Professional Documents

Culture Documents

The Investigation To Determine The Tensile Strength of Plant Fibre and Compares It To Tensile Strength of Concrete

Uploaded by

Huy PhuocOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Investigation To Determine The Tensile Strength of Plant Fibre and Compares It To Tensile Strength of Concrete

Uploaded by

Huy PhuocCopyright:

Available Formats

The Investigation To Determine The Tensile Strength Of Plant Fibre And Compares It To Tensile Strength Of Concrete

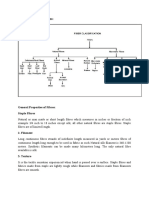

I/ Introduction Fibres have been extracted from plant stems for centuries and used in the commercial manufacture of a wide range of textiles and paper. The term fibres is used to describe a range of fibres-like structures, not just the scherenchyma. The used of different fibres depend on ther properties( table 1).

Figure 1 PLant fibre

Useful part of the plant Applications Stem of flax plant Linen for clothing. Hairs on the seeds of a plant belonging to Cotton for clothing. the mallow family. Hemp Fibres from the stem/leaves of the hemp Used for roped and plant. carpet-backing Coir Fibre from the husks of the fruit of the Floor coverings, ropes. coconut. Manila Hard fibres from the leaves of a type of Marine cables and other banana. ropes, net and matting. Table1 : The uses of plant fibre Tensile strength is the maximum stress caused by a pulling force that a material can withstand without falling. Concrete has a tensile strength of 2x106Nm-2-. This experiment is carry out to measure the tensile strength of nettle fibres and compare it to the strength fibres of concrete. II/Prediction Nettle fibres have higher tensile strength than concrete. III/Equipment Stems of nettles Bucket or bowl. Rubber gloves Scissors Paper towerls Eye protection Ruler Clamp stand

Fibre Flax Cotton

Masses (100g)

III/ Safety Put all stuff away and leave enough space to work. Wear eyes protection and gloves when handling the plant material. Wash your hands after handing the soaked material. When testing fibres to breaking point, make sure the loads on the material can fall without causing injury.

III/Method A/Extracting fibres from plant stem ( retting) 1. Remove leaves and any flowers from stems of plants are removed using scissors. 2. The stems are then place in a bowl and let them fully immerse in water. 3. The stems are then left soaked for a week. 4. Stems are removed from water after a week and washed to remove softened tissue and fungus. 5. The stem is rubbed by hand gently under running tap water to remove stem tissues around bundle and extract the fibres. 6. The fibres are separated using hands into single fibres. 7. Dry the fibres 8. The outside cuticle and epidermal layer will rub away and the central pith will be left when the fibres are peeled away. B/ Measuring the tensil strength 1. A strand of dried fibre is cut into 3 cm long 2. Attach the fibre to a clamp stand and hang a weight (100g) from the other end. 3. Keep adding weights , one at a time, until the fibre breaks. 4. Record the mass needed to break the fibre ( the higher the mass, the higher the tensile strength. 5. Repeat the experiment with different samples of the same fibre with the same length. 6. Throughout the experiment all other variables, like temperature and humidity, must be keep constant. IV/ Result Fibre sample Length (cm) Mass which caused fibre to break(g) 1 3 2 3 3 3 4 3 Average 3

You might also like

- SSP421 Body BasicsDocument76 pagesSSP421 Body Basicsmamuko100% (3)

- Introduction To TextilesDocument13 pagesIntroduction To TextilesJashwa Paul ChhettriNo ratings yet

- Basic Textiles StudyDocument2 pagesBasic Textiles StudyMaria ElizabethNo ratings yet

- Study The Effect of Acids and Bases On The Tensile Strength of A FibreDocument15 pagesStudy The Effect of Acids and Bases On The Tensile Strength of A FibreHiaderKhokhawala75% (67)

- Fibres To FabricDocument23 pagesFibres To FabricPallavi Luthra KapoorNo ratings yet

- Medical Supplies, Equipment: & Lab Reagent ManagementDocument173 pagesMedical Supplies, Equipment: & Lab Reagent ManagementABAS MOSSA100% (3)

- IGCSE Topical Past Papers PhysicsDocument64 pagesIGCSE Topical Past Papers PhysicsHubert DMelloNo ratings yet

- Textile Basics NotesDocument33 pagesTextile Basics Notesparthraj89100% (3)

