Professional Documents

Culture Documents

DC Motor

Uploaded by

jiwani87Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DC Motor

Uploaded by

jiwani87Copyright:

Available Formats

Analysis of Electric DC Drive Using Matlab Simulink and SimPower Systems

Miklosevic, Kresimir ; Spoljaric, Zeljko & Jerkovic, Vedrana

Department of Electromechanical Engineering Faculty of Electrical Engineering, J. J. Strossmayer University of Osijek Osijek, Croatia kresimir.miklosevic@etfos.hr, zeljko.spoljaric@etfos.hr, vedrana.jerkovic@etfos.hr

Abstract In this paper model for analysis electric DC drive made in Matlab Simulink and Matlab SimPower Systems is given. Basic mathematical formulation which describes DC motor is given. Existing laboratory motor is described. Simulation model of DC motor drive and model of discontinuous load is made. Comparison of model made in Matlab Simulink and existing model in SimPower Systems is given. Essential parameters for starting simulation of used DC motor drive is given. Dynamical characteristics of DC motor drive as results of both simulation are shown. Practical use of simulation model is proposed. Keywords analysis, DC drive, Matlab, SimPower Systems, model, simulation.

Figure 1. Model building process.

I.

INTRODUCTION

The basic problem of this paper is building simulation model of DC motor by using one of programs for modeling called Matlab Simulink. This will provide testing of motor dynamic characteristics and motor performance on model instead original. This is specially desirable for large DC motors over 50 kW, because testing of motor for different kinds of load and testing motors dynamic can prevent some malfunctions and damages of motor. Model can also be used for testing motor performances and for testing motor prototypes because it provides possibility of changing motor parameters. More about essential motor parameters that are crucial for building a motor model will be discussed further in paper. Motor model in Simulink will be compared with motor model from SimPower Systems library which contains different kinds of models for typical power equipment. This library includes models of: electric transformer, asynchronous motor, synchronous motor and generator, DC motor and some other power electronics elements. SimPower Systems provides application for modeling and simulation of electric motor drives in three levels: modeling of simple drives by using classical electrical devices, modeling more complex drives by using semi-conductor elements and circuits and modeling very complex drives by using subsystems for control and regulation of electric machines [1]. Purpose of these two different motor models is analysis and comparison of possibilities that each model gives. Similar comparison of possibilities in model constructing using Matlab Simulink is done by [2]. In that paper model for dynamic testing of asynchronous motor using specified load is made. Dynamic simulation of direct current motor is also made in one other simulation program called

LabVIEW by [3]. The principle of making simulation model in LabVIEW is similar to making model in Matlab Simulink. In LabVIEW there is virtual instrument panel that provides real time control and simulation start. This part is separated from part called Block Diagram where program for simulation is made. In that way all wanted motor parameters, diagrams and schemes are visible [9]. The building of motor model is based on mathematical equations. Process of model building process is shown on Fig.1. These equations can be found in numerous literature. In this paper equations are used from [4], [5], [6] and [7]. II. MATHEMATICAL MODEL OF DC MOTOR

Modeling of any kind of electrical machines such is DC motor starts with measurements on real model because it is necessary to determine motor parameters. The other possibility is to get the motor parameters from manufacturer or determinate our own parameters if motor prototype is being build. After that motor model can be made by using all mathematical equations that describe the motor.

i ia if

Ra Rf La

u TL J TM

DC motor

Lf

Figure 2. Equivalent circuit of a DC parallel motor [4].

Mathematical equations that describe DC parallel motor derives from equivalent scheme (Fig. 2.). DC parallel motor is the DC motor that has parallel field winding. As shown on Fig. 1, after configuration of mathematical model, simulation model can be made in Matlab Simulink. Functioning of DC motor can be explained by using two electrical circuits. Exciting (field) circuit creates magnetic flux and in armature circuit armature current from power source causes appearance of force on motor windings. Parallel DC motor can be described by using following equations as given in [7]. The equation that describes the armature circuit is: U = E + Ia Ra (1)

TM TL = J

d dt

(11)

where TL is load torque, J is moment of inertia and is angular speed. Sum of current is represented with instant values of currents in armature and field circuit:

i = ia + if.

