Professional Documents

Culture Documents

33 KV Switch Gear Specification

Uploaded by

pokiriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

33 KV Switch Gear Specification

Uploaded by

pokiriCopyright:

Available Formats

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

ROLTA INDIA LIMITED

Project Name:NPCIL TEST FACILITY Project No:1001041

Engineering Specification (ES) Doc No. 1001041-S-E-1001-00

Revision History

Revision Level Revision Date Revision Description Department Head (Approver)

This Document and all contained herein are proprietary of ROLTA INDIA LIMITED and is subjected to confidentiality restrictions between ROTLA INDIA LIMITED and he Recipient. Copyright Reserved.

Copyright Rolta India Limited. All Rights Reserved. Prepared By:

Date:

Checked By: Approved By:

Page 1 of 25

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

1. 2. 2.1 2.2 2.2.1 2.2.2 3. 3.1 3.1.1 3.1.2 3.1.3 3.1.4 3.2 3.2.1 3.3 3.3.1 3.3.2 3.4 3.4.1 3.4.2 3.5 3.5.1 3.5.2

TABLE OF CONTENTS Page No SCOPE ......................................................................................................................4 GENERAL REQUIREMENTS........................................................................................4 Operating Conditions ................................................................................................. 4 Codes and Standards .......................................................................................... 4 General Standards ...................................................................................4 Specific Standards .......................................................................................4 BASIC REQUIREMENTS ..........................................................................................5 Construction.............................................................................................................5 Switchgear Assembly ..................................................................................5 Switchgear Units .........................................................................................6 Main Bus .....................................................................................................6 Earth Bus......................................................................................................7 Power Circuit Breakers ...........................................................................................8 Type and Characteristics..............................................................................8 Control Circuit ......................................................................................................13 Control Power............................................................................................13 Breaker Control, Indication and Alarm ........................................................13 Protection & Metering Transformers .......................................................................13 Current Transformers ...............................................................................13 Potential Transformers .............................................................................14 Relays ...................................................................................................................14 Protection Relays ......................................................................................14 Auxiliary Relays........................................................................................17 Date: Page 2 of 25

Checked By: Approved By:

Copyright Rolta India Limited. All Rights Reserved. Prepared By:

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

3.6 3.7 3.8

Instrument .............................................................................................................17 Fuse .......................................................................................................................... 19 Terminal Block ........................................................................................ 19

3.9 Cable Box and Gland ....19 3.10 3.11 3.12 3.13 Accessories................................................................... 20 Heater............................................................................................................20 Spare Parts .......................................................................................................20

Connection and wiring...........................................................................................20

3.13.1 Power connection.......20 3.13.2 Control wiring andconnection .......................................................................................20 3.14 3.15 3.16 3.17 Nameplates ....21 Finish.....21 Field assembly.......21 Painting .....21

3.18 Tests And Test Reports22 3.19 Drawings and data. ...23

Copyright Rolta India Limited. All Rights Reserved. Prepared By:

Date:

Checked By: Approved By:

Page 3 of 25

ELECTRICAL SPECIFICATION 1. SCOPE

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

This Specification defines the technical requirements related to the design and supply of the distribution switchgear, including all equipment, manufacture, assembly, factory wiring, inspection, testing and delivery. 2. 2.1 GENERAL REQUIREMENTS Operating Conditions The switchgear shall be suitable for installation indoor in a ventilated electrical room. Considering Geographic, Climatic and Non-Seismic . 2.2 2.2.1 Codes and Standards General Standards Design, fabricate and test equipment in accordance with the latest revision of applicable standards of the following regulatory agencies and institutes. International Electrotechnical Comission (IEC) Indian Standard (IS) International Organisation for Standardization (ISO) Local regulatory bodies having jurisdiction over such apparatus

2.2.2

Specific Standards In addition to the general standards listed above, the latest editions of the following specific standards shall apply to the extent specified herein: International Electrotechnical Commission (IEC) And Indian Standard (IS) IS -13118. IS-5 (693) IS-2705 IS 3156 Applicable standards for busbar Colour finish shade Exterior for Switchgear Applicable standards for Current transformer

Page 4 of 25

Applicable standards for voltage transformer Copyright Rolta India Limited. Date:

All Rights Reserved. Prepared By: Checked By: Approved By:

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

IS: 9224, IS: 9385 IS: 1248, IS: 722 IS:3231 IEC 60044 IEC 60255 IEC 60265 IEC 60269 IEC 60282 IEC 60417 IEC 60446

Applicable standards for HRC Fuses Applicable standard for Meters

Application standard for Relays. Instrument transformers Electrical relays High-voltage switches Low voltage fuses High voltage fuses Graphical symbols for use on equipment Basic and safety principles for man-machine interface, marking and identification - Identification of conductors by colours or numerals High-voltage alternating current contactors and contactor-based motor-starters Degrees of protection provided by enclosures (IP Code) Common specifications for high-voltage switchgear Low-voltage switchgear and controlgear Electromagnetic Compatibility High-voltage switchgear and controlgear

IEC 60470 IEC 60529 IEC 60694 IEC 60947 IEC 61000 IEC 62271

3. 3.1 3.1.1

BASIC REQUIREMENTS Construction Switchgear Assembly

The assembly shall be made up of metal-clad switchgear units of standard dimensions bolted together to form an enclosed, self-contained, self-supporting Copyright Rolta India Limited. Date: Page 5 of 25

All Rights Reserved. Prepared By: Checked By: Approved By:

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

structure mounted on base channels with anchor bolt holes for installation on concrete floor. The assembly shall be equipped with common power and ground busses and shall be suitable for the future addition of units at each end. 3.1.2 Switchgear Units Each unit shall be provided with: a) b) c) d) e) f) g) 3.1.3 Earthed metal barriers to isolate control compartments from power compartments. Separate front hinged doors to provide access to circuit breaker and auxiliary compartments. Removable rear panels, with suitable fastening devices of the captive type, to permit access to bus work and to current transformers and cable compartments. Screened louvers for ventilation and relieving of pressure caused by circuit interruption. Protective shutters to automatically close the openings to the primary disconnects when the circuit breaker is withdrawn from its connected position. Fixed guide rails for easy racking-in/out of the circuit breakers. Anti-condensation, thermostatically-controlled space heater with independent protective device.

