance function, production function, maintenance function etc. will have to be well appreciated. While defining the inventory management function, the objective was stated as o ne of providing the pre-determined service to customers at a minimum total cost. 1.2. Problem statement Inventory management study conducted in Reid &Taylor (In dia) Ltd. 1.3. Objectives To study work flow of stores department in Reid & Tayl or (India) Ltd . To study how effectively inventories are maintained in Reid and Taylor. To know the relationship between raw materials and sales. To study the selective inventory control system adopted in the organisation. 1.4. Scope of th e study Inventory management is a very simple concept - don't have too much stoc k and don't have too little. Since there can be substantial costs involved in st raying above and below the optimal range, careful inventory management can make a huge difference in the profitability of a business. Although the concept is si mple, the process of getting the right balance can be quite a complex and time c onsuming task without the right technology. Inventory Management is very importa nt for Reid and Taylor. It enables the business to meet or exceed expectations o f the customer by making the product readily available. Haranahalli Ramaswamy In stitute of Higher Education, Hassan 2 Inventory Management If managed properly, it can help the organization reduce it s costs, achieve economies of scale and prepares the organization for uncertaint y. The importance of proper management of materials need hardly be emphasised in a developing country like India considering the fact that crores together worth of materials and components enter into production process each year. In any man ufacturing industry, nearly 60-70% of the total funds employed are tied up in cu rrent assets, of which inventory is the most significant component. In the cost structure of most of the products materials constitute 40-60% of the total cost again pointing to the need for proper budgeting and control of materials expense s. In a competitive environment, no customer will be willing to pay the enhanced price and the manufacturer may well end up with losing his existing business. C ompany has its own limitation. Firstly marketing may find it difficult to improv e sales due to stiff competition. Secondly production needs to be raised which i n turn needs additional resources by way of capital man power etc. since capital

is scarce, this is also not a practical solution to improve profits. That leave s only cost effective techniques such as 1) Reduction in material cost by using superior design which needs less material or saves on labour 2) Inventory reduct ion and control by stopping wastage or leakage by 3) Enforce strict consumption control 4) Eliminating all wastages at all places where they occur 5) Disposal o f scrap as it arises. 1.5. Data collection methods Primary data Primary data has been collected from observation and discussion with guide, other officials. Har anahalli Ramaswamy Institute of Higher Education, Hassan 3 Inventory Management Secondary data Secondary data collected from past records. Secondary data collected from company annual report. Secondary data collected fr om company website. 1.6. Techniques for data analysis Data has been analyzed by using Regression analysis Graphs 1.7. Limitations of the study As this is a stud y under taken to full fill the academic requirement it is bound to have certain limitation. Study was bounded for only stores department. Detail study about all the materials was not possible because of time limit. Some of the information w ere kept confidential Haranahalli Ramaswamy Institute of Higher Education, Hassa n 4 Inventory Management Chapter2 literature review 2.1. Introduction to inventory m anagement Inventories constitute the most significant part of current assets of a large majority of companies in India. On an average, inventories are approxima tely 60 percent of current assets in public limited companies in India. Because of the large size of inventories maintained by firms, a considerable amount of f unds is required to be committed to them. It is, therefore, absolutely imperativ e to manage inventories efficiently and effectively in order to avoid unnecessar y investment. A firm neglecting the management of inventories will be jeopardisi ng its long-run profitability and may fail ultimately. It is possible for a comp any to reduce its level of inventories to a considerable degree e.g., 10 to 20 p er cent, without any adverse effect on production and sales, by using simple inv entory planning and control techniques. The reduction in excessive inventories car ries a favourable impact on a companys profitability. 2.2. Definition and meaning Inventories are consumed are unsold goods purchased or manufactured according t o the accounting standard: 2 (Revised), inventories are asset: a) Held for sale in the ordinary course of business. b) In the process of production for such sal e or. c) In the form of materials or supplies to be consumed in the production p rocess or in the rendering of service. Thus, that term inventory includes stock of Raw materials and components:- Raw materials are those basic inputs that are converted into finished product through the manufacturing process. Raw materials inventories are those units which have been purchased and stored for future pro ductions. Work in process:- work in process inventories are semi-manufactured pr oducts. They represent products that need more work before they become finished products for sale. Haranahalli Ramaswamy Institute of Higher Education, Hassan 5 Inventory Management Finished goods:- Finished goods inventories are those compl etely manufactured products which are ready for sale. Stocks of raw materials an d work-in-process facilitate production, while stock of finished goods is requir ed for smooth marketing operations. Thus, inventories serve as a link between th e production and consumption of goods. The levels of three kinds of inventories for a firm depend on the nature of its business. A manufacturing firm will have substantially high level of all three kinds of inventories, while a retail or wh olesale firm will have a very high level of finished goods inventories and no ra w material and work-in- process inventories. Within manufacturing firms, there w ill be differences. Large heavy engineering companies produce long production cy cle products; therefore, they carry large inventories. On the other hand, invent ories of a consumer product company will not be large because of short productio n cycle and fast turnover. Firm also maintain a fourth kind of inventory, suppli es or stores and spares. Supplies include office and plant cleaning materials li ke soap, brooms, oil, fuel, light bulbs etc. These materials do not directly ent er production, but are necessary for production process. Usually, these supplies are small part of the total inventory and do not involve significant investment . Therefore, a sophisticated system of inventory control may not be maintained f or them. 2.3. Need to hold inventories The question of managing inventories aris

es only when the company holds inventories. Maintaining inventories involves tyi ng up of the companys fund and incurrence of storage and handling costs. If it is expensive to maintain inventories, why do companies hold inventories? There are three general motives for holding inventories. Transaction motive emphasises th e need to maintain inventories to facilitate smooth production and sales operati ons. Precautionary motive necessitates holding of inventories to guard against t he risk of unpredictable changes in demand and supply forces and other factors. Speculative motive influences the decision to increase or reduce inventory level to take advantage of price fluctuations. . Haranahalli Ramaswamy Institute of H igher Education, Hassan 6 Inventory Management The procurement of materials may be delayed because of such factors as strike, transport disruption or short supply. Therefore, the firm sh ould maintain sufficient stock of raw materials at a given time to streamline pr oduction. Work-in-process inventory builds up because of the production cycle. P roduction cycle is the time span between introduction of raw material into produ ction and emergence of finished product at the completion of production cycle. T ill production cycle completes, stock of work-in-process has to be maintained. E fficient firms constantly try to make production cycle smaller by improving thei r production techniques. Stock of finished goods has to be held because producti on and sales are not instantaneous. A firm cannot produce immediately when consu mers demand goods. Therefore, to supply finished goods on a regular basis, their stock has to be maintained. Stock of finished goods has also to be maintained f or sudden demand from customers. The level of finished goods inventories would d epend upon the coordination between sales and production as well as on productio n time. 2.4. Objective of inventory management In the context of inventory manag ement, the firm is faced with the problem of meeting two conflicting needs: To m aintain a large size of inventories of raw material and work- in-process for eff icient and smooth production and of finished goods for uninterrupted sales opera tions. To maintain a minimum investment in inventories to maximise profitability . Both excessive and inadequate inventories are not desirable. These are two dan ger points within which the firm should avoid. The objective of inventory manage ment should be to determine and maintain optimum level of inventory investment. The optimum level of inventory will lie between the two danger points of excessi ve and inadequate inventories. The firm should always avoid a situation of over investment or under-investment in inventories. The major dangers of over investm ent are; a) Unnecessary tie-up of the firms fund and loss of profit, Haranahalli Ramaswamy Institute of Higher Education, Hassan 7 Inventory Management b) Excessive carrying costs, and c) Risk of liquidity. The excessive level of inventories consumes funds of the firm, which cannot be used for any other purpose, and thus, it involves an opportunity cost. The carrying c osts, such as the costs of storage, handling, insurance, recording and inspectio n, also increase in proportion to the volume of inventory. These costs will impa ir the firms profitability further. Excessive inventories carried for long-period increase chances of loss of liquidity. It may not be possible to sell inventori es in time and at full value. Raw materials are generally difficult to sell as t he holding period increases. There are exceptional circumstances where it may pa y to the company to hold stock of raw materials. Maintaining an inadequate level of inventories is also dangerous. The consequences of under-investment in inven tories are: a) Production hold-ups and b) Failure to meet delivery commitments. Inadequate raw materials and work-in-process inventories will result in frequent production interruptions. Similarly, if finished goods inventories are not suff icient to meet the demand of customers regularly, they may shift to competitors, which will amount to a permanent loss to the firm. The aim of inventory managem ent, thus, should be to avoid excessive and inadequate levels of inventories and to maintain sufficient inventory for the smooth production and sales operations . Efforts should be made to place an order at the right time with the right sour ce to acquire the right quantity at the right price and quality. An effective in ventory management should Ensure a continuous supply of raw materials to facilit ate uninterrupted production, Maintain sufficient stocks of raw materials in per iod of short supply and anticipate price changes. Maintain sufficient finished g