(12)

where U is armature voltage, E is induced voltage, Ia is armature current and Ra is armature resistance. Induced voltage can be expressed with following equation: E = ke n (2)

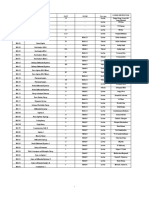

A. Motor model parameters As mentioned, before starting of simulation building it is necessary to have all relevant motor parameters that describe the motor. All this parameters are implemented in mathematical equations that describe the model. Parametars for motor model made in Matlab Simulink are given in Table 1.

TABLE I. MOTOR PARAMETERS FOR MATLAB SIMULINK MODEL

where ke is electrical constant of specified DC motor, is magnetic flux and n is motor speed in rpm. The equation that describes field circuit can be expressed as: U = If Rf (3)

where If is field circuit current, Rf resitance of field circuit. Torque on motor shaft (TM) can be expressed as: TM = km Ia (4)

Parametar PN UN nN Ra Rf If Ia

Value 3 kW 220 V 1500 min-1 0.87 550 0.4 A 16.5 A

Parametars for motor model made in Matlab SimPower Systems are given in Table 2.

TABLE II. MOTOR PARAMETERS FOR MATLAB SIMPOWER SYSTEMS MODEL

where km is mechanical constant of specified DC motor. It can be seen on Fig. 1. that sum of currents for parallel DC motor is: I = I a + I f. (5) Following equations given above are used for model building in Matlab Simulink. This model is used to obtain motor static characteristics. Motor dynamic characteristic can be obtained from motor model in SimPower Systems. The equations that are used for this model are differential equations as given in [4]. For motor armature and field circuit, field current, field flux and motor torque can be expressed by following equations: di (6) u = Ra ia + La a + e dt

Parametar PN UN nN J Ra Rf La Lf Laf

Value 150 kW 250 V 618 min-1 25 kgm2 0.012 12 0.00035 9H 0.036 H

In Table 2. parameter Laf is parameter that is determining mutual inductance. III. MATLAB SIMULINK MODEL

e = ke

u = Rf if + Lf

= f( if )

(7) (8) (9) (10)

di f dt

TM = km ia .

One more equation that describes Newton low for concentrated mass as given in [4] is:

Simulink is software package or program tool developed in Matlab graphic interface. It provides modeling, simulation and analysis of different kinds of continuous and discrete systems. In that way Simulink can be used for exploring the behavior of a wide range of real world dynamic systems including electrical circuits and many other electrical and mechanical systems [8]. System that is being built in Simulink is consisting of a number of blocks which are connected with signal lines in one functionally group. In Fig.3. Matlab Simulink library is presented. It consist from

Figure 3. Matlab Simulink library.

different kinds of blocks such as: sources, sinks, subsystems etc. Each block given above represents one group of elements. In Fig. 4, simulation model of parallel DC motor is presented. As mentioned, in Simulink model are directly implemented equations from (1) to (5). Different blocks are used for presentation of different motor parameters that are beeing observed, like motor electric and mechanic power, current, speed, torque etc. With this model it is posible to relate two motor parametars and this reperesents motor static characteristuics.

Figure 6. Matlab SimPower Systems library.

information about numeric value of torque. IV. SIMPOWER SYSTEMS MODEL

Figure 4. Matlab Simulink model of parallel DC motor.

Fig. 5 presents model of discontinuous load for DC motor. It consists from ramp function, relation operator and block that determines maximal torque. With block Scope instant value of motor torque can be observed. Block Display gives

SimPower Systems is the part of Matlab Simulink and it operates in Simulink environment [6]. It consists of electrical power circuits and electromechanical devices such as motors and generators. It is supposed to be used for simulation of electrical drive systems, in witch, in combination with machines, elements of energetic and control electronic are present. In Fig. 6 SimPower Systems library is presented together with toolbox that contains all types of motors and generators. In toolbox on the down left side elements of energetic electronics (tiristors, diodes, IGBT transistors etc.) are presented. In each of this modules mathematical model of device is implemented. For simulation start it is only necessary to input parameters for simulated device. In this paper it is necessary to input parameters of DC motor, which is shown on Fig. 7 together with part for motor load, motor source, timer and bracker for simulation start and part for results export. Fig 8 presents DC motor under the mask. It is now visible that motor consists of all elements that are shown in Fig 2 (elements of equivalent scheme). The subsystem block called Mechanics describes the mechanical equation given in relation (11). In subsystem block called Measurement list all wanted electrical and mechanical values can be presented in diagram, in function of time. These characteristics are motor dynamic characteristics.

