Professional Documents

Culture Documents

Metric Bolt Torque - Thread Strength

Uploaded by

bakellyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metric Bolt Torque - Thread Strength

Uploaded by

bakellyCopyright:

Available Formats

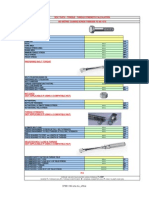

BOLT TORQUE - THREAD STRENGTH CALCULATION ISO METRIC SCREW THREADS TO AS 1721 BOLT DATA

MATERIAL THREAD TOLERANCE CLASS DIAMETER THREAD PITCH THREAD NOMINAL THREAD PITCH DIAMETER THREAD MINIMUM MAJOR DIAMETER THREAD MINIMUM PITCH DIAMETER MINIMUM TENSILE STRESS YIELD STRESS PROOF STRESS CORE AREA TENSILE STRESS AREA SHANK AREA mm

MPa MPa MPa 0 0 0 mm2 2 mm mm2

PREFERRED BOLT LOAD & TORQUE

BOLT UTILISATION BASED ON PREFERRED BOLT UTILISATION BOLT CONDITION TORQUE COEFFICIENT (NUT FACTOR) BOLT LOAD BASED ON PREFERRED BOLT LOAD PREFERRED BOLT TORQUE

% OF YIELD STRESS #N/A 0 #N/A kN Nm

NUT DATA

NUT MATERIAL THREAD TOLERANCE CLASS THREAD MAXIMUM PITCH DIAMETER THREAD MAXIMUM MINOR DIAMETER ULTIMATE TENSILE STRESS YIELD STRESS

mm

MPa MPa

THREAD STRENGTH

ULTIMATE BOLT LOAD THREAD ENGAGEMENT TO DEVELOP FULL BOLT STRENGTH THREAD ENGAGEMENT TO YIELD THREADS AT FULL BOLT STRENGTH #DIV/0! FORCE REQUIRED TO STRIP mm LENGTH OF THREADS FORCE REQUIRED TO YIELD mm LENGTH OF THREADS

0 #DIV/0! #DIV/0! #DIV/0! #DIV/0!

kN mm mm mm kN kN

SELECTED BOLT LOAD & TORQUE

REQUIRED SAFETY FACTOR ON THREAD YIELD RECOMMENDED BOLT LOAD RECOMMENDED BOLT LOAD AS A % OF YIELD STRESS RECOMMENDED BOLT TORQUE SELECTED BOLT TORQUE SELECTED BOLT LOAD SELECTED BOLT LOAD AS A % OF YIELD STRESS

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

kN % Nm Nm kN %

FAILURE OCCURS SIMULTANEOUSLY IN BOTH PARTS, AT THE PITCH LINE & YIELD OCCURS SIMULTANEOUSLY IN BOTH PARTS, AT THE PITCH LINE TORQUE VALUES CALCULATED USING FORMULA T = KDP WHERE T = TORQUE (Nm), K = TORQUE COEFFICIENT, D = NOMINAL DIAMETER (mm), P = BOLT CLAMP LOAD (kN)

97961274.xls.ms_office

BOLT DIAMETERS 5 6 8 10 12 14 16 18 20 22 24 27 30 33 36 39 42 45 48 52 56 60 64

BOLT AREAS BOLT SIZE (mm) 0 PITCH CORE (mm) 0 0 AREAS (mm2) TENSILE SHANK STRESS 0 0

BOLT MECHANICAL PROPERTIES MIN TENSILE STRESS (MPa) 0 YIELD STRESS (MPa) 0 PROOF STRESS (MPa) 0

NUT MECHANICAL PROPERTIES MIN TENSILE STRESS (MPa) 0 YIELD STRESS (MPa) 0

STRENGTH OF METRIC THREADS BOLT TORQUE COEFFICIENTS 1 BOLT CONDITION 2 K BOLT MATERIAL = TENSILE STRENGTH OF THE BOLT MATERIAL, Sst = YIELD STRESS OF THE BOLT MATERIAL = NUT MATERIAL = NUT PLATE THICKNESS = ULTIMATE TENSILE STRENGTH OF THE NUT MATERAL, Snt = YIELD STRENGTH OF THE NUT MATERIAL = 0.0 0 0 0 0 0 0