oods inventory for smooth sales operation, and efficient customer service. Minim ise the carrying cost and time, and Control investment in inventories and keep i t at an optimum level. Haranahalli Ramaswamy Institute of Higher Education, Hass an 8 Inventory Management 2.5. INVENTORY SYSTEMS. Records pertaining to quantity and value of inventory in- hand can be maintained according to any of the following two systems: 1) Periodic Inventory system. 2) Perpetual Inventory system. Period ic inventory system In case of periodic inventory system the quantity and the va lue of inventory is found out only at the end of the accounting period after hav ing a physical verification of the units in hand. The system does not provide th e information regarding the quantity and value of material in hand on a continuo us basis .the cost of material used is obtained by adding the total value of goo ds purchased during the period to the value of inventory in hand in the beginnin g of the of the period and subtracting the value of inventory at the end of the period. However review period is fixed in this inventory system. This inventory is also known as fixed period or replenishment inventory system or P-system. In the periodic review system, the inventory is being reviewed at periodic interval s and therefore there is no flexibility in the order period. Hence the fluctuati on in the demand is taken care of by the safety stock. The periodic inventory sy stem requires more inventory on hand, for a given frequency of shortage, as comp ared to perpetual inventory system. Perpetual inventory system It is also known as Automatic inventory system. According to the Charted Institute of Management Accountants London, it is A system of records maintained by controlling departmen t, which reflects the physical movements of stocks and their current balance. Har anahalli Ramaswamy Institute of Higher Education, Hassan 9 Inventory Management The definition given by Wheldon is more exhaustive and expl anatory. According to him, it is A method of recording inventory balances after e very receipt and issue to facilitate regular checking and to obviate closing dow n for stocktaking. In case of this system the stores ledger gives balance of raw materials, work-in-progress and finished goods on a continuing basis. The basic objective of this system is to make available details about the quantity and val ue of stock of each item at all times. The system, thus, provides a rigid contro l over stock of materials, as physical stock can regularly be verified with the stock records kept in the stores and the cost office. Since the perpetual invent ory system requires perpetual auditing of the system, the cost of operating the system is higher. However, because of the computer facilities, cost advantage of periodic review system is withering away and many companies are resorting to th e perpetual inventory system. 2.6. Methods of valuation of inventories According to International Accounting standard:2 (IAS:2), the inventories should be value d at the lowest of historical cost and net realizable value. Historical price Histo rical cost of inventories is the aggregate of cost of purchase, cost of conversi on, and other costs incurred in bringing the inventories to their present locati on and condition. Thus, cost includes not only the price paid for acquisition of inventories but also all costs incurred for bringing and making them fit for us e in production or for sale, e.g., transportation costs, duties paid, insurance, manufacturing expenses, wages or manufacturing expenses incurred for converting raw materials into finished products, etc. selling expenses such as advertiseme nt expenses or storage costs should not be included. A major objective of accoun ting for inventories is the proper determination of income through the process o f matching appropriate costs against revenues. It requires assigning of proper c osts to inventory as well as goods sold. However, it should be needed that assig ning of such costs need not conform to the physical flow of goods. 1) First In F irst Out Haranahalli Ramaswamy Institute of Higher Education, Hassan 10 Inventory Management Under this method, it is assumed that the materials/goods f irst received are the first to be issued/ sold. Thus, according to this method, the inventory on a particular date is presumed to be composed of the items which have been acquired most recently. This method of pricing issued material is bas ed on the theory that material is first issued from the earliest lot on hand and should be priced at the cost at which the lot was placed in stock. It is assume d that the materials purchased are issued in strict chronological order that it

is materials are issued from the oldest supply in stock and that units issued ar e priced at the oldest cost price listed on the stock ledger sheets, that materi als on hand at all times being the most recent purchases, when a requisition for a certain type of material is presented to the store keeper, he uses the cost p rice of the first lot of materials received which is still on hand. If the quant ity required is greater than the units remaining the first lot, he uses the cost price of the second lot, than of the third and fourth until enough material is obtained to fill the requisition Advantages:- The FIFO method has the following advantages: a) It values stock nearer to current market prices since stock is pr esumed to be consisting of the most recent prices. b) It is based on cost and, t herefore, no unrealised profit enters into the financial accounts of the company . c) The method is realistic since it takes into account the normal processor fo r utilizing slash selling those materials/goods which have been longest in stock . Disadvantages: The method suffers from the following disadvantages: a) It invo lves complicated calculation and hence increases the possibility of clerical err ors. b) Comparison between different jobs using the same type of materials becom es sometimes difficult. c) A job commenced a few minutes after another jobs may have to bear an entirely different charges of materials because the first job co mpletely exhausted the supply of materials of particular lot. The FIFO method of valuation of inventories is particularly suitable in the following circumstance s. a) The materials / goods are of a perishable nature. b) The frequency of purc hases is not large. c) There on only moderate fluctuations in the prices of mate rials or goods purchased. d) Materials are easily identifiable as belonging to a particular purchase lot. Haranahalli Ramaswamy Institute of Higher Education, H assan 11 Inventory Management 2) Last in last out method This method is based on the assu mption that last item of material/goods purchased are the first to be issued/sol d. Thus, according to this method, inventory consists of items purchased at the earliest cost. Under this method, which assumes that most current prices should be charged for the cost of materials which enter into the goods manufactured and sold, which stands for Last in first out flow of costs assumptions produce a lowe r income during rising prices since stated materials costs are higher than under FIFO method. When prices are falling, it shows a higher income and thus tends t o washout paper profits that results from a closing inventory and opening invent ory stated at different prices. LIFO method of inventory accounting can, however , in periods of inflation help approximate contemporary income and loss. LIFO me thod charges materials account with current replacement cost of inventory. For p rofit and loss account, it gives clear insight, the underlying purpose of which is to match current cost with current revenues. It, however, can result in an un realistic inventory valuation for purpose of the balance sheet, sometimes distor ting the current ratio and current assets relationship. But the choice between t he FIFO and LIFO methods is still a choice between methods of accounting practic e of historical costs and neither of the two methods meets the need for a valuat ion of materials and inventories at current market prices. The method is most su itable for materials which are of a bulky and non-perishable type. Advantages Th e method has the following advantages: 1) It takes into account the current mark et conditions while valuing the materials issued to different jobs or calculatin g the cost of goods sold. 2) The method is based on cost and, therefore, no unre alised profit or loss is made on account of use of this method. 2.7. SELECTIVE I NVENTORY CONTROL 2.7.1. INTRODUCTION: The inventory of any industrial firm gener ally comprises thousands of times with diversified prices, usage and lead-time, as well as procurement and / or technical problems. Thus, in the case, the best approach to solve any problem is to tackle the important aspects more rigorously . Selective inventory control is one such basic analytical tool, which enables m anagement to place efforts where the results will be Haranahalli Ramaswamy Insti tute of Higher Education, Hassan 12 Inventory Management greatest. It is a known fact that the managers time is limit ed and he cant spend his time on all aspects. He has to devote his time such that it rewards him. This technique is a cost and time saving technique, which conce ntrates more on few materials which are expensive or more vital to a organisatio