Figure 5. Matlab Simulink model of discontinous load.

Figure 7. DC motor model in SimPower Systems.

Figure 10. Motor static characteristic: n = f(T), = f(T), Ia = f(T).

Figure 8. DC motor model under the mask.

V.

RESULTS

As mentioned before, the main topic of paper is building simulation model of parallel DC motor in Matlab Simulink and testing the possibilities of DC motor dynamic performance by using SimPower Systems model library, which contains model of DC motor. Motor used for Simulink model is laboratory motor (3 kW) given in Fig. 9. Some parameters for this motor are obtained from manufacturer and some parameters are measured as shown in Table 1. The motor data used for simulation in SimPower Systems is given in [5] and all relevant data are shown in Table 2.

parameter are shown. Uppermost characteristic presents the characteristic when field current changes from 0.4 A to 0.35 A. Second characteristic is the nominal characteristic with values from Table 1. The third characteristic is the characteristic with changed armature resistance and the last characteristic is the characteristic with changed source (armature) voltage. From these curves motor behavior during mentioned changes can be observed.

A. Results of simulation in Matlab Simulink Results of simulation model made in Matlab Simulink are static characteristics. Some of these characteristics are shown in Fig. 10. In Fig. 10 presented characteristics are: speed in function of torque, armature current in function of torque and efficiency in function of torque. It is possible to obtain some other characteristic also, and see their mutual dependence. Fig. 11 presents one experiment with given four different characteristics n = f(T). On these torque characteristics changes which occur during the change of one motor

Figure 11. Torque characteristic for different motor parameters [1].

B. Results of simulation in SimPower Systems Results of simulation model made in SimPower Systems are motor dynamic characteristics. Some of these characteristic are presented on Fig. 12. These characteristics

Figure 9. Paralell DC laboratory motor 3 kW [1].

Figure 12. Load characteristics.

present motor behaviour during motor start. All values are in function of time. Because simulated motor is in group of large DC motors (over 50 kW), the time necessary for stabilization of each value is longer. Fig. 12 presents four motor values: speed, armature and field current and motor torque as function of time. It is possible to monitor dynamic changes in small period of time (a few ms) after starting the motor, when armature current has high amounts. This model also gives possibility of changing the motor parameters and testing the motor for different kinds of load. VI. CONCLUSION

REFERENCES

Z. Valter, Electrical Mashines and Drives in Matlab, Faculty of Electrical Engineering, Osijek, Croatia, unpublished. [2] K. Miklosevic, Z. Spoljaric and Z. Valter, Modeling and Simulation of Induction Motor for Dynamic Behaviour Testin using Specified Load , DAAAM International, Vienna, Austria, pp. 861-862, October 2008 [Proceedings of 19-th International DAAAM Symposium, Trnava, Slovakia], ISBN 978-3-901-509-68-1, ISSN 1726-9679. [3] N. Ertugrul, LabVIEW for Electric Circuits, Machines, Drives and Laboratories. Prentice Hall PTR, Upper Saddle River, New Jersey, USA, 2002, pp. 297-300, ISBN 0-13-061886-1. [4] W. Leonhard, Control of Electrical Drivers. Springer, Berlin, Heidelberg, NewYork, 2001, pp. 51-63, ISBN 3-540-41820-2. [5] M. Jadric, B. Francic, Dynamic of Electric Machines. Graphis, Zagreb, Croatia, 1995, pp. 158-165, ISBN 953-96399-2-1. [6] G. Sibille, L.A. Dessant, SimPowerSystems For Use with Simulink, The Math Works, Inc., Natic, USA, 2006. [7] Z. Valter, Electrical Mashines, Faculty of Electrical Engineering, Osijek, Croatia, unpublished. [8] The Math Works, Learning Simulink, The Math Works, Inc., Natic, USA, 2006, ISBN 0-9755787-7-4. [9] Z. Valter, Proces Meassurements. Grafika, Faculty of Electrical Engineering, Osijek, Croatia, 2008, pp. 81-96, ISBN 978-953-6032-594. [10] B. Skalicki, J. Grilec, Electrical Machines and Drivers. FSB, University of Zagreb, Zagreb, Croatia, 2005, pp. 175-185, ISBN 953-6313-67-7. [11] B. Jurkovic, Electro-motor Drives. School Book, Unoversity of Zagreb, Zagreb, Croatia, 1990, pp. 347-404, ISBN 86-03-99990-2. [1]

