Professional Documents

Culture Documents

D&H World's Fair Cars

Uploaded by

staustell92Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D&H World's Fair Cars

Uploaded by

staustell92Copyright:

Available Formats

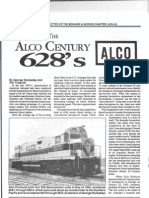

8 THE CALL BOARD

NEWSLETTER

OF THE MOHAWK & HUDSON CHAPTER, N.R.H.S.

March 1991

The Delaware & Hudson's World's Fair Cars

By Dick Barrett, J.R. Williams and Tim Truscott

The Delaware & Hudson purchased six passenger coaches from American Car & Foundry Company in 1939 in the railroad's efforts to capitalize on the popularity of the 1939 New York World's Fair. Consequently, these cars have come to be known as the Delaware & Hudson's "World's Fair" coaches. The coaches, which were built to D&H specifications, were styled by the famed industrial designer Raymond Loewy and carried the numbers 201-206. They were the first light-weight passenger cars to be acquired by the D&H, as well as the last new cars to be purchased by the railroad. They were introduced on "The Laurentian," operating between Albany and Montreal. These were probably the only cars of their type to be built by American Car & Foundry Co. and were constructed at ACF's Berwick, PAplant. Specifications for the cars included a length of 84 ft. 9 in. over buffers, with an exterior width of 10 ft. and an interior width of 9 ft. 5 3/8 in. The distance between the centers of the trucks was 58 ft. 6 in., with the wheelbase of each truck being an even 9 ft. Overall height of the cars from rail to rooftop was 13 ft. 6 in. and the cars weighed 112,920 lbs. without passengers or water. (See Table 1;) The lightweight steel construction was performed using semi-automatic spot welding machinery. Side framing and roof framing were constructed on jigs by spot welding. Side sheets and roof sheets were then attached to their respective framing by means of the automated spotwelding technique. Sides, roof and ends were then assembled and spot welded to form a complete car shell. Four-wheel trucks were constructed with cast steel frames. The 36 in. diameter wheels were equipped with A.S.F. roller bearing units with SKF bearings. During assembly of the wheelsets, the wheels were balanced before mounting on the axles, the treads were ground after mounting and the wheel pairs were once again balanced to provide a maximum ride. Truck-mounted brakes consisted of Simplex cylinder clasp brakes. The coaches were equipped with New York Air Brake Schedule D-22-A brake equipment. The cars were also equipped with National tight lock couplers and Miner friction draft gear and buffers. A very attractive exterior paint scheme was applied which consisted of a dark green body with a soft gray window band. The window band was accented by an orange stripe near its border, with both the gray window band and the stripe following the contour of the distinctive Raymond Loewy semi-circular end windows. The cars also featured circular windows in the vestibule doors, a characteristic of Loewey's design technique. All lettering and numbering, including the well-known D&H monogram, was done in a golden yellow. Three different attractive color schemes were used on the interiors of the cars (See Table 2). These three schemes involved the walls, ceilings, bulkheads, seats, interiors of the shades and flooring. In addition, soft gray and mahogany red colors were used in the vestibules of the cars, while the wash-

D&H Coach #202, one of the "World's Fair Cars" built for the Delaware & Hudson in 1939 by American Car & Foundry Co. at their Berwick, PA, car works. The cars were painted dark green with a soft gray window band area. An orange stripe accented the edge of the window band with numbers and letters in a golden yellow. (Photo collection of the authors)

March 1991

NEWSLETTER

OF THE MOHAWK & HUDSON CHAPTER, N.R.H.S. many areas of the cars. Marlite, a tile-like material of the time, was used as wainscoating in the lavatories. Black Micarta, a plastic-like material produced by the Westinghouse Co., was used as window capping on all windows. Large luggage racks running the full length of the car were constructed of satinfinish aluminum. In addition, each car had a luggage locker at one end for the stowage of heavier luggage. This locker was located in the restroom end of the cars. Interior lighting consisted of a combina-

THE CALL BOARD 9

room fixtures were of a "sun tan" color. Pantasote shades which were gray on their exterior matched the gray panel of the exterior of the cars, giving a modem effect. The color schemes on the bulkheads was divided into two sharply contrasting panels. The inner panel carried through to the ceiling while the outer panel was continuous with the side wall. The floor covering consisted of a simple geometric design of inlayed linoleum in two schemes. Materials which were considered to be the most modem at the time were utilized in