1px1 (MOLY)V 0.18 AS RECEIVED 0.20 AS RECEIVED OR LIGHTLY OILED & LOCTITE 771 0.13 BOWMAN ANTI-SEIZE 0.12 CADMIUM PLATED 0.17 CADMIUM PLATED (DEGREASED) 0.20 CADMIUM PLATED (LIGHTLY OILED) 0.14 CADMIUM PLATED (LIGHTLY OILED & LOCTITE 243) 0.13 CLEAN, NONPLATED, AS RECEIVED 0.20 COPPER BASED ANTI-SEIZE 0.16 DEGREASED & LOCTITE 243 0.20 DRY 0.30 EXPOSED TO ELEMENTS, BEGINNING TO OXIDISE0.30 GALVANISED (DEGREASED) 0.42 GALVANISED (LIGHTLY OILED) 0.22 GENERAL MACHINE OIL 0.20 GREASE 0.16 GREASE (HEAVY) 0.14 HOT DIPPED GALVANISED 0.25 INORGANIC SILICATE (IOZ) 0.17 LIGHTLY OILED 0.20 LIGHTLY OILED & LOCTITE 243 0.14 LOCTITE MOLY PASTE 0.11 LOW FRICTION OIL 0.15 MOLYBDENUM DISULPHIDE BASED GREASE 0.14 MOLYBOND GA50 0.14 MOLYKOTE 0.18 MOLYKOTE P74 0.14 NICKEL BASED ANTI-SEIZE 0.15 NEVER-SEIZE (PASTE) 0.17 NONPLATED, BLACK FINISH 0.30 PHOSPHATED (LIGHTLY OILED) 0.14 PHOSPHATED (LIGHTLY OILED & LOCTITE 243) 0.11 PHOSPHATED (DEGREASED) 0.24 PHOSPHATED (DEGREASED & LOCTITE 243) 0.14 SOLID PTFE FILM 0.12 TEFLON 7630 0.09 WAXED 0.10 XYLAN 0.10 ZINC PLATED 0.22

BOLT DIAMETER = BOLT THREAD PITCH = TENSILE STRESS AREA = ULTIMATE BOLT LOAD = LENGTH OF THREAD ENGAGEMENT REQUIRED TO DEVELOP FULL STRENGTH:

0 0.00 0.0 0.0

NUT AND BOLT ARE OF EQUAL-STRENGTH MATERIALS. .: FAILURE OCCURS SIMULTANEOUSLY IN BOTH PARTS, AT THE PITCH BOLT TOLERANCE CLASS = NUT TOLERANCE CLASS = 0 0

NOMINAL PITCH DIAMETER OF THE BOLT, d2 = LENGTH OF THREAD ENGAGEMENT REQ'D TO DEVELOP FULL STR., LE = SHEAR AREA AT PITCH LINE OF BOTH THREADS, AS= ULTIMATE SHEAR STRENGTH OF THE MATERIAL, SU ~= FORCE REQUIRED TO STRIP THREADS, F = LENGTH OF THREAD ENGAGEMENT REQUIRED TO YIELD THREAD AT FULL STRENGTH #DIV/0! #DIV/0! #DIV/0!

0.000

0.0

NUT AND BOLT ARE OF EQUAL-STRENGTH MATERIALS. .: YIELD OCCURS SIMULTANEOUSLY IN BOTH PARTS, AT THE PITCH LIN

NOMINAL PITCH DIAMETER OF THE BOLT, d2 = LENGTH OF THREAD ENGAGEMENT REQ'D TO DEVELOP FULL STR., LE = #DIV/0!

0.000

ZINC PLATED (DRY) ZINC PLATED (DEGREASED) ZINC PLATED (DEGREASED & LOCTITE 243) ZINC PLATED (LIGHTLY OILED) ZINC PLATED (LIGHTLY OILED & LOCTITE 243) 0

0.29 0.14 0.15 0.18 0.16 #N/A

SHEAR AREA AT PITCH LINE OF BOTH THREADS, AS= ULTIMATE SHEAR STRENGTH OF THE MATERIAL, SU ~= FORCE REQUIRED TO STRIP THREADS, F = LENGTH OF THREAD ENGAGEMENT REQUIRED TO YIELD THREAD AT FULL STRENGTH, L = SELECTED LENGTH OF THREAD ENGAGEMENT SELECTED LENGTH OF THREAD ENGAGEMENT = FORCE REQUIRED TO STRIP THREADS, F = FORCE REQUIRED TO YIELD THREADS, F = RECOMMENDED BOLT TORQUE BOLT CONDITION = 0 BOLT PRELOAD = TORQUE CO-EFFICIENT = SAFETY FACTOR ON THREAD YIELD = YIELD STRESS OF THE BOLT MATERIAL = = RECOMMENDED BOLT LOAD = % OF YIELD STRESS = RECOMMENDED BOLT TORQUE = SELECTEDED BOLT TORQUE SELECTED BOLT TORQUE = SELECTED BOLT LOAD = % OF YIELD STRESS =

#DIV/0! 0.0 #DIV/0! #DIV/0!