Usage of different kinds of programs, such as Matlab, provides complete static and dynamic state analysis, and testing different kinds of machines by using simulation model instead original. With analysis of mathematical model expensive and unwanted testing of original can be avoided. Model can also be used for testing motor performances and for testing motor prototypes because it provides possibility of changing motor parameters. Simulation programs provide understanding DC motor behaviour under transient and stedy-state operating conditions. This can be used to understand starting problems, specialy in case of large motors (like tested, 150 kW) because of appearance of high armature current. Also motor can be tested for different kinds of load torque. In this way many kinds of drives in wich motor could be implemented can be tested before real application in industrial envirement. There is also possibility of testing motor protoypes with easy way of changing motor parameters. In this paper all mentioned possibilities include work with Matlab Simulink or SimPower Systems tools for modeling. The other avaliable programs can also be implemented because the procedure for modeling is the same. It is important to mention that for good model all parametars have to be reliable. It is good if there exist posibility of testing the simulation model on real laboratory model, so that characteristics can be compared and calibrated. In this way one model of DC motor (in example) can be used for all DC motors with other parameters. Further research will include complete evaluation of real and simulation model, testing of model for different types of load and motor, and determination of dynamical parameters. Also there is possibility of testing the SimPower System program for modelling asynchronous motors and synchronous generators.

You might also like

- Synchronous Generator Modeling Using MatlabDocument6 pagesSynchronous Generator Modeling Using MatlabJennifer AndersonNo ratings yet

- EEE 1206 011 Direct Quadrate Modeling Induction Motor MatLab Simulink PDFDocument7 pagesEEE 1206 011 Direct Quadrate Modeling Induction Motor MatLab Simulink PDFFiaz KhanNo ratings yet

- Modeling and Simulation of Reluctance Motor Using Digital ComputerDocument5 pagesModeling and Simulation of Reluctance Motor Using Digital ComputerroyourboatNo ratings yet

- Gts Ggas ModellingDocument36 pagesGts Ggas ModellingSyed Zain BukhariNo ratings yet

- Synchronous Generator Modeling Using MatDocument6 pagesSynchronous Generator Modeling Using MatdhilieaymeneNo ratings yet

- Simulation of IEEE First Benchmark Model For SSR StudiesDocument4 pagesSimulation of IEEE First Benchmark Model For SSR StudiesPabloNalogowskiNo ratings yet

- Untitled 1Document4 pagesUntitled 1Temesgen MekonenNo ratings yet

- A Unified Method For Modeling and Simulation of Three Phase Induction Motor DrivesDocument5 pagesA Unified Method For Modeling and Simulation of Three Phase Induction Motor Drivesdhirajbharat20No ratings yet

- Modelling and Simulation of The Three-Phase Induction Motor Using SimulinkDocument10 pagesModelling and Simulation of The Three-Phase Induction Motor Using SimulinkÁron FehérNo ratings yet

- Salimin2013 PDFDocument5 pagesSalimin2013 PDFAhmad RobbyNo ratings yet

- 480 586 1 PBDocument6 pages480 586 1 PBapi-261065870No ratings yet

- DC Motor Speed Control Methods Using MATLAB - Simulink and Their Integration Into Undergraduate Electric Machinery CoursesDocument9 pagesDC Motor Speed Control Methods Using MATLAB - Simulink and Their Integration Into Undergraduate Electric Machinery CoursesWen ZJNo ratings yet

- Mathematical Modeling and Speed Torque Analysis of Three Phase Squirrel Cage Induction Motor Using Matlab Simulink For Electrical Machines LaboratoryDocument10 pagesMathematical Modeling and Speed Torque Analysis of Three Phase Squirrel Cage Induction Motor Using Matlab Simulink For Electrical Machines LaboratoryjhonnydesaNo ratings yet

