Professional Documents

Culture Documents

Asphalt Safety: Fire Prevention and Control

Uploaded by

jarso01Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asphalt Safety: Fire Prevention and Control

Uploaded by

jarso01Copyright:

Available Formats

Texas Department of Insurance Division of Workers Compensation Safety Education & Training Programs

Asphalt Safety

HS05-047A (1-06)

Introduction

Asphalt is a strong adhesive used for road paving, roofing tar, roll-roofing, roofing felt, shingles, pipe covering, floor tile, waterproofing, and many other products and processes. Asphalt is a dark brown or black substance derived from crude oil. It may be a solid, a semi-solid, or a liquid. Other names for asphalt include road tar, road binder, mineral pitch, petroleum pitch, petroleum asphalt, and seal-coating material. Asphalt is often mistakenly confused with tar, coal tar, or pitch because the appearance is similar and the substances may be used interchangeably in many industrial processes. Tar and pitch are derived from coal products that are chemically and physically different. There are two main types of asphalt: straight-run asphalt or asphalt cement and air-blown or oxidized asphalt. Straight-run asphalt is used for paving roads, airport runways, and parking lots. Because of its solid to semi-solid nature, it must first be cut with a solvent to bring it to a more liquid state; this is known as cut-back asphalt. Highway workers are most likely to use straight-run asphalt. Air-blown asphalt has a high softening point and is used primarily in roofing, pipe covering, and similar situations. Millions of tons of asphalt are produced and used every year in the paving and roofing industries. Over a half-million workers are exposed to fumes from asphalt. Health effects from exposure to asphalt fumes can include headache, skin rash, sensitization, fatigue, reduced appetite, throat and eye irritation, cough, and skin cancer. There are currently no specific Occupational Safety and Health Administration (OSHA) standards or directives for asphalt fumes. However, exposures to various chemical components of asphalt fumes are addressed in specific standards for general industry, such as the use of personal protective equipment (PPE).

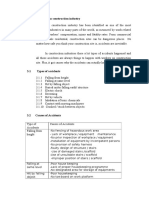

Fire Prevention and Control

Since asphalt products are often stored and handled at elevated temperatures, fire prevention is extremely important. One of the greatest hazards in handling hot asphalt is exposure to a source of ignition. Sparks, electricity, open flames, incandescent material (lighted cigarette), or other possible ignition sources should be prohibited or otherwise strictly controlled in the vicinity of asphalt operations.

Distributors

Asphalt that is applied while at temperatures above flash point is especially vulnerable to combustion. For example, applying a prime coat with a distributor involves using cutback asphalt heated above its flash point. If a fire is initiated at the spray bar it may spread through accumulated asphalt deposits on the distributor chassis and destroy the vehicle. Therefore, asphalt distributors should be kept clean and free from asphalt accumulations. Before spraying begins, the burners must be shut off. If practical, the hot parts of the burner should be permitted to cool. Exterior parts of the distributor truck exhaust systems should be kept clean by wire brushing to remove debris that could ignite and fall in the path of the spray-bar. When spraying is in progress, there is always the danger of a fire starting from a cigarette or match thrown down by a passerby. It is advisable to post a warning with the traffic signs indicating roadwork ahead and that spraying operations are underway. A distributor spray-bar fire can be put out quickly if dealt with in the early stages. The spray-bar must be shut off at the earliest possible moment by closing the spray valve, or, if necessary, by stopping the pump. To help ensure success, the distributor crew should be trained to put out this kind of fire. Dry chemical or carbon dioxide extinguishers should be stored in the cleanest place on the vehicle, preferably in the cab. A second extinguisher should also be available in case the first fails to operate.

Hazards

There are two main hazards associated with asphalt: fire and explosion hazards, and health hazards associated with skin contact, eye contact, and/or inhalation of fumes and vapors.

