Professional Documents

Culture Documents

BCH AC Brake Motor Write Up

Uploaded by

Naveen GuptaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BCH AC Brake Motor Write Up

Uploaded by

Naveen GuptaCopyright:

Available Formats

INTRODUCTION

CONSTRUCTION: GENERAL GUIDELINES FOR SELECTION OF SUITABLE BRAKE

MODEL:

Brake Motors are used for various applications where

instantaneous stopping of the driven load is required. The The Brakes are rated by torque & selection of suitable model can be

operation of the brake is “FAIL SAFE TYPE” i.e. normally ON. made by calculating the required torque, rating of the brake & then

When the electrical power to the motor is cut–off or the power matching it with static torque.

fails, the brake is applied.

Torque (Nm) = 9550 x (KW / RPM) x Safety Factor (SF)

Brake motor is a combination of an A.C. induction motor and an where kW-Kilowatts of motor,

electromagnetic AC or DC brake. The electromagnetic brake is RPM-Speed of motor,

mounted on the non–driving end of the motor. SF-Safety Factor depending on type of prime mover & load.

For electric motor, SF = 2 to 3

DC brake motors are provided with a rectifier which provides the For diesel engine, SF = 4 to 5

required DC voltage to the brake coil which in turn operates the For compressor, SF = 5 to 6.

brake. The supply to the rectifier is fed from any two terminals

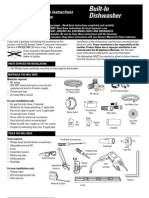

(between any two phases) in the main terminal box of the motor. BRAKE COIL CONNECTION DIAGRAM:

General applications of Brake motors are printing machinery,

textile machinery, rolling mills, cranes & hoists, material handling RECTIFIER

equipments, machine tools etc.

WORKING:

Grey

Grey

When the power to the motor is switched off, a braking torque is

generated which presses the armature plate of the brake against

the mounting flange. When the supply resumes, a magnetic field Red (+)

is produced in the brake coil and this pulls the armature plate R Y B To Brake Coil

against the spring force and the shaft is now free to rotate. Black (-)

RANGE OF BCH ELECTRIC BRAKE MOTORS:

Brake coil is energized by DC side switching as shown in the

KW : 0.093 to 15.0 kW diagram.

RPM : 3000, 1500, 1000, 750

Mounting : Foot (B3), flange (B5), face (B14) & APPLICATIONS:

combinations

Frame : 63 to 160L BCH Brake motors can be used in many applications. A few of them

Voltage : 415V or as required are listed below;

Frequency : 50Hz • Machine tools

Braking torque : Upto 250Nm • Textile machinery

Brake coil voltage : 190V DC (Other voltages on request) • Cranes & hoists

Degree of protection : IP54 • Printing Machinery

Duty cycle : S1 – S8 • Material handling equipments

• Geared motors

SPECIAL FEATURES: • Cable reeling drums

• Rolling mills

• The brake motors are simple & rugged & so easy for

maintenance. ENQUIRY DETAILS:

• No separate DC supply is required as the rectifier is

provided which gives the required DC voltage for When placing an enquiry, please furnish the following details;

energisation of the brake. • Application details

• The rectifier is mounted inside the main terminal box so no • Motor power & speed

separate terminal box required. • Brake size / required braking torque

• Mounting

• No. of start/stops per hour

• Duty cycle

SELECTION CHART

Brake Brake

Motor Type Speed Torq. Brake Motor Type Speed Torq. Brake

KW HP Torque S. F. KW HP Torque S. F.