0.0 #DIV/0! #DIV/0!

0 #N/A 0.00 0 0.0 #DIV/0! #DIV/0! #DIV/0!

0 #DIV/0! #DIV/0!

THREAD LIMITING DIMENSIONS NOMINAL BOLT NUT PITCH MIN. MAJOR MIN. PITCH MAX. MINOR MAX. PITCH DIAMETER DIAMETER DIAMETER DIAMETER DIAMETER d2 dmin d2min D1max D2max (mm) (mm) (mm) (mm) (mm) 0.000 0 0 0 0 FAILURE OCCURS SIMULTANEOUSLY IN BOTH PARTS, AT THE PITCH LINE YIELD OCCURS SIMULTANEOUSLY IN BOTH PARTS, AT THE PITCH LINE

MPa MPa

mm MPa MPa

mm mm mm2 kN

ANEOUSLY IN BOTH PARTS, AT THE PITCH LINE.

mm mm mm2 MPa kN

EOUSLY IN BOTH PARTS, AT THE PITCH LINE.

mm mm

mm2 MPa kN mm

mm kN kN

% OF YIELD STRESS

MPa mm2 kN % Nm

Nm kN %

You might also like

- ASME B16.5 Class 150 & 300 Flanges Studbolt LengthDocument3 pagesASME B16.5 Class 150 & 300 Flanges Studbolt LengthbakellyNo ratings yet

- Final Weld Strength CalnsDocument3 pagesFinal Weld Strength CalnsSajal KulshresthaNo ratings yet

- Flange From Plate - Asme 16.5Document1 pageFlange From Plate - Asme 16.5Rey Fiedacan100% (1)

- Blind Flange Thickness Calculation Under 40 CharactersDocument6 pagesBlind Flange Thickness Calculation Under 40 Charactersshazan0% (1)

- Welding Calculations For Base PlateDocument116 pagesWelding Calculations For Base PlateSyedZainAli100% (2)

- Bolt Torque Calculation - Apr19Document69 pagesBolt Torque Calculation - Apr19Raj SNo ratings yet

- Bolt Torque ASME B16.5 Flanges - Spiral Wound GasketsDocument31 pagesBolt Torque ASME B16.5 Flanges - Spiral Wound Gasketsbakelly100% (5)

- Bolt Torque CalculatorDocument9 pagesBolt Torque Calculatoraauppal100% (3)

- Bolt Tension & Torque CalculationDocument1 pageBolt Tension & Torque CalculationhuangjlNo ratings yet

- Bolt TorqueDocument20 pagesBolt TorqueArjun Singh AroraNo ratings yet

- Design of Flanges - Full-Face Gasket 2010Document29 pagesDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- Torque CalculatorDocument2 pagesTorque CalculatorDanhHoNo ratings yet

- Metric Bolt Torque Requirement CalculationDocument4 pagesMetric Bolt Torque Requirement CalculationPieter van der WaltNo ratings yet

- Bolt Up CalculationDocument12 pagesBolt Up CalculationAniket GaikwadNo ratings yet

- Product Form Table 1A: Maximum Allowable Stress Values for Ferrous Materials at Design TemperatureDocument10 pagesProduct Form Table 1A: Maximum Allowable Stress Values for Ferrous Materials at Design TemperatureSalvador MalagoNo ratings yet

- Weld Calculation Equivalent To BoltsDocument3 pagesWeld Calculation Equivalent To Boltskalpanaadhi100% (2)

- MRCB Piepeline: Pipe Wall Thickness Checking (T)Document5 pagesMRCB Piepeline: Pipe Wall Thickness Checking (T)amirthraj74No ratings yet

- ASME B16.5 2013 FlangeRating 1.0Document4 pagesASME B16.5 2013 FlangeRating 1.0sanjaysyNo ratings yet

- Sight Glass Flange AnalysisDocument4 pagesSight Glass Flange AnalysisOmil Rastogi0% (2)

- Flange CalculationsDocument3 pagesFlange CalculationssanjaysyNo ratings yet

- Part 2 Pressure Vessel DesignDocument281 pagesPart 2 Pressure Vessel DesignSyedZainAli100% (1)

