Professional Documents

Culture Documents

Compressed Air Dryer BOREAS

Uploaded by

Yanuar ZulkarnainOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compressed Air Dryer BOREAS

Uploaded by

Yanuar ZulkarnainCopyright:

Available Formats

Refrigeration Compressed Air Dryer BOREAS

Member of

SA 10724

Why treat compressed air?

Compressed air is an important and indispensable drive and process medium in almost all productive and treatment ranges: something natural which should be there in any case. Therefore, treatment of compressed air is important for your operating expenses since the total costs are considerably influenced by it.

with ultratronic, a pressure dew point monitoring system containing a dew point sensor directly placed at the compressed air outlet. This sensor generates an alarm when a programmed limiting value is exceeded. The microprocessor controlled SAB-processor is a standard equipment.

Responsibility and warranty

When it comes to quality, we do not make any compromises. Intelligent, perfected technology of the best quality: thats our strength and the basis of our success. We have very simple and clear principles which are written down in the Quality Control Manual in accordance with DIN EN ISO 9001. QUALITY MANAGEMENT SYSTEM CAGI ADF 100 is taken as a standard for the evaluation of the given performance data of refrigeration compressed air dryers. DQS-certification according to Certified Perfor- DIN EN ISO 9001 Reg.-No. 24 234.01 mance Certified Safety means more than just standards - all performance data are constantly tested and confirmed by the independent Fraunhofer-Institute. In addition to this our equipment is subject to security inspections of cUL.

There is more to compressed air than just compressing air

Compressed air is generated by compressing ambient air. This often contains contaminants and in all cases humidity in the form of water vapour, which can condense in the compressed air in an uncontrolled way. It will then lead to operation failures and to considerable costs which can be avoided, however.

BOREAS: reliable and safe

The refrigeration compressed air dryers BOREAS DSM series are produced with 3 housing sizes and 10 types in total. They are therefore the optimal and appropriate solution for each field of application. These dryers are available air- or watercooled for capacities from 1,200 to 7,400 cfm of airflow. BOREAS dryers can optionally be equipped

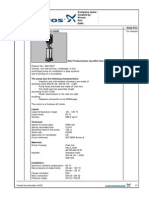

Technical concept BOREAS DSM

The BOREAS DSM series and its significant advantages:

Low pressure drop due to large flow channels Pollution repellent aluminium plates Cyclone separator Microprocessor controlled zero loss drain SAB-Processor SP 3 Constant pressure dew point by means of thermostatic expansion valve and power control Electronic control of major functions by state-of-the-art technology Space-saving installation by front operating elements, condensate drain and cooling air inlet Application of solid, fully hermetic refrigerant compressors Galvanised, stove-enamel sheet steel case in modern industrial design No TV-approval required cUL approval

Aluminium heat exchangers with large flow channels

SAB-Processor SP 3

The microprocessor controlled monitoring system SAB-processor SP 3 controls operating data such as: Current temperatures values Alarms Operating hours It records and stores: The development of the temperatures over the last 24 hours of operation The previous 8 alarm messages including date, time and the corresponding temperature The temperature development prior to the last alarm Total of alarm and fault messages since commissioning Date and time of commissioning. Dry contacts for pressure dew point-alarm and generel-alarm.

Compressed air dryer BOREAS DSM

1 2 3 4 5 6 7 8 9 10 Compressed-air inlet Compressed-air outlet Air-to-air heat exchanger Refrigerant-to-air heat exchanger Condensate separator Microprocessor controlled condensate drain Hermetically sealed refrigerant compressor Refrigerant condenser Thermostatic expansion valve Refrigerant capacity control SAB- PROZESSOR SP 3

* All BOREAS DSM dryers are equipped with ultramat as standard - the automatic level controlled, zero air loss electronic condensate drain, coated for use with oilfree aggressive condensate.