Frame Designation (rpm) (Nm) Size Frame Designation (rpm) (Nm) Size

(Nm) (Nm)

0.09 0.125 71 870 0.99 K1 4.5 4.56 1.5 2.0 100L 935 15.30 K5 35.0 2.29

71 665 1.29 K1 4.5 3.49 112M 705 20.29 K6 60.0 2.96

0.18 0.25 63 2740 0.63 K1 4.5 7.18 2.2 3.0 90L 2860 7.34 K4 16.0 2.18

63 1350 1.27 K1 4.5 3.54 100L 1425 14.73 K5 35.0 2.38

71 900 1.91 K1 4.5 2.36 112M 940 22.32 K6 60.0 2.69

80 680 2.52 K2 8.0 3.17 132S 710 29.55 K6 60.0 2.03

0.25 0.33 63 2760 0.86 K1 4.5 5.21 3.7 5.0 100L 2880 12.25 K5 35.0 2.86

71 1370 1.74 K1 4.5 2.59 112M 1430 24.68 K6 60.0 2.43

71 900 2.65 K1 4.5 1.70 132S 950 37.15 K7 80.0 2.15

80 685 3.48 K2 8.0 2.30 132M 710 49.71 K8 150.0 3.02

0.37 0.50 71 2800 1.26 K1 4.5 3.57 5.5 7.5 112M 2900 18.09 K5 35.0 1.93

71 1380 2.56 K1 4.5 1.76 132S 1440 36.43 K7 80.0 2.20

80 910 3.88 K2 8.0 2.06 132M 955 54.93 K8 150.0 2.73

90S 690 5.11 K4 16.0 3.13 160M 710 73.89 K8 150.0 2.03

0.55 0.75 71 2820 1.86 K1 4.5 2.42 7.5 10.0 132S 2910 24.58 K6 60.0 2.44

80 1400 3.75 K2 8.0 2.13 132M 1440 49.68 K8 150.0 3.02

80 910 5.76 K3 12.0 2.08 160M 960 74.52 K8 150.0 2.01

90L 690 7.60 K4 16.0 2.10 160L 710 100.76 K9 250.0 2.48

0.75 1.0 80 2840 2.52 K2 8.0 3.18 9.3 12.5 132M 2915 30.43 K6 60.0 1.97

80 1405 5.09 K3 12.0 2.36 160M 1450 61.18 K8 150.0 2.45

90S 925 7.73 K4 16.0 2.07 160L 960 92.40 K9 250.0 2.71

100L 695 10.29 K5 35.0 3.40 11.0 15.0 160M 2915 35.99 K7 80.0 2.22

1.1 1.5 80 2840 3.69 K2 8.0 2.17 160M 1450 72.36 K8 150.0 2.07

90S 1415 7.41 K4 16.0 2.16 160L 965 108.73 K9 250.0 2.30

90L 925 11.34 K5 35.0 3.09 15.0 20.0 160M 2920 49.00 K8 150.0 3.06

100L 695 15.10 K5 35.0 2.32 160L 1450 98.67 K9 250.0 2.53

1.5 2.0 90S 2850 5.02 K3 12.0 2.39 18.5 25.0 160L 2920 60.43 K8 150.0 2.48

90L 1415 10.11 K5 35.0 3.46

NOTE:

1. Mechanical manual release arrangement can be provided for 4. Motors upto frame sizes 90L can also be provided in

all frames as an optional feature. This can be used to release aluminium housings.

the brake manually with a lever, in case of power failure. 5. The motor must never be switched “ON” unless brake is

2. Selection chart is a general guideline for selection of brake energised & the brake should never be de-energised when

size. If braking torque required is other than that mentioned the motor is “ON”.

in selection chart, this can be provided on request. 6. Brake motors with higher braking torque can also be

3. Brake motors with safety factor less than 3 are not suitable provided.

for crane/hoisting applications. 7. Motor performance is as per IS: 325.

All relevant IS tolerances are applicable.

.