- Construction of A Dynamic Model For A Transverse Flux Motor: Marcin KOWOL Janusz KołodziejDocument11 pagesConstruction of A Dynamic Model For A Transverse Flux Motor: Marcin KOWOL Janusz KołodziejBOUZ2010No ratings yet

- Transient Response of A Separately Excited DC Motor Under No-Load ConditionDocument6 pagesTransient Response of A Separately Excited DC Motor Under No-Load ConditionSaad0806No ratings yet

- BLDC SimulationDocument4 pagesBLDC SimulationSiva GuruNo ratings yet

- PMBLDC-Simulink - Permanent Magnet Brushless DC Motor Simulink Model.Document5 pagesPMBLDC-Simulink - Permanent Magnet Brushless DC Motor Simulink Model.Kidus DawitNo ratings yet

- Modeling and Simulation of The DC Motor Using Matlab and LabviewDocument6 pagesModeling and Simulation of The DC Motor Using Matlab and LabviewnghiepmechanNo ratings yet

- Mathematical Modeling and Analysis of Different VeDocument13 pagesMathematical Modeling and Analysis of Different Veramadhanifarahum19No ratings yet

- Specijalni Elektrici MasiniDocument22 pagesSpecijalni Elektrici MasiniIgor JovanovskiNo ratings yet

- Control Tutorials For MATLAB and Simulink - Motor Speed - System ModelingDocument6 pagesControl Tutorials For MATLAB and Simulink - Motor Speed - System Modelingdisposable505No ratings yet

- Investigation of The Dynamic Performance of Hysteresis Motors Using Matlab/SimulinkDocument4 pagesInvestigation of The Dynamic Performance of Hysteresis Motors Using Matlab/SimulinkmakroumNo ratings yet

- Effect of Temperature Rise On The Performance of Induction MotorsDocument2 pagesEffect of Temperature Rise On The Performance of Induction Motorsud54No ratings yet

- M Phase MototrDocument6 pagesM Phase MototrRija AliNo ratings yet

- Modelling and Simulation LabDocument55 pagesModelling and Simulation LabNobita NobiNo ratings yet

- Ac 2011-1439: Fuzzy Logic-Based PMDC Motor Controller - An Undergraduate Student ProjectDocument13 pagesAc 2011-1439: Fuzzy Logic-Based PMDC Motor Controller - An Undergraduate Student ProjectFlorin CiudinNo ratings yet

- Modelling &simulation of A Three-Phase Electric Traction Induction Motor Using Matlab SimulinkDocument7 pagesModelling &simulation of A Three-Phase Electric Traction Induction Motor Using Matlab SimulinkkrcdewanewNo ratings yet

- Stepper Motor ArticleDocument6 pagesStepper Motor ArticleJhon Bairon Velásquez MiraNo ratings yet

- Simulation of Electric Machinery and Power Electronics InterfacingDocument6 pagesSimulation of Electric Machinery and Power Electronics Interfacingadilo7780No ratings yet

- Modeling and Simulation of A Serial - Parallel Hybrid Electrical VehicleDocument5 pagesModeling and Simulation of A Serial - Parallel Hybrid Electrical VehicleChennupati PremchandNo ratings yet

- Modelling and Simulation of A DC Motor DriveDocument12 pagesModelling and Simulation of A DC Motor DriveMi HoangNo ratings yet

- DC Motor SimulinkDocument8 pagesDC Motor SimulinkMELVINNo ratings yet

- Dynamic Simulation of Brushless DC Motor DrivesDocument7 pagesDynamic Simulation of Brushless DC Motor DrivesMehmet KırgözoğluNo ratings yet

- DQ Modeling of SEIG in SimulinkDocument5 pagesDQ Modeling of SEIG in SimulinkBhushan MankarNo ratings yet

- Transient Stability Analysis of Power System Using MatlabDocument5 pagesTransient Stability Analysis of Power System Using MatlabSaddam HussainNo ratings yet

- Stepper Motor ArticleDocument6 pagesStepper Motor Articlesolomonlemma14No ratings yet

- Dynamic Model of A Permanent Magnet DC Motor: Projects For StudentsDocument8 pagesDynamic Model of A Permanent Magnet DC Motor: Projects For StudentsAlyssonAlmeidaNo ratings yet

