Professional Documents

Culture Documents

Water deluge systems testing and performance

Uploaded by

Mark ShalkowskiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water deluge systems testing and performance

Uploaded by

Mark ShalkowskiCopyright:

Available Formats

Water deluge systems: Testing and performance measurements

Offshore Information Sheet No. 1/2010

(Issued January 2010)

Contents

Introduction Background Water deluge systems, descriptions and guidance Key performance parameters of water deluge systems Best practice in deluge performance measurements Useful performance data (examples) Relevant legal requirements References

Introduction

This information sheet provides guidance on water deluge systems, their testing requirements, data recording in relation to performance standards, and new knowledge of fire attack scenarios. It is noted that deluge testing offshore is generally being carried out as required. However some flow measurements are not being recorded effectively, and data recorded is not being analysed to provide the best information for use in optimising maintenance and performance. This note does not cover water mist, or spray systems in enclosed spaces.

Background

In the event of fire on offshore installations, the primary protection of pressurised process vessels and pipework is a combination of emergency depressurisation (EDP) via the blow-down system and passive and/or active fire protection. The EDP systems are currently designed to industry guidance American Petroleum Institute Recommended Practise (API RP 521)1. However, it is widely recognised that in some respects this is inadequate and inappropriate for offshore installations, for which it was not originally intended2. For example, in designing an EDP system only heat transfer from ~100 kW m2 fires to the liquid wetted wall is considered. A major concern is that heat loads from fire attack, quoted in the current guidance, are much lower than can be expected. Based on latest knowledge2 severe fires that may occur on offshore installations may generate thermal fluxes of up to 400 kW.m2 and thus EDP may not guarantee vessel or structural steel protection. In a fire attack situation steels strength starts to decrease significantly once a critical temperature is reached; generally taken as ~450-500oC. With a protected vessel (passive or active protection), EDP reduces the internal applied stress by removing the internal vapour. If the same vessel does not have fire protection the higher heat flux on the vessel walls causes the vessel temperature to rise more rapidly and hence the vessel wall strength to decrease more rapidly. The vessel may be depressurised at the same rate as before, but the wall strength is dropping too rapidly and the vessel will fail (rupture) once its strength is less than the applied internal stress caused by the internal vapour pressure. Structural steel is usually protected from fire by passive fire protection but in some cases also by water sprays. EDP can benefit structural steel work under fire attack by reducing the time of jet fire impingement.

Water deluge systems, descriptions and guidance

1

ISO standard, ISO 13702:1999 (1-4)3, has set out the requirements and guidelines for the control and mitigation of fires and explosions on offshore production installations. A water deluge system can either be designed for general area coverage, or a directed water spray protecting a specific equipment item. Both are delivered from fixed pipework and independent fire pumps and provide protection to:-

control pool fires and thus reduce the likelihood of escalation; provide cooling of equipment not impinged by jet fires; provide a means to apply foam to extinguish hydrocarbon pool fires; and limit effects of fires to facilitate emergency response and evacuation escape and rescue (EER) activities.

The four broad types of deluge system include:

area protection designed to provide non-specific coverage of pipework and equipment within process areas; equipment protection designed to provide dedicated coverage of critical equipment such as vessels and wellheads; structural protection designed to provide dedicated coverage of structural members; water curtains to reduce thermal radiation and to control the movement of smoke in order to provide protection to

personnel during escape and evacuation. Historically most active fire protection systems offshore were designed for compliance with SI 611, "Offshore Installations: Guidance on Fire Fighting Equipment". Current legislation is goal setting but SI 611 remains a good basis for reference. Other standards containing useful information include ISO 104184 and API RP 14C5. OTO 2000 051

2

provides useful details of fire types, thermal fluxes, source terms, flame geometries, combustion products that

may be useful in an installations fire and explosion strategy (FES) analysis. Table 2 for example, provides further guidance on the uncertainties in the knowledge of certain fire types. It also references the original HSE OTI Reports that may have been used in the original safety cases. This may be beneficial to newer duty holders if they have difficulties in finding the origin of the datasets used in the initial hazard analysis of their acquired installations.