Detail of vestibule area of lightweight streamlined "World's Fair Car" showing semi-circular end window (for restroom) with gray window band curving around it and round "porthole" window in vestibule door. These features were virtual trademarks of industrial designer Raymond Loewy. Note tightlock coupler and folding steps with trap. (Photo collection of the authors)

tion of direct and indirect lighting, with the indirect lighting and air conditioning ducts involving a common center ceiling fixture running the length of the car. Indirect lighting derived from this aluminum lacquered light trough, which contained 64 thirtywatt Lumiline lamps. The louvers of the air ducts were trimmed with a bright red. Direct lighting was provided by 38 forty-watt Safety circular ceiling lights with double prismatic lenses. One of these light fixtures was located over each double seat, while two of them were located in the passageways and one in the men's room. The women's room used column light fixtures. The vestibule lights were Safety units with semaphore lenses. The total lighting load in the car was 3,640 watts. All of the cars had 64-\'olt DC electrical systems deriving their power from truckmounted Spicer drives with half of the cars powered by 20 kw General Electric generators and the other half equipped with 20 kw Safety Genemotors. The storage battery equipment consisted of 50 cells of batteries with a capacity of 510 amp. hrs. at 64 volts. An unusual feature of the battery compartment was the balanced door, which would swing underneath when open; no part of the door would come closer than approximately 6 112 in. to the third rail in electrified yards. All six of the cars were. air conditioned with seven-ton capacity electro-mechanical units. Three of the cars were outfitted with General Electric equipment, while the other three had Safety equipment. Interior temperature regulation was provided by Vapor Corp. control systems. Supplementing the air-conditioning system were four fans behind bulkhead grilles exhausting to the exterior. Double window sash manufactured by O. M. Edwards Co. was used, with the inner sash being 114 in. safety glass to protect passengers. The inner sash was hinged to facilitate window cleaning. Activated alumena was used between the sash to absorb moisture from condensation. In order to provide a comfortable interior temperature year round, the cars were well insulated. Two inches of insulation was used in the roof, sides and ends, while 1 1/2 inches of insulation was used in the floor. The design of the toilet facilities was unusual for the time in that all of the pipes and fittings were concealed. The space under the wash stands was enclosed with the waste paper towel receptacle built into this space; this was apparently a novel idea at the time. In conjunction with the acquisition of

10 THE CALL BOARD

NEWSLETTER

OF THE MOHAWK & HUDSON CHAPTER, N.R.H.S.

March1991

Table 1.

Dimensions & Weights of D&H "World's Fair" Coaches

Length over buffers, uncoupled Length over coupler, putting faces Truck wheelbase Truck centers Width over side posts Width inside Height, rail to floor Height, rail to top of roof Weight, light, total Weight of one truck, without generator drive Weight of truck with Spicer drive 84 ft. 9 in. 84 ft. 3 in. 9 ft. 0 in. 58 ft. 6 in. 10 ft. 0 in. 9 ft. 53/8 in. 4 ft. 33/4 in. 13 ft. 6 in. 112,920 Ibs. 18,140Ibs. 18,800Ibs.

the "World's Fair" coaches, the Delaware & Hudson rebuilt two diner-lounge cars, No. 151 and No. 152, for use on the "Laurentian." These cars, which were rebuilt at Colonie, wore a Raymond Loewyinspired paint scheme which matched the 1939 "World's Fair" cars and had a contemporary interior design consistent with them. The Mohawk & Hudson Chapter owns the only known remaining "World's Fair" coach, No. 203. This car, which was discovered on a weed-grown siding in Vermont a few years ago, will undergo refurbishment soon. References : D&H Lightweight Coaches for the "Laurentian", Railway Age, Vol. 107, No. 22, November 25, 1939, pgs. 812-816. D&H Lightweight Coaches, Railway Mechanical Engineer, January, 1940, pgs. 820.

View of restroom end of interior of 200-series D&H cars showing luggage locker and passageway at restroom-end of car. Three different attractive color schemes were used on the interiors of the cars involving the walls, ceilings, bulkheads,seats, interiors of the shades and flooring, as shown in Table 2. (Photo collection of the authors)

View looking through car away from restroom end. Note aluminum luggage racks, round incandescent light fixtures for direct lighting and combination air conditioning/indirect lighting fixture running the length of the ceiling. (Photo collection of the authors)

March 1991

NEWSLETTER

OF THE MOHAWK & HUDSON CHAPTER, N.R.H.S.