Main Bus The main bus bars shall be of high strength, high-conductivity Aluminium (D50 SWP) with non-hygroscopic, flame-retardant insulation (PVC, epoxy, etc.) braced to withstand the maximum short circuit current of the system. Bus joints shall be silver plated and shall utilize non-corrosive hardware. Busbars shall be rated in accordance with the service conditions and the rated continuous and short time current ratings specified in Data Sheet.Maximum temperature of the main busbars and busbar connections, under operating conditions, when carrying rated normal current at rated temperature shall not exceed 90/105 Deg. C for non-silver plated / silver plated joints/connections. Busbar temperature limits shall be adhered to without forced cooling method. For tap off busbars, the current ratingshall be at least equal to corresponding breaker(s) rating.

Copyright Rolta India Limited. All Rights Reserved. Prepared By:

Date:

Checked By: Approved By:

Page 6 of 25

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

All busbar joints and bus tap joints shall be preferably be silver faced. In case of aluminium busbars with bare joints, suitable neutral grease shall be applied to the meeting surfaces after finishing the surfaces to prevent oxide formation. For joints to be made at site, sufficient quantity of grease shall be supplied by the VENDOR in suitable containers. Unless supported by impulse voltage withstand test results, phase to phase and phase to earth clearances in air of the busbars and live parts shall not be less than those specified in Data Sheet. Busbars shall be adequately supported on insulators, to withstand dynamic stresses due to short circuit current specified in Data Sheet. Busbar support insulators shall conform to relevant standards specified in Data Sheet. Main busbars shall be located in air insulated enclosures and segregated from all other compartments of the cubicle. Direct access or accidental contact with busbars and primary connections shall not be possible. To provide a seal between adjacent cubicles, busbars shall be taken through sealoff bushing or insulating blocks. Busbars and Sleeves The busbars when sleeved shall be with flame retardant heat/cold shrinkable sleeve. All joints shall be provided with removable shrouds. The busbar sleeves, shrouds material shall be suitable for continuous operating temperature of 5 Deg. C higher than the maximum permissible operating temperature of busbars / joints.The sleeving material shall not crack, peel or loosen on the busbars when subjected to thermal cycling during service and shall be of such quality as not to require replacement for life of switchgear. It shall be possible to remove and refix the shrouds repeatedly without damaging them. Test certificates pertaining to the quality of the sleeving material and shrouds shall be submitted by Bidder.

3.1.4

Earth Bus

An earthing bus shall be provided and extended throughout the length of the switchgear. It shall be bolted to the framework of each unit and brazed to each breaker earthing contact bar.The earth bus shall have sufficient cross section to carry the momentary short circuit and short time fault current for at least (1) second or higher as specified in Data Sheet, without exceeding maximum allowable temperature rise causing damage to the switchgear.Suitable clamp type terminals at each end of the earth bus

Copyright Rolta India Limited. All Rights Reserved. Prepared By:

Date:

Checked By: Approved By:

Page 7 of 25

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

shall be provided to suit the size of the PURCHASERS earthing conductors.Bolted joints, slices, taps etc. to the earth bus shall be made with at least two bolts.Positive earthing of circuit breaker frame shall be maintained when it is in the connected position and in all other positions whilst the auxiliary circuits are not totally disconnected.Hinged doors shall be earthed through flexible earthing braid of adequate cross section. All non-current carrying metal work of the switchgear shall be effectively bonded to the earth bus. A continuous earth bus of high-strength, high-conductivity copper of size 50 X 6.mm shall be provided the length of the assembly and solidly bolted to the steel framework. It shall be capable to carry the rated short circuit current of any breaker in the assembly for a period of one second without exceeding maximum withstanding temperature . 3.2 3.2.1 Power Circuit Breakers Type and Characteristics The circuit breaker shall be 3-pole, single throw, vacuum , draw-out type with self-aligning primary and secondary disconnecting devices. The breaker shall be mechanically and electrically trip-free equipped with stored energy closing and antipump operation mechanisms and suitable for 110V DC (-15 to +10%) closing and trip. The circuit breakers shall be operated from the cubicles front. Each circuit breaker shall have three, clearly-marked definite positions within its enclosure, i.e. "service", "test" and "fully withdrawn" positions. Mechanical interlocks shall be provided to prevent inserting or withdrawing a closed breaker and also to prevent closing the breaker unless it is in the "service" or "test" positions.

CIRCUIT BREAKERS, VACUUM CONTACTORS & DISCONNECTORS:

Circuit breakers shall be one of the following types and selection shall be as specified in Data Sheet. a) Sulphur Hexafluoride Breaker (SF6) b) Vacuum Circuit Breaker (VCB) These shall conform to relevant standards specified in Data Sheet and shall be of the horizontal draw-out type. Circuit breakers shall comprise three separate identical single pole units operated through a common insulated shaft by the operating mechanism. Breakers of identical ratings shall be fully interchangeable without any adjustment.Circuit Breaker with forced air-cooling for increasing its rating will not be acceptable. insulated shaft by the operating mechanism. Breakers of identical ratings

Copyright Rolta India Limited. All Rights Reserved. Prepared By:

Date:

Checked By: Approved By:

Page 8 of 25

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

shall be fully interchangeable without any adjustment.Circuit Breaker with forced aircooling for increasing its rating will not be acceptable. Circuit Breaker Duty. Circuit breakers shall be suitable for switching duty of transformer whose maximum capacity is furnished in Data Sheet and other devices specified in Data Sheet. adequate provision shall be made on circuit breakers for motor switching to limit the over voltage to 2.2 p.u. rated peak line to earth voltage (1.0 microsec. to crest).Closing and Opening operation time difference shall be limited to 2 cycles (40 ms) to facilitate fast bus transfer operation.The breakers controlling motors shall be provided with suitable devices to operate satisfactorily under the following conditions : a) Direct-on-line starting of motor whose maximum capacity and starting time are furnished in Data Sheet. b) The frequency of motor starting can be either one start from hot condition or two successive starts from cold condition or three equally spaced starts in an hour from hot condition. c) Suitable shunt resistors or surge arrestors, if necessary shall be provided to restrict the voltage peaks during switching off motor, to 2.2 p.u. of rated peak line to earth voltage. Circuit breaker along with its operating mechanism shall be mounted on a wheeled carriage moving on guides, designed to align correctly and allow easy movement. Plugs and sockets for power circuits shall be silver faced and shall be insulated with suitable insulating material shrouds. There shall be Service, Test Fully withdrawn positions for the breakers. In the Test position the circuit breaker shall be capable of being tested for operation without energising the power circuits, i.e. the control circuits shall remain undisturbed while the power contacts shall remain disconnected. Separate limit switches, each having a minimum of 2 NO + 2 NC contacts, shall be provided for both Service and Test positions of the circuit breakers for Purchasers use. These contacts shall be rated for 10 amps, 240 V AC and 0.5 amp (inductive breaking) at 220V DC. Auxiliary Connection / Contacts : Connection of the control/interlocking circuits between the fixed portion of the cubicle and the breaker carriage shall be preferably by means of plug socket arrangement.Self aligning disconnects shall have adequate number of contacts to meet the requirements of control and interlocking scheme. Contact between the fixed and moving parts of the disconnects shall be established to enable testing of breaker outside panel.Plug and socket arrangement when provided, shall have adequate number of pins to meet the requirements of control and interlocking scheme with a minimum Copyright Rolta India Limited. Date: Page 9 of 25