n, where the control to the maximum, brings in more benefit through cost reducti on and effective utilization. The motive behind any selective control is that an equally critical analysis of all items will be very expensive. This being the c ase, few need more analysis than the other. The importance of the material can b e due to its costs, its criticality, its availability and its consumption. Selecti ve inventory control becomes the spotlight of attention to be given in respect o f the following areas: Loss Wastage Scrap Quantity Price variance Usage varianc Inventory turnovers There are different methods of classifying the item for inv entory control purposes, ABC Analysis (Always better control) Here annual values of consumption Of items are considered and are Classified as A, B and C class i tems. HML Classification (High- medium-Low Here unit price of the materials are Price) Considered. Haranahalli Ramaswamy Institute of Higher Education, Hassan 1 3 Inventory Management FSN Classification Based on the materials issue from (Fast, Slow, and Non- moving) The stores, this analysis is carried Out. 2.7.2 FSN ANAL YSIS This classification is based on the consumption pattern of the materials. i .e. movement analysis forms the basis. Here the items are classified into Fast m oving, slow moving, and non- moving on the basis of frequency of transaction. FS N analysis is especially useful to combat obsolete items whether spare parts are raw materials or components. It helps in arrangement of stocks in stores and th eir distribution and handling methods. The main aim of this analysis is to contr ol obsolescence of the inventories. If there is a rapid change in technology the n this classification will have to be updated more often. FSN analysis is stock turnover ratio based analysis. Stock turnover ratio is defined as the ratio of a nnual consumption of a material divided by its average inventory i. e. The items can be classified into three categories viz FAST MOVING (F) Those items whose s tock turnover ratio is greater than 3. SLOW MOVING(S) Those items whose stock tu rnover ratio is between 1 and 3. NON- MOVING (N) Those items whose stock turnove r ratio is below 1. 2.7.3. VED ANALYSIS VED Analysis can be defined as the analy sis of maintenance spares in to V Items Items of vital importance, Haranahalli R amaswamy Institute of Higher Education, Hassan 14 Inventory Management E Items Items of essential importance, D Items Items of des irable importance. Vital importance in the way of indicating the fact that machi ne cant run without V Item. Essential importance in the sense impart that machine c an run but without parameters as such efficiency, noise reduction etc. Desirable importance in the way denotes machine can run but factor of safety, industrial formalities cant be satisfied. Vital (V) spares are those whose non availability results in very high loss due to production down and a very high cost due to eme rgency purchases. Essential (E) spares are those non availability is expected to cause moderate production down time loss. Desirable (D) spares are those whose non availability does not result into any significant production down loss. 2.7. 4. ABC Classification / Analysis of Inventory ABC analysis is a popular inventor y control technique, which is an adaptation of Paretos law. This is the well- kno wn method called ABC approach or Always Better Control. ABC is also known as Alp habetical Approach offers a basic analytical tool to concentrate the efforts whe re the results will be the greatest. This technique aims at keeping the investme nt low and also avoids stock out of critical items. It tries to analyze the dist ribution of inventory items annual consumption value so as to determine relative priority. This method is based on annual consumption value, which is obtained b y the multiplication on unit price by the annual consumption quantity. The ABC c lassification process is an analysis of a range of objects, such as finished pro ducts, items lying in inventory or customers into three categories. It s a syste m of categorization, with similarities to Pareto analysis, and the method usuall y categorizes inventory into three classes with each class having a different ma nagement control associated: Haranahalli Ramaswamy Institute of Higher Education , Hassan 15 Inventory Management A - Outstandingly important; B - of average importance; C relatively unimportant as a basis for a control scheme. Each category can and s ometimes should be handled in a different way, with more attention being devoted to category A, less to B, and still less to C. Thus, applied in the context of

inventory, it s a determination of the relative ratios between the number of ite ms and the currency value of the items purchased / consumed on a repetitive basi s: 10-20% of the items ( A class) account for 70-80% of the consumption the nex t 15-25% ( B class) account for 10-20% of the consumption and the balance 65-75 % ( C class) account for 5-10% of the consumption High value (A), Low value (C) , intermediary value (B) A,B & C , all have a purchasing / storage policy - "A" , most critically reviewed , "B" little less while "C" still less with greater r esults. Inventory Control Application: The ABC classification system is to group ing items according to annual issue value, (in terms of money), in an attempt to identify the small number of items that will account for most of the issue valu e and that are the most important ones to control for effective inventory manage ment. The emphasis is on putting effort where it will have the most effect. All the items of inventories are put in three categories, as below: A Items : These Items are seen to be of high Rupee consumption volume. "A" items usually include 10-20% of all inventory items, and account for 50-60% of the total Rupee consum ption volume. B Items : "B" items are those that are 30-40% of all inventory ite ms, and account for 30-40% of the total Rupee consumption volume of the inventor y. These are important, but not critical, and don t pose sourcing difficulties. C Items : "C" items account for 40-50% of all inventory items, but only 5-10% of the total Rupee consumption volume Table 2.1 . Table showing the suggested poli cy guidelines for A , B & C classes of items A items (High cons. Val) B items (M oderate cons.Val) C item (Low cons. Val) Very strict cons. control Moderate cont rol Loose control No or very low safety stock Low safety stock High safety stock Haranahalli Ramaswamy Institute of Higher Education, Hassan 16 Inventory Management Phased delivery (Weekly) Once in three months Once in 6 mon ths Weekly control report Monthly control report Quarterly report Maximum follow up Periodic follow up Exceptional As many sources as possible Two or more relia ble Two reliable Accurate forecasts Estimates on past data Rough estimate Centra l purchasing /storage Combination purchasing Decentralised Max.efforts to contro l LT Moderate Min.clerical efforts To be handled by Sr.officers Middle level Can be delegated OBJECTIVE OF ABC ANALYSIS The ABC analysis enables the materials m anager to exercise selective control when he is confronted with a large number o f items. Tighter and accurate procedures are essential for A value items relating to materials planning, forecasts, ordering, review, records, postings, revisions , lead time analysis, safety stock, materials consumption control, purchase budg et, delivery schedule, Value analysis, follow- up, clerical efforts, physical st ock verification, receipts, issues, stores accounting and inspection. The degree of control should rigorous for A items and should be minimum for C items. ABC analy sis is also helpful to rationalize the number of orders and reduce the overall i nventory. All in all, the objectives of ABC analysis can be summarized as follow s: To restrict the control to and appreciable level. To concentrate on maximum d egree of coverage of inventory value. LIMITATIONS OF ABC ANALYSIS ABC analysis, in order to be fully effective, should be carried out with standardization and c odification. ABC analysis is based on grading the items according to the importa nce of performance of an item that is by V.E.D- Vital, essential and desirable a nalysis. Some items, though negligible in monetary value, may be vital for runni ng the plant, and constant attention is needed. If the inventory position is ana lysed Haranahalli Ramaswamy Institute of Higher Education, Hassan 17 Inventory Management according to the value, commonly known as XYZ analysis, the n results of ABC and XYZ analysis will be different, depending upon the nature o f obsolete items. The results of ABC analysis have to be reviewed periodically a nd updated. However, ABC analysis is a powerful approach in the direction of cos t reduction as it helps to control items with a selective approach. 2.7.5. HML A NALYSIS Since the annual usage is considered in case of ABC analysis, we may com e across a few items which fall B category, although the unit cost i.e. (cost per piece or unit) is quite high. If controls are exercised on the basis of ABC only , the importance of these items will be much less then A or B items even though the inventory transaction of one unit of these items will mean quite a lot money. Th erefore, it is necessary that unit cost is also considered in order to find out the importance of the items on the basis of unit costs. This method resembles AB