Asphalt will support combustion if overheated in the presence of an adequate air (oxygen) supply. Some asphalt cements and air-blown asphalts are not combustible until heated above 232 C (450 F). The combustibility of asphalt varies with the type and amount of solvent. Therefore, rapid-curing cut-backs are the most susceptible to combustion because their solvents have flash points near those of gasoline and naphtha. Mediumcuring cutbacks contain solvent with a flash point near that of kerosene. Slow-curing cut-backs contain oil of lower volatility and higher flash point as a solvent, and therefore these cutbacks are the least susceptible to combustion. Asphalt cements and oxidized asphalts require heating to high temperatures for transfer and application. The resultant high temperature materials can cause severe burns, and precautions are necessary to prevent injury. Emulsified and cut-back asphalts may also be heated sufficiently to cause severe burns on contact.

Boots with tops at least 150 mm (6 inches) high and laced without openings. Pants without cuffs which extend over the tops of the boots. Safety shoes at least 15 centimeters (cm) high and laced. Barrier creams and lotions leave a thin film on skin and act as a barrier against skin irritants worn with protective clothing. Long handled sprayers with flexible hoses should be used when emulsified asphalts are applied by hand for tack coats, or when cut-back asphalts are applied by hand for prime coats. First Aid Whenever a person is injured from exposure to asphalt fumes, cold asphalt, or hot asphalt, obtain first aid/medical attention immediately. To prevent the possibility of future medical complications, have the victim examined by a physician even if the injury does not appear to be serious. Asphalt Fumes Move victim to fresh air. Administer oxygen if breathing is difficult. Start artificial respiration if breathing stops. Have victim examined by a physician. Cold Asphalt Remove cold asphalt from skin with waterless hand cleaner [warm mineral oil 43 C (110 F) can also be used]. Wash skin thoroughly with soap and water. Remove contaminated clothing and shower victim at once. Flush out contaminants from eyes for at least 5 minutes with water, lifting upper and lower eyelids occasionally. Have victim examined by a physician. Hot Asphalt Apply cold water or ice pack to asphalt skin burns. If burns cover more than 10 percent of body (about equal to surface of one arm or one half a leg) apply lukewarm water, or warmer if needed to alleviate pain, but heat in the asphalt must be removed as rapidly as possible. Do not remove asphalt from skin.

Personal Protective Equipment

OSHA requires employers to use personal protective equipment (PPE) to reduce employee exposure to hazards when engineering and administrative controls are not feasible or effective. Employers are required to determine all exposures to hazards in their workplace and determine if PPE should be used to protect their workers. If PPE is to be used to reduce the exposure of employees to hazards, according to 29 Code of Federal Regulations (CFR) 1910.132, a written PPE program must be developed and maintained. This program should contain identification and evaluation of hazards in the workplace and if use of PPE is an appropriate control measure; if PPE is to be used, how it is selected, maintained, and its use evaluated; training of employees using the PPE; and vigilance of the program to determine its effectiveness in preventing employee injury or illness. PPE is necessary to protect workers from asphalt burns and irritation. In addition, many of the solvents used to cut asphalt can be absorbed through unprotected skin into the bloodstream, where they can travel throughout the body and cause damage to many different organs. PPE recommended when handling heated asphalt Chemical goggles and a 200 mm (8 inches) minimumsized face shield. Loose clothing in good condition with collars closed and cuffs buttoned at the wrist. Thermally insulated gloves with gauntlets that extend up the arm and worn loosely so that they can easily be flipped off if covered with hot asphalt.

Do not bandage burn. Have victim examined by a physician.

General Dilution Ventilation General dilution ventilation involves flooding a work area with uncontaminated air in an attempt to remove contaminants from the workers breathing zone. The use of fans and blowers set up for this purpose, however, is often not adequate to remove the contaminants. This is generally not the most effective way of removing contaminants from the workers breathing zone, but may be used to supplement local exhaust ventilation. Respiratory Protection While engineering controls are the preferred method for controlling worker exposure to fumes and vapors, respirators should be worn where this is not possible. In selecting the proper respirator, it is important to know all of the hazards to which workers may be exposed. A NIOSH-approved dust respirator will control exposure to asphalt fumes, but will do nothing to protect the worker against exposure to the toxic vapors given off by the solvent in the mix. In situations where vapors are concerned, the minimum requirement would be for a full-face mask respirator with organic vapor and particulate cartridges. Because of the possibility of eye irritation a halfface mask respirator would be inadequate. Improper Use of Respirators is Dangerous The employer must have a written respirator program that takes into account workplace conditions, requirements for worker training, respirator fit testing, and medical exams, as described in OSHA standard 29 CFR 1910.134. Asphalt Safety Reminders When working with any asphaltic material, avoid prolonged contact of the material with skin. Excessive breathing of asphalt materials should be avoided. Wear PPE (heavy work gloves, old clothing, protective shoe, etc.) to protect against asphalt spatters. When chipping or chiseling old blacktop, wear eye protection. Also, dont chisel with a carpenters hammer, because it isnt designed for this type of job and may chip; use a hand-drilling hammer or machinists hammer. Keep all asphalt materials away from high heat. Keep solvent-thinned materials away from open flames. Close containers after each use. Always follow the manufacturers instructions for the product being used. Remember to practice safety, dont learn it by accident.