6 7 8 10 9 4

Technical data Boreas DSM

Model Volume flow cfm SD 1200 A60 SD 1400 A60 SD 1600 A60 SD 2000 A60 SD 2400 A60 SD 3000 A60 SD 4000 W60 SD 5000 W60 SD 6200 W60 SD 7400 W60 1200 1400 1600 2000 2400 3000 4000 5000 6200 7400 Cooling air cfm 5880 5880 5880 5500 5500 5500

water cooled water cooled water cooled water cooled

Power consumption kW 3.78 4.44 5.28 6.84 7.56 9.84 11.3 13.8 20.0 23.5

Max. Conden- Refrigerant Weight Air Pressure working drop connection sate pressure drain ANSI psig Ibs. Flange psig 150 150 150 150 150 150 150 150 150 150 2.9 3.1 3.6 2.3 3.2 3.6 3.1 3.1 3.0 3.0

Compressed air inlet

4" 4" 4" 6" 6" 6" 8" 8" 10" 10"

3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4"

R R R R R R R R R R

134 a 134 a 134 a 134 a 134 a 134 a 134 a 134 a 134 a 134 a

Cooling air outlet

948 992 1014 1322 1345 1422 2227 2602 3212 3674

Housing Type 1

Main Dimensions Housing Type 1 Housing Type 2 Housing Type 3

Width inches 48 88 88

Height inches 75 75 93

Depth inches 48 48 59

Cooling air inlet

Standard equipment

- Fully hermetic and maintenance-free refrigerant compressor - Refrigerant condenser - Aluminium air/air and refrigerant/air-heat exchanger - Maintenance-free separator - Electronically level-controlled condensate drain, ultramat - Refrigerant capacity control - Thermostatic expansion valve - Insulation free of CFC - Galvanised, stove-enamel sheet steel case - Dry contact for generel alarm - Dry contact for dew point alarm - Working hour meter

Compressed air outlet

Special equipment

- Standard bypass feeder - Special varnish - 50 Hz operation - Water cooled condenser - Energy saving application - ultratronic - Antifreezing indoor installation

Product range:

Cyclone Separator: High-capacity filters: Compressed air fridge dryer: Adsorption dryer: ultrapac 2000 ultrapac classic oilfreepac Condensate Management: ultramat condensate drains ultrasep superplus UFS-SP 70 8,600 cfm 3 16,000 cfm 5 7,400 cfm 3 60 cfm 3 5,000 cfm 3 5,000 cfm

Donaldson Company, Inc. Ultrafilter 3560 Engineering Drive Norcross, GA 30092

Telephone: 770.448.3363 Telefax: 770.448.3854 Toll free: 800.543.3634 E-mail: info@ultrafilter-us.com Web: www.ultrafilter-us.com

75 4,000 cfm

You might also like

- At ThermostarDocument8 pagesAt ThermostarLam Ch100% (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Air TowerDocument4 pagesAir Towersergio.gonzalezbaNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Air Compressor ASK-27TDocument5 pagesAir Compressor ASK-27TJonson CaoNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- SSCDW-1112 R134a Water Cooled Screw Chiller SSCX (55-300RT) (Rev2 230413)Document12 pagesSSCDW-1112 R134a Water Cooled Screw Chiller SSCX (55-300RT) (Rev2 230413)Naing Oo KyawNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- CD+ 25-260 Product Description EN Antwerp API 146E 46L1 Ed 00 PDFDocument6 pagesCD+ 25-260 Product Description EN Antwerp API 146E 46L1 Ed 00 PDFJesus MartinezNo ratings yet

- Esm 7-22Document8 pagesEsm 7-22Endre FarkasNo ratings yet

- Boge Compressed Air TreatmentDocument36 pagesBoge Compressed Air TreatmentAir Repair, LLCNo ratings yet

- Secador SchulzDocument16 pagesSecador SchulzSantiagoAlpala100% (1)

- 1000 CFM Non Datasheet - Docx 1Document3 pages1000 CFM Non Datasheet - Docx 1Ingeniería AplicacionesNo ratings yet

- Airtower 26 CompressorDocument4 pagesAirtower 26 CompressorJonson Cao0% (1)