Benefits of liquid retaining bunds and hazardous drains

The effectiveness of water deluge systems is significantly enhanced when used in conjunction with a fire retarding foam. Aqueous film forming foam (AFFF) when added to water spray systems forms a foam blanket over a pool of burning liquid and is highly effective in extinguishing a pool fire. Fire extinguishing times of foam blankets are significantly faster than those of water deluge alone. Foam blankets are most easily formed and retained when the liquid spill is contained in a bund allowing a rapid foam buildup within the confines of the bund. This has the added advantage that the burning hydrocarbon fire does not move around the deck. Please see Offshore Information Sheet 9/2008 - Modeling pool fires in offshore hazard assessment6 for additional guidance. It is recommended that all main process vessels should have a liquid retaining bund beneath, connected to the hazardous area drain system, via a drain valve that removes liquid from the bottom of the liquid pool. Removing liquid from the pool bottom preserves the fire extinguishing properties of the foam blanket by not disturbing its surface. The drainage system should be designed to cope with the full rate of discharge, both the deluge water and the vessels inventory.

Key performance parameters of water deluge systems

The prime objective of a water deluge system is to cool equipment in a fire incident. Cooling water should arrive onto a designated target (valve, vessels, critical structural component etc) as soon as possible, to maintain the targets temperature below 100oC. Any surface above 100oC will be difficult to cool as the water will tend to boil off and the surface will not wet. If a surface is significantly above 100oC, it may become very difficult to wet and hence a hot spot will occur. In process vessels this has the potential to cause asymmetric stress in the vessel wall, leading to possible catastrophic failure in a very short time span i.e. minutes.

ISO 13702 provides generally accepted specifications for a water deluge system for general area coverage (Table C.3) some of which is reproduced below:A general area coverage of 10 12 Litres min-1 m-2 (LPMM) to protect most platform area against pool fires, with 20 LPMM recommended for pumps/compressors and 60 LPMM for chainlockers. It is advised that these are minimum flowrates and that larger flowrates and accurately aligned nozzles can only benefit the fire protection of both vessels and structural steel. Specific or directed deluge is sometimes employed instead of, or as well as, the general area protection. Individual items, such as vessels or heat exchangers, are protected as described in National Fire Protection Association standard NFPA 157. Most offshore water deluge systems provide flowrates in excess of these values. For wellhead valve systems a rate of 400 litres per Wellhead is recommended. Nozzle alignment to direct water accurately onto its target is recognised as a key parameter in deluge effectiveness. The number of blocked nozzles is also significant in that uneven distribution of water may result. During routine maintenance and performance evaluation of the number of blocked nozzles, and the pattern of blockage, should be measured and recorded. A performance standard for the maximum number of blocked nozzles should be based on the FES analysis of each fire area. Additionally, the blockage pattern should also be observed and recorded. Random distribution of blockage is acceptable; a cluster of blocked nozzles is not, as it could result in an uneven distribution of cooling. Tests carried out by HSL and Shell Global Solutions2 on deluges and liquefied petroleum gas (LPG) tanks indicated that a considerable amount of the water directed at the tank may miss the target. Hence, an application rate calculated as the amount of water leaving the nozzles divided by the tank surface area is a poor measure of how well a tank is protected by a deluge system. It should be noted that water deluge systems are generally designed with about a 30% overcapacity to account for wind shear. It is important that during a water deluge test the water flowrate at the target is measured and not just the water flowrate leaving the nozzles. i.e. elephant trunking can give a false, optimistic, measure of water flowrates. Accurate water flow onto a target is best achieved by the use of 2 or 3 trays laid around the local area that will provide a more accurate measure of the water volumes averaged from several nozzles. If a tray of 1m2 area is used water flowrate measurement is a straightforward calculation.

Best practice in deluge performance measurements

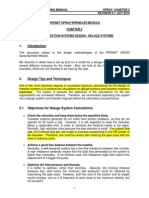

Fig 1.1 - Vessel survives

Fig 1.2 - Vessel fails The analysis of each fire scenario on an Installation should focus on the two illustrative graphs (Figs 1.1 & 1.2) contained on page 1 (Introduction) of OTO 2000 051 (see below). Control and protection systems should be developed such that the stress and time curves are in line with Fig 1.1 particularly for hydrocarbon containing vessels. Fig 1.2 illustrates failure mode from fire attack.