Safe Work Procedures

Training All workers who can be exposed to asphalt fumes should be trained about hazards and safe work procedures. This training should include specific information about the solvents used in mixing the asphalt. Material Safety Data Sheets (MSDS) should be made available to each employee assigned to work with or near asphalt processes. The MSDS should include specific information on the solvents present in the asphalt mix and should list all pertinent information including flashpoint, boiling point, acute and chronic effects of all chemical ingredients in the solution, recommended PPE, as well as other fire and emergency cleanup information.

Engineering Controls

Substitution The best method of controlling exposure to asphalt fumes and solvent vapors is to substitute a safer asphalt mix. If explosion hazards are a problem in a paving operation, MC-250 may be substituted for RC-250. The flashpoint of the mix is nearly doubled, which means that the mix is less likely to ignite. If the toxicity of the chemical is a problem, the employer may be able to order an asphalt mixture which contains a less toxic solvent (for example, using toluene instead of benzene). Enclosure Enclosing the process where the asphalt is used is not possible in road paving and roofing operations. It may, however, be possible for smaller operations such as pipe covering processes. Mechanization and Automation Certain parts of asphalt processes may be mechanized. For example, stirring asphalt in a tar kettle exposes the worker to asphalt fumes, solvent vapors, and potentially severe burns; mechanical devices can accomplish this task without exposing the employee to such risks. Local Exhaust Ventilation Local exhaust ventilation may be an effective way to control worker exposure to fumes and vapors, particularly in areas where enclosure of the operation is impossible.

This Safety Training Program was published with information from the Jebro Incorporated, National Asphalt Pavement Association, Centers for Disease Control, Occupational Health and Safety Administration, and the Texas Department of Insurance, Division of Workers Compensation and is considered factual at development.

Answers

1. Health effects from exposure to asphalt fumes can include headache, skin rash, sensitization, fatigue, reduced appetite, throat and eye irritation, cough, and skin cancer. 2. The two main hazards associated with asphalt are fire and explosion hazards, and health hazards associated with skin contact, eye contact, and/or inhalation of fumes and vapors. 3. Protective clothing is necessary to protect workers from asphalt burns and irritation. In addition, many of the solvents used to cut asphalt are readily absorbed through unprotected skin into the bloodstream, where they can travel throughout the body and cause damage to many different organs. 4. The MSDS should include specific information on the solvents present in the asphalt mix and should list all pertinent information including flashpoint, boiling point, acute and chronic effects of all chemical ingredients in the solution, recommended PPE, as well as other fire and emergency cleanup information.

Review Questions

1. What are some of the health risks from exposure to asphalt fumes? 2. What are the two main hazards associated with asphalt? 3. Why is it important to wear protective clothing when working with asphalt? 4. What information must the MSDS contain to protect the worker?

Resources

The Texas Department of Insurance (TDI), Division of Workers Compensation (DWC) Resource Center offers a workers health and safety video tape library. Call (512) 804-4620 for more information or visit our web site at www.tdi.state.tx.us. Disclaimer: Information contained in this training program is considered accurate at time of publication.

The Texas Department of Insurance (TDI), Division of Workers Compensation (DWC) E-mail resourcecenter@tdi.state.tx.us or call 1-800-687-7080 for more information.