- RLC PRC005 E4 - 0110Document60 pagesRLC PRC005 E4 - 0110jefhdez0% (1)

- 1905 - Carrier 30 GZ 190 PDFDocument6 pages1905 - Carrier 30 GZ 190 PDFbilal almelegyNo ratings yet

- SullaireDocument12 pagesSullaireAnonymous 61zHIpNo ratings yet

- FD Dryers CatalogDocument13 pagesFD Dryers CatalogmasrooorNo ratings yet

- EDT GBTRDocument4 pagesEDT GBTRAlistair Ciantar100% (1)

- CompAir L23 - L29 - RS Compressor Brochure PDFDocument8 pagesCompAir L23 - L29 - RS Compressor Brochure PDFbulentbulutNo ratings yet

- COMPRESSED AIR TREATMENT - Product Catalogue - EnglishDocument124 pagesCOMPRESSED AIR TREATMENT - Product Catalogue - EnglishOMEGA AIR d.o.o. LjubljanaNo ratings yet

- DryPower refrigeration dryers optimize compressed air purificationDocument6 pagesDryPower refrigeration dryers optimize compressed air purificationYanuar ZulkarnainNo ratings yet

- FOCSWATER.C Water Cooled Chiller - R134aDocument8 pagesFOCSWATER.C Water Cooled Chiller - R134antt_121987No ratings yet

- Boge Refrigerant Dryers - DS SeriesDocument8 pagesBoge Refrigerant Dryers - DS SeriesAir Repair, LLC100% (1)

- RTHD RLC Slb010 en SalesDocument4 pagesRTHD RLC Slb010 en Salesphilip-i-ibesate-7171No ratings yet

- Air Cooled Chillers1Document6 pagesAir Cooled Chillers1jonathandacumosNo ratings yet

- FDbrochureDocument13 pagesFDbrochureAyman Mohammed Ibrahim AbdouNo ratings yet

- Afe Main Acc EsdDocument2 pagesAfe Main Acc EsdEthan HuntNo ratings yet

- USAIRTOWER AirtowerSeries 07-2019!46!37027Document8 pagesUSAIRTOWER AirtowerSeries 07-2019!46!37027vkees1987No ratings yet

- ZEKS HeatSink 150-2400 (Aug 2013)Document6 pagesZEKS HeatSink 150-2400 (Aug 2013)Sandro ChavezNo ratings yet

- Adsorption Dryer CatalogueDocument8 pagesAdsorption Dryer CatalogueAmirArmanNo ratings yet

- Donaldson Indust Water Process ChillersDocument6 pagesDonaldson Indust Water Process ChillersJeEJyZaNo ratings yet

- Multi Stack Chiller Srw150c Mv6 v1.0Document9 pagesMulti Stack Chiller Srw150c Mv6 v1.0Nico RobinNo ratings yet

- FX 400-2000Document8 pagesFX 400-2000francisco jose arruda de sousaNo ratings yet

- DGHDocument8 pagesDGHEdison F Montaluisa100% (1)

- Comp Air Compressor D Series CatalogDocument8 pagesComp Air Compressor D Series CatalogFerio ArsyadNo ratings yet

- Chillere Daikin MariDocument12 pagesChillere Daikin MariProiectare InstalatiiNo ratings yet

- Hankison - Secador Adsorcion HPD 300-3200 SCFM - EsDocument8 pagesHankison - Secador Adsorcion HPD 300-3200 SCFM - EsrobertohugosanchezNo ratings yet

- Accessories - ESD DrainDocument2 pagesAccessories - ESD Drainmuhamad.badar9285No ratings yet

- FOCSWATER.C Water Cooled Chiller - R134a - 2012!01!01Document15 pagesFOCSWATER.C Water Cooled Chiller - R134a - 2012!01!01ntt_121987No ratings yet

- Dew Point Meter-Model Amm-15Document2 pagesDew Point Meter-Model Amm-15Juan Ricardo Ordoñez GamezNo ratings yet