THE CALL BOARD 11

Table 2.

Color Schemes for Interiors

Location

Ceiling , Bulkhead panels

Scheme No.1

Pale yellow Silver opalescence & moss green Various tones & shades of moss green Soft gray & cedar rose Red & yellow Beige

Scheme No.2

~ale yellow Silver opalescence & delft blue Various tones & shades of delft blue Soft gray & cedar rose Dusty rose Beige

Scheme No.3

Suntan Rose opalescence & apple green Various tones & shades of apple green Mahogany rose & Moorish green Yellow & autumn red Beige

. Walls, pier panels, dace and Pantasote curtains Seats

Color accents Headrests

One of the D&H "World's Fair Cars" on the transfer table during construction at A.C.F.'s Berwick, PA, carworks. Note the lightweight welded construction, the curved framework for the roof ends and the opening in the roof on the restroom end (left end) where the air conditioning equipment will be installed.

You might also like

- Bub GB LyedaaaambajDocument245 pagesBub GB LyedaaaambajBrankoSalvari100% (1)

- C&NW RS36 HO Scale ModelDocument12 pagesC&NW RS36 HO Scale ModelpwmvsiNo ratings yet

- HK 450Document31 pagesHK 450Julian PascuNo ratings yet

- Racing Gas Engine: Building A Twin CylinderDocument12 pagesRacing Gas Engine: Building A Twin Cylinder2n Tv100% (1)

- Hahn MethodDocument2 pagesHahn MethodLucianNo ratings yet

- 58 Pioneer Zephyr 1934Document6 pages58 Pioneer Zephyr 1934Martin J.No ratings yet

- Learjet 45 Pilot Traning Manual Volumen 2Document539 pagesLearjet 45 Pilot Traning Manual Volumen 2Agustin Bernales88% (8)

- Baltimore Harbor DistrictDocument0 pagesBaltimore Harbor DistrictbuchkasperNo ratings yet

- The Walschaerts Valve GearDocument2 pagesThe Walschaerts Valve Gearstaustell92No ratings yet

- The Walschaerts Valve GearDocument2 pagesThe Walschaerts Valve Gearstaustell92No ratings yet

- Tales of Battle CreekDocument177 pagesTales of Battle CreekTaylor A. Warsop100% (1)

- A Guide to Model Locomotives - A Collection of Vintage Articles on the Design and Construction of Model Trains and RailwaysFrom EverandA Guide to Model Locomotives - A Collection of Vintage Articles on the Design and Construction of Model Trains and RailwaysNo ratings yet

- Coversion of Marklin 3709 BR 85 Steam LocomotiveDocument4 pagesCoversion of Marklin 3709 BR 85 Steam Locomotivexxl2damaxNo ratings yet

- 52MRH14 06 Jun2014 LDocument135 pages52MRH14 06 Jun2014 Latsfr100% (1)

- Round The Bend... : Folding Metal in Loco Construction Folding Metal in Loco ConstructionDocument52 pagesRound The Bend... : Folding Metal in Loco Construction Folding Metal in Loco ConstructionFombiNo ratings yet

- Getting Started in Proto 87Document48 pagesGetting Started in Proto 87peNo ratings yet

- Gate of Edoras Gate TemplateDocument7 pagesGate of Edoras Gate TemplatepopedopeNo ratings yet

- Model Railroader - November 2021 (-Model Railroader) (Z-Library)Document76 pagesModel Railroader - November 2021 (-Model Railroader) (Z-Library)akshatmondal2009No ratings yet

- Floor ManualDocument35 pagesFloor ManualGihan ChathurangaNo ratings yet

- Welding Amateurshandbook00phinDocument78 pagesWelding Amateurshandbook00phincarlossegoviaNo ratings yet

- Grinding Machinery GuideDocument472 pagesGrinding Machinery Guidetm100% (1)

- Grade 9 ICT Network Configuration GuideDocument15 pagesGrade 9 ICT Network Configuration GuideMark Anthony Nieva RafalloNo ratings yet

- 1099935205four SpeedDocument6 pages1099935205four SpeedchzhptopNo ratings yet

- B&O Railroad North Vernon ArticleDocument6 pagesB&O Railroad North Vernon ArticlewicksjrNo ratings yet