You might also like

- ZF W1900 Data Sheet 042013Document4 pagesZF W1900 Data Sheet 042013LisandroNo ratings yet

- Ac Solenoid & Solenoid BrakesDocument6 pagesAc Solenoid & Solenoid BrakesPrajapati AtulkumarNo ratings yet

- Nomi.... 1111Document9 pagesNomi.... 1111Noman SaleemNo ratings yet

- Drive SystemsDocument17 pagesDrive SystemstchepssilveiraNo ratings yet

- 6 Motor Basics HandoutDocument18 pages6 Motor Basics HandoutTan Yit KeongNo ratings yet

- Load Test on Separately Excited DC MotorDocument12 pagesLoad Test on Separately Excited DC MotorShinthu Bargavi VenkatesanNo ratings yet

- Nomi.... 1111Document9 pagesNomi.... 1111Noman SaleemNo ratings yet

- Moog Wind PitchServoMotor Datasheet en PDFDocument4 pagesMoog Wind PitchServoMotor Datasheet en PDFMaria TzagarakiNo ratings yet

- Drive System Bearings: June 1, 2018Document24 pagesDrive System Bearings: June 1, 2018Anonymous YggO6T6GzNo ratings yet

- CDA - Elecon Flexible CouplingDocument5 pagesCDA - Elecon Flexible CouplingMohit GuptaNo ratings yet

- Motor of VTOL Aircraft PDFDocument22 pagesMotor of VTOL Aircraft PDFvimarsh joshiNo ratings yet

- Motor of VTOL AircraftDocument22 pagesMotor of VTOL Aircraftvimarsh joshiNo ratings yet

- PDFDocument44 pagesPDFRebecca Hartman75% (4)

- Drum BrakesDocument7 pagesDrum BrakesZahir KhiraNo ratings yet

- RMD Motor TypesDocument19 pagesRMD Motor TypesMuhammed AyyubNo ratings yet

- 2005 FZ6-S Service ManualDocument20 pages2005 FZ6-S Service ManualBratkó BenceNo ratings yet

- AC Motor and Servo Driver Configuration and Parameter ListDocument37 pagesAC Motor and Servo Driver Configuration and Parameter ListJean GrimNo ratings yet

- Basic Engine Model and Performance DataDocument6 pagesBasic Engine Model and Performance DataGermán Andrés100% (1)

- Permanent Magnet Motor GuideDocument36 pagesPermanent Magnet Motor GuidekkarthiksNo ratings yet

- CL - TechnologyOvr - R3a - STD (Vantagens de Motor DC Coreless) PDFDocument2 pagesCL - TechnologyOvr - R3a - STD (Vantagens de Motor DC Coreless) PDFLeonardo MartinsNo ratings yet

- MSM Series Brushless Servo Motor Manual: © 2003 Sheffield Automation, LLC. All Rights ReservedDocument11 pagesMSM Series Brushless Servo Motor Manual: © 2003 Sheffield Automation, LLC. All Rights Reservedsppa1No ratings yet

- Ishaq Final Year Project Report PDFDocument28 pagesIshaq Final Year Project Report PDFAmazon fbaNo ratings yet

- Kirloskar Brothers SP Series Self Priming PumpsDocument2 pagesKirloskar Brothers SP Series Self Priming PumpsasdjhfkadhfNo ratings yet

- Group 6 - DC Motors PDFDocument22 pagesGroup 6 - DC Motors PDFRashen DilNo ratings yet

- Servo-Motor: Batch 7: Mouli R N Nagaaswin N Naveen K Nilesh Ram Praveen K Nirmal Kumar SDocument27 pagesServo-Motor: Batch 7: Mouli R N Nagaaswin N Naveen K Nilesh Ram Praveen K Nirmal Kumar SThameem AbbasNo ratings yet

- Chapter 7: Alternating Current Motors: Electrical MachineDocument28 pagesChapter 7: Alternating Current Motors: Electrical MachineThe zeroNo ratings yet

- Single-Phase Motors: by Wan Marlina BT Wan AhmadDocument34 pagesSingle-Phase Motors: by Wan Marlina BT Wan AhmadOhmae BaranskiNo ratings yet

- Complete Range of BBL Crane & Hoist Duty Motors (0.12kW to 1250kWDocument64 pagesComplete Range of BBL Crane & Hoist Duty Motors (0.12kW to 1250kWgayathrikanduriNo ratings yet

