Professional Documents

Culture Documents

GS - Sect15 - 63 - Hot Dip Galvanizing

Uploaded by

Mathieu B SsodesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GS - Sect15 - 63 - Hot Dip Galvanizing

Uploaded by

Mathieu B SsodesCopyright:

Available Formats

Section 15 Structural Steel Work

Redecoration of existing painted surfaces

15.62

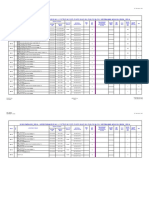

For redecoration of existing painted surfaces of structural steelwork, clean the existing paint coat with an approved detergent, remove loose and flaking portions with wire brush and grind rusted areas back to bare metal as instructed by the SO, care being taken to avoid producing a smooth surface by excessive grinding. Where the existing coating is intact after cleaning, apply the proposed paint coating over a trial panel and examine for adherence after the curing period as recommended by the paint manufacturer. Do not use the paint until the trial is passed. Where bare metal is exposed, apply primer, undercoat and finishing coat as directed by the SO. Unless approved otherwise by the SO, galvanizing to steelwork shall not be carried out until all welds for steelwork have been completed. Prior to galvanizing, the following requirements have to be satisfied: (i) All welding slags and paints on the steel surface shall be removed. (ii) All cut surfaces shall be ground smooth. (iii) Adequate number of vent and drainage holes in accordance with BS EN ISO 14713 shall be provided for closed end hollow sections. The position of the holes and any requirements for subsequent sealing shall be agreed by the SO. Apply hot dip galvanized coatings to BS EN ISO 1461. Small areas of galvanized coating damaged by welding, cutting or by rough treatment during transit or erection shall be made good by: (a) the use of at least two coats of zinc rich paint to BS 4652. Thoroughly clean all areas affected by welding with abrasives or mechanical driven tools before applying the zinc rich paint; or (b) if specified, by blast cleaning to not inferior to Swedish Standard SIS 055900 Sa 2.5 and followed by 2-packed epoxy based zinc rich primer to BS 4652. Painting to galvanized structural steel shall be as Table 15.7 Type F or Type G as specified in the Contract.

Hot dip galvanizing 15.63

Painting to joints

15.64

As soon as possible after joints have been completed and approved, the parent and the joint material, exposed parts of bolts, nuts and washers and weld affected areas shall be brought up to the same standard of preparation and painting as the adjoining surfaces. Paint shall be supplied in sealed containers of not more than 5 litres capacity. Each container shall be marked on the side to show the following: (a) (b) (c) (d) (e) the name of the manufacturer, the paint manufacturers reference number, intended purposes, type of pigment and binder, batch number, date of manufacture, expiry date and pot life, and colour, gloss, drying times and flash point.

Paint

15.65

15-14

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 01 Introduction To Press ToolsDocument31 pages01 Introduction To Press ToolsNiranjan HalgarNo ratings yet

- In Process InspectionDocument4 pagesIn Process InspectionSuraj RawatNo ratings yet

- PART 66 ASME IX - Part 2 Essential Variable For Welder QualificationDocument13 pagesPART 66 ASME IX - Part 2 Essential Variable For Welder Qualificationravindra_jivaniNo ratings yet

- Management 14th Edition Robbins Test BankDocument35 pagesManagement 14th Edition Robbins Test BankKeithMitchelltofsm100% (15)

- Figure 1: Basic Design of Fluidized-Bed ReactorDocument3 pagesFigure 1: Basic Design of Fluidized-Bed ReactorElany Whishaw0% (1)

- Rubber Product AhmedabadDocument33 pagesRubber Product AhmedabadKrupam Thetenders.comNo ratings yet

- Butt WrapFiberglassJointManual Pages 37 41Document5 pagesButt WrapFiberglassJointManual Pages 37 41anon_913434021No ratings yet

- Casting Glass - TechniqueDocument3 pagesCasting Glass - TechniqueChris Borrel100% (1)

- Mechanical Working of MetalsDocument96 pagesMechanical Working of Metalsashoku2No ratings yet

- ME206 Manufacturing Process I Lecture OverviewDocument14 pagesME206 Manufacturing Process I Lecture OverviewHarsh ShahNo ratings yet

- Cutting ToolsDocument8 pagesCutting ToolsWinta BreaNo ratings yet

- Module 6 BmeDocument293 pagesModule 6 BmeEshan ChowdhuryNo ratings yet

- Metric Tolerance Chart PDFDocument6 pagesMetric Tolerance Chart PDFSinan YıldırımNo ratings yet

- 52812-FiatDocument10 pages52812-FiatAndres SuarezNo ratings yet

- Information Sheet 8.2.1 Striking An ArcDocument4 pagesInformation Sheet 8.2.1 Striking An ArcJerryson CabriasNo ratings yet

- Kusile Power Station South Africa: EnterprisesDocument50 pagesKusile Power Station South Africa: EnterprisesDeepak DasNo ratings yet

- 5 - Types of Casting Furnaces (Cupola and Electric Furnaces)Document20 pages5 - Types of Casting Furnaces (Cupola and Electric Furnaces)SaniyahNo ratings yet

- Nippon Crystalux Alkyd Resin Enamel TDS 1Document2 pagesNippon Crystalux Alkyd Resin Enamel TDS 1Sabrina Nur AfiahNo ratings yet

- Extrusion and DrawingDocument9 pagesExtrusion and Drawingdema_dias0% (1)

- FWDS 0236 ADocument2 pagesFWDS 0236 AAlanka PrasadNo ratings yet

- DJFPT MCQDocument9 pagesDJFPT MCQBappi ChamuaNo ratings yet

- GFG High-Efficiency Fluidized Bed DrierDocument3 pagesGFG High-Efficiency Fluidized Bed DrierFarhatNo ratings yet

- 4 Metal Cutting PDFDocument42 pages4 Metal Cutting PDFaviraj2006No ratings yet

- Main MaterialsDocument424 pagesMain MaterialsAnaly DizonNo ratings yet

- AC1030U Series: Grade For Small Parts MachiningDocument6 pagesAC1030U Series: Grade For Small Parts MachiningAlejandro SantanaNo ratings yet

- Technical Data A-325 Heavy Hex Structural BoltsDocument1 pageTechnical Data A-325 Heavy Hex Structural BoltsZak OxmaniNo ratings yet

- Process Validation RecordDocument11 pagesProcess Validation RecordRodrigo KawamuraNo ratings yet

- Design and Analysis of Pressure Die Casting For Door HandleDocument6 pagesDesign and Analysis of Pressure Die Casting For Door HandleEditor IJTSRDNo ratings yet

- DIN 580.phpDocument13 pagesDIN 580.phprajeskumarNo ratings yet

- 2 Introduction To Mineral ProcessingDocument94 pages2 Introduction To Mineral Processingzainab alkhafafNo ratings yet