- Flange Design Mmcobc 3.3 2010Document3 pagesFlange Design Mmcobc 3.3 2010bakellyNo ratings yet

- Double V Weld CalculationDocument8 pagesDouble V Weld CalculationHgagselim SelimNo ratings yet

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- Blind Flange CalculationDocument12 pagesBlind Flange CalculationrajarajanNo ratings yet

- Torque Wrench Tightening Torque CalculationDocument2 pagesTorque Wrench Tightening Torque CalculationAlupole_AlbertLim100% (1)

- Design of Flanges - Welded-On Integral Type 2010Document59 pagesDesign of Flanges - Welded-On Integral Type 2010bakellyNo ratings yet

- Square Blind Flange With Stiffener ULDocument5 pagesSquare Blind Flange With Stiffener ULjoeriji100% (1)

- ASME VIII CalculationDocument14 pagesASME VIII CalculationWan Wei100% (1)

- Screw Threads #2Document221 pagesScrew Threads #2boo huNo ratings yet

- Asme BPVC II Part D Material Strengths 01Document7 pagesAsme BPVC II Part D Material Strengths 01bakellyNo ratings yet

- Weld CalculatorDocument6 pagesWeld Calculatorshahid khanNo ratings yet

- Mechanical Design SpreadsheetDocument1 pageMechanical Design SpreadsheetHoney TiwariNo ratings yet

- Blind Flange Design Calculations - by Abdel Halim GalalaDocument6 pagesBlind Flange Design Calculations - by Abdel Halim GalalaNirmalraj Manoharan67% (3)

- Calculating bolt torque for sealing a 30Document4 pagesCalculating bolt torque for sealing a 30souren1975No ratings yet

- Metric Bolt Data - Torque - Thread StrengthDocument10 pagesMetric Bolt Data - Torque - Thread StrengthbakellyNo ratings yet

- ChimneyDocument15 pagesChimneyLILISNo ratings yet

- Base PlateDocument6 pagesBase PlatejasonjasonNo ratings yet

- Lifting Lug DesignDocument27 pagesLifting Lug Designmramico100% (1)

- Thickness Cal. Fo DM Water Storage Tank-API 650Document15 pagesThickness Cal. Fo DM Water Storage Tank-API 650Jose Rodriguez50% (2)

- TrunnionDocument7 pagesTrunnionRUDHRA DHANASEKAR100% (1)

- 11 TrunnionDocument21 pages11 TrunnionMitul PatelNo ratings yet

- Section Size: W200X36: Refer Appendix D For Support ReactionsDocument10 pagesSection Size: W200X36: Refer Appendix D For Support Reactionsramuce04No ratings yet

- Purlin Cleat 220908Document24 pagesPurlin Cleat 220908kalpanaadhi100% (2)

- Provided THK Is Sufficient: Result 2Document5 pagesProvided THK Is Sufficient: Result 2sagar1503No ratings yet

- Radial Stiffener PDFDocument6 pagesRadial Stiffener PDFsagar1503No ratings yet

- Engineering Design Report for Cast-Insitu PilesDocument85 pagesEngineering Design Report for Cast-Insitu Pileshameed6101986No ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleChagar HarshpalNo ratings yet

- Retaining Wall DesignDocument168 pagesRetaining Wall DesignSuraj Muley0% (1)

- Guide PV analysis resultsDocument4 pagesGuide PV analysis resultsSiri SiriNo ratings yet

- Mat 3 DDocument14 pagesMat 3 Dhilbert_garlando1112No ratings yet

- 26 Pressure VesselDocument21 pages26 Pressure VesseljnmanivannanmechNo ratings yet

- Propeller PushupDocument7 pagesPropeller PushupMannMannNo ratings yet

- API 650 Design TanksDocument39 pagesAPI 650 Design TanksAhmedAli25% (4)

- Gusset Plate Design for Cleveland Clinic Abu DhabiDocument4 pagesGusset Plate Design for Cleveland Clinic Abu Dhabikalpanaadhi75% (4)

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- Retaining Wall DesignDocument168 pagesRetaining Wall DesignAlfonso PatuktokNo ratings yet

- Footings For ColumnsDocument9 pagesFootings For ColumnsNidhi Sharma KhandelwalNo ratings yet

- 321 Chapter 5 Splice DesignDocument91 pages321 Chapter 5 Splice DesignHemant Ramesh NarkarNo ratings yet

- SA-240 304L lifting lug stress analysisDocument2 pagesSA-240 304L lifting lug stress analysisEngr Khurram Jaan RamayNo ratings yet