- 04 129284 - Electric - MotorsDocument22 pages04 129284 - Electric - Motorskara_25No ratings yet

- 03 - SSW IntroductionDocument19 pages03 - SSW IntroductionRajasekaran PuthiyavapillaiNo ratings yet

- Engine Performance Data at 1500 RPM: QSK 1 Cummins IncDocument4 pagesEngine Performance Data at 1500 RPM: QSK 1 Cummins Incmohsen_cumminsNo ratings yet

- PMBLDC Motor DriveDocument55 pagesPMBLDC Motor DriveSushant SinghNo ratings yet

- Special - Electrical - Machines QBDocument25 pagesSpecial - Electrical - Machines QBVel MuruganNo ratings yet

- Ed About Brushless MotorsDocument7 pagesEd About Brushless MotorsAddo AdhiyaksaNo ratings yet

- MOTOR SELECTION GUIDE: AC, DC, BRUSHLESS, AND MOREDocument11 pagesMOTOR SELECTION GUIDE: AC, DC, BRUSHLESS, AND MOREabid azizNo ratings yet

- AC MotorsDocument52 pagesAC Motorsjennybunnyomg50% (6)

- SBPT Catalogue DC CouplingDocument11 pagesSBPT Catalogue DC CouplingEserNo ratings yet

- Stepping Motors 3 PhasesDocument12 pagesStepping Motors 3 PhasesTamas RaduNo ratings yet

- Induction Motor BasicsDocument19 pagesInduction Motor BasicsPUSHPAN DAHARWALNo ratings yet

- KX Series Brochure (715-3300kVA)Document12 pagesKX Series Brochure (715-3300kVA)Paulo MandingaNo ratings yet

- 1012E Engine Powers Construction EquipmentDocument6 pages1012E Engine Powers Construction EquipmentSiding BarroNo ratings yet

- Step 1: Let's Look at A Typical Motor: Stator Cooling FanDocument17 pagesStep 1: Let's Look at A Typical Motor: Stator Cooling FanrodrigomessiasNo ratings yet

- Motor Selection 1Document2 pagesMotor Selection 1s_mahes100% (1)

- Basics of Motors & Control PanelDocument59 pagesBasics of Motors & Control PanelPraveen BalakrishnanNo ratings yet

- DC Motor Specifications and CharacteristicsDocument16 pagesDC Motor Specifications and Characteristicsjonoc90No ratings yet

- Caterpillar 3512Document10 pagesCaterpillar 3512marvinmoalNo ratings yet

- Chapter 4Document27 pagesChapter 4Selemon AssefaNo ratings yet

- Marine Propulsion Systems: DescriptionDocument6 pagesMarine Propulsion Systems: DescriptionJuniorJavier Olivo FarreraNo ratings yet

- College of Engineering: - Topic: BLDC MotorDocument38 pagesCollege of Engineering: - Topic: BLDC MotorjitbakNo ratings yet

- Module 2 - DC Motor DrivesDocument61 pagesModule 2 - DC Motor DrivesMohammad Amirul ShafiqNo ratings yet

- Exp 13518Document25 pagesExp 13518Elie KhawandNo ratings yet

- Motor Sincrono SYNCGUIDEDocument48 pagesMotor Sincrono SYNCGUIDEluisfilipeminenervaNo ratings yet

- Kaizen - Motor Selection GuideDocument11 pagesKaizen - Motor Selection GuideAmory Sabri AsmaroNo ratings yet

- Mellor Brochure en LRDocument20 pagesMellor Brochure en LRmohamed moussaNo ratings yet

- Marine Transmission SystemsDocument6 pagesMarine Transmission SystemsJuniorJavier Olivo FarreraNo ratings yet

- DC MotorsDocument80 pagesDC MotorsRaja Desingu100% (1)

