Professional Documents

Culture Documents

SOP Gas Cutting and Heating .

Uploaded by

aarunsnair0 ratings0% found this document useful (0 votes)

2K views1 pagePersonal Protective Equipment (PPE) Required Safety helmet Safety Goggle Hand Gloves (leather) Safety Shoe. Respiratory Protection Wear Aprons Risk Analysis : Toppling of cylinders,Fire and Explosion, Fumes, Burn injury.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPersonal Protective Equipment (PPE) Required Safety helmet Safety Goggle Hand Gloves (leather) Safety Shoe. Respiratory Protection Wear Aprons Risk Analysis : Toppling of cylinders,Fire and Explosion, Fumes, Burn injury.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2K views1 pageSOP Gas Cutting and Heating .

Uploaded by

aarunsnairPersonal Protective Equipment (PPE) Required Safety helmet Safety Goggle Hand Gloves (leather) Safety Shoe. Respiratory Protection Wear Aprons Risk Analysis : Toppling of cylinders,Fire and Explosion, Fumes, Burn injury.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 1