Useful performance data (examples)

To generate the best and useable information from deluge test data a simple test data table is recommended. An example is given below with arbitrary performance standard values included. Accurate performance standards need to be based on the fire analysis of each designated fire area of an Installation. OTO 2000 051 probably contains the best current advice for developing scenario specific fire attack and protection strategies.

Example Illustrative water deluge data sheet

Fire area. Process Area 1 Performance Standard Previous Measurement Current Measurement (L/min/m2) Duty Pump tested Standby Pump tested

Time of water flow from most remote nozzle (s)

<30 seconds

15secs

18secs

Pressure at control valve (bar)

5.5barg

7.2barg

6.4barg

Response time for control valve to operate

5secs

3.5secs

4.3secs

Visual Inspection of nozzles No. blocked

5% evenly distributed

3.8%

4.5%

Number laydown trays used

Flowrate onto trays

12 litres/m2/min Visual confirmation 14.5 barg

14.5 Yes 14.5

15.0 Slow drain away 13.5

Adequate drainage? Water pressure at Fire pump

The performance standard column should be populated with data from the original hydraulic balance and the fire hazard analysis of each designated fire area or zone. This is usually found in the installations safety case. Account should be taken of any changes in the platforms hazard profile in terms of increased or reduced fire hazard. It is advised that the installations hazard profile and associated fire hazard analysis is reviewed periodically but not less than 5-yearly. A performance standard for nozzle blockage should be based on the fire hazard analysis of each fire area. It is generally accepted in the UK offshore industry that 5% nozzle blockage is a failure criterion and that several blocked nozzles occurring on one leg of an area deluge is also regarded as a failed test. It is recommended that the flowrates are taken from the volumes captured in the laydown trays and not from elephant trunking around the nozzles. A simple isometric drawing of the nozzle arrangements for each fire area could be used to mark any blocked nozzles, to provide a quick effective guide to systematic blockage.

Relevant legal requirements

Offshore Installations (Safety Case) Regulations 2005 be complied with. Offshore Installations (Prevention of Fire, Explosion and Emergency Response) Regulations 1995 (PFEER) Regulation 13(a) & (b) Mitigation of fire and explosion, Regulation 14(1) Muster areas etc and Regulation 19(1) Suitability and condition of plant (SCR05) Regulation 12(1) requires that all major accident risks have been evaulated and measures have been, or will be, taken to control those risks to ensure that the relevant statutory provisions will

References

1. API RP 521 Guide for pressure-relieving and depressurising systems, March 1997. 2. OTO 2000 051 - Review of the Response of Pressurised Process Vessels and Equipment to Fire Attack. T A Roberts (HSL), S Medonos CREA Consultants, L C Shirvill Shell Global Solutions. HSE Books 2000 http://www.hse.gov.uk/research/otopdf/2000/oto00051.pdf 3. ISO 13702:1999, Petroleum and natural gas industries - Control and mitigation of fires and explosions on offshore production installations - Requirements and guidelines. 4. ISO 10418 Petroleum and natural gas industries-Offshore production installations-Basic surface process safety systems. 5. API RP 14C Analysis, Design, Installation and Testing of basic surface safety systems on offshore production platforms 6. Offshore Information Sheet 9/2008 Modelling pool fires in offshore hazard assessments HSE 2008 http://www.hse.gov.uk/offshore/infosheets/is9-2008.pdf 7. NFPA 15 (2-11) Standards for water spray fixed systems for fire protection National Fire Protection Association 2007 This information sheet contains notes on good practice which are not compulsory but which you may find helpful in considering what you need to do American Petroleum Institute, Fourth Edition,

You might also like

- Water Deluge Systems - Testing and Performance MeasurementsDocument7 pagesWater Deluge Systems - Testing and Performance MeasurementsgeroboamoNo ratings yet

- Firewater System DesignDocument8 pagesFirewater System Designkenoly123No ratings yet

- Water Deluge Protection of LPGDocument20 pagesWater Deluge Protection of LPGVivi OktaviantiNo ratings yet

- Tac SprayDocument86 pagesTac SprayparthasutradharNo ratings yet

- Fire Water Requirement PresentationDocument17 pagesFire Water Requirement PresentationOlumuyiwa FasehunNo ratings yet