- Hoccokhi - VN Bai Tap Tu Hoc Catia P1editDocument10 pagesHoccokhi - VN Bai Tap Tu Hoc Catia P1editKiệt LêNo ratings yet

- Transportation System, Analysis and Modelling (CE-632) : Carried Out by Group-3Document15 pagesTransportation System, Analysis and Modelling (CE-632) : Carried Out by Group-3Naman Kumar100% (2)

- Very Much ImprovedDocument5 pagesVery Much ImprovedAndy LNo ratings yet

- The Development of Modern Steam 1: Andre Chapelon and His Steam LocomotivesDocument16 pagesThe Development of Modern Steam 1: Andre Chapelon and His Steam LocomotivesJohann Nunweiller100% (1)

- Rail Engineering 101Document131 pagesRail Engineering 101Lee WebbNo ratings yet

- Pennsylvania Flyer Ready-To-Run Train Set Owner's ManualDocument20 pagesPennsylvania Flyer Ready-To-Run Train Set Owner's ManualFrank SchipaniNo ratings yet

- MRH11 05 May2011 PDFDocument115 pagesMRH11 05 May2011 PDFDarius GussoNo ratings yet

- The 1953 Paxton Phoenix Brooks Stevens Designed Steam Car Fiberglass Bodied PrototypeDocument14 pagesThe 1953 Paxton Phoenix Brooks Stevens Designed Steam Car Fiberglass Bodied Prototypetzababagita936No ratings yet

- Electronics QuestionnaireDocument4 pagesElectronics QuestionnaireRenie FedericoNo ratings yet

- MAY 2023 Walthers New Product Announcement PDFDocument7 pagesMAY 2023 Walthers New Product Announcement PDFColin 't HartNo ratings yet

- Hospital Building Civil ProjectDocument128 pagesHospital Building Civil ProjectArun Ragu100% (6)

- Prices RoundhouseDocument8 pagesPrices RoundhouseFrancisco FerrandoNo ratings yet

- Kickout TraditionalDocument28 pagesKickout TraditionalNelson TinocoNo ratings yet

- DL&W Scranton Yard and ShopsDocument3 pagesDL&W Scranton Yard and Shopsstaustell92100% (1)

- Complete Checklist for Manual Upgrades to Oracle Database 12c R1Document27 pagesComplete Checklist for Manual Upgrades to Oracle Database 12c R1Augustine OderoNo ratings yet

- ECoS 2 Handbuch ESUKG en User Manual Edition I February 2010 EbookDocument48 pagesECoS 2 Handbuch ESUKG en User Manual Edition I February 2010 Ebookmodeltog_tossenNo ratings yet

- Green Finance For Green GrowthDocument24 pagesGreen Finance For Green GrowthSreejith BhattathiriNo ratings yet

- Model Railroader 1954-03 - U.P. 4-8-8-4 Big Boy 1200 DpiDocument1 pageModel Railroader 1954-03 - U.P. 4-8-8-4 Big Boy 1200 DpiNickiedeposieNo ratings yet

- Polly Catalogue Oct 2013Document100 pagesPolly Catalogue Oct 2013Stephanie BeckNo ratings yet

- Central Station Realizing A VisionDocument129 pagesCentral Station Realizing A VisionjaayersmanNo ratings yet

- Selkirk's Last MohawkDocument1 pageSelkirk's Last Mohawkstaustell92No ratings yet

- The Last of The D&H Commuter TrainsDocument3 pagesThe Last of The D&H Commuter Trainsstaustell92No ratings yet

- East Broad Top Study 1990Document170 pagesEast Broad Top Study 1990jhfriedmNo ratings yet

- Albany Union Station L&RP No. 12 Jan. - Feb. 1988Document14 pagesAlbany Union Station L&RP No. 12 Jan. - Feb. 1988staustell92100% (1)

- Braintree Marshfield RRDocument1 pageBraintree Marshfield RRsdNo ratings yet

- March 08 Logging Town 25 North Part 2Document2 pagesMarch 08 Logging Town 25 North Part 2api-190819948No ratings yet

- Engineering Vol 72 1901-11-22Document32 pagesEngineering Vol 72 1901-11-22ian_newNo ratings yet

- Railwaylocomotiv 36 NewyuoftDocument426 pagesRailwaylocomotiv 36 NewyuoftKrishna VamsiNo ratings yet