- Aquaforce Liquid Chiller High-Efficiency Industrial ChillerDocument24 pagesAquaforce Liquid Chiller High-Efficiency Industrial ChilleragbekasNo ratings yet

- ASK Series Rotary Screw Compressors - Reliable, Efficient, QuietDocument5 pagesASK Series Rotary Screw Compressors - Reliable, Efficient, QuietMarko Peric100% (1)

- Брошюра - Осушители Bd100-3000Document8 pagesБрошюра - Осушители Bd100-3000airpartNo ratings yet

- Fiche Technique M135Document7 pagesFiche Technique M135Kheggar SamirNo ratings yet

- M220 KaeserDocument4 pagesM220 KaeserVictor Angel Miranda CorderoNo ratings yet

- Air DryerDocument4 pagesAir Dryerrashm006ranjanNo ratings yet

- TS Refrigerated Dryer Brochure - A4Document4 pagesTS Refrigerated Dryer Brochure - A4Yashiro AlvaradoNo ratings yet

- Quanta Freeze DryerDocument11 pagesQuanta Freeze DryercristinatubleNo ratings yet

- Basics - Dew Point Measurement - P60 P63 PDFDocument4 pagesBasics - Dew Point Measurement - P60 P63 PDFAnonymous o38k1iEKFNo ratings yet

- Compressed Air Dryer - USA - FinalDocument14 pagesCompressed Air Dryer - USA - FinalMohammad KhreibehNo ratings yet

- ESP 20-37 BrochureDocument6 pagesESP 20-37 BrochurecivodulNo ratings yet

- Lochinvar Water HeatersDocument52 pagesLochinvar Water HeatersJohn MoreNo ratings yet

- Almig Combi GB WebDocument8 pagesAlmig Combi GB WebRomanCHubaNo ratings yet

- Sauer SohnDocument12 pagesSauer SohnHanif FadIllah Budiman AkbarNo ratings yet

- Gardner Denver - ESM30Document8 pagesGardner Denver - ESM30namnt11100% (1)

- Fd60hz Secador Atlas Copco - ManualDocument8 pagesFd60hz Secador Atlas Copco - ManualEdvaldo França100% (1)

- ZR-ZT55-90 VSD-FFDocument22 pagesZR-ZT55-90 VSD-FFrodrigodiazsilvaNo ratings yet

- Superior Temperature Control Equipment: VWR Circulators and ChillersDocument28 pagesSuperior Temperature Control Equipment: VWR Circulators and Chillersfranky7485973No ratings yet

- Provit ChartDocument2 pagesProvit ChartYanuar ZulkarnainNo ratings yet

- 512-552 EOTech PDFDocument2 pages512-552 EOTech PDFYanuar ZulkarnainNo ratings yet

- SIMOPRIME A4 Circuit Breaker SwitchgearDocument11 pagesSIMOPRIME A4 Circuit Breaker SwitchgearYanuar ZulkarnainNo ratings yet

- Chairman Katalog PDFDocument27 pagesChairman Katalog PDFYanuar ZulkarnainNo ratings yet

- 512-552 EOTech PDFDocument2 pages512-552 EOTech PDFYanuar ZulkarnainNo ratings yet

- Stabiliser Assisted Vertical Mast Aerial Work Platform: Singapore Indonesia Philippines Malaysia Thailand VietnamDocument1 pageStabiliser Assisted Vertical Mast Aerial Work Platform: Singapore Indonesia Philippines Malaysia Thailand VietnamYanuar ZulkarnainNo ratings yet

- 512-552 EOTech PDFDocument2 pages512-552 EOTech PDFYanuar ZulkarnainNo ratings yet

- Belden 9841Document3 pagesBelden 9841Felipe GomezNo ratings yet

- SIMOPRIME A4 Circuit Breaker SwitchgearDocument11 pagesSIMOPRIME A4 Circuit Breaker SwitchgearYanuar ZulkarnainNo ratings yet