Safety Violations Hotline

1-800-452-9595

safetyhotline@tdi.state.tx.us

You might also like

- Asphalt Safety and Best Practices: Table AC-1 of Cal/OSHA Code 5155Document7 pagesAsphalt Safety and Best Practices: Table AC-1 of Cal/OSHA Code 5155Olivia BugayNo ratings yet

- Asphalt: Safety Training ProgramDocument6 pagesAsphalt: Safety Training Programmohamad Reza huzainNo ratings yet

- Information Sheet 1 SealantDocument7 pagesInformation Sheet 1 SealantCourei-FxAlcazarNo ratings yet

- Presentation Safety 45 MenitDocument42 pagesPresentation Safety 45 Menithendra headbangerNo ratings yet

- Asphalt HazardDocument1 pageAsphalt Hazardmujahid1137No ratings yet

- Dulux Water BasedDocument7 pagesDulux Water BasedDya PratamaNo ratings yet

- Soldering SafetyDocument2 pagesSoldering SafetyGem Lam SenNo ratings yet

- SDS447 Dulux Trade Diamond Matt Safety Data SheetDocument8 pagesSDS447 Dulux Trade Diamond Matt Safety Data SheetjustinNo ratings yet

- TM 9-3990-206-10 Flatrack M1077/a1 and M1Document260 pagesTM 9-3990-206-10 Flatrack M1077/a1 and M1Advocate0% (2)

- TM 1 1500 204 23 3Document127 pagesTM 1 1500 204 23 3Ahmad FaizNo ratings yet

- 10 TBT 04 Respiratory SystemDocument3 pages10 TBT 04 Respiratory SystemZemran AsherNo ratings yet

- Thermal Ceramics Superwool Coshh SheetDocument6 pagesThermal Ceramics Superwool Coshh Sheetstuart3962No ratings yet

- Castrol Non-Detergent Motor Oil 30Document6 pagesCastrol Non-Detergent Motor Oil 30ΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣNo ratings yet

- Adhesives and Sealants PDFDocument3 pagesAdhesives and Sealants PDFNerinel CoronadoNo ratings yet

- 110006castrol EDGE 5W-30Document6 pages110006castrol EDGE 5W-30amiller1987No ratings yet

- Standard Operating Procedure: AmmoniaDocument6 pagesStandard Operating Procedure: AmmoniaRASHEED YUSUFNo ratings yet

- Msds Sigma Phenguard 930-935-940 (Sigma Phenguard) HardenerDocument8 pagesMsds Sigma Phenguard 930-935-940 (Sigma Phenguard) HardenerkumarNo ratings yet

- Spray Painting, WHSPRO-018 CMDocument6 pagesSpray Painting, WHSPRO-018 CMsanthoshNo ratings yet

- Msds Sigms Alphagen 650Document8 pagesMsds Sigms Alphagen 650kumarNo ratings yet

- Wood Working Information SheetDocument2 pagesWood Working Information SheetTim BladecutterNo ratings yet

- S T T - R P: Afety Oolbox Raining Espiratory RotectionDocument3 pagesS T T - R P: Afety Oolbox Raining Espiratory RotectionKukuh WidodoNo ratings yet

- Safety Equipment and Emergency ProceduresDocument2 pagesSafety Equipment and Emergency ProceduresctcasipleNo ratings yet

- Msds Sigma Ecofleet 530 (Ecol Ha)Document8 pagesMsds Sigma Ecofleet 530 (Ecol Ha)kumarNo ratings yet

- N95 Plus Nuisance Ov/Ozone Relief Features: 2850 Respirator LockerDocument2 pagesN95 Plus Nuisance Ov/Ozone Relief Features: 2850 Respirator LockerLuis Fernando Giraldo OspinaNo ratings yet

- AsphaltDocument2 pagesAsphaltNurNo ratings yet

- Anti Toxic PicklingDocument2 pagesAnti Toxic PicklingGaurav Bedi0% (1)

- Abrasive Blasting Safe Work PDFDocument2 pagesAbrasive Blasting Safe Work PDFamirthraj74100% (1)

- Msds Sigma Alphagen 50 SeriesDocument8 pagesMsds Sigma Alphagen 50 SerieskumarNo ratings yet

- SAFETY INDICATIONS DOCUMENT TITLEDocument3 pagesSAFETY INDICATIONS DOCUMENT TITLETrịnh Minh KhoaNo ratings yet