- Vess FireDocument21 pagesVess FirecsNo ratings yet

- Blow DownDocument108 pagesBlow DownMahesh AsapuNo ratings yet

- Design of Sprinklered Shopping Centre Buildings For Fire SafetyDocument42 pagesDesign of Sprinklered Shopping Centre Buildings For Fire SafetyZyron BatacNo ratings yet

- Ball Valves vs Gate Valves: Which is Best for Your ApplicationDocument4 pagesBall Valves vs Gate Valves: Which is Best for Your Applicationrenjithv_4No ratings yet

- Designing a firewater network for a gas plantDocument11 pagesDesigning a firewater network for a gas plantHedi Ben MohamedNo ratings yet

- Fire Protection System (Water Based System) Basis & DesignDocument17 pagesFire Protection System (Water Based System) Basis & DesignbushraNo ratings yet

- TFBP Deluge and Preaction Systems BrochureDocument6 pagesTFBP Deluge and Preaction Systems BrochureangeltandinganNo ratings yet

- Protection For High Voltage TransfromersDocument4 pagesProtection For High Voltage TransfromersMani KumarNo ratings yet

- FTPDocument12 pagesFTPaymansafetyNo ratings yet

- Appendix 13P.2-Firewater EquipmentDocument22 pagesAppendix 13P.2-Firewater EquipmentdidoniphicNo ratings yet

- Compressed Air Foam Outperforms Foam-Water SprinklersDocument34 pagesCompressed Air Foam Outperforms Foam-Water SprinklersDayanne MartinsNo ratings yet

- Fire Water DemandDocument8 pagesFire Water DemandShariq KhanNo ratings yet

- Firewater SystemDocument69 pagesFirewater SystemSyed HameedNo ratings yet

- Article 5 Piping Design Part 5 Installation and CleaningDocument9 pagesArticle 5 Piping Design Part 5 Installation and Cleaningharoon_siyech_engg100% (1)

- Deluge Sprinkler SystemDocument8 pagesDeluge Sprinkler SystemRaed Al-nomanNo ratings yet

- Fire Protection Facilities FOR Petroleum Depots, Terminals, Pipeline Installations AND Lube Oil InstallationsDocument50 pagesFire Protection Facilities FOR Petroleum Depots, Terminals, Pipeline Installations AND Lube Oil InstallationsrohitNo ratings yet

- Deluge System Definition Working Applications and Advantages With PDFDocument4 pagesDeluge System Definition Working Applications and Advantages With PDFSiwaNo ratings yet

- Tyco Building Services Special Hazard Fire ProtectionDocument8 pagesTyco Building Services Special Hazard Fire ProtectionAhrian BenaNo ratings yet

- Area Deluge Skid No Deluge Valve No Equipments ProtectedDocument4 pagesArea Deluge Skid No Deluge Valve No Equipments ProtectedRiyadh SalehNo ratings yet

- Phast Manual Installation Notes PDFDocument14 pagesPhast Manual Installation Notes PDFElena RicciNo ratings yet

- Waterspray MistextinguishingsystemDocument10 pagesWaterspray MistextinguishingsystemSalley BukhariNo ratings yet

- Break TanksDocument3 pagesBreak TanksReza Khaje100% (1)

- LPG FsaDocument301 pagesLPG Fsakailash chatooNo ratings yet

- Water Mist Nozzle GW M5 PDFDocument6 pagesWater Mist Nozzle GW M5 PDFZulfi Andrie ZulkiarNo ratings yet

- PipenetDocument47 pagesPipenetKalyana Ayyaswamy100% (1)

- Buckling Pin Pressure Relief Technology PDFDocument12 pagesBuckling Pin Pressure Relief Technology PDFfkboulosNo ratings yet

- Fire Protection Systems - 3ra EdiciónDocument141 pagesFire Protection Systems - 3ra EdiciónFelipe de Jesús Patlán RomoNo ratings yet

- Oil&Gas Hazard ZonesDocument31 pagesOil&Gas Hazard ZonesrakicbgNo ratings yet

- Fs2011 FullDocument242 pagesFs2011 FullryankckoNo ratings yet

- SPC-0804.02-90.03 Rev D2 FG Detection and ProtectionDocument16 pagesSPC-0804.02-90.03 Rev D2 FG Detection and ProtectionSofiane MoussaouiNo ratings yet

