Professional Documents

Culture Documents

Material

Uploaded by

Muskan KhanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material

Uploaded by

Muskan KhanCopyright:

Available Formats

Introduction A drill is a tool with a rotating drill bit used for drilling holes in various materials significance.

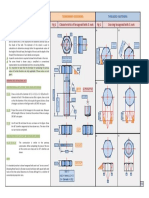

The drills are used for foundation construction in the building industry. Drilling is accomplished most typically by using a twist drill. The twist drill is most commonly used variety of drill, and twist drills are specified according to the end by which they are held, called shank. Drills may be taper shank of parallel shank and the chips must exit through the flutes of the twist to the outside of the tool. Drill bits may be made of either carbon steel or high speed steel and high speed steel is used 85% in the world for cutting. The feed and speed are also main things. The cutting speed is the speed at which the cutting edge passes over the material and it is usually expressed in meters per minute and the feed of the tool is the distance it moves along for each revolution of the work.

Drilling Characteristics The characteristics of drilling that set it apart from other powered metal cutting operations are:

The chips must exit out of the hole created by the cutting. Chip exit can cause problems when chips are large and/or continuous. The drill can wander upon entrance and for deep holes. For deep holes in large workpieces, coolant may need to be delivered through the drill shaft to the cutting front. Of the powered metal cutting processes, drilling on a drill press is the most likely to be performed by someone who is not a machinist

Drill Press Work Area The workpiece is held in place by a clamp since cutting forces can be quite large. It is dangerous to hold a workpiece by hand during drilling since cutting forces can unpredictably get quite large and wrench the part away. Wood is often used underneath the part so that the drill bit can overshoot without damaging the table. Various types 1. Multispindle The multispindle drilling machines is commonly referred to as a multispindle drill press. This type of drilling machine is especially useful when you have a large number of parts with many holes located close together. 2. Bench drill The bench drill is used for drilling holes through materials including a range of woods, plastics and metals. It is normally bolted to a bench so that it cannot be pushed over and that larger pieces of material can be drilled safely.

3. Pedestal drilling machine Pedestal drilling machine is a machine which is used for drilling metals and other elements Radial drill 4. Radial Drilling machine is a machine fitted with a rotating cutting tool called drill bit. This radial drilling machine is used for drilling holes in various materials such as steel, cast iron and. The use of machine is in the metal working industry. 5. Numerical controlled drill machine

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Pre-Registration Form at Isabela State UniversityDocument2 pagesPre-Registration Form at Isabela State UniversityKristelle V. TorrealbaNo ratings yet

- William Atienza's ResumeDocument4 pagesWilliam Atienza's ResumeMarie TamayoNo ratings yet

- Technical Data: TORQUE SETTINGS (Tightening Torques For Nuts, Bolts and Studs)Document1 pageTechnical Data: TORQUE SETTINGS (Tightening Torques For Nuts, Bolts and Studs)David RichardsonNo ratings yet

- Domestic building regulations contents guideDocument618 pagesDomestic building regulations contents guidedncservices100% (1)

- 3 Wolter ProfileDocument34 pages3 Wolter ProfiletejasNo ratings yet

- PP80E-XI Parts ManualDocument162 pagesPP80E-XI Parts ManualJet acostaNo ratings yet

- AlhambraDocument10 pagesAlhambraapi-377767762No ratings yet

- Building PermitDocument2 pagesBuilding PermitLilian Laurel CariquitanNo ratings yet

- UCSanDiegoBEPTemplate v1.1 CompleteSampleDocument26 pagesUCSanDiegoBEPTemplate v1.1 CompleteSampleMarvvvNo ratings yet

- VGC50 VGC Product Data: Vinylester Glass Capsule Anchoring AdhesiveDocument5 pagesVGC50 VGC Product Data: Vinylester Glass Capsule Anchoring AdhesiveJonathan DouglasNo ratings yet

- Towards Understanding Client Quality Requirements On Public Building Construction ProjectsDocument11 pagesTowards Understanding Client Quality Requirements On Public Building Construction ProjectsJohn Muhumuza KakitahiNo ratings yet

- clark-public-utilities-ICEA S-94-649-AEIC CS8Document21 pagesclark-public-utilities-ICEA S-94-649-AEIC CS8chrisNo ratings yet

- Astm A182 - Astm A182Document7 pagesAstm A182 - Astm A182phresendeNo ratings yet

- Sika PDS E SikaPumpDocument2 pagesSika PDS E SikaPumplwin_oo2435No ratings yet

- Volume Loss in Shallow TunnellingDocument14 pagesVolume Loss in Shallow TunnellingAida RafrinNo ratings yet

- DME Chapter 2Document5 pagesDME Chapter 2dhananjayvermaNo ratings yet

- Injection Moulding ProcessDocument5 pagesInjection Moulding ProcessSteven ChengNo ratings yet

- Steam Room Construction & Generator Sizing GuideDocument2 pagesSteam Room Construction & Generator Sizing GuideasdthuNo ratings yet

- BS StandardsDocument13 pagesBS StandardsShyam Prasad K S100% (3)

- Machine Drawing: Hexagonal Bolts & NutsDocument1 pageMachine Drawing: Hexagonal Bolts & Nutsyesbee100% (1)

- How to Cut and Strip a VGA Cable for DIY ProjectsDocument7 pagesHow to Cut and Strip a VGA Cable for DIY ProjectsDlanor AvadecNo ratings yet

- Max-3 Plus (420-2700) Technical Information & Assembly Instructions Manual PDFDocument60 pagesMax-3 Plus (420-2700) Technical Information & Assembly Instructions Manual PDFFlorentina SanduNo ratings yet

- Selangor Uniform Building By-Laws 1986-Sel.P.U. 26 - 1985Document175 pagesSelangor Uniform Building By-Laws 1986-Sel.P.U. 26 - 1985Ignatios StaboulisNo ratings yet

- DESHIDRATADOR Exc10elDocument1 pageDESHIDRATADOR Exc10elVictor Hugo Quiñonez QuintanaNo ratings yet

- Da Costa - Sagaseta - Castro - Geotechnical Aspects of An Airport Extension On Soils of Very Low StrengthDocument7 pagesDa Costa - Sagaseta - Castro - Geotechnical Aspects of An Airport Extension On Soils of Very Low StrengthgianniorlatiNo ratings yet

- INB301 Assignment Team 6008Document36 pagesINB301 Assignment Team 6008Ajwad HuqNo ratings yet

- Tires CPH v1.1 03.13.14Document75 pagesTires CPH v1.1 03.13.14samsularief03100% (1)

- Company Profile: Design and Consultancy ServicesDocument12 pagesCompany Profile: Design and Consultancy ServicesMd. Biplob HossainNo ratings yet

- KI-SV-F005, REV.05 Start Up Data SheetDocument1 pageKI-SV-F005, REV.05 Start Up Data SheetMike BongolanNo ratings yet

- Motor Hyundai D4eb-Diesel 2.2Document91 pagesMotor Hyundai D4eb-Diesel 2.2Igatech Diesel82% (11)