- Safety in Pathology LaboratoryDocument15 pagesSafety in Pathology LaboratoryMohammed Yousif mzoriNo ratings yet

- Working Safely With Conformal Coatings - A Guide To Safe Working PracticesDocument4 pagesWorking Safely With Conformal Coatings - A Guide To Safe Working PracticesLee HitchensNo ratings yet

- TM 5-3895-369-14Document1,307 pagesTM 5-3895-369-14Advocate100% (1)

- 009 - SafetyDocument6 pages009 - SafetyALP ASLANNo ratings yet

- 03 - Safety PrecautionsDocument3 pages03 - Safety PrecautionsChrisDanger2No ratings yet

- Jet Fuel A & A-1Document7 pagesJet Fuel A & A-1JodyNo ratings yet

- Msds Sigma Alphagen 20 SeriesDocument8 pagesMsds Sigma Alphagen 20 SerieskumarNo ratings yet

- UCON Metalworking Lubricant EPML-577 - MSDS (2015.03.16)Document15 pagesUCON Metalworking Lubricant EPML-577 - MSDS (2015.03.16)Spotamya Öte AlemNo ratings yet

- College Engineering Lab Safety GuideDocument24 pagesCollege Engineering Lab Safety GuideHarry TrumanNo ratings yet

- Thermit PortionsDocument9 pagesThermit PortionsMix MiscevicNo ratings yet

- U2L3.Personal Protective EquipmentDocument5 pagesU2L3.Personal Protective EquipmentNaveen KrishnaNo ratings yet

- OLIN - Curing Agent Easy-Fit ADocument9 pagesOLIN - Curing Agent Easy-Fit ABoyet BaldeNo ratings yet

- Ammonium PerchlorateDocument6 pagesAmmonium Perchloratehyde2520015754No ratings yet

- Caterpillar Model d7f Operators ManualDocument181 pagesCaterpillar Model d7f Operators ManualClifton Jamison88% (8)

- Road Surfacing ReportDocument3 pagesRoad Surfacing Reportkundayi shavaNo ratings yet

- TM 5-3805-261-10 Cat 130G MilDocument272 pagesTM 5-3805-261-10 Cat 130G MilAdvocate100% (2)

- Spray Painting FullDocument10 pagesSpray Painting Fullatul100% (1)

- Shell Dromus Oil B: Safety Data SheetDocument8 pagesShell Dromus Oil B: Safety Data SheetRicky AriefNo ratings yet

- 915a4 1 ManualDocument260 pages915a4 1 Manualchaz derfNo ratings yet

- Msds Sigma Vikote 56 (Sigma Topacryl Finish) (Chrome)Document8 pagesMsds Sigma Vikote 56 (Sigma Topacryl Finish) (Chrome)kumarNo ratings yet

- Hebel AdhesiveDocument7 pagesHebel AdhesiveNathan CoomberNo ratings yet

- Freightliner Con DdecDocument1,898 pagesFreightliner Con DdecPablo Portillo100% (1)

- TM 9 2320 360 20 1Document1,137 pagesTM 9 2320 360 20 1Deen-Paul Zoto100% (2)

- Compressed Air: Toolbox TalksDocument2 pagesCompressed Air: Toolbox TalksmahlasbarlasNo ratings yet

- Light Cycle Oil: Material Safety Data SheetDocument7 pagesLight Cycle Oil: Material Safety Data Sheetkhairil_amrieNo ratings yet

- TM 5 3805 290 23 1Document1,017 pagesTM 5 3805 290 23 1Eduardo100% (1)

- Hi-Stick Spray Paint MsdsDocument6 pagesHi-Stick Spray Paint MsdszayzanNo ratings yet

- Imcasf09 03 PDFDocument7 pagesImcasf09 03 PDFPepe PompinNo ratings yet

- Workplace Vocabulary for Esl Students: With Exercises and TestsFrom EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsNo ratings yet

- Nijukti Khabar 21 - 27 April 2012Document16 pagesNijukti Khabar 21 - 27 April 2012pratidinNo ratings yet

- Assigment 1 Osha UthmDocument10 pagesAssigment 1 Osha UthmInahMisumi100% (1)