- HydraulicDocument8 pagesHydraulicOsama OmayerNo ratings yet

- Optimization of Water Reuse Network Using Water Pinch Technology WPT by Considering Single Contaminant For Kaduna Refinery and Pet 2375 4397 1000173Document6 pagesOptimization of Water Reuse Network Using Water Pinch Technology WPT by Considering Single Contaminant For Kaduna Refinery and Pet 2375 4397 1000173Brario AninditoNo ratings yet

- Water Spray SystemDocument5 pagesWater Spray SystemNguyenThanhdungNo ratings yet

- Fire Extinguishers SpecsDocument2 pagesFire Extinguishers SpecsVuong BuiNo ratings yet

- Piping Design 5 PDFDocument9 pagesPiping Design 5 PDFSandra MArrugo100% (1)

- New Blast Curves from Vapor Cloud ExplosionsDocument6 pagesNew Blast Curves from Vapor Cloud ExplosionsAntioco LopezNo ratings yet

- Spray - Chapter 4 - Advanced TopicsDocument73 pagesSpray - Chapter 4 - Advanced TopicsEslam ShiblNo ratings yet

- HYDRANT System Demand: Full Unit: Annexure - 1 Fire Water Demand Calculation For SUG Facilities Fire Fighting SystemDocument11 pagesHYDRANT System Demand: Full Unit: Annexure - 1 Fire Water Demand Calculation For SUG Facilities Fire Fighting SystemJMVNo ratings yet

- Utility - Fire Water SystemDocument17 pagesUtility - Fire Water SystemGloria HamiltonNo ratings yet

- Pipenet Vision Training Manual Spray: Chapter 2 Page 1 of 45 REVISION 2.1, OCT 2010Document45 pagesPipenet Vision Training Manual Spray: Chapter 2 Page 1 of 45 REVISION 2.1, OCT 2010Sivareddy Induri100% (1)

- Tes-B-106.04-R0-Deluge SystemDocument37 pagesTes-B-106.04-R0-Deluge SystemUtkucan KILIÇNo ratings yet

- Elastopipe A Flexible Piping SystemDocument2 pagesElastopipe A Flexible Piping SystemRuano StumpfNo ratings yet

- Considerations in Designing Multiphase Flow LinesDocument8 pagesConsiderations in Designing Multiphase Flow LinesCuando la dictadura es un hecho, la Revolución es un derechoNo ratings yet

- A Partial History of Hydrofluoric Acid IncidentsDocument17 pagesA Partial History of Hydrofluoric Acid IncidentsJorge Alberto Uribe RojasNo ratings yet

- Theoretical overview of surge analysesDocument14 pagesTheoretical overview of surge analysesdNo ratings yet

- A Guide To European (Eec) Certification For Hzardus AreasDocument5 pagesA Guide To European (Eec) Certification For Hzardus AreasDeepak DinkarNo ratings yet

- Pipe NetDocument99 pagesPipe NetSARFRAZ ALI100% (1)

- Firewater Demand CalculationDocument6 pagesFirewater Demand Calculationkenoly123No ratings yet

- Active Passive Fire ProtectionDocument7 pagesActive Passive Fire Protectionwbsetyawan_jkt0% (1)

- Tanques PVSVDocument13 pagesTanques PVSVwfjerrNo ratings yet

- 12 PDFDocument12 pages12 PDFAndi SungNo ratings yet

- 800 Fire and Safety DesignDocument31 pages800 Fire and Safety Designjhon smith100% (1)

- Project Standards and Specifications Fire Water Systems Rev01Document10 pagesProject Standards and Specifications Fire Water Systems Rev01Almer Ibnu FarhanNo ratings yet

- Relief Systems Vent SystemsDocument10 pagesRelief Systems Vent Systemsaugur886No ratings yet

- 800 - Fire and Safety DesignDocument32 pages800 - Fire and Safety DesignShinji46No ratings yet

- An'rgrkv: Wig "CO ZW 41cit4aDocument10 pagesAn'rgrkv: Wig "CO ZW 41cit4aShubham BaderiyaNo ratings yet