C classification except for the difference in the consumption value and unit val ue. Here the materials are classified according to their unit price as high cost items (H), medium cost items (M), and low cost items (L). This being similar to ABC analysis, usually, they are combined to arrive at a very effective satisfac tory analysis. This is mainly used for controlling the purchase prices. HML anal ysis is the price bond analysis. This analysis is generally used for control of space. The criteria used are: HIGH(H)- Those items, which have unit price (say a bove rs.1000) MEDIUM (M) Those item that have moderate unit price (say between r s.100 and rs.1000). LOW(L)- Those items that have low unit price (say below rs.1 00) 2.8. Spare parts management Spare parts represent a major part of maintenanc e expenses in a plant- ranging from 50 % in low technology to as high as 80% in high technology and process industries. The investment in spare parts range betw een 5% to 15%of the value of plant and machinery in a factory-and most of this i nventory is idle or non-moving. Yet, despite the enormous range and value of inv entory there is shortage of some critical spare parts or other, which often has a crippling effect on production. This situation is mainly due to the unpredicta ble nature of failures which creates the need for spare parts. All these matters make management of spare parts a hazardous and frustrating experience. The main problem with spares required for day-to-day Haranahalli Ramaswamy Institute of Higher Education, Hassan 18 Inventory Management repair maintenance of plant and machinery is that there nev er seem to be enough of them when required and too many in stock of spare which are not required. This is only the symptom of illness. The main causes are: 1) T he usage rates of spares are very low as compared to raw materials or as general stores. This causes their requirement to be highly fluctuating from period to p eriod. 2) The range of spare rates is very large and their individual values, re latively small. Thus rise the problem of the level of control. Unfortunately, mo st spare parts inventory management is done at the lowest organisational level. 3) The usage rate itself is difficult to establish from past records- especially for the slow movers which form the bulk of the spare parts inventory. Little us age history is available and the material variability of usage causes over estim ates of requirement. Categories of spares Spares can basically be classified int o four categories: 1) Consumable spares 2) Replacement spares 3) Rotable spares 4) Insurance spares Consumable spares are those which due to normal wear and tea r have considerably short life and are required regularly either as replacement of parts which wear out, or as replacement of part after specified period of ser vice.. Replacement spares are those parts or assemblies which are ordered on the basis of prior inspection against planned overhaul schedules. Rotable spares ar e those which are repaired after use and kept in stock to be used again. Haranah alli Ramaswamy Institute of Higher Education, Hassan 19 Inventory Management Insurance spares also called capital spares or emergency sp ares are those which do not wear and tear during the working life of the equipme nt yet they are stocked to safeguard high down time cost in the event of their b reakdown. 2.9. Inventory management techniques In managing inventories, the firms objective should be in consonance with the shareholder wealth maximisation prin ciple. To achieve this, the firm should determine the optimum level of inventory . Efficiently controlled inventories make the firm flexible. In efficient invent ory control results in unbalanced inventory and inflexibility the firm may someti mes run out of stock and sometimes may pile up unnecessary stocks. This increase s the level of investment and makes the firm unprofitable. To manage inventories efficiency, answers should be sought to the following to questions: How much sh ould be ordered? When should it be ordered? The first question, how much to orde r, relates to the problem of determining economic order quantity (EOQ), and is a nswered with an analysis of cost of maintaining certain level of inventories. Th e second question, when to order, arises because of uncertainty and is a problem of determining the re-order point. ECONOMIC ORDER QUANTITY (EOQ) One of the maj or inventory management problems to be resolved is how much inventory should be added when inventory is replenished. If the firm is buying raw materials, it has to decide lots in which it has to be purchased on replenishment. If the firm is planning a production run, the issue is how much production to schedule (or how

much to make). These problems are called order quantity problems, and the task of the firm is to determine the optimum or economic order quantity (or economic lot size). Determining an optimum inventory level involves two types of costs: a ) Ordering costs and Haranahalli Ramaswamy Institute of Higher Education, Hassan 20 Inventory Management b) Carrying costs. The economic order quantity is the inven tory level that minimises the total of ordering and carrying costs. Ordering cos ts The term ordering costs is used in case of raw materials (or supplies) and in cludes the entire costs of acquiring raw materials. They include cost incurred i n the following activities: requisitioning, purchase ordering, transporting, rec eiving, inspecting and storing (store placement). Ordering costs increase in pro portion to the number of orders placed. The clerical and staff costs, however, d o not have to vary in proportion to the number of orders placed, and one view is that so long as they are committed costs, they need not be reckoned in computin g ordering cost. Alternatively, it may be argued that as the number of orders in creases, the clerical and staff costs tend to increase. If the number of orders are drastically reduced, the clerical and staff force released now can be used i n other departments. Thus, these costs may be included in the ordering costs. It is more appropriate to include clerical and staff costs on a pro rata basis. Or dering cost increase with the number of orders, thus the more frequently invento ry is acquired, the higher the firms ordering costs. On the other hand, if the fi rm maintains large inventory levels, there will be few orders placed and orderin g costs will be relatively small. Thus, ordering costs decrease with increasing size of inventory. Carrying costs Costs incurred for maintaining given level of inventory are called carrying costs. They include storage, insurance, taxes, det erioration and obsolescence. The storage costs comprise cost of storage space (w arehousing cost), stores handling costs and clerical and staff service costs (ad ministrative costs) incurred in recording and providing special facilities such as fencing, lines, racks etc. EOQ is calculated by using the following formula E OQ = 2AO c Where, Haranahalli Ramaswamy Institute of Higher Education, Hassan 21 Inventory Management EOQ = Economic Order Quantity A = Annual consumption or ann ual requirement O = Ordering cost C = Carrying cost Reorder Point The problem, h ow much to order, is solved by determining the economic order quantity, yet the answer should be sought to the second problem, when to order. This is a problem of determining the reorder point. The reorder point is that inventory level at w hich an order should be placed to replenish the inventory. To determine the reor der point in certainty, we should know: a) Lead time b) Average usage, and c) Ec onomic order quantity. Lead time is the time normally taken in replenishing inve ntory after order has been placed. By certainty we mean that usage and lead time do not fluctuate. Under such a situation, reorder point is simply that inventor y level which will be maintained for consumption during the lead time. That is: Reorder point = Lead Average usage Safety stock The reorder point was computed u nder the assumption of certainty. It is difficult to predict usage and lead time accurately. The demand for material may fluctuate from day-to-day or from weekto- week. Similarly, the actual delivery time may be different from the normal l ead time. If the actual usage increases or the delivery of inventory is delayed, the firm can face a problem of stock-out which can prove to be costly for the f irm. Therefore, in order to guard against the stock-out, the firm may maintain a safety-stock some minimum or buffer inventory as cushion against expected increa sed usage and/or delay in delivery time. 2.10. Ratio Analysis Haranahalli Ramasw amy Institute of Higher Education, Hassan 22 Inventory Management Ratio analysis is a powerful tool of financial analysis. A ratio is defined as the indicated quotient of two mathematical expressions and as the relationship between two or more things. In financial analysis, a ratio is us ed as a benchmark for evaluating the financial position and performance of a fir m. Activity ratios Funds of creditors and owners are invested in various assets to generate sales and profits. The better the management of assets, the large am ount of sales. Activity ratios are employed to evaluate the efficiency with whic h the firm manages and utilises its assets. These ratios are also called turnove r ratios because they indicate the speed with which assets are being converted o