- Lecture 12 - NSCA3E - PP - Chap24 - Facility and Equipment Layout and MaintenanceDocument37 pagesLecture 12 - NSCA3E - PP - Chap24 - Facility and Equipment Layout and Maintenancek9vcfxjyjsNo ratings yet

- Use of Steroid OintmentsDocument6 pagesUse of Steroid OintmentsPal KuriaNo ratings yet

- Neuromuscular Co-Ordination: BY: Suman Shaikh DPT 3 Year Cop, JPMCDocument13 pagesNeuromuscular Co-Ordination: BY: Suman Shaikh DPT 3 Year Cop, JPMCAli Mahdi AliNo ratings yet

- Emergency Action Code 2013Document200 pagesEmergency Action Code 2013MiguelNo ratings yet

- Literature ReviewDocument5 pagesLiterature Reviewapi-582477812No ratings yet

- Cfda-Nrega Monitoring and Evaluation ReportDocument87 pagesCfda-Nrega Monitoring and Evaluation ReportAnand SugandheNo ratings yet

- Sample Endorsement Invitation Letter To CandidatesDocument3 pagesSample Endorsement Invitation Letter To CandidatesKarl King EsmeraldaNo ratings yet

- Nur 097 Sas 1 3Document9 pagesNur 097 Sas 1 3gekkonoojiNo ratings yet

- Child AbuseDocument3 pagesChild AbuseUthuriel27No ratings yet

- SenateDocument261 pagesSenateTinsae Mulatu86% (7)

- Facials Handouts NewDocument5 pagesFacials Handouts NewMARIALUPE ESTOQUE100% (1)

- Employers Cited For MIOSHA Violations at Holland Warehouse Totaling $357,000 in Proposed PenaltiesDocument3 pagesEmployers Cited For MIOSHA Violations at Holland Warehouse Totaling $357,000 in Proposed PenaltiesMichigan NewsNo ratings yet

- Fon Unit - 5 Elimination NeedsDocument106 pagesFon Unit - 5 Elimination NeedsAshwathy ThomasNo ratings yet

- FastingDocument36 pagesFastingMaja Anđelković92% (12)

- Science Month Celebration 2018Document3 pagesScience Month Celebration 2018Ra MilNo ratings yet

- Food EssayDocument4 pagesFood Essayapi-253819140No ratings yet

- Clean Premises & Equipment PDFDocument11 pagesClean Premises & Equipment PDFGiabell100% (2)

- Delta-Product - M1304VWCDocument3 pagesDelta-Product - M1304VWCdhruvit_159737548No ratings yet

- Leon Guinto Memorial College Action PlanDocument2 pagesLeon Guinto Memorial College Action Planrhiantics_kram11No ratings yet

- Effects of Processing On Physicochemical Properties and Efficacy of B-Glucan From Oat and BarleyDocument5 pagesEffects of Processing On Physicochemical Properties and Efficacy of B-Glucan From Oat and BarleyCQ SHONo ratings yet

- Factors That Determine Community HealthDocument6 pagesFactors That Determine Community HealthMarz AcopNo ratings yet

- Benefits of GLP Compliance in MalaysiaDocument10 pagesBenefits of GLP Compliance in MalaysiapremasarthyNo ratings yet

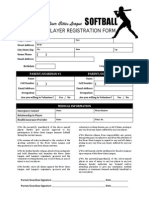

- RCL Softball Registration FormDocument1 pageRCL Softball Registration FormRyan Avery LotherNo ratings yet

- Understanding The RFA ("Relaxed Focused Attention") ProcessDocument5 pagesUnderstanding The RFA ("Relaxed Focused Attention") ProcessFriends of Max SkousenNo ratings yet

- CBR Guidelines 1st Meeting ReportDocument26 pagesCBR Guidelines 1st Meeting ReportJeffery SamuelNo ratings yet

- Ajptr 35003 3 - 7103Document18 pagesAjptr 35003 3 - 7103Naomita JoiceNo ratings yet

- Ginecologic ExaminationDocument24 pagesGinecologic ExaminationPeter HoNo ratings yet

- Rachael Lewkowiez Resume 7 14 17Document3 pagesRachael Lewkowiez Resume 7 14 17api-364212510No ratings yet