All Rights Reserved. Prepared By: Checked By: Approved By:

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

of 24 pins. The plug and socket arrangement shall be so designed that it shall be possible to insert the plug in the socket in one position only. The plug, after insertion, shall be secured in position by spring clamps, which need considerable force to operate. The length of the plug chord will be such that the plug can be inserted into the socket only when the breaker is pushed into the test position. Suitable interlock will be provided to permit further pushing of the breaker only if the plug is inserted correctly into the socket. It shall not be possible to remove the plug when the breaker is in service position and it shall be necessary to withdraw the plug from the socket before the breaker can be pulled out from the test position to fully withdrawn position. When a service isolating switch is furnished as an integral part of the circuit breaker, the operation of the Disconnector shall be co-ordinated with that of the circuit breaker to ensure that it opens after the power break and is not required to interrupt the load current. Service Disconnectors however, may be allowed to interrupt the residual current through quenching or damping resistors incorporated in the circuit breakers. SF6 BREAKERS SF6 breakers shall be of puffer type or self extinguishing type with rotating arc of dead tank and single pressure design. The movement of piston attached to moving linkage mechanism shall be designed in such a way that the build-up of dielectric strength inside the chamber is proportional to the current to be interrupted in order to avoid prolonged arcing in the event of short circuit and current chopping in the event. low load currents. SF6 pressure/density monitoring switch/contacts shall be provided. Materials such as activated alumina or molecular sieve shall be provided at appropriate locations to absorb products of decomposition of SF6 gas and for moisture absorption. Under no operating conditions, the moisture content in the SF6 gas shall be allowed to exceed 15 ppm. The second stage density switches provided shall be as follows : a) Under pressure - I STAGE Low pressure alarm and locking out of the closing circuit shall be incorporated. b) Under pressure - II STAGE This pressure shall be above the safe lowest operating pressure for the breaker as guaranteed and tested by the manufacturer. Breaker shall be tripped with annunciation. 5.9 Vacuum breakers shall have completely sealed interrupting units for interruption of arc inside the vacuum. The breakers shall be provided with contact wear indicator visible from the front of the equipment, without requiring opening of the cubicle door, allowing the operator to assess the Copyright Rolta India Limited. Date: Page 10 of 25

All Rights Reserved. Prepared By: Checked By: Approved By:

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

conditions of the interrupters whilst the unit is in service. It shall be possible to isolate easily the vacuum interrupter unit from the operating mechanism for mechanical testing of the interrupter to check loss of vacuum. The vacuum breakers shall be complete with surge arrestors to provide protection to the equipment against switching surges.

DISCONNECTOR / SWITCH DISCONNECTOR / FUSE UNIT: Unless otherwise stated Data Sheet, Disconnectors shall be of the offload and drawout type. On load Disconnectors (load break switches) shall be provided in place of breakers and be complete with suitably sized HRC or expulsion type fuses, as specified. Short time rating of the Disconnector shall be same as that of the associated breakers. Disconnector shall be capable of making and breaking capacitive current of associated equipment such as busbars, cable(s) and transformer(s). Position indicating Red and Green lamps shall be provided on theDisconnector cubicles. In addition, contacts shall be wired upto terminal blocks for connecting lamps for remote indication of Disconnector position.Mechanical and electrical interlocks shall be provided where applicable to ensure that the Disconnectors cannot be operated unless the associated breakers are open.Disconnectors shall be provided with suitably designed motor drive if specified in Data Sheet. Motor drive shall be complete with suitably rated starter including fused disconnects. VACUUM CONTACTORS The vacuum contactors shall be in medium voltage operation range of 1.5--7.0 kV. The fixed contact shall be brazed to the lower end plate and the moving contact shall be guided by self lubricating bearings. Bellows shall be provided to allow free contact movement. The bellows shall be brazed to the copper end plate and to the bottom of the moving contact system. The end plates shall be jointed and insulated by a tubular glass section, the complete assembly forming the contactor enclosure. Aspatter shield shall collect any spray arcing material and prevent a tracking path from accumulating on the inside of glass envelope.Evacuation of the contactor shall be achieved through diffusion pumping while the contactor is being baked. The contactor shall then be subjected to d.c. arcing, to condition and out-gas the component materials and to achieve a vacuum of better than 10-3 Torr. The contact faces shall be machined to provide center and annular reservoirs, which shall be filled with a suitable alloy.The vacuum contactors shall be either of mechanically latched or electrically held type. The electrically held Copyright Rolta India Limited. Date: Page 11 of 25

All Rights Reserved. Prepared By: Checked By: Approved By:

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

contactor shall be just like a low voltage contactor.In applications where switching frequency is very low, mechanically latching device shall be provided and armature shall be held in close position by means of a mechanical device during working and detached by means of a shut trip coil, as specified. CIRCUIT BREAKER OPERATING MECHANISM Circuit breaker shall be power operated by a motor charged spring operated mechanism. It shall be strong, rigid, positive and fast in operation to ensure that a) Main poles of the breakers shall be such that unless otherwise specified, the maximum difference between instants of contacts touching during closing shall not exceed half cycle of rated frequency. b) Main poles of the breakers shall operate simultaneously. There shall be no objectionable rebound of moving contacts and the mechanism shall not require any critical adjustment. Operating mechanism shall be non-pumping electrically and mechanically under every method of closing (except during manual closing of a breaker for maintenance). Electrical antipumping feature shall be obtained by means of an auxiliary relay and use of a contactor to achieve this feature shall not be acceptable. Mechanism shall be such that failure of any auxiliary spring shall not prevent tripping and will not cause tripping or closing operation of the power operated closing devices. When the circuit breaker is already closed, failure of any auxiliary spring shall not cause damage to the circuit breaker or endanger the operator.The closing release shall operate correctly at all values of voltage between 85% and 110% of the rated voltage. A shunt trip shall operate correctly under all operating conditions of the circuit breaker upto the rated breaking capacity of the circuit breaker and all values of supply voltage between 70% and 110% of rated voltage. Working parts of the mechanism shall be of corrosion resistant material.Bearings which require grease shall be equipped with pressure type grease fittings. Bearing pin, bolts, nuts and other parts shall be adequately pinned and locked to prevent loosening or changing adjustment with repeated operation of the breaker.Auxiliary switches mounted on the fixed portion of the cubicles and directly operated from the breaker operating mechanism on each breaker having 6 NO and 6 NC potentialfree contacts rated for 10 amp, 240V AC and 0.5 amp (inductive breaking) 220V DC shall be provided.

Copyright Rolta India Limited. All Rights Reserved. Prepared By:

Date:

Checked By:

Page 12 of 25 Approved By:

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

contacts shall be in addition to those utilised in the control circuit of each breaker and shall be exclusively meant for the PURCHASERS use in external interlocks and controls. SPRING OPERATED MECHANISM Spring operated mechanism, shall be complete with motor of adequate rating, opening spring, closing spring with limit switch for automatic charging and all necessary accessories to make the mechanism a complete operating unit. As long as power is available to the motor, a continuous sequence of closing and opening operations shall be possible. After failure of power supply to the motor, at least one openclose-open operation of the circuit breaker shall be possible. Breaker operation shall be independent of the motor which shall be used solely for charging the closing spring. Closing action of the circuit breaker shall compress the opening spring ready for tripping. When closing springs are discharged, after closing a breaker, closing springs shall automatically be charged for the next operation. Motor shall be such that it requires only about 30 sec. for fully charging the closing spring. Motors shall be rated for 220 V DC and/or 240 V AC and/or 110V DC as specified in Data Sheet and shall operate satisfactorily at all values of voltage between 85% to 110% of rated voltage. Motor shall be protected against overloads and stalling. Mechanical indicators to indicate charged and discharged condition of spring shall be provided. Alternate means must be provided to charge the closing springs manually. Necessary handles shall be supplied with Circuit Breakers. OPERATING MECHANISM CONTROL : Operating mechanism shall normally be operated by remote electrical control when the breaker is in Service or Test position. Electrical tripping shall be performed by shunt trip coils. Provision shall also be made for local electrical control when the breaker is in Test position by a control switch on the switchgear cubicle door. Also, Local/Remote selector switch lockable in Local position shall be provided on the cubicle door. `Red and `Green indicating lamps shall be provided on cubicle door to indicate breaker close and open positions. Breaker Service and Test positions shall be indicated by separate indicating lamps on the cubicle door, in case mechanical indication of Service and Test positions are not available on the cubicle door.

Copyright Rolta India Limited. All Rights Reserved. Prepared By:

Date:

Checked By:

Page 13 of 25 Approved By:

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

3.3 3.3.1

Control Circuit Control Power Control power for breaker closing and tripping circuits shall be 110VDC (unless otherwise indicated) from a source external to the switchgear.

3.3.2

Breaker Control, Indication and Alarm Breaker control switch shall be heavy duty, rotary type with pistol grip handle, two-position "close-trip" spring return with target to indicate the last operation. Minimum indication requirements per breaker are as follows: Trip voltage available Test and Service position indication. All alarms, pre-warnings, etc., to be gathered in one common signal for remote indication. Transformer gas and temperature signals will be hard wired from transformer to transformer feeder cubicles.

3.4

Protection & Metering Transformers Current Transformers (For metering) One set of three (3) C.T. per incomer and feeder with 1A secondary shall be provided for metering and wired through current test blocks for incomers and tie breakers and for feeder breakers. The transformers shall be of the dry type insulated for the full voltage rating of the switchgear and shall have their thermal and mechanical rating capable of withstanding the short circuit rating of the associated circuit breaker.

The transformers shall have their accuracy established in accordance with the connected burden and IS 2705. Current transformers for metering applications shall have Class 1 accuracy or better. In special cases where low CT turns ratio and high burden requirements are specified, the accuracy class of CT shall be 3.0. With these CTs the overall error shall be limited to 4.5% Copyright Rolta India Limited. Date: Page 14 of 25

All Rights Reserved. Prepared By: Checked By: Approved By:

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

with an accuracy class 1.5 for indicating instruments. When auxiliary CTs are used the overall error ofthe combination shall be restricted to 1%. CTs shall have the following burdens unless otherwise specified. Motor & other feeders - 10 VA Instrument security factor shall be less than 5 unless otherwise specified. Current Transformers (For Protection) Protection CTs shall have class of accuracy of 5P20 and minimum burden 10 VA unless otherwise specified. Core balance CTs shall be such that the earth fault relay should be able to operate over its entire range. 3.4.2 Potential Transformers One (1) set of two (2) potential transformers per incomer, connected in open delta, With 110/3 volt secondary shall be provided for metering and protection for each bus section. The transformers shall be of the draw-out type protected by HRC fuses on their primary and secondary and shall be designed to withstand the basic impulse level of the switchgear and with interrupting ratings corresponding to breaker rating in accordance with IS 3156. It shall be possible to replace the secondary fuses safely when the switchgear is energised. Precautions shall be made such that the primary fuses can be handled only in the de-energised position. Drawout contacts for Phase and Neutral terminals shall be identical. Alternatively, MCB having auxiliary contact shall be provided. 3.5 3.5.1 Relays Protection Relays

The relays shall be square or rectangular in shape and shall have dust tight, transparent covers removable from the front. Relay cases shall be suitable for flush mounting with only flanges projecting on the front with connections from the rear. Relay cases shall have adequate number of terminals for making potential free connections to the relay coils and contacts including spare

Copyright Rolta India Limited. All Rights Reserved. Prepared By:

Date:

Checked By:

Page 15 of 25 Approved By:

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

contacts.Relay case size shall be so chosen as not to introduce any limitations on the use of available contacts of the relay due to inadequate number of terminals. Provision shall be made for easy isolation of trip circuits of each relay for the purpose of testing and maintenance. Relay Contacts / Output: Relays when specified or required in specific application shall have electrically independent output contacts for the following purposes: a) Tripping circuit. b) Remote/local annunciation. c) Data Acquisition System. d) Spare (for event recorder, etc.) If the main relay does not have sufficient number of output contacts inherently, these shall be multiplied using auxiliary relays, to be covered in the Vendors scope of supply. Relay contacts shall be silver faced with spring action. Output elements of all static relays shall consist of electromechanical relays only. Except as noted otherwise in Data Sheet-A, all AC relays shall be suitable for operation on 50 Hz. Voltage operated relays shall be suitable for 110V AC and current operated relays for 5 amps or 1 amp. CT secondary, as specified in Data Sheet-A1. Auxiliary relays and timers shall be suitable for specified voltage and operate satisfactorily between 80% and 110% of rated voltage. Voltage operated relays shall have adequate thermal capacity for continuous operation. Auxiliary seal-in units provided on the protective relays shall be preferably of shunt reinforcement type. If series relays are used the following shall be strictly ensured: a) The operating time of the series seal-in unit shall be sufficiently shorter than the trip coil in series with which it operates to ensure definite operation of the flag indicator. b)Seal-in unit shall obtain adequate current for operation when one or more relays operate simultaneously. c) Impedance of the seal-in unit shall be small enough to permit satisfactory operation of the trip coils when the DC supply voltage is minimum (i.e. 70% of rated value).

Copyright Rolta India Limited. All Rights Reserved. Prepared By:

Date:

Checked By:

Page 16 of 25 Approved By:

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

d) Series seal-in units shall have two taps, one rated for 0.2 amps and the other rated for 2.0 amps. The protective relays shall conform to following requirements: All the relays shall be wired in such a way that power supply failure to the relay does not cause maloperation of another relay. Unless otherwise specified in Data Sheet-A1, type of relays either static or electro- mechanical which meet the various performance requirements stipulated herein are considered acceptable. The protective relays shall have high degree of reliability, low power consumption and plug-in or draw-out type, of modular assembly to facilitate maintenance. The modularisation shall be provided as per the recommendations of relevant specifications. The relays shall be equipped with either hand reset type mechanically operated operation indicator or LEDS for visual indication. The LED lamps shall be resettable by a push button located in an easily accessible place on relay case. On 3-phase relays with separate operation indicator for each phase, the indicator shall be clearly marked with the reference phase. Each operation indicator shall have its function and the principle of operation in a symbol inscribed clearly. Protective relays shall be suitable for secondary rating of CTs and when drawn out should short CT secondary which should not even momentarily get open circuited. Protection relays shall be electronic (3 years minimum of power service) and shall withstand surge test in accordance with the applicable IEC standards. Relays shall be provided as per the data sheet. As a minimum the following protective functions shall be provided: Incomers: ANSI 27,98,59, 50/51, 50N / 51N. Feeders: ANSI 98,27, 50/51, 50N/51N Bus Tie: ANSI 50/51, 50N/51N. Tripping Relays: The tripping relays shall be latch-in type with hand reset facility and shall

Copyright Rolta India Limited. All Rights Reserved. Prepared By:

Date:

Checked By:

Page 17 of 25 Approved By:

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

preferably have operating time not exceeding 20 ms. Each tripping relay shall have adequate number of normally open (NO) and normally closed (NC) heavy duty contacts as specified either in Section-C or Data Sheet-A. Barriers shall be provided between each set of contacts. If sufficient contacts are not available on each tripping relay, more tripping relays may be used. The tripping relays shall be preferably of hand reset type. If electrical reset type of relays are used, a push button shall be provided on the panel for resetting the relay. All tripping relays used shall be so connected that supervision of each relay is possible. For facilitating supervision of these tripping relays, high burden tripping relays shall be provided. Supervision relays having three output contacts for annunciation, DAS and event recorder where specified, shall be provided for supervision of each tripping relay. 3.5.2 Auxiliary Relays Auxiliary relays(4 NO + 4 NC) shall be switchgear type with coil and heavy duty contacts rated for operation on 110V DC. 3.6 Instruments:

Indicating Instrument: Unless otherwise specified, all electrical indicating instruments shall be 96 mm square, with 240 degrees scale. They shall be suitable for flush mounting on vertical panels and inclined faces of desks whose inclination from horizontal or vertical shall not exceed 20o. Instrument dials shall be white with black numerals and lettering. Knife edge pointers and parallax free dials shall be preferred. Instruments shall be provided with non-reflecting glass. Instruments shall have accuracy class of 1.5 or better. The design of the scales shall be such that it can read to a resolution corresponding to 50% of the accuracy class index. Ammeters and Current Coils of Wattmeters and VARmeters shall continuously withstand 120% of rated current and 10 times the rated current for 0.5 secs. without loss of accuracy. Voltmeters and Potential Coils of wattmeters and VARmeters shall withstand 120% of rated voltage continuously and twice the rated voltage for 0.5 secs without loss of accuracy.

Copyright Rolta India Limited. All Rights Reserved. Prepared By:

Date:

Checked By:

Page 18 of 25 Approved By:

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

Ammeters for motor feeders shall have compressed extended scale to read upto six to nine times the rated current of the motor. Metering Instrument: Meters shall be electronic type meters that collect, process and store electrical parameters, energy use and demand data on a time of the day or demand basis. Meters shall measure all electrical parameters like Voltage,Current, Watt, Watthrs, Var, Var-hrs and Power factor in all phases.Meters shall preferably be of accuracy class 0.5. Watt-hour and Varhour measurement shall be suitable for unbalanced loads in three phase three wire circuits. They shall be suitable for flushmounting or semiflush mounting on vertical panels with only flanges projecting outside with back connected terminals. The meters shall be suitable for operation from the secondary of CTs andVTs. They shall be provided with a separate test block for the testing of the meters without disturbing the CT and PT secondary connections. Meters shall provide enhanced LCD display which, shall include but not limited to (a) Six digits display of metered quantities and constants (b) Potential indication for each phase. The display can be programmed to scroll through the sequence of programmed display items in any sequence. Meter shall have non-volatile memory such that in the event of line voltage interruption, the meter circuit immediately transits to a mode of orderly shut down and data gets preserved. When power is restored data collection resumes. Meters shall be equipped with communications interface with MODBUSor any other open type of protocol, which permits meters to be read or reprogrammed from remote locations. Maximum demand (MD) indicators if specified, shall process all the three demands kW/kVAR/kVA simultaneously. Demand intervals shall be programmable from 1 minute to 60 minutes in step of one minute. The MD computation may be on block interval / rolling time basis. In addition, demand quantities may be displayed on cumulative/continuous cumulative basis. MD indicators can be reset with the Reset push button or can be programmed to reset automatically at periodic intervals. Meters shall have tamper detection facility. Meters shall detect any possible form of tamper like PT removal/CT reversal etc & shall store Copyright Rolta India Limited. Date: Page 19 of 25