r turned over into sales. Inventory turnover Inventory turnover indicates the ef ficiency of the firm in producing and selling its product. It is calculated by d ividing the cost of goods sold by the average inventory: Inventory turnover = co st of goods sold Average inventory The average inventory is average of opening a nd closing balances of inventory. In a manufacturing company inventory of finish ed goods is used to calculate inventory turnover. Debtors turnover A firm sells g oods for cash and credit. Credit is used as a marketing tool by a number of comp anies. When the firm extends credits to its customers, debtors are created in th e firms accounts. Debtors are convertible into cash over a short period and, ther efore, are included in current assets. The liquidity position of the firm depend s on the quality of the debtors to a great extent. Financial analysts apply thre e ratios to judge the quality or liquidity of debtors: a) Debtors turnover, b) C ollection period, Haranahalli Ramaswamy Institute of Higher Education, Hassan 23 Inventory Management c) Aging schedule of debtors. Debtors turnover = Credit sal es Average debtors Collection period = 360 days Debtors turnover ratio Creditors Turnover Ratio It is also known as Accounts Payable Ratio. This ratio gives the average credit period enjoyed from the creditor. A low ratio indicates that cre ditors are not period in time while a high ratio gives an idea that business is not taking full advantages of credit period allowed by the creditor. Creditors T urnover Ratio = Credit Purchase Average creditors Chapter 3 company analysis 3.1 . Profile of the industry 3.1.1Meaning The textile industry is a term used for i ndustries primarily concerned with the design or manufacture of clothing as well as the distribution and use of textiles. The history of development in World Te xtile industry was started in Britain as the spinning and weaving machines were invented in that country. High production of wool, cotton and silk over the worl d has boosted the industry in recent years. Though the industry was started in U K, still in 19th Century the textile production passed to Europe and North Ameri ca after mechanization process in those areas. From time to time Japan, China an d India took part in industrializing their economies and concentrated more in th at sector. Haranahalli Ramaswamy Institute of Higher Education, Hassan 24 Inventory Management Japan, India, Hong Kong and China became leading producers due to their cheap labour supply, which is an important factor for the industry. 3.1.2.Global Textile Scenario According to statistics, the global textile marke t possesses a worth of more than $400 billion presently. In a more globalize env ironment, the industry has faced high competition as well as opportunities. It i s predicted that Global textile production will grow by 25 percent between 2002 and 2010 and Asian region will largely contribute in this regard. The World Trad e Organization (WTO) has taken so many steps for uplifting this sector. In the y ear 1995, WTO had renewed its MFA and adopted Agreement on Textiles and Clothing (ATC), which states that all quotas on textile and clothing will be removed amo ng WTO member countries. However the level of exports in textiles from developin g countries is increasing even if in the presence of high tariffs and quantitati ve restrictions by economically developed countries. New innovations in clothing production, manufacture and design came during the Industrial Revolution - thes e new wheels, looms, and spinning processes changed clothing manufacture forever . The rag trade, as it is referred to in the UK and Australia is the manufacture, trade and distribution of textiles. There were various stages - from a historica l perspective - where the textile industry evolved from being a domestic small-s cale industry, to the status of supremacy it currently holds. The cottage stage wa s the first stage in its history where textiles were produced on a domestic basi s. During the Industrial Revolution, new machines such as spinning wheels and ha ndlooms came into the picture. Making clothing material quickly became an organi zed industry - as compared to the domesticated activity it had been associated w ith before. A number of new innovations led to the industrialization of the text ile industry in Great Britain Haranahalli Ramaswamy Institute of Higher Educatio n, Hassan 25 Inventory Management 3.1.3.Textile Industry in India India Textile Industry is o ne of the leading textile industries in the world. Though was predominantly unor ganized industry even a few years back, but the scenario started changing after the economic liberalization of Indian economy in 1991. The opening up of economy

gave the much-needed thrust to the Indian textile industry, which has now succe ssfully become one of the largest in the world. India textile industry largely d epends upon the textile manufacturing and export. It also plays a major role in the economy of the country. India earns about 27% of its total foreign exchange through textile exports. Further, the textile industry of India also contributes nearly 14% of the total industrial production of the country. It also contribut es around 3% to the GDP of the country. India textile industry is also the large st in the country in terms of employment generation. It not only generates jobs in its own industry, but also opens up scopes for the other ancillary sectors. I ndia textile industry currently generates employment to more than 35 million peo ple. It is also estimated that, the industry will generate 12 million new jobs b y the year 2010. Indian textile industry can be divided into several segments, s ome of which can be listed as below: Cotton Textiles Silk Textiles Woollen Texti les Readymade Garments Hand-crafted Textiles Jute and Coir 3.2.S.Kumars Nationwi de Limited S.Kumars group was founded in 1948 by two brothers Mr.Abhayakumar S.Ka sliwal and Mr.Shambhukumar S.Kasliwal . The group consist of a conglomeration of several manufacturing,trading, Haranahalli Ramaswamy Institute of Higher Educat ion, Hassan 26 Inventory Management marketing and service companies. Each of which is decentral ised and run as an independent operating unit by well qualified personnel. S.Kum ars under the dynamic leadership of Mr.Nithin Kasliwal, not only continues to gro w in its existing line of synthetic fabrics but has also firmly committed itself to major investments in cotton, synthetic and woollen fibre groups. The sprawli ng 40 acres of Reid & Taylor plant for worsted suiting in Mysore in south India is a living testimony of the S.Kumars firm resolve to emerge as one of the most i mportant and diversified textile group in India. 3.2.1. Four Pillars of S.Kumars Nationwide Limited SKNL s success is based on its four pillars of strength - Ma nufacturing, Distribution, Brands and Human Capital. These four pillars have mad e the company stand apart and succeed in a highly competitive market scenario. M anufacturing Maintaining world-class quality has been a corner stone in SKNL s b usiness strategy. The company has invested extensively in manufacturing faciliti es to maintain high quality standards. Four state of art manufacturing units bas ed in Mysore (Karnataka) and Dewas (Madhya Pradesh) collectively produce over 2, 00,000 meters of high-quality fabrics each day. Luxury Textile fabrics are manuf actured at a world-class integrated facility situated near Mysore (Karnataka). I ts high quality fabrics are well received in the domestic as well as internation al market. In fact, Reid & Taylor - Scotland, sources its fabrics from this mill as well for its international markets. SKNL is the only manufacturer of fine co unt Damask in India. Its Chamunda Standard Mills and Amana Manufacturing Unit in the outskirts of Dewas (Madhya Pradesh) manufactures this fine fabric to cater to Indian & European markets. Distribution The companys wide network reaches both domestic as well as overseas market. SKNL caters to the entire socio-economic s egments of the Indian market across 30,000 outlets through 300 dealers. Haranaha lli Ramaswamy Institute of Higher Education, Hassan 27 Inventory Management Today, SKNL is the largest institutional supplier in India in the organized sector. The company plans to establish high impact presence thr ough multi-brand outlets, large format chain stores and exclusive stores for all its brands. Brands Ability to build brands, across the socio-economic segments has been one of the key factors in SKNL s success. A keen understanding of the d ynamic market trends, while keeping abreast with the changing usage patterns, at titudes and preferences of the consumers has been the foundation of creating suc cessful brands. Reid & Taylor caters to the premium and upper-middle strata of t he Indian suiting market. Since its national launch in 1999, the brand has accel erated to the second position in a highly competitive market. The brand s growth has been hailed by marketing professionals and is a case study for launching in ternational brands in India. No surprise that Superbrands Council, the worlds lea ding authority on marketing and advertising; has awarded it a Superbrand status, s econd time running. Belmonte offers a wide range of polyester and viscose blend fabrics for office, leisure and evening wear catering to the mid-premium consume r. It is available across top 100 cities in India. Uniformity by Belmonte is the s