- Belden 9841Document3 pagesBelden 9841Felipe GomezNo ratings yet

- Tricon Cable Ladder - Price ListDocument6 pagesTricon Cable Ladder - Price ListYanuar ZulkarnainNo ratings yet

- XPS2 User ManualDocument38 pagesXPS2 User ManualYanuar ZulkarnainNo ratings yet

- Stabiliser Assisted Vertical Mast Aerial Work Platform: Singapore Indonesia Philippines Malaysia Thailand VietnamDocument1 pageStabiliser Assisted Vertical Mast Aerial Work Platform: Singapore Indonesia Philippines Malaysia Thailand VietnamYanuar ZulkarnainNo ratings yet

- 512-552 EOTech PDFDocument2 pages512-552 EOTech PDFYanuar ZulkarnainNo ratings yet

- Pump Specification SheetDocument7 pagesPump Specification SheetYanuar ZulkarnainNo ratings yet

- Nyfgby 4coreDocument2 pagesNyfgby 4coreDaniel Wahyu ChristyawanNo ratings yet

- CM3-4 A-R-G-V AQQV: Position Qty. Description Single PriceDocument3 pagesCM3-4 A-R-G-V AQQV: Position Qty. Description Single PriceYanuar ZulkarnainNo ratings yet

- Demag Chain and Rope Hoists: Generation OverviewDocument1 pageDemag Chain and Rope Hoists: Generation OverviewYanuar Zulkarnain100% (1)

- CM3-4 A-R-G-V AQQV: Position Qty. Description Single PriceDocument3 pagesCM3-4 A-R-G-V AQQV: Position Qty. Description Single PriceYanuar ZulkarnainNo ratings yet

- Pump Specification SheetDocument7 pagesPump Specification SheetYanuar ZulkarnainNo ratings yet

- Load Break Switches & Motorized OptionsDocument1 pageLoad Break Switches & Motorized OptionsYanuar ZulkarnainNo ratings yet

- Description Value: Printed From Grundfos CAPSDocument1 pageDescription Value: Printed From Grundfos CAPSYanuar ZulkarnainNo ratings yet

- ATV58 enDocument38 pagesATV58 enYanuar ZulkarnainNo ratings yet

- Changeover Switches: General Catalogue 2011-2012Document4 pagesChangeover Switches: General Catalogue 2011-2012Yanuar ZulkarnainNo ratings yet

- Kaeser FlowmeterDocument1 pageKaeser FlowmeterYanuar ZulkarnainNo ratings yet

- Pt. Denko Wahana Sakti: Jakarta, Febuari 2011Document4 pagesPt. Denko Wahana Sakti: Jakarta, Febuari 2011Yanuar ZulkarnainNo ratings yet

- Quick Installation Instructions: Automatic Transfer SwitchDocument1 pageQuick Installation Instructions: Automatic Transfer SwitchAlejandro Alberto Robalino MendezNo ratings yet

- CS Power Meter CS 110: Technical DataDocument2 pagesCS Power Meter CS 110: Technical DataYanuar ZulkarnainNo ratings yet

- ATV32 Price ListDocument2 pagesATV32 Price ListYanuar ZulkarnainNo ratings yet

- Price ATNS SetDocument1 pagePrice ATNS SetYanuar ZulkarnainNo ratings yet

- Sag Slurry PoolingDocument10 pagesSag Slurry PoolingalgroneNo ratings yet

- ES 15 Lec 9 Dimensional Analysis and SimilitudeDocument28 pagesES 15 Lec 9 Dimensional Analysis and SimilitudeAngela Mae LopezNo ratings yet

- Ssph011 Session 15 Biomechanic Moments (Torque) and ElasticityDocument55 pagesSsph011 Session 15 Biomechanic Moments (Torque) and ElasticityPortia NyakaneNo ratings yet

- Universal cleaner for ultrasonic bathsDocument1 pageUniversal cleaner for ultrasonic bathsJuan ShunaNo ratings yet

- DWC ElecConduit Is 16205 P24 2018Document11 pagesDWC ElecConduit Is 16205 P24 2018Vamsi Manoj60% (5)