- (Developments in Geotechnical Engineering 75) Sven Hansbo (Eds.) - Foundation Engineering-Academic Press, Elsevier (1994) PDFDocument534 pages(Developments in Geotechnical Engineering 75) Sven Hansbo (Eds.) - Foundation Engineering-Academic Press, Elsevier (1994) PDFপ্রিয়দীপ প্রিয়মNo ratings yet

- Static Electricity and Charge AccumulationDocument75 pagesStatic Electricity and Charge AccumulationArjav DesaiNo ratings yet

- LN Tutorial Services - Machine Design, Materials & Shop PracticesDocument4 pagesLN Tutorial Services - Machine Design, Materials & Shop PracticesEngr Amethyst RiegoNo ratings yet

- Service Manual: GTH-2506 AGRI-625 GTH-3007 AGRI-730Document194 pagesService Manual: GTH-2506 AGRI-625 GTH-3007 AGRI-730jayrreyes12No ratings yet

- Fiber Textile Fashion IndustriesDocument33 pagesFiber Textile Fashion IndustriesRishi KumarNo ratings yet

- 5 - FlaxDocument30 pages5 - FlaxHassaan ShamshadNo ratings yet

- Rcs454: Python Language Programming LAB: Write A Python Program ToDocument39 pagesRcs454: Python Language Programming LAB: Write A Python Program ToShikha AryaNo ratings yet

- Affect of Acid and Alkaline On Tensile Stength of Fibers.Document26 pagesAffect of Acid and Alkaline On Tensile Stength of Fibers.Pranjal Mehta57% (70)

- Non WovenDocument9 pagesNon WovenIbrahim Khalil100% (1)

- Practical 8 Tensile StrengthDocument3 pagesPractical 8 Tensile StrengthmitNo ratings yet

- Extraction of - Fibres - From PlantsDocument3 pagesExtraction of - Fibres - From PlantsPa Ges0% (1)

- Tensile Strength of Plant FibreDocument22 pagesTensile Strength of Plant FibreTootsie83% (6)

- 79 1 ET V1 S1 - Unit - 1 PDFDocument14 pages79 1 ET V1 S1 - Unit - 1 PDFvandana upadhyayNo ratings yet

- Prepared By: Aryan Shandilya Roll - No.03 Subject: Chemistry Submitted To: Umesh PandeyDocument16 pagesPrepared By: Aryan Shandilya Roll - No.03 Subject: Chemistry Submitted To: Umesh PandeyTHE TALKIESNo ratings yet

- Vegetable Fibres: Types, Properties and UsesDocument11 pagesVegetable Fibres: Types, Properties and UsessbcmkjNo ratings yet

- Eoj52jdur1azduktpypb Different Types of Fabrics 220813191820 7d5d1a08Document43 pagesEoj52jdur1azduktpypb Different Types of Fabrics 220813191820 7d5d1a08dr beshoy awadNo ratings yet

- Introduction To FiberDocument12 pagesIntroduction To FiberTowfic Aziz KanonNo ratings yet

- Different Types of FabricsDocument17 pagesDifferent Types of Fabricsdr beshoy awadNo ratings yet

- Chemistry ProjectDocument15 pagesChemistry ProjectAina shivhare0% (1)

- How To Determine The Tensile Strength of Plant Fibres PracticallyDocument4 pagesHow To Determine The Tensile Strength of Plant Fibres Practicallyeclipsegirl_1994100% (5)

- Chemistry Investigatory Project: Ystatement of Problem: ObjectiveDocument9 pagesChemistry Investigatory Project: Ystatement of Problem: ObjectiveVikas ThakurNo ratings yet

- Classification of FibresDocument12 pagesClassification of FibresARYAN RATHORENo ratings yet

- Properties of An Ideal Canvas Fabric For Tents or Tarpaulins or Like-End Uses AreDocument10 pagesProperties of An Ideal Canvas Fabric For Tents or Tarpaulins or Like-End Uses AreArviSanNo ratings yet

- To Find The Effect of Acids and Alkalies On Tensile Strength of Cotton, Silk and Wool Fibers.Document18 pagesTo Find The Effect of Acids and Alkalies On Tensile Strength of Cotton, Silk and Wool Fibers.Yogesh SinghNo ratings yet

- Chemistry Project: Effect of Acid and Base On The Tensile Strenght of FibresDocument31 pagesChemistry Project: Effect of Acid and Base On The Tensile Strenght of FibresNirupam GuptaNo ratings yet

- Tensile Strength of FibresDocument14 pagesTensile Strength of FibresRavi Pratap SinghNo ratings yet

- 561566642977unit-3 - TextilesDocument11 pages561566642977unit-3 - TextilesGaganpreet Kaur Fashion DesigningNo ratings yet

- Textile Fibers 9 Mansoor IqbalDocument8 pagesTextile Fibers 9 Mansoor IqbalMansoor IqbalNo ratings yet

- TextileDocument67 pagesTextileBunty NagapNo ratings yet

- Grade 6 Fibre To Fabric Sample QuestionsDocument3 pagesGrade 6 Fibre To Fabric Sample Questionsmohamedaahil12318No ratings yet

- Fibre in DetailsDocument32 pagesFibre in Detailssundarcheers33320% (1)

- Introd TextileDocument25 pagesIntrod TextileNila Kumar SinghaNo ratings yet

- Banana Fiber Extraction MethodsDocument15 pagesBanana Fiber Extraction MethodsRoem EsmernaNo ratings yet

- Properties and uses of cotton fibreDocument20 pagesProperties and uses of cotton fibreAlen Jose ThomasNo ratings yet

- Unconventional Fibre PlantsDocument18 pagesUnconventional Fibre PlantsRajendra Singh MeenaNo ratings yet

- CGTPaper IIDocument130 pagesCGTPaper IIMd. Humayun KabirNo ratings yet

- ResearchDocument2 pagesResearchJamez VargazNo ratings yet

- Ijftr 37 (3) 231-237 PDFDocument7 pagesIjftr 37 (3) 231-237 PDFPriya LathaNo ratings yet

- Properties Natural FibresDocument46 pagesProperties Natural FibresanishaNo ratings yet

- Chemsitry Investigatory ProjectDocument13 pagesChemsitry Investigatory ProjectRishabh DesaiNo ratings yet

- FYT Unit 1Document27 pagesFYT Unit 1Sanjit janaNo ratings yet

- Fibre IntroductionDocument18 pagesFibre IntroductionKunal SuvarnaNo ratings yet

- A Review On Natural Fibers Its Properties and Application Over Synthetic FibersDocument6 pagesA Review On Natural Fibers Its Properties and Application Over Synthetic FibersIJRASETPublicationsNo ratings yet

- Kehe 105Document16 pagesKehe 105Saisab AhmedNo ratings yet

- Bijendra Public School: Class - 6 Subject - SCIENCE Chapter - 3 Fibre To FabricDocument4 pagesBijendra Public School: Class - 6 Subject - SCIENCE Chapter - 3 Fibre To Fabricsmitha_gururaj100% (1)

- Fiber Identification TechniquesDocument5 pagesFiber Identification TechniquesMarijana NikolicNo ratings yet

- Cotton Fabric SewabilityDocument9 pagesCotton Fabric SewabilityTuan Nguyen MinhNo ratings yet

- Textile Technology 1 CourseDocument6 pagesTextile Technology 1 Coursefatima hussainNo ratings yet

- 1.textile Terms and DefinitionDocument4 pages1.textile Terms and DefinitionAravind Aston100% (2)

- Fibre To Fabric: 1. What Are Fibres ? Explain How Do You Classify Them ?Document7 pagesFibre To Fabric: 1. What Are Fibres ? Explain How Do You Classify Them ?madhugangulaNo ratings yet

- Textile TechnologyDocument6 pagesTextile TechnologyHarmeetBhawraNo ratings yet

- Relations Between Fiber Structure and PropertiesDocument7 pagesRelations Between Fiber Structure and PropertiesChikam BuraNo ratings yet

- Kapok Fiber InfoDocument3 pagesKapok Fiber InfoErfan TanhaeiNo ratings yet

- Study The Effect of Acids and Bases On The Tensile Strength of A FibreDocument15 pagesStudy The Effect of Acids and Bases On The Tensile Strength of A Fibrepimic.businessNo ratings yet

- 8 - ENG 2 ET V1 S1 - LessonDocument12 pages8 - ENG 2 ET V1 S1 - LessonMaruf BillahNo ratings yet

- Forensics-Hair+and+Fiber+Analysis LabDocument8 pagesForensics-Hair+and+Fiber+Analysis LabMusic78No ratings yet

- Textiles, for Commercial, Industrial, and Domestic Arts Schools: Also Adapted to Those Engaged in Wholesale and Retail Dry Goods, Wool, Cotton, and Dressmaker's TradesFrom EverandTextiles, for Commercial, Industrial, and Domestic Arts Schools: Also Adapted to Those Engaged in Wholesale and Retail Dry Goods, Wool, Cotton, and Dressmaker's TradesNo ratings yet

- Design of Foundations On Sensitive Champlain Clay Subjected To Cyclic LoadingDocument9 pagesDesign of Foundations On Sensitive Champlain Clay Subjected To Cyclic LoadingRamiro ChairezNo ratings yet

- AMSOIL 10W40 and 10W30 Synthetic Metric Motorycle Oils (MCT - MCF)Document2 pagesAMSOIL 10W40 and 10W30 Synthetic Metric Motorycle Oils (MCT - MCF)amsoildealerNo ratings yet

- 72.core Cut Reference SP-24Document1 page72.core Cut Reference SP-24DMJ NagpurNo ratings yet

- Unit-4 (Wireless Communication)Document15 pagesUnit-4 (Wireless Communication)Anonymous EjQbY1CNo ratings yet

- Westinghouse Manuals PDFDocument38 pagesWestinghouse Manuals PDFCarl HensonNo ratings yet

- Aceros PoscoDocument35 pagesAceros PoscoregistrosegNo ratings yet

- Numerical SolutionDocument7 pagesNumerical SolutionemebusamuelNo ratings yet

- Monarch Industrial Products (I) Pvt. Ltd. Decorative Floor Toppings Supply Order Price ListDocument1 pageMonarch Industrial Products (I) Pvt. Ltd. Decorative Floor Toppings Supply Order Price ListgangadevimgmNo ratings yet

- Foundation DesignDocument7 pagesFoundation DesignPrasad GNNo ratings yet

- AP238 PS09 ManualDocument28 pagesAP238 PS09 ManualEuro-Kitchen, Inc.100% (4)

- Pilot Operated Safety Relief ValvesDocument6 pagesPilot Operated Safety Relief ValvesfabioNo ratings yet

- Secure ID PIN Generation - Guide: DisclaimerDocument7 pagesSecure ID PIN Generation - Guide: DisclaimerSunitha RathnamNo ratings yet

- Solid WastesDocument47 pagesSolid WasteskevinjorgeramosNo ratings yet

- Carbon Compounds: Standard/ Class/ Grade - 10 SSC, CBSE - 8 ICSEDocument53 pagesCarbon Compounds: Standard/ Class/ Grade - 10 SSC, CBSE - 8 ICSEsaintEmNo ratings yet

- Bulb Flat Sizes, Dimensions and Weight - Steel Bulb Flats - Weight Table - Rushmore Enterprises IncDocument3 pagesBulb Flat Sizes, Dimensions and Weight - Steel Bulb Flats - Weight Table - Rushmore Enterprises IncHerlambang Miracle YudhianNo ratings yet

- Car Brochure Hyundai Ioniq PX 929 RDocument13 pagesCar Brochure Hyundai Ioniq PX 929 RHalil KayaNo ratings yet

- Seismic Analysis of A Valley-Fill Heap Leach PadDocument17 pagesSeismic Analysis of A Valley-Fill Heap Leach PadMARCOS ABRAHAM ALEJANDRO BALDOCEDA HUAYASNo ratings yet

- Is 2705 PDFDocument17 pagesIs 2705 PDFArijit Das100% (2)

- 11 Iso 10110Document28 pages11 Iso 10110fmeylanNo ratings yet

- Catalogue Cable Tray RevDocument40 pagesCatalogue Cable Tray RevhardiyantodonniNo ratings yet

- Um String Code 2 0 eDocument46 pagesUm String Code 2 0 ehydrasearchNo ratings yet

- Xxxpol / 65° Az 17.3 / 17.0 / 17.3 Dbi: DiplexedDocument2 pagesXxxpol / 65° Az 17.3 / 17.0 / 17.3 Dbi: DiplexedMahamoud HamoudNo ratings yet

- XT316 Air SockerDocument4 pagesXT316 Air Sockeryudiar djamaldilliahNo ratings yet