ub-brand which offers a wide range of uniform fabrics for professional work-wear across industries. Carmichael House is a new entrant in the Home Textile catego ry. This mass premium brand offers a wide range of home textile solutions for th e entire abode in a variety of fabrics and weaves. Since its launch, Carmichael House, has received fast recognition among its consumers. Human Capital Haranaha lli Ramaswamy Institute of Higher Education, Hassan 28 Inventory Management SKNL has developed highly effective management capabilities due to a unique fusion of entrepreneurship with professional expertise. The Boa rd of Directors includes eminent people from industry, law, banking, finance and economic sectors. The business at SKNL is divided into product-wise Strategic B usiness Units viz, Consumer Textiles (work wear, mid premium and daily wear), Ho me Textiles (THE), Premium cotton fabric (HVFC) and Ready to Wear (Total Wardrob e Solutions),Luxury Textiles. Each SBU operates as an independent profit center and is lead by a seasoned professional. Service functions like Human Resources, Corporate Finance, Corporate Planning, Research, Marketing & Communications and Legal are centralized. 3.3. REID AND TAYLOR (INDIA) LTD Reid & Taylor (India) Lt d., is a subsidiary of SKNL. Synonymous with British tradition, Reid & Taylor ha s been styling the world s elite for over 170 years. It all began in the 1830 s with Alexander Reid, an enterprising Scottish gentleman, embarking on a journey to make his vision a reality. Using locally available Cheviot wool he created Ch eviot cloth that soon caught on the fancy of the landed gentry. As the clientele and reputation grew, he was joined by financer Joseph Taylor. Thus, began the e nduring partnership of creating finest cloths in the world, which today is bette r known as Reid & Taylor. Reid & Taylor continues the journey to create the fine st fabric passionately and has thus carved out a distinguished name for itself i n the industry. Reid & Taylor was launched by SKNL in India in 15th December 199 8 with the inauguration of a state-of-the-art fabric plant at Mysore in 40 acres of land . The discerning consumers in India now can experience international-qu ality garments in their own cities and towns. Today, Reid & Taylor has emerged a s a leading brand in the worsted suiting segment with sales turnover of Rs. 2200 Million and a market share of 18 %, propelling the brand to grow at a rapid rat e of 25% p.a. The manufacturing facilities for Reid & Taylor includes; 13600 sta te-of-the-art worsted spindles, complete and comprehensive facilities for dyeing of wool tops, yarn and fabrics , the latest Dornier Rapier looms , well-equippe d finishing department with the ultra modern fabric processing gadgets. All thes e have churned out over 600 designs in the first year of operation. Reid & Taylo r is the first brand in India to offer both fabrics and apparel under one label. The fine quality of garments and sharp styling has created a space for itself i n the customers mind. Haranahalli Ramaswamy Institute of Higher Education, Hassan 29 Inventory Management After an initial flush of success the brand once again face d the grim future of stagnation. Research by ACNielsen concluded that it needed to reach a wider audience in metros without losing the premium values associated with the brand .The challenge required a brand ambassador who was a style icon for Indians, was equally popular with both the masses as well as the elite. Also , his personality had to jell with the brand platform. Amitabh Bachchan clearly fitted this role. The association has helped the brand consolidate its positioni ng of Bond with the Best. This is because Bachchan stands head and shoulders above his peers, defining the outstanding values that always accompany style, groomin g and professional excellence. Reid & Taylor manufactures suit lengths in superf ine merino fleece and superfine polyester executive wear in wool and polyester a nd other popular blends. The composition, too, is more adventurous. Linen Kraft is a unique combination of linen with 10% polyester for an unruffled look. Speci ally developed for ceremonial wear is Silk Ovation a 100% silk fabric with a cle ar understanding of major user segments and usage environments, the product offe ring has been created to exceed customer expectations. Rewriting the rules with dynamic colours, attractive selvedge and competitive pricing, Reid & Taylor has made its mark across all segments in the market. The plant has 12960 spindles an d 56 looms and has a captive power generating capacity of 70MW.All the machinery is imported from Germany, France, Italy, Switzerland and England. The range of

the products varies from medium to higher range. The 25% of its production are e xported to foreign countries like U.K, Middle east, Japan and UAE etc. The plant having technical collaboration with Reid &Taylor Scotland . The company has pro vided direct employment to 1200 workers including staff and indirect employees. The workmen are employed as company apprentice on training period of two years a nd over 95% of the workmen are recruited from in and around Nanjangud and adjoin ing villages. 3.3.1.Mission Statements To ensure the consumer remains the focal point of all our activities by offering him high value for money. To pursue our goals in a just and ethical manner. Haranahalli Ramaswamy Institute of Higher Ed ucation, Hassan 30 Inventory Management To provide every opportunity to our business associates and employees to realise their potential to the fullest extent. To blend modern tec hnology with traditional values in our endeavour to be a world class, Indian com pany globally. 3.3.2.Objectives To be Indias leading textile group and a world cl ass entity. To continue and expand the leadership position in uniforms/ workday materials. To consolidate and expand in the household material sector. To reinfo rce and expand the position in shirting and prints. To enter made-ups and value added products. To expand exports to 20% of group activity. To enter retailing o f apparel and soft goods country-wide in a big way. To become a global player in textiles. 3.3.3. Quality policy We are committed to be a world class company by consistently designed and manufacturing suiting to the highest standards and cu stomer expectations. We shall operate in a just and ethical manner providing opp ortunity to employees and associates to realise their potential to the fullest e xtent. We are committed to comply with ISO 9001 and for continual improvement of the quality management system . Haranahalli Ramaswamy Institute of Higher Educa tion, Hassan 31 Inventory Management 3.3.5.Products and services Fabrics Reid & Taylor manufactu res a wide range of Worsted and Premium suitings including: All Wool Superfine P olywool Blends Wool Cashmere Blends Wool Linen & Wool Silk Polyester Blends Poly ester Viscose Blends Polyester Viscose worsted Value added Polyester Viscose ble nds Wrinkle resistant suitings ECOFRESH suitings Apparel In the ready to wear se gment, Reid & Taylor has launched Suits Jackets Trousers Shirts T-Shirts golfin Haranahalli Ramaswamy Institute of Higher Education, Hassan 32 Inventory Management 3.3.7.SWOT Analysis Strengths Outstanding brand equity. 30, 000 strong retailer networks all over the country. Professional management with entrepreneurial outlook. Excellent track record in business administration. Hara nahalli Ramaswamy Institute of Higher Education, Hassan 33 Inventory Management Broad market coverage. Good materials management systems. H uman resource competencies. Appropriate organizational structure. Management sup port. Work union support. R&D skills. Technology used. 25 retail shops. Weakness Depend on single supplier for some materials. High cost for procurement of wool . High cost for procurement of polyester. Opportunities Expand core business(es) . Widen product range. Expand into foreign markets. Seek fast market growth. Gov ernment support. Haranahalli Ramaswamy Institute of Higher Education, Hassan 34 Inventory Management Support from banks and financial institutions. Investors. O vercome barriers to entry. Enlarge corporate portfolio. Technical collaboration with Reid & Taylor Scotland. Threats Increases in domestic competition. Increase in foreign competition. Changes in economic factors. Downturn in economy. Stron g competition from Raymond. Chapter 4 analysis 4.1. Stores procedure Chart4.1. C hart showing Stores procedure Material receiving Haranahalli Ramaswamy Institute of Higher Education, Hassan 35 Supplier Receiving stores Inspection Rejection b ay Inventory Management If ? Not Ok Ok Holding stores STORES PROCEDURE To ensure 10 0% uptime of all manufacturing activity as related to stores function. 4.1.1 MAT ERIALS RECEIVING Haranahalli Ramaswamy Institute of Higher Education, Hassan 36 Stores receive materials from various vendors through RPP/L Inventory Management R/RR/BANK/Representative collection along with dc/invoice copies in duplicate. c heck for purchase order on dc/invoice Unpack the material, check for quantity, s pecification, correctness of the material and acknowledge. If found damaged/exce ss supplied/short supplied, generate discrepancy note and send a copy to purchas