- Ijert Ijert: Control of Three Phase BLDC Motor Using Fuzzy Logic ControllerDocument5 pagesIjert Ijert: Control of Three Phase BLDC Motor Using Fuzzy Logic ControllergbksnNo ratings yet

- SJAS Vol2 Issue8 004Document11 pagesSJAS Vol2 Issue8 004gedebe_koolNo ratings yet

- Labview Simulation of Induction Motors: Zhaoxian Zhou and James Matthew JohnsonDocument8 pagesLabview Simulation of Induction Motors: Zhaoxian Zhou and James Matthew JohnsonR Sathish Kumar KumarNo ratings yet

- MATLAB Speed Control DC MotorDocument4 pagesMATLAB Speed Control DC MotorEngineering and Scientific International JournalNo ratings yet

- Simulink Platform. The Circuit Equations Can Be Written As FollowsDocument3 pagesSimulink Platform. The Circuit Equations Can Be Written As FollowsNazmul islamNo ratings yet

- Electrical Machine Drive DC Motor Parameter Estimation: Institute of Technology of Cambodia Ecam LasalleDocument12 pagesElectrical Machine Drive DC Motor Parameter Estimation: Institute of Technology of Cambodia Ecam LasalleDanin kimNo ratings yet

- EE 392 Lab 2: DC Motor Speed Control DesignDocument4 pagesEE 392 Lab 2: DC Motor Speed Control DesignAbdalla FathyNo ratings yet

- BLDC: Motor FailureDocument5 pagesBLDC: Motor FailureInternational Association of Scientific Innovations and Research (IASIR)No ratings yet

- Experiment 3 DC Motor Modeling: 3.0 ObjectiveDocument6 pagesExperiment 3 DC Motor Modeling: 3.0 Objectivecomplex72No ratings yet

- PSMS Lab ManualDocument42 pagesPSMS Lab ManualIrfan Ali100% (1)

- DC Machine SimulationDocument12 pagesDC Machine Simulationkiranch219No ratings yet

- Separately Excited DC Motor Parametric Control Using Electronic WorkbenchDocument8 pagesSeparately Excited DC Motor Parametric Control Using Electronic WorkbenchIJERDNo ratings yet

- Speed Control of Switched Reluctance Motor-LibreDocument9 pagesSpeed Control of Switched Reluctance Motor-LibreIndrajithSrNo ratings yet

- MathsDocument13 pagesMathsBUKENYA BEEE-2026No ratings yet

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorFrom EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNo ratings yet

- Power Electronics and Electric Drives for Traction ApplicationsFrom EverandPower Electronics and Electric Drives for Traction ApplicationsNo ratings yet

- Electric Powertrain: Energy Systems, Power Electronics and Drives for Hybrid, Electric and Fuel Cell VehiclesFrom EverandElectric Powertrain: Energy Systems, Power Electronics and Drives for Hybrid, Electric and Fuel Cell VehiclesNo ratings yet

- Electrical Machines: Lecture Notes for Electrical Machines CourseFrom EverandElectrical Machines: Lecture Notes for Electrical Machines CourseNo ratings yet

- Fundamentals and Applications of Lithium-ion Batteries in Electric Drive VehiclesFrom EverandFundamentals and Applications of Lithium-ion Batteries in Electric Drive VehiclesNo ratings yet

- The LME From A To ZDocument42 pagesThe LME From A To Zjiwani87No ratings yet

- The Last Journey, Translation of Manazil Al - Akhirah PDFDocument148 pagesThe Last Journey, Translation of Manazil Al - Akhirah PDFjiwani87100% (1)

- PDFDocument13 pagesPDFjiwani87No ratings yet

- Economic System in Islam Compared With Capitalism and SocialismDocument16 pagesEconomic System in Islam Compared With Capitalism and SocialismDania AliNo ratings yet

- Okoko Okoko OkokDocument269 pagesOkoko Okoko Okokjiwani87No ratings yet

- Pak WheelsDocument23 pagesPak WheelsMuhammad100% (1)

- Life Sketches of the Fourteen InfalliblesDocument868 pagesLife Sketches of the Fourteen Infalliblesmr0j0No ratings yet