All Rights Reserved. Prepared By: Checked By: Approved By:

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

date/time of tamper and restoration in the meter. Further, it shall have provision of seals. Meter shall also have a feature for working satisfactorily in absence of neutral. Electro mechanical types of meters are also acceptable and its type shall be subject to approval. Recording Instrument: Recording instruments shall be rectangular in shape and shall be suitable for semi-flush mounting on panels with only flanges projecting. They shall be of drawout type for chart replacement and suitable for back connection. Provision shall be made for automatic shorting of CT leads,when the recorder is drawout. Watt and VAR recorders shall be suitable for recording of unbalanced loads in 3 phase 3 wire circuits. The equipment shall consist of Watt & VAR transmitters (transducers) of output range 0-5 mA, accuracy class 0.5, suitable for the input quantities from specified CTs & VTs. The Watt & VAR transmitters shall be either separately mounted or integral with the recorder and they may be used to feed the summating indicator Watt/VAR meter.

3.7

Fuses

Fuses generally shall be of the HRC cartridge fuse- link type having adequate rupturing capacity.

3.8

Terminal Block

Terminal blocks shall be colour coded 650 V grade, 10 Amps rated, one piece moulded, complete with insulated barriers, stud type terminals, washers nuts and lock nuts and identification strips. Markings on the terminal strips shall correspond to wire numbers on the wiring diagrams. Terminal blocks for CT and PT secondary leads shall be provided with test links and isolating facilities. Also CT secondary leads shall be provided with short circuiting and earthing facilities. Not more than one wire shall be terminated on either side of a terminal.When it is required to terminate two or more wires on the same terminal, the wires shall be terminated on adjacent terminals and these terminals shall be shorted using suitable shorting links.At least 10% spare terminals shall be provided on each panel and these spare terminals shall be uniformly distributed on all terminal blocks.

Copyright Rolta India Limited. All Rights Reserved. Prepared By:

Date:

Checked By:

Page 20 of 25 Approved By:

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

This shall include 10% spare terminals for inter cubicle wiring also. All spare contacts and terminals of the panel mounted equipment and devices shall be wired to terminal blocks.Protective covers of transparent plastic for placing over live parts of the terminal blocks shall be provided.Unless otherwise specified, terminal blocks shall be suitable for connecting the following conductors of the PURCHASERS cables on each side : a) All circuits except CT : Minimum of two 2.5 mm2 circuits copper b) CT circuits : Minimum of four 2.5 mm2 copper There shall be a minimum clearance of 250 mm between the first row of terminal blocks and the associated cable gland plate. Also the clearance between two rows of terminal blocks shall be a minimum of 150 mm. Moulding terminals shall be self extinguishing or resistant to flame propogations, substantially non-hygroscopic and shall not carbonise when tested for tracking. The insulation between any terminal & framework or between adjacent terminals shall withstand a test of 2 kV for one minute. The mouldings shall be mechanically robust to withstand handling while making terminations.Suitable barriers shall be provided between two terminals connected to different voltage supplies. 3.9 Cable Box and Gland: Cable boxes/pot heads and glands shall be provided in the switchgear, if called for in Data Sheet Cable boxes/pot heads for power cables shall be suitable for stranded aluminium or copper conductor, PVC insulated cables or cross-linked polyethelene insulated cables, as specified in Data Sheet.Cable terminating boxes along with termination kits shall be supplied complete with all accessories (including epoxy resin compound) required for terminating PURCHASERS cables shall be furnished by the VENDOR. The accessories shall include but not be limited to compound, tapes, binding wires, filters, armour clamps, brass gland etc.Connecting leads of adequate size with terminal clamps for connecting cable box terminals to switchgear equipment terminals shall be included. Cable box shall withstand the short circuit rating of the switchgear. Necessary number of cable glands shall be provided for terminating auxiliary power and control cables.Glands shall be of heavy duty brass castings, machine finished and complete with check nut, washers, neoprene compression ring etc.Whenever core balance C.T. is mounted outside the panel, sufficiently long pigtail shall be provided to enable the pig tail to be threaded through the core balance C.T. before connecting to earth. 3.10 Accessories: Suitably rated MCB(s) shall be used for protection of auxiliary supplies. Copyright Rolta India Limited. Date: Page 21 of 25

All Rights Reserved. Prepared By: Checked By: Approved By:

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

3.11 Heater: Each switchgear cubicle shall be equipped with heaters to prevent moisture condensation within the enclosure and shall be complete with switch fuse unit for power supply. Heaters and switch fuse units shall be suitable for continuous operation on 240V, 1 phase, 50 Hz AC supply.Plug Point A 240V, 1 phase, 50 Hz. AC plug point shall be provided in the interior of each cubicle with an on-off switch for connection of hand lamps.Interior Illumination.Metering/wiring cubicle shall be provided with CFL fitting for illumination. 3.12 Spare Parts: A list of spares is provided in the Data Sheet. Whether included in the VENDORsrecommendations or not, unit prices of all the items in this list shall be quoted together with their suggested quantities for three (3) years satisfactory operation along with the catalogue numbers.

3.13

Connections and Wiring

3.13.1 Power Connections The switchgear shall be provided with the following items for power connections: a) Compression-type lugs and supports for the incoming and outgoing cables. b) Sufficient space for stress cones. c) Removable plate (non-magnetic for single conductor) where cable entry is from the top of the switchgear. 3.13.2 Control Wiring and Connections Control wiring shall be 2.5 sqmm minimum, single conductor stranded copper (5/7 cores) having 1.1KV flame-retardant insulation. Connections to the Owners external circuits shall be brought to pressure type terminal blocks with marking strips. 3.14 Nameplates The following nameplates shall be provided: a) Rating nameplate for each switchgear unit showing as a minimum: Tag No., rated voltage, rated current, interrupting current, frequency, manufacturer's Copyright Rolta India Limited. Date: Page 22 of 25

All Rights Reserved. Prepared By: Checked By: Approved By:

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

shop reference and drawing number. b) Circuit identification nameplate on front of each cell. c) Device identification nameplates for instruments, meters, relays, fuses etc. d) Main identification nameplate for the switchgear assembly. e) High voltage warning nameplate for the switchgear assembly. 3.15 Finish Metal surfaces shall be cleaned, given rust-inhibiting treatment, primed and painted with a minimum of two coats of finish paint. Paint finish color shall be BS 4800 Grey shade 10A3.