- Magneto Ignition SystemsDocument20 pagesMagneto Ignition SystemsSteve FoleyNo ratings yet

- Kertas A3 - Freight-Lorry-Jdw 2Document3 pagesKertas A3 - Freight-Lorry-Jdw 2Pemesinan SMK Migas CepuNo ratings yet

- The World Commuter Great Journeys by TrainDocument400 pagesThe World Commuter Great Journeys by TrainMuluken MesfinNo ratings yet

- United Traction Co. Last Trolley Rides August 10, 1946Document2 pagesUnited Traction Co. Last Trolley Rides August 10, 1946staustell92100% (1)

- Lionel Catalogue 2002Document8 pagesLionel Catalogue 2002Monica Monica MonicaNo ratings yet

- Ariel 6Document20 pagesAriel 6raleigh_bsa0% (1)

- Lucas Mag SpecsDocument7 pagesLucas Mag SpecsThunderbird3No ratings yet

- Ubrass InstructionsDocument4 pagesUbrass InstructionsBenito SilvaNo ratings yet

- The Road To ParadiseDocument40 pagesThe Road To ParadiseBob Diamond100% (1)

- FMS-L7R Chassis Assembly GuideDocument5 pagesFMS-L7R Chassis Assembly GuideWalter R. FriggiNo ratings yet

- Rewinding A BLDC MotorDocument22 pagesRewinding A BLDC MotorUday WankarNo ratings yet

- FasTrack Modular Railroad Manual Ver 2Document45 pagesFasTrack Modular Railroad Manual Ver 2riofelizNo ratings yet

- Scratchbuilding Concrete Bridge PiersDocument9 pagesScratchbuilding Concrete Bridge PiersrwaidaabbasNo ratings yet

- The Norris Locomotive Works: A Forgotten Industrial Giant of PhiladelphiaDocument4 pagesThe Norris Locomotive Works: A Forgotten Industrial Giant of PhiladelphiaHarry KyriakodisNo ratings yet

- Lucas Generator Troubleshooting GuideDocument7 pagesLucas Generator Troubleshooting GuideepicenterrulezNo ratings yet

- Montreal-New York VHSR Prefeasibility Study 1985Document146 pagesMontreal-New York VHSR Prefeasibility Study 1985EmpireCorridorNo ratings yet

- Commuter Route Alternatives & Sweeney LetterDocument2 pagesCommuter Route Alternatives & Sweeney Letterstaustell92No ratings yet

- Slingerlands D&H StationDocument1 pageSlingerlands D&H Stationstaustell92No ratings yet

- United Traction Co. Last Trolley Rides August 10, 1946Document2 pagesUnited Traction Co. Last Trolley Rides August 10, 1946staustell92100% (1)

- The Foibles of Early DieselsDocument1 pageThe Foibles of Early Dieselsstaustell92No ratings yet

- United Traction Co. Snow SweepersDocument4 pagesUnited Traction Co. Snow Sweepersstaustell92No ratings yet

- A Winter InterludeDocument1 pageA Winter Interludestaustell92No ratings yet

- S&HR Where Were You?Document2 pagesS&HR Where Were You?staustell92100% (2)

- United Traction Co. Trolley Last Day of Operation August 31, 1946Document1 pageUnited Traction Co. Trolley Last Day of Operation August 31, 1946staustell92No ratings yet

- Castleton Cut-Off of The New York CentralDocument2 pagesCastleton Cut-Off of The New York Centralstaustell92100% (1)

- United Traction Co. 301Document3 pagesUnited Traction Co. 301UnitedTractionCoNo ratings yet

- Albany Union Station L&RP No. 12 Jan. - Feb. 1988Document14 pagesAlbany Union Station L&RP No. 12 Jan. - Feb. 1988staustell92100% (1)

- Alco Nothing Serious, You KnowDocument3 pagesAlco Nothing Serious, You Knowstaustell92No ratings yet

- The New York Central's Schenectady Detour ProjectDocument1 pageThe New York Central's Schenectady Detour Projectstaustell92No ratings yet

- Railroad Historical Articles ListDocument2 pagesRailroad Historical Articles Liststaustell92No ratings yet

- Testing The Alco HaulicsDocument3 pagesTesting The Alco Haulicsstaustell92No ratings yet