- Rectilinear Motion and Rotating VesselDocument4 pagesRectilinear Motion and Rotating VesselJack PresadoNo ratings yet

- Lab 6 SpectrophotometerDocument11 pagesLab 6 SpectrophotometerChing Wai YongNo ratings yet

- Chemistry Project: To Study The Quantity of Casein Present in Different Samples of MilkDocument14 pagesChemistry Project: To Study The Quantity of Casein Present in Different Samples of Milkveenu68No ratings yet

- Weather in Kuttiadi - Google SearchDocument1 pageWeather in Kuttiadi - Google Searchsorry Its My StyleNo ratings yet

- Final PPT 3rd SemDocument16 pagesFinal PPT 3rd SemmonuNo ratings yet

- Hooke's Law and Property of MaterialsnotesDocument5 pagesHooke's Law and Property of MaterialsnotesPrithu PareekNo ratings yet

- C-30 Concrete Mix Design RatiosDocument5 pagesC-30 Concrete Mix Design RatiosAtm Tjah Radix LoegoeNo ratings yet

- Nonnewtonian and Newtonian Blood Flow in Human Aorta A Transient AnalysisDocument10 pagesNonnewtonian and Newtonian Blood Flow in Human Aorta A Transient AnalysisDivyaVatsNo ratings yet

- Q3 ST 1 GR.6 Science With TosDocument4 pagesQ3 ST 1 GR.6 Science With TosRed MariposaNo ratings yet

- Bridge Design Report - Docx 150Document17 pagesBridge Design Report - Docx 150nephembaniNo ratings yet

- Transmision de Potencia NewDocument12 pagesTransmision de Potencia NewGustavo ArmellaNo ratings yet

- Introducing JiFi ST Petersburg 2014Document4 pagesIntroducing JiFi ST Petersburg 2014danjohhnNo ratings yet

- Ordinary Differential EquationDocument20 pagesOrdinary Differential EquationRadeanindaNo ratings yet

- Methods of Re-Apportioning Service Cost Centre CostsDocument7 pagesMethods of Re-Apportioning Service Cost Centre CostsUserNo ratings yet

- Rebound Hammer Test Procedure For Concrete HardnessDocument4 pagesRebound Hammer Test Procedure For Concrete HardnessSite Engineer.2p2No ratings yet

- Open Stent Design: Craig Bonsignore NDC 47533 Westinghouse Drive Fremont, CA, 94566Document93 pagesOpen Stent Design: Craig Bonsignore NDC 47533 Westinghouse Drive Fremont, CA, 94566akire_aicragNo ratings yet

- About The Company: Machined and Forged ComponentsDocument18 pagesAbout The Company: Machined and Forged ComponentsankitNo ratings yet

- The Second Term Exam of EnglishDocument2 pagesThe Second Term Exam of Englishsof chimiste100% (1)

- Fluid Mechanics II: Key Concepts of Fluid KinematicsDocument18 pagesFluid Mechanics II: Key Concepts of Fluid KinematicsYousef FarajNo ratings yet

- Stress Analysis of Flat Plates With Attached NozzlesDocument125 pagesStress Analysis of Flat Plates With Attached NozzlesZarra FaktNo ratings yet

- Shoot For Your Grade Lab Write UpDocument5 pagesShoot For Your Grade Lab Write Upapi-254812059No ratings yet

- Introduction to Nanorobotics and Their ApplicationsDocument25 pagesIntroduction to Nanorobotics and Their ApplicationsSharifa RahamadullahNo ratings yet

- Text - Anuario Cader 2018 INGLÉS PDFDocument57 pagesText - Anuario Cader 2018 INGLÉS PDFmicaelaNo ratings yet

- Quatitative Microscopy Cog PDFDocument6 pagesQuatitative Microscopy Cog PDFNiyati GuptaNo ratings yet

- Alpha 900 and HD LineDocument32 pagesAlpha 900 and HD Linebertan dağıstanlıNo ratings yet