- Asme Sec II D Ma App 2Document3 pagesAsme Sec II D Ma App 2GicuNo ratings yet

- Task Analysis For Intensive Braking of A Motorcycle in A Straight LineDocument17 pagesTask Analysis For Intensive Braking of A Motorcycle in A Straight LineAlexandru Catalin GradinaruNo ratings yet

- GB GroutDocument4 pagesGB Groutengrrahman3135No ratings yet

- Engine Workshop Manual Section 6 Troubleshooting GuideDocument360 pagesEngine Workshop Manual Section 6 Troubleshooting GuideAlbert Briceño81% (21)

- Hill-Rom Air-Shields Resuscitaire RW82VHA-1CDocument16 pagesHill-Rom Air-Shields Resuscitaire RW82VHA-1Cﺑﺮﻫﺎﻥ ﺍﻟﺘﻤﻴﻤﻲNo ratings yet

- Practical Non-Scientific Field or Bench TestDocument12 pagesPractical Non-Scientific Field or Bench TestPaulNo ratings yet

- Journey Management Plan - March 17Document3 pagesJourney Management Plan - March 17alanbozic50% (2)

- How to Read a LEAF CardDocument4 pagesHow to Read a LEAF CardAntonio GNo ratings yet

- SOP - Portable Gas ChromatographyDocument19 pagesSOP - Portable Gas ChromatographyKishanNo ratings yet

- SGXVPN OvpnDocument4 pagesSGXVPN OvpnLuqi LuqiNo ratings yet

- IPA Liberia TOR - National RADocument2 pagesIPA Liberia TOR - National RAAEG EntertainmentNo ratings yet

- C Programming Language Functions NotesDocument35 pagesC Programming Language Functions NotesnagajaneehaNo ratings yet

- Modbus PVC To PowerFlex4MDocument4 pagesModbus PVC To PowerFlex4MEduardo Pinto VargasNo ratings yet

- CDMA Non Availability Certificate For Death Application Form PDFDocument1 pageCDMA Non Availability Certificate For Death Application Form PDFjeeva prakash AmarlapudiNo ratings yet

- Remittance Advice: Dear CustomerDocument7 pagesRemittance Advice: Dear Customerbluesandy1No ratings yet

- SH CX 9.0.0Document32 pagesSH CX 9.0.0nonename1030No ratings yet

- AAM Applications Chassis and SuspensionDocument4 pagesAAM Applications Chassis and SuspensionBejai Alexander MathewNo ratings yet

- Hitachi excavator technical manual overviewDocument6 pagesHitachi excavator technical manual overviewyasirNo ratings yet

- ConfigurationData 2020 06 16 12 17 09Document4,077 pagesConfigurationData 2020 06 16 12 17 09Anonymous oLo6cDDNo ratings yet

- Static Discharger Maintenance PracticesDocument3 pagesStatic Discharger Maintenance PracticesSahil SodhiNo ratings yet

- Design of Normal Concrete Mixes: D C Teychenné, R E Franklin, H C Erntroy, D W Hobbs, B K MarshDocument9 pagesDesign of Normal Concrete Mixes: D C Teychenné, R E Franklin, H C Erntroy, D W Hobbs, B K MarshSamuel SinteiNo ratings yet

- Regulatory Guide 1.71Document5 pagesRegulatory Guide 1.71Siis IngenieriaNo ratings yet

- Rev - 09 - Ms - Installation of Nurse Call SystemDocument10 pagesRev - 09 - Ms - Installation of Nurse Call Systemanon_534254691No ratings yet

- 8BK80 ModifiedDocument57 pages8BK80 Modifiedrohitvdave5250% (2)

- Maytag Dryer Installation ManualDocument6 pagesMaytag Dryer Installation ManualRob HilliardNo ratings yet

- Developing XML SolutionsDocument392 pagesDeveloping XML Solutionsapi-3738603No ratings yet

- AAI - Fire AlarmDocument23 pagesAAI - Fire AlarmGirish Mohan KaulNo ratings yet

- Hoja Tecnica Caterpillar GCM34 50HzDocument2 pagesHoja Tecnica Caterpillar GCM34 50HzEdutamNo ratings yet

- EHS Plan - SiemensDocument15 pagesEHS Plan - Siemensabbas100% (1)