e department for information and further action. Prepared goods received note (G RN) and send it to the concerned department head for inspection. If quality acce pted, take concerned head of Department signature and store the material in predetermined location. If rejected based on concerned H.O.Ds remark prepare reject ion report and arrange to send the material back to the supplier through non-ret urnable gate pass and inform purchase department and accounts for further action . In case of materials unloaded at shop, stores put the tag materials for inspect ion/can have demarcated physical area for materials under inspection. And same pr ocedure may be followed for regularization. 4.1.2 INSPECTION Receiving inspectio n checks the material with respect to purchase order for specification and quali ty. If found ok, accepted sticker will be put on the material, prepare final sto res document. Stores lift the material and storage will be made in predetermined area. If found not ok, a rejected sticker will be put on the material. Stores l ift the material and keep it in rejected stores. A copy of rejection report will be given to purchase for further action. Inspection report may be prepared for vendor rating analysis 4.1.3 PURCHASE ORDER Purchase department prepares purchas e orders for the required materials and will be sent to the vendor. Haranahalli Ramaswamy Institute of Higher Education, Hassan 37 Inventory Management Procurement of material is against purchase order only. Pur chase order should have all the details like Terms of purchase Mode of transport Modvat details In case of excisable goods Delivery schedules Lead time Packagin g and freight details 4.1.4 ISSUE PROCEDURE Receive indents/material request not e from users Check for authorization, stock availability etc. , Issue slips crea tion, take printout and issue the right material. File a copy of issue slip duly signed as acknowledgement. 4.1.5 STORAGE Codification of materials. Put identif ication tags on material. Allot a particular area for storage of items and updat e the location in the system for easy traceability. Separate stores should be ma de for shelf life items, paints, resin and hardeners, chemicals etc., Shelf life i tems should be periodically checked for its validity. Electronic/Electro static devises should be stored in specific recommended ESD area only-can be stored in electronic lab. Storage racks, storage shelves/bins should be properly identifie d. Haranahalli Ramaswamy Institute of Higher Education, Hassan 38 Inventory Management Ensure proper handling and storing of materials in a dust f ree area. Maintain good housekeeping. 4.1.6 OLD/DAMAGED PARTS ACCOUNTING Get old /unusable/damaged materials during process from users. Classify the materials as usable or not usable. Further classify the materials as PVC/rubber /metallic et c. , If material can be rectified and reused, inform purchase to send the materi al for repair /follow up- prepare RGP, have a track of it. If material cannot be used, call for tender from scrap vendors and arrange for auction or generate sc rap note for scraping the material. Take a care of excise related items while se nding out of repair / scraping(duty reversal) Same procedure may be followed eve n for capital equipments. 4.1.7 PASSING Receive inspection report If material is ok, check for identification tag, accepted sticker and quantity and move the ma terial to holding stores. If material is rejected, check for rejected sticker, r ejection report, and quantity. Put rejected tag giving all the details like PO N O., date, quantity, and reason for rejection. Lift and store the material in rej ected stores. Purchase takes the responsibility of sending back the rejected mat erial in coordination with stores for preparation of RGP/NRGP etc., Clear invoic e/bill and pass it to accounts/ finance. Rejected materials can be replaced on o ne-one basis and can be regularised on the same invoice /bill. In case of excise duty related materials, excise duty gate pass should be handed over to the conc erned to avail the Modvat facility. Haranahalli Ramaswamy Institute of Higher Ed ucation, Hassan 39 Inventory Management 4.1.8 GATE PASSES Returnable gate pass (RGP) and non return able gate pass (NRGP) may be maintained as applicable to send the material out o f the company. Stores should have control over gate passes. 4.1.9 REPORTS Stores must be able to generate all inventory-related reports as required by the manag ement. Stores should ensure availability of right material in right place as per stock ledger during inventory checking by the statutory auditors. 4.2.STORES RE CORDS Delayed documentation of all the transactions is one of the major function