- The D&H BuildingDocument5 pagesThe D&H Buildingstaustell92No ratings yet

- D&H Colonie ShopDocument7 pagesD&H Colonie Shopstaustell92100% (1)

- West Albany's Last Steam Locomotive The 5270Document4 pagesWest Albany's Last Steam Locomotive The 5270staustell92No ratings yet

- The Century Mark A Century Later NYC 999Document3 pagesThe Century Mark A Century Later NYC 999staustell92No ratings yet

- D&H Albany MainDocument3 pagesD&H Albany Mainstaustell92No ratings yet

- D&H Colonie Shop Conversion For ChallengersDocument2 pagesD&H Colonie Shop Conversion For Challengersstaustell92No ratings yet

- Albany Union Station L&RP No. 12 Jan. - Feb. 1988Document14 pagesAlbany Union Station L&RP No. 12 Jan. - Feb. 1988staustell92100% (1)

- Alco Century 628'sDocument5 pagesAlco Century 628'sstaustell92100% (1)

- The Last of The D&H Commuter TrainsDocument3 pagesThe Last of The D&H Commuter Trainsstaustell92No ratings yet

- United Traction Co. Snow SweepersDocument4 pagesUnited Traction Co. Snow Sweepersstaustell92No ratings yet

- 220 KV GSS, HeerapuraDocument56 pages220 KV GSS, Heerapurapikeshjain33% (3)

- User Home - MoneyEasilyDocument1 pageUser Home - MoneyEasilyEbenezer NyantakyiNo ratings yet

- Top 145 Database Terms DictionaryDocument13 pagesTop 145 Database Terms DictionaryUnais_No ratings yet

- Slabs Are Plate Elements Forming Floors andDocument5 pagesSlabs Are Plate Elements Forming Floors andyasas89No ratings yet

- MCQ - QuestionsTM P-1 PDFDocument8 pagesMCQ - QuestionsTM P-1 PDFRislan MohammedNo ratings yet

- Occupant Manikin Introduction: 95th Percentile Male Driver ModelDocument9 pagesOccupant Manikin Introduction: 95th Percentile Male Driver ModelarstjunkNo ratings yet

- Unix For Beginners - SLDocument220 pagesUnix For Beginners - SLPavan VasanthamNo ratings yet

- Transistor InfoDocument3 pagesTransistor InfoErantha SampathNo ratings yet

- Communication in AfricaDocument5 pagesCommunication in AfricaJaque TornneNo ratings yet

- Aztech+700WR-3G User ManualDocument57 pagesAztech+700WR-3G User Manualkero_the_hero67% (3)

- Lets Play BingoDocument17 pagesLets Play BingoRosana SanchezNo ratings yet

- Monocrystalline - 50Wp - 200Wp: 50W - 200W 17.20V - 30.10V 27.5A - 7.85A 21.10V - 36.10V 2.95A - 8.34ADocument2 pagesMonocrystalline - 50Wp - 200Wp: 50W - 200W 17.20V - 30.10V 27.5A - 7.85A 21.10V - 36.10V 2.95A - 8.34ARia IndahNo ratings yet

- Manual, contact info and schematic for GSM moduleDocument10 pagesManual, contact info and schematic for GSM modulethaiNo ratings yet

- Built-In Exceptions in PythonDocument6 pagesBuilt-In Exceptions in PythonUjwala BhogaNo ratings yet

- Machine TimeDocument11 pagesMachine TimeFRANCIS THOMASNo ratings yet

- LCD panel and module replacement parts for saleDocument1 pageLCD panel and module replacement parts for saleValeria bolañosNo ratings yet

- Wireless DoorbellDocument20 pagesWireless Doorbellmujahed1987No ratings yet

- Tomtom Device ForensicsDocument5 pagesTomtom Device ForensicsSwaroop WaghadeNo ratings yet

- Online School Management System Integrated With Accounting Management SystemDocument24 pagesOnline School Management System Integrated With Accounting Management SystemKIRUTHIKA SNo ratings yet

- Block Out TimeDocument3 pagesBlock Out TimeschumangelNo ratings yet

- Waterfall Model - The Original Software Development Process ModelDocument3 pagesWaterfall Model - The Original Software Development Process ModelmushfiqNo ratings yet

- Certification Authorities Software Team (CAST) Cast 10Document8 pagesCertification Authorities Software Team (CAST) Cast 10Anastasia SuckallahNo ratings yet