3.16

Field Assembly Equipment shall be shipped completely assembled whenever feasible. When equipment must be shipped in sections, materials and instructions for field assembly shall be provided. Terminal strips and wiring diagrams shall be provided to facilitate reconnection of wiring at the shipping splits with each wire and terminal identified with permanent markers.

3.17 Painting Rust and scale shall be removed by pickling with dilute acid followed by washing with running water, rinsing with slightly alkaline hot water and drying. Oil, grease, dirt and swarf shall be thoroughly removed by emulsion cleaning. All sheet steelwork shall be phosphated in accordance with the standard procedures (seven-tank process) and conforming to relevant standard for phosphating iron and steel. After phosphating, thorough rinsing shall be carried out with clean water, followed by final rinsing with dilute dichromate solution and oven drying.The phosphate coating shall be sealed by the application of two coats of ready mixed, stoving type primer. The first coat may be flash driedwhile the second coat shall be stoved. After application of the primer, two coats of finishing paint shall be applied, with first coat of paint followed by stoving. The type of paint and paint shade shall be as specified in Data Sheet. Manufacturerrecommendations on use of suitable primer and painting procedure shall be adhered to. Each coat of primer and finishing paint shall be of a slightly different shade to enable inspection of the painting.The final finished thickness of paint film on steel

Copyright Rolta India Limited. All Rights Reserved. Prepared By:

Date:

Checked By:

Page 23 of 25 Approved By:

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

shall not be less than 100 microns, and shall not be more than 150 microns. For painting by electrostatic process the minimum thickness can be 50 microns.Vendor can offer powder coating method as an alternative to the above but this technique shall be fully detailed for approval.Finished painted appearance of equipment shall present an aesthetically pleasing appearance, free from dents and uneven surfaces. If better painting standard is offered the same shall be clearly elaborated in detail. Material not complying with the foregoing requirements are liable to be rejected.

3.18 Tests And Test Reports: All meters and other reference devices used for testing shall have valid calibration Certificate traceable to reputed national laboratories/institutes.Inspection by Purchaser/Engineer will not be carried out unless the vendor confirms that such calibrated equipment are ready for proceeding with the tests.Instruments and gauges to be used for testing and inspection of critical parameters as identified in the specification shall have valid calibration and the accuracy traced to national standards.The VENDOR shall completely assemble, install all the associated equipment including brought out items mounted and wired and test eachcubicle as per relevant standards specified in Data Sheet. Routine tests shall be carried out on completely assembled equipment as per relevant standards specified in Data Sheet.Functional tests shall be carried out to demonstrate the specified control and interlocks.Copies of the test certificates for all brought out items shall be submitted for the PURCHASERS approval before despatch of the switchgear.Bound copies of complete test results as specified in the distribution schedule shall be furnished with the switchgear. These shall include complete reports and results of the routine tests as also certified copies of type tests carried out on equipment of identical design.Oscillographic test records for closing and tripping timings of the breakers shall also be furnished.The VENDOR shall indicate the manufacturers standard routine tests for vacuum contactors. The VENDOR shall completely assemble and test each vacuum contactor to ensure satisfactory working of all component parts and also assembled contactor and submit test certificates. BIDDER shall furnish copies of all type test reports required as per the relevant standards. If required by the PURCHASER/CONSULTANT, any of these type tests shall be conducted by the VENDOR at unit rates for each of

Copyright Rolta India Limited. All Rights Reserved. Prepared By:

Date:

Checked By:

Page 24 of 25 Approved By:

ELECTRICAL SPECIFICATION

33 KV SWITCHGEAR SPECIFICATION

DOC NO. 1001041-S-E-1001-00

the type tests to be furnished in the PRICE SCHEDULE by the BIDDER. Without the type test reports, the BID shall be considered incomplete. 3.19 Drawings and data: As part of the proposal, the VENDOR shall furnish relevant descriptive and illustrative literature on breakers and associated equipment and the following for preliminary study. a) Complete assembly drawings of the switchgear showing plan, elevation and typical section views and locations of cable boxes/pot heads, busbar chamber, metering and relay compartment and terminal blocks for external wiring connections. b) Typical and recommended schematic diagrams for control and supervision of circuit breakers. c) Foundation plan showing location of foundation channels, anchor bolts and anchors, floor plans and openings for cables etc. d) Type test certificates along with oscillograms for breakers of identical design. e) All drawings and data shall be annotated in English. NOTE : Relevant standard control schematic diagrams are enclosed for bidders guidance in estimation of Scope of work involved as regards provision of equipment / devices / wiring etc.

Copyright Rolta India Limited. All Rights Reserved. Prepared By:

Date:

Checked By:

Page 25 of 25 Approved By:

You might also like

- Basic First Aid 0808Document70 pagesBasic First Aid 0808pokiriNo ratings yet

- Cable Calculations - Voltage Drop and Ampacity. LV & MV Armored CablesDocument9 pagesCable Calculations - Voltage Drop and Ampacity. LV & MV Armored CablespokiriNo ratings yet

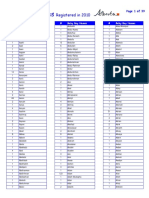

- Baby Boy Names: Registered in 2010Document39 pagesBaby Boy Names: Registered in 2010Arivazhagan ManickamNo ratings yet

- Basic First Aid 0808Document70 pagesBasic First Aid 0808pokiriNo ratings yet

- Calculation For CTs Used in Differential ProtectionDocument7 pagesCalculation For CTs Used in Differential ProtectionpokiriNo ratings yet

- PDMS EquipmentDocument53 pagesPDMS EquipmentPrasanta Kumar Behera100% (2)

- 12 Section Text and NotesDocument39 pages12 Section Text and NotespokiriNo ratings yet

- Thiruppavai Divyadesams EnglishDocument10 pagesThiruppavai Divyadesams EnglishpokiriNo ratings yet

- Thiruppavai Divyadesams EnglishDocument41 pagesThiruppavai Divyadesams EnglishSiva YellampalliNo ratings yet