- Yield Strength 01Document2 pagesYield Strength 01bakellyNo ratings yet

- Horizontal Cylindrical Pressure Vessvessel Zick 03Document12 pagesHorizontal Cylindrical Pressure Vessvessel Zick 03bakelly0% (1)

- Youngs Modulus b3 2010Document2 pagesYoungs Modulus b3 2010bakellyNo ratings yet

- Pipe Pressure RatingDocument1 pagePipe Pressure RatingbakellyNo ratings yet

- Lifting Lug Design AnalysisDocument22 pagesLifting Lug Design AnalysisbakellyNo ratings yet

- Asme BPVC II Part D Material Strengths 01Document7 pagesAsme BPVC II Part D Material Strengths 01bakellyNo ratings yet

- Linear Thermal Expansion b4 2010Document2 pagesLinear Thermal Expansion b4 2010bakellyNo ratings yet

- Monorail Beam Design 07Document5 pagesMonorail Beam Design 07bakellyNo ratings yet

- Bolt Torque ASME B16.5 Flanges - Spiral Wound GasketsDocument31 pagesBolt Torque ASME B16.5 Flanges - Spiral Wound Gasketsbakelly100% (5)

- Metric Bolt Data - Torque - Thread StrengthDocument10 pagesMetric Bolt Data - Torque - Thread StrengthbakellyNo ratings yet

- Bolt Torque ASME B16.5 Flanges - Sheet Gaskets 02Document26 pagesBolt Torque ASME B16.5 Flanges - Sheet Gaskets 02bakelly100% (7)

- Metric Bolt Data - Torque - Thread StrengthDocument10 pagesMetric Bolt Data - Torque - Thread StrengthbakellyNo ratings yet

- Expansion Loop Flexibility Analysis (Weaver)Document3 pagesExpansion Loop Flexibility Analysis (Weaver)bakellyNo ratings yet

- Bolt Torque ASME B16.5 Flanges - Sheet Gaskets 02Document26 pagesBolt Torque ASME B16.5 Flanges - Sheet Gaskets 02bakelly100% (7)

- Pipe Span Without Point LoadsDocument36 pagesPipe Span Without Point Loadsbakelly100% (4)

- Flange Design Mmcobc 3.1 2010Document6 pagesFlange Design Mmcobc 3.1 2010bakellyNo ratings yet

- Design of Flanges - Full-Face Gasket 2010Document29 pagesDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- Design of Flanges - Welded-On Integral Type 2010Document59 pagesDesign of Flanges - Welded-On Integral Type 2010bakellyNo ratings yet

- Design of Flanges - Weld Neck Type 2010Document58 pagesDesign of Flanges - Weld Neck Type 2010bakellyNo ratings yet

- Flange Design Mmcobc 1.1 2010Document5 pagesFlange Design Mmcobc 1.1 2010bakellyNo ratings yet

- Design of Flanges - Optional Type 2010Document59 pagesDesign of Flanges - Optional Type 2010bakellyNo ratings yet

- Design of Flanges - Loose Type 2010Document53 pagesDesign of Flanges - Loose Type 2010bakellyNo ratings yet

- Pipe Span Without Point LoadsDocument36 pagesPipe Span Without Point Loadsbakelly100% (4)

- Flange Design Mmcobc 3.3 2010Document3 pagesFlange Design Mmcobc 3.3 2010bakellyNo ratings yet

- Design of Flanges - Loose Hub Type 2010Document58 pagesDesign of Flanges - Loose Hub Type 2010bakellyNo ratings yet

- Flange Design Mmcobc 1.3 2010Document3 pagesFlange Design Mmcobc 1.3 2010bakellyNo ratings yet

- Effects of Nimodipine, Vinpocetine and Their Combination On Isoproterenol-Induced Myocardial Infarction in RatsDocument9 pagesEffects of Nimodipine, Vinpocetine and Their Combination On Isoproterenol-Induced Myocardial Infarction in RatsBilal AbbasNo ratings yet

- Proceeding Book SIBE 2017Document625 pagesProceeding Book SIBE 2017Yochanan meisandroNo ratings yet

- Mole Conversions Extra Practice Answer KeyDocument1 pageMole Conversions Extra Practice Answer Keyapi-376281962No ratings yet

- XCKN2145G11: Limit Switch XCKN - TH - Plastic Roller Lever Var - Length - 1NO+1NC - Snap - Pg11Document2 pagesXCKN2145G11: Limit Switch XCKN - TH - Plastic Roller Lever Var - Length - 1NO+1NC - Snap - Pg11Boby SaputraNo ratings yet