- Constructing A Strategy Map For Banking Institutions With Key PerformanceDocument18 pagesConstructing A Strategy Map For Banking Institutions With Key Performancejiwani87No ratings yet

- Select The Right Crane For Your BusinessDocument12 pagesSelect The Right Crane For Your BusinessOscar CurimanyaNo ratings yet

- IAM Beginners Guide Low 9Document32 pagesIAM Beginners Guide Low 9andcrisdanmat100% (1)

- The Real Cost of CapitalDocument9 pagesThe Real Cost of Capitaljiwani87No ratings yet

- Accenture Creating Customer Loyalty A Customer Centric ApproachDocument12 pagesAccenture Creating Customer Loyalty A Customer Centric ApproachNicholasChai100% (1)

- Accenture Destined To Diversity Health and Public Service PostalDocument4 pagesAccenture Destined To Diversity Health and Public Service Postaljiwani87No ratings yet

- Deloitte - Tax Issues and EntitiesDocument34 pagesDeloitte - Tax Issues and Entitiesjiwani87No ratings yet

- Accenture Emerging Market Entry Candidates IndonesiaDocument16 pagesAccenture Emerging Market Entry Candidates Indonesiatsr123321No ratings yet

- IAM Beginners Guide Low 9Document32 pagesIAM Beginners Guide Low 9andcrisdanmat100% (1)

- Accenture Federal Implementing Business Process Standardization in Government OrganizationsDocument4 pagesAccenture Federal Implementing Business Process Standardization in Government Organizationsjiwani87No ratings yet

- Accenture CM AWAMS High Performance Asset ManagementDocument12 pagesAccenture CM AWAMS High Performance Asset Managementpearlramar100% (1)

- Https Business - Usa.gov Export-Portal Static BMI Market Overview KSA Electricity Webinar 20120131 Latest Eg Main 045421Document9 pagesHttps Business - Usa.gov Export-Portal Static BMI Market Overview KSA Electricity Webinar 20120131 Latest Eg Main 045421jiwani87No ratings yet

- Im Speed Control PDFDocument64 pagesIm Speed Control PDFseshubabu_999No ratings yet

- Case Study Eskom FINAL December 2007Document9 pagesCase Study Eskom FINAL December 2007jiwani87No ratings yet

- 02BoostingPowerAR2008ENkwemfewmfkwefmkewfew FewfkemwkfmwekfmwekfmDocument6 pages02BoostingPowerAR2008ENkwemfewmfkwefmkewfew Fewfkemwkfmwekfmwekfmjiwani87No ratings yet

- Oman Uae Border CrossingDocument10 pagesOman Uae Border CrossingSellappan MuthusamyNo ratings yet

- Select The Right Crane For Your BusinessDocument12 pagesSelect The Right Crane For Your BusinessOscar CurimanyaNo ratings yet

- EICO Company Profile Ekfmwekf Ewfkmkwefm WekfmwekfmefkwDocument23 pagesEICO Company Profile Ekfmwekf Ewfkmkwefm Wekfmwekfmefkwjiwani87No ratings yet

- 2013 Gccia Project Middle Estfffff, KimfkfDocument1 page2013 Gccia Project Middle Estfffff, Kimfkfjiwani87No ratings yet

- Re PolicyDocument50 pagesRe Policymastoi786No ratings yet

- 06NationalGridAR2012Engewkfmwekf Ewfwef We Fkew Fke Fkew Fkwe KFDocument5 pages06NationalGridAR2012Engewkfmwekf Ewfwef We Fkew Fke Fkew Fkwe KFjiwani87No ratings yet

- Final - USAID-Pakistan Circular Debt Report-Printed Mar 25, 2013Document52 pagesFinal - USAID-Pakistan Circular Debt Report-Printed Mar 25, 2013jiwani87No ratings yet

- Maths UG Syllabus CCSU July26Document20 pagesMaths UG Syllabus CCSU July26RahujNo ratings yet

- Solving Differential Equations (Sect. 7.4) : TodayDocument7 pagesSolving Differential Equations (Sect. 7.4) : TodayJayson J. PagalNo ratings yet

- New 18th Order Iterative Method Solves Nonlinear EquationsDocument10 pagesNew 18th Order Iterative Method Solves Nonlinear EquationsImportadora Boliviana de MedicamentosNo ratings yet