- Al Wasl2Document3 pagesAl Wasl2pokiriNo ratings yet

- The Middle East's Top 25 Oil & Gas EPC ContractorsDocument14 pagesThe Middle East's Top 25 Oil & Gas EPC ContractorspokiriNo ratings yet

- Load List For B-12-1Document5 pagesLoad List For B-12-1pokiriNo ratings yet

- Abu Dhabi CityDocument1 pageAbu Dhabi CitypokiriNo ratings yet

- PDMS ManualDocument272 pagesPDMS Manual최우혁No ratings yet

- Battery SizingDocument28 pagesBattery SizingpokiriNo ratings yet

- Bus DuctDocument18 pagesBus DuctpokiriNo ratings yet

- CSMDocument10 pagesCSMpokiriNo ratings yet

- Cable Attachment 1-8Document10 pagesCable Attachment 1-8pokiriNo ratings yet

- Power FactorDocument18 pagesPower FactorpokiriNo ratings yet

- Siemens Loher Flameproof & Special Designed MotorsDocument21 pagesSiemens Loher Flameproof & Special Designed Motorspokiri100% (1)

- Load List For B127 Cluster Well PlatformDocument24 pagesLoad List For B127 Cluster Well Platformpokiri100% (1)

- Load List For B-12-1Document5 pagesLoad List For B-12-1pokiriNo ratings yet

- Liodel ATPS6500 Wind Turbine Technical SpecificationsDocument1 pageLiodel ATPS6500 Wind Turbine Technical SpecificationspokiriNo ratings yet

- Barrel Type LED Indicating LampsDocument2 pagesBarrel Type LED Indicating Lampschidambaram kasiNo ratings yet

- Heavy Duty 4 Pole Contactor Maintenance Made EasyDocument4 pagesHeavy Duty 4 Pole Contactor Maintenance Made EasypokiriNo ratings yet

- Ace MCCBDocument4 pagesAce MCCBnicesreekanthNo ratings yet

- Chalmlite Tutorials CompleteDocument80 pagesChalmlite Tutorials Completepokiri75% (4)

- Overcurrent ProtectionDocument3 pagesOvercurrent ProtectionpokiriNo ratings yet

- Electrical TerminologyDocument41 pagesElectrical TerminologypokiriNo ratings yet

- Offshore Design Manual GuideDocument155 pagesOffshore Design Manual GuidealekyaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- AOCGO 2020 CatalogueDocument24 pagesAOCGO 2020 CatalogueSantiagoTenesacaNo ratings yet

- ZL-7901A Intelligent Temperature and Humidity Controller: FeatureDocument8 pagesZL-7901A Intelligent Temperature and Humidity Controller: FeatureBasemNo ratings yet

- Irdh265 365 PDFDocument52 pagesIrdh265 365 PDFmodelador3dNo ratings yet

- Digital Thermometer Ds1620& PicDocument5 pagesDigital Thermometer Ds1620& Picsafet100% (2)

- Kohler LP OM PDFDocument96 pagesKohler LP OM PDFOscar BucciarelliNo ratings yet

- Relay MaterialDocument46 pagesRelay MaterialNagu BandaruNo ratings yet

- 0-Wiring-Conquest 425-D2534-1-13Document505 pages0-Wiring-Conquest 425-D2534-1-13Eric Dirksen100% (1)

- Product CatalogDocument48 pagesProduct CatalogSella KumarNo ratings yet

- 7SJ602 ShortDocument14 pages7SJ602 ShortFarhan ShahNo ratings yet

- Avtron Neutral Grounding ResistorsDocument6 pagesAvtron Neutral Grounding ResistorsRaul CasperNo ratings yet

- AC001 Carrier 30HWC035 Chiller Wiring-30HWADocument12 pagesAC001 Carrier 30HWC035 Chiller Wiring-30HWACelso OtalNo ratings yet

- Manual Woodward 723 PDFDocument166 pagesManual Woodward 723 PDFjarol100% (2)

- EZM-9930 en MDocument48 pagesEZM-9930 en MFawzi AlzubairyNo ratings yet

- Emco DCMT3 en PDFDocument2 pagesEmco DCMT3 en PDFcherif yahyaoui100% (2)

- Data Sheet US - K3G450PB2401 KM88828Document6 pagesData Sheet US - K3G450PB2401 KM88828Jackson WongNo ratings yet

- Irjet V3i6570 PDFDocument4 pagesIrjet V3i6570 PDFArjunNo ratings yet

- User Manual Module HGM400 SeriesDocument30 pagesUser Manual Module HGM400 SeriesRahmat Nur IlhamNo ratings yet

- Series 26NMDocument2 pagesSeries 26NMHassen LazharNo ratings yet

- Design and Construction of Microcontroller-Based Telephone Exchange SystemDocument7 pagesDesign and Construction of Microcontroller-Based Telephone Exchange SystembhanuNo ratings yet

- IoT Based Gas Leakage DetectionDocument24 pagesIoT Based Gas Leakage Detectionakashlogic100% (1)

- SS Instruction Sheet-English-20060505 PDFDocument2 pagesSS Instruction Sheet-English-20060505 PDFstgpereiraNo ratings yet

- Canny Serial Control Manual InglesDocument117 pagesCanny Serial Control Manual InglesBeltran Héctor100% (2)

- Types of Comparator - My Tech InfoDocument6 pagesTypes of Comparator - My Tech Infojitendra jhaNo ratings yet

- RSD6Series Benshaw SSDocument48 pagesRSD6Series Benshaw SSDinhnamsgpNo ratings yet

- PCS-902 X Instruction Manual en Overseas General X R2.02Document578 pagesPCS-902 X Instruction Manual en Overseas General X R2.02Trần Xuân GiangNo ratings yet

- ITAS - 1362706 - 170 KW - INGLESEDocument222 pagesITAS - 1362706 - 170 KW - INGLESEJuan de Dios Romero ChumpitazNo ratings yet

- Viper 600 HF InstallDocument26 pagesViper 600 HF InstallshelterbNo ratings yet

- 12092Document53 pages12092rfcbaccaratNo ratings yet

- Generator ProtectionDocument12 pagesGenerator ProtectionFarrukh IlyasNo ratings yet

- DGT801 TECHNICAL MANUAL V1.3-090108(印刷) PDFDocument108 pagesDGT801 TECHNICAL MANUAL V1.3-090108(印刷) PDFdwilaksmana0150% (2)