- Gar PPT PDFDocument18 pagesGar PPT PDFGilberto MejiaNo ratings yet

- Engine Performance Data at 1500 RPM: Displacement: In) Bore: No. of Cylinders: AspirationDocument6 pagesEngine Performance Data at 1500 RPM: Displacement: In) Bore: No. of Cylinders: Aspirationsorangel_123No ratings yet

- Motores Serie Estandar ACDocument9 pagesMotores Serie Estandar ACRiki TardiansyahNo ratings yet

- Series: General Purpose Standard Motors Inverter Duty Motors (Forced Cooling)Document8 pagesSeries: General Purpose Standard Motors Inverter Duty Motors (Forced Cooling)Naveen GuptaNo ratings yet

- Curriculum VitaeDocument2 pagesCurriculum VitaeNaveen GuptaNo ratings yet

- Product Presentation Motors Part IDocument40 pagesProduct Presentation Motors Part INaveen Gupta100% (2)

- Product Presentation Motors Part IIDocument10 pagesProduct Presentation Motors Part IINaveen GuptaNo ratings yet

- GTP - Eff 1 Endura SeriesDocument11 pagesGTP - Eff 1 Endura SeriesNaveen GuptaNo ratings yet

- GTP - Eff 2 Endura SeriesDocument24 pagesGTP - Eff 2 Endura SeriesNaveen GuptaNo ratings yet

- BCH Endura Series Motor - Product SpecificationsDocument4 pagesBCH Endura Series Motor - Product SpecificationsNaveen Gupta100% (1)

- BCH Crane Duty Motors-Technical Data SheetDocument1 pageBCH Crane Duty Motors-Technical Data SheetNaveen GuptaNo ratings yet

- Extra Price CircularDocument2 pagesExtra Price CircularNaveen GuptaNo ratings yet

- BCH Crane Duty MotorsDocument2 pagesBCH Crane Duty MotorsNaveen GuptaNo ratings yet

- BCH Crane Duty Motors-MSPDocument1 pageBCH Crane Duty Motors-MSPNaveen GuptaNo ratings yet

- What Is EOCR ?: Mechanical Load Current of Motor Detecting Current With CT SensorDocument13 pagesWhat Is EOCR ?: Mechanical Load Current of Motor Detecting Current With CT SensorNaveen Gupta100% (1)

- BCH Ac Brake Motors-MspDocument1 pageBCH Ac Brake Motors-MspNaveen GuptaNo ratings yet

- BCH Crane Duty MotorsDocument2 pagesBCH Crane Duty MotorsNaveen GuptaNo ratings yet

- Ss e (Bocr) ManualDocument2 pagesSs e (Bocr) ManualNaveen GuptaNo ratings yet

- External CT Usage-EOCRDocument3 pagesExternal CT Usage-EOCRNaveen GuptaNo ratings yet

- ZCT DetailsDocument1 pageZCT DetailsNaveen GuptaNo ratings yet

- 3DE Manual EleboratelDocument11 pages3DE Manual EleboratelNaveen GuptaNo ratings yet

- 3ez e (Bocr) .ManualDocument4 pages3ez e (Bocr) .ManualNaveen Gupta67% (3)

- 3de e (Bocr) ManualDocument6 pages3de e (Bocr) ManualNaveen Gupta100% (1)

- Simocrane Drive Basedtechnology v10 Sp1Document67 pagesSimocrane Drive Basedtechnology v10 Sp1Nakpane SonhayeNo ratings yet

- Air Conditioning Temp Control: Erj 145 Customer TrainingDocument17 pagesAir Conditioning Temp Control: Erj 145 Customer TrainingPablo BeltranNo ratings yet

- Siemens Power Engineering Guide 7E 370Document1 pageSiemens Power Engineering Guide 7E 370mydearteacherNo ratings yet

- B Band FaultDocument3 pagesB Band FaultJay R SVNo ratings yet

- Beyer TR145:BV35570 Input TransformerDocument1 pageBeyer TR145:BV35570 Input Transformerblondeb3No ratings yet