- EMT 3100 Engineering Math IVDocument2 pagesEMT 3100 Engineering Math IVAmy AdamsNo ratings yet

- National Test in Mathematics Course C SPRING 2002 (Syllabus 1994) DirectionsDocument20 pagesNational Test in Mathematics Course C SPRING 2002 (Syllabus 1994) DirectionsEpic WinNo ratings yet

- MathematicsDocument10 pagesMathematicsAnonymous sYjudINo ratings yet

- Autumn 2018 19Document3 pagesAutumn 2018 19Nishal CalebNo ratings yet

- Solution Book For Engineering Mechanics by S TimoshenkoDocument4 pagesSolution Book For Engineering Mechanics by S TimoshenkoALIEN GYPZYNo ratings yet

- Solving Systems of Linear EquationsDocument13 pagesSolving Systems of Linear EquationsatNo ratings yet

- Quantitative Reasoning Test 3 PDFDocument21 pagesQuantitative Reasoning Test 3 PDFjcargs3No ratings yet

- Complex Vector Model of The Squirrel Cage Induction Machine Including Instantaneous Rotor Bar CurrentsDocument8 pagesComplex Vector Model of The Squirrel Cage Induction Machine Including Instantaneous Rotor Bar CurrentsJorge Luis SotoNo ratings yet

- BSC Bed Math Syllabus 2 YearDocument3 pagesBSC Bed Math Syllabus 2 Yearlelico724No ratings yet

- Independent and Dependent Variables in Acid-Base ControlDocument18 pagesIndependent and Dependent Variables in Acid-Base ControlLenin Pazmiño CanoNo ratings yet

- Maths JSS 3 Term 3Document164 pagesMaths JSS 3 Term 3Fatuhu Abba dandagoNo ratings yet

- Section A: CLASS IX (2019-20) Mathematics (041) Sample Paper-10Document5 pagesSection A: CLASS IX (2019-20) Mathematics (041) Sample Paper-10Dheer AgrawalNo ratings yet

- 11th Class Mathematics Full Book Definitions PDF q3jDocument10 pages11th Class Mathematics Full Book Definitions PDF q3jAhsanNo ratings yet

- 05-Differential Equation and Special Function NotesDocument170 pages05-Differential Equation and Special Function NotesAntar Singh ThakurNo ratings yet

- Cape Pure Mathematics Paper 2 2004Document5 pagesCape Pure Mathematics Paper 2 2004Kevin RogersNo ratings yet

- Mathematics A: Paper 4H Higher TierDocument28 pagesMathematics A: Paper 4H Higher Tiermanz 123No ratings yet

- BYJU ShortcutsDocument10 pagesBYJU ShortcutsSiddharth JaiswalNo ratings yet

- June 1998 CAPE Pure Mathematics Pilot U1 P1Document5 pagesJune 1998 CAPE Pure Mathematics Pilot U1 P1Ilijah CorbinNo ratings yet

- Algebra Formulas 2022 - Algebraic Expressions & Formulas - EmbibeDocument13 pagesAlgebra Formulas 2022 - Algebraic Expressions & Formulas - Embibesheerclothings.comNo ratings yet

- Teaching and Examination Scheme For Second Year Computer Science & Engineering (W.e.f. Academic Year 2009-10)Document10 pagesTeaching and Examination Scheme For Second Year Computer Science & Engineering (W.e.f. Academic Year 2009-10)VISION GAMINGNo ratings yet

- QM 10 DynareDocument28 pagesQM 10 DynareAmil MusovicNo ratings yet

- The Basic Finite Volume MethodDocument15 pagesThe Basic Finite Volume MethodAlasdi AhmedNo ratings yet

- Linear programming solutions and analysisDocument4 pagesLinear programming solutions and analysisNashon Reiner KNo ratings yet

- Business Mathematics FinalDocument93 pagesBusiness Mathematics FinalEbisa Deribie100% (1)

- Fma - 1Document60 pagesFma - 1Hammad QasimNo ratings yet

- Time Domain Finite Element Method For Maxwells EquationsDocument16 pagesTime Domain Finite Element Method For Maxwells EquationsCreativ PinoyNo ratings yet

- Analog ComputerDocument2 pagesAnalog ComputerRana Faryad AliNo ratings yet