- TOS in PRE-CALCULUSDocument2 pagesTOS in PRE-CALCULUSSerjohnRapsingNo ratings yet

- Administering Agilent 3070 Systems (MS Windows NT and 2000) Chapter 8Document60 pagesAdministering Agilent 3070 Systems (MS Windows NT and 2000) Chapter 8Adam KaNo ratings yet

- MK-PPT Chapter 1Document37 pagesMK-PPT Chapter 1Nicolás SánchezNo ratings yet

- Frege: Sense and Reference One Hundred Years LaterDocument215 pagesFrege: Sense and Reference One Hundred Years LaterfabioingenuoNo ratings yet

- CREATE A CORRECTLY SCALED NETWORK FROM SCRATCHDocument5 pagesCREATE A CORRECTLY SCALED NETWORK FROM SCRATCHMauricio Senior RamírezNo ratings yet

- Tunnel NoiseDocument11 pagesTunnel Noisesylvestrew100% (1)

- Kalman Filter Tutorial - PresentationDocument65 pagesKalman Filter Tutorial - Presentationcarlazar100% (2)

- Clustering Methods for Data MiningDocument60 pagesClustering Methods for Data MiningSuchithra SalilanNo ratings yet

- Effect of SR, Na, Ca & P On The Castability of Foundry Alloy A356.2Document10 pagesEffect of SR, Na, Ca & P On The Castability of Foundry Alloy A356.2jose.figueroa@foseco.comNo ratings yet

- Drum RudimentsDocument4 pagesDrum Rudimentsmaame nyarkoaNo ratings yet

- Week 3: Experimental Design Energy Transfer (Mug Experiment)Document3 pagesWeek 3: Experimental Design Energy Transfer (Mug Experiment)Kuhoo UNo ratings yet

- The Gist of NCERT General Science PDFDocument148 pagesThe Gist of NCERT General Science PDFSatyajitSahooNo ratings yet

- Eaton 290376 NZMH4 VE800 S1 en - GBDocument10 pagesEaton 290376 NZMH4 VE800 S1 en - GBkarthik01heroNo ratings yet

- CE 308 Plain and Reinforced Concrete - Ii Determination of Size, Spacing and Cover in Reinforced Concrete Slab by Cover MeterDocument9 pagesCE 308 Plain and Reinforced Concrete - Ii Determination of Size, Spacing and Cover in Reinforced Concrete Slab by Cover MeterumairNo ratings yet

- 4PH0 1P Que 20160119 PDFDocument28 pages4PH0 1P Que 20160119 PDFschlemielzNo ratings yet

- Certificate: Shear MachineDocument3 pagesCertificate: Shear MachinegilbertoNo ratings yet

- User's Manual: Electrolyte AnalyzerDocument25 pagesUser's Manual: Electrolyte AnalyzerNghi NguyenNo ratings yet

- EC424 Monetary Economics (Michaelmas Term) Additional QuestionsDocument5 pagesEC424 Monetary Economics (Michaelmas Term) Additional QuestionsSteamPunkNo ratings yet

- Problem Solving 1 Arithmetic SequenceDocument62 pagesProblem Solving 1 Arithmetic SequenceCitrus National High SchoolNo ratings yet

- Fractional Brownian Motions in Financial Models, Simulation and PricingDocument111 pagesFractional Brownian Motions in Financial Models, Simulation and Pricingnahv_08No ratings yet

- Development and Validation of UV Spectrophotometric Method For The Estimation of Curcumin in Bulk Drug and Pharmaceutical Dosage FormsDocument6 pagesDevelopment and Validation of UV Spectrophotometric Method For The Estimation of Curcumin in Bulk Drug and Pharmaceutical Dosage FormswiracanaNo ratings yet

- tc107 Research PaperDocument6 pagestc107 Research PaperAtharva BhideNo ratings yet

- Endothermic Reactions Absorb HeatDocument2 pagesEndothermic Reactions Absorb HeatRista WaniNo ratings yet

- Hikmayanto Hartawan PurchDocument12 pagesHikmayanto Hartawan PurchelinNo ratings yet

- GAS-RELEASE CALCULATORDocument3 pagesGAS-RELEASE CALCULATOREduardo Paulini VillanuevaNo ratings yet

- R Fulltext01Document136 pagesR Fulltext01vhj gbhjNo ratings yet