- Irf 530 NPBFDocument9 pagesIrf 530 NPBFGabiBaciuNo ratings yet

- IEEE Guide For Field Testing and EvaluaDocument4 pagesIEEE Guide For Field Testing and EvaluavelisbarNo ratings yet

- ELK-3 550 1HC0000742AFEnDocument20 pagesELK-3 550 1HC0000742AFEnOnur FişekNo ratings yet

- Microwave Engineering: Matching Load ImpedancesDocument7 pagesMicrowave Engineering: Matching Load ImpedancesAzmat GuldastaNo ratings yet

- OpAmp 4580 M Data SheetDocument14 pagesOpAmp 4580 M Data SheetedzitroNo ratings yet

- Nichiyu Fb10 30p Dc70 Series TrsDocument83 pagesNichiyu Fb10 30p Dc70 Series TrsJuli Nugroho SuSanto100% (1)

- Beginners Guide To Going SolarDocument18 pagesBeginners Guide To Going SolarRogelio AlvaradoNo ratings yet

- Q875-0200-6.0-ENG INSIGHT Operating ManualDocument65 pagesQ875-0200-6.0-ENG INSIGHT Operating ManualxtrahighgradeNo ratings yet

- My ModulesDocument273 pagesMy Modules1100% (1)

- Mechanical Designer or PCB Designer or Electronics Packaging orDocument4 pagesMechanical Designer or PCB Designer or Electronics Packaging orapi-121406632No ratings yet

- A Circularly Polarized Patch Antenna Array For Ku-Band Data-LinkDocument2 pagesA Circularly Polarized Patch Antenna Array For Ku-Band Data-LinkTolgahan TÜYLÜNo ratings yet

- Aiwa S/M Code No. 09-01C-359-3R1Document75 pagesAiwa S/M Code No. 09-01C-359-3R1Aston Charles RadfordNo ratings yet

- Technical Description Sigma Air Manager: GSM Modem Retrofit KitDocument20 pagesTechnical Description Sigma Air Manager: GSM Modem Retrofit KitEvandro Jva compressoresNo ratings yet

- Mercedes (DTC) 968590102650 20210422094641Document4 pagesMercedes (DTC) 968590102650 20210422094641Wtennessee GoesNo ratings yet

- GE Built-In Dishwasher GuideDocument8 pagesGE Built-In Dishwasher GuideHenri Ghattas100% (2)

- Model DB4005 Model DB4005Document2 pagesModel DB4005 Model DB4005Denis CvetojevicNo ratings yet

- Delta VFD E Series User ManualDocument399 pagesDelta VFD E Series User ManualTendai AlfaceNo ratings yet

- 3731 High Side DriversDocument24 pages3731 High Side Driversbillium34No ratings yet

- Troubleshooting Guide: Manual No: 577014-010 Revision: ADocument13 pagesTroubleshooting Guide: Manual No: 577014-010 Revision: AVERY SYAYIDINANo ratings yet

- 6MF28520AA00 Datasheet enDocument3 pages6MF28520AA00 Datasheet enIvan JeremicNo ratings yet

- Canon IR Advance C5030 Trouble Error CodesDocument73 pagesCanon IR Advance C5030 Trouble Error Codesnafees100% (8)

- Study of Resonant Microstrip Antennas On Artificial Neural NetworksDocument6 pagesStudy of Resonant Microstrip Antennas On Artificial Neural NetworksresearchparksNo ratings yet

- Relay Universal UF - High Reliability Twin Contact RelayDocument4 pagesRelay Universal UF - High Reliability Twin Contact RelayArdhana ArdhanaNo ratings yet

- DG BusductDocument16 pagesDG BusductanandpurushothamanNo ratings yet

- Bandwidth Enhancement Using Microstrip Patch Antenna - Project Phase-1Document104 pagesBandwidth Enhancement Using Microstrip Patch Antenna - Project Phase-1Rbalaji BeeceNo ratings yet