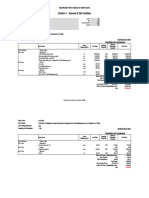

s of the Materials management Department. Any ignorance or negligence in this pr ocess would lead to dire consequences at the later point of time wherein without the essential records, certain transactions that need verification cannot be su bject to the same. Thus, these stores records are valuable pieces of information that form the base for further reference. Some of the stores records are as fol lows: 4.2.1 .BINCARD This is a card, which is attached to each bin, rack, shelf, or other container for stores. A record of all materials entering or leaving th e bin and balance of materials in hand is kept in this card. The storekeeper ent ers these cards and only the quantities are recorded. These should tally with th e quantities of materials as shown in the relevant account in the stores ledger. This will enable the storekeeper ascertain the quantity of materials in stock a nd remind him to send requisition of fresh stock, when the minimum stock has bee n reached. In some factories duplicate bin cards are being used. In such cases o ne card is attached to the bin and the storekeeper on his table for ready refere nce keeps the duplicate. The inspectors check bin cards from time to time and th ey put their initials and take down their discrepancies. 4.2.2.STORES LEDGER It is a detailed record of the receipt and issue of material with respect to rate o f item, issues, transactions, opening and closing balance and value of all items kept in the store. A separate sheet or card is maintained for each article. It contains the name, description, bin number etc. It records the receipts, issues, and balance in hand of each and every article. At the time of physical verifica tion, verifying officer, after inspection of records gives his recommendations i n remarks column. Haranahalli Ramaswamy Institute of Higher Education, Hassan 40 Inventory Management 4.2.3. MATERIAL ISSUE REQUISITION An important rule, which should be strictly followed, does not allow any material to pass from stores dep artment into the works except upon the authority of written requisitions. These indents on stores are demands upon the store the storekeeper signed by authorize d persons, issued to the bearer, to be charged to a particular job or department specified therein. Such indents are made out in triplicate from bound books and are supplied to each department. As it is in triplicate, the original copy is s ent to the cost department for costing, duplicate retained by the storekeeper an d the triplicate in the bound book by way of indent or by way of permanent recor d. 4.2.4.MATERIAL RETURNED NOTE Material issued for department use are sometimes not required and returned to storekeeper. They must be properly recorder and th eir value may be duly entered in the store records and these values may be credi ted to the accounts of the departments concern by the cost department. For this purpose material returned notes are written out in triplicate. Two copies being sent to the storekeeper along with the returned material. One of these is return ed to the foreman with the storekeepers acknowledgement. The copy retained by the storekeeper is entered by him on the bin cards and then passed to stores accoun t and to be priced and entered in the relative stores card. 4.2.5. GOODS RECEIVE D NOTES (GRN) To the existing goods received note, three additional columns for entering details about the quantity entered, quantity received and quantity reje cted has been provided for appendix. Another column is provided for entering mat erial codes. On receipt of the goods, physical verification of the goods is done in presence of one person each from the security; stores, purchase department a nd the supplier. If found correct, by comparing the consignment with that of the order placed, the GRN is prepared and the concerned department is asked to chec k the quality of the items. If the items need to be tested on t he machine, the item is taken to the department, along with the GRN and sent to the stores, alon g with the payment card. One copy of the GRN is retained with the department. At this, the goods are taken in to the stock and the purchase order is transferred from order pending file to the orders completed file. 4.2.6. GATE PASS Returnable g ate pass (RGP) and Non Returnable Gate Pass (NRGP) may be maintained as applicab le to send the material out of the company. Stores should have control over gate passes. Haranahalli Ramaswamy Institute of Higher Education, Hassan 41 Inventory Management 4.3. Study on sales and raw material consumption Table 4.1. Table showing the raw material consumed and the sales for 5 years. SL NO YEAR R AWMATERIAL SALES 1 2004-05 254.14 344.53 2 2005-06 640.71 889.73 3 2006-07 886.8 4 1229.54 4 2007-08 1112.32 1748.65 5 2008-09 1541.61 2260.36 Chart 4.2. Chart s

howing the sales and raw materials consumed for 5 years Analysis Study on raw ma terial consumption and sales has be carried out from 2004 to 2009. Intepretation Haranahalli Ramaswamy Institute of Higher Education, Hassan 42 Inventory Management Percentage of raw materials on sales for 5 years are as fol lows Year Percentage 2004-05 73.76 2005-06 72.01 2006-07 72.13 2007-08 63.61 200 8-09 68.2 From this we can findout that the percentage of raw materials consumpt ion increases in the year 2006-07 and again in 2008-09. It shows that in these y ears cost has increased in the organization. Table 4.2. Table showing the regres sion analysis taking two variables they are rawmaterials and sales. RAWMATERIAL dx=x- dy=Y- SALES (x) (y) A(1229.54) dx2 A(886.84) 344.53 254.14 -885.01 783242. 7001 -632.7 889.73 640.71 -339.81 115470.8361 -246.13 1229.54 886.84 0 0 0 1748. 65 1112.32 519.11 269475.1921 225.48 2260.36 1541.61 1030.82 1062589.872 654.77 X =6472.81 Y=4435.62 dx=325.11 dx2=2230778.6003 dy=1.42 dy2 dxdy 400309.29 559945.827 60579.9769 83637.4353 0 0 50841.2304 117048.9228 428723.7529 674950.0114 2 dy =94 0454.2502 dxdy=1435582.14 Haranahalli Ramaswamy Institute of Higher Education, Ha ssan 43 Inventory Management = 5(1435582.14)-(325.11)(1.42) 5(2230778.6003)-(105696.5121) 5(940454.2502)-(2.0164) = 7177449.044 5(2125082.0882)5(940452.2338) = 7177449.044 1 625410.441 4702261.169 = 7177449.044 3259.6642 2168.4697 = 7177449.044 7068483.04 987 = 1.0154 r = ndxdy-dx*dy ndx2-(dx)2 ndy2(dy)2 Analysis Regression analysis has arried out taking sales and raw material consumption into consideration for 5 ye ars. Interpretation Regression analysis is a powerful statistical tool used to k now the relationship between two variables in any field. From this analysis regr ession of 1.0154 shows the positive relationship between sales and raw Haranahal li Ramaswamy Institute of Higher Education, Hassan 44 Inventory Management materials. From this it shows that there is proper relation ship between cost and income of the organization. It shows that company consumin g good proportion of raw materials every year. 4.4. Calculation of debtors and c reditors turnover ratio. Table 4.3. Table showing average debtors and sales for last 5years SL NO YEAR Average debtors SALES 1 2004-05 391.14 344.53 2 2005-06 4 48.855 889.73 3 2006-07 549.765 1229.54 4 2007-08 705.05 1748.65 5 2008-09 1002. 93 2260.36 Calculation of Debtors Turnover Ratio and Debt Holding Period Debtors Turnover Ratio = Net sales Average debtors DTR For 2004-05 = 344.53 391.14 = 0. 880835506 Times DTR For 2005-06 = 889.73 448.855 = 1.98222143 Times DTR For 2006 -07 = 1229.54 549.765 = 2.23648286 Times DTR For 2007-08 = 1748.65 705.05 Harana halli Ramaswamy Institute of Higher Education, Hassan 45 Inventory Management = 2.480178711 Times DTR For 2008-09 = 2260.36 1002.93 = 2.2 53756493 Times Calculation of Debt Holding Period Debt Holding Period = 360 Days Debtors Turnover Ratio DHP For 2004-05 = 360 Days 0.880835506 = 414.3792993 day s DHP For 2005-06 = 360 Days 1.98222143 = 184.1368449 Days DHP For 2006-07 = 360 Days 2.23648286 = 163.2026816 Days DHP For 2007-08 = 360 Days 2.480178711 = 147 .1668144 Days DHP For 2008-09 = 360 Days 2.253756493 = 161.9518351 Days Analysis Haranahalli Ramaswamy Institute of Higher Education, Hassan 46 Inventory Management Debtors turnover ratio and debt holding period has been cal culated for 5 years from 2004-05 to 2008-09. Interpretation Debtors turnover rat ios is very low in the company. It shows the inefficient management of debtors. Debt holding period is high in the years and it indicates on an average that cre dit sales are pending uncollected by the concern. Table 4.4. Table showing avera ge creditors and purchases for 5years: SL NO YEAR Purchases Average creditors 1 2004-05 254.14 103.995 2 2005-06 640.71 108.045 3 2006-07 886.84 127.515 4 200708 1112.32 147.815 5 2008-09 1541.61 191.17 Calculation of Creditors Turnover Ra tion And Credit Payment Period Creditors Turnover Ratio = Net Purchases Average creditors CTR For 2004-05 = 254.14 103.995 = 2.443771335 Times Haranahalli Ramas wamy Institute of Higher Education, Hassan 47 Inventory Management CTR For 2005-06 = 640.71 108.045 = 5.930029155 Times CTR Fo r 2006-07 = 886.84 127.515 = 6.954789633 Times CTR For 2007-08 = 1112.32 147.815 = 7.525082028 Times CTR For 2008-09 = 1541.61 191.17 = 8.064079092 Times Calcul ation of Credit Payment Period Credit Payment Period = 360 Days Creditors Turnov er Ratio CPP For 2004-05 = 360 Days 2.443771335 = 149.3593098 Days CPP For 200506 = 360 Days 5.930029155 = 61.55113078 Days CPP For 2006-07 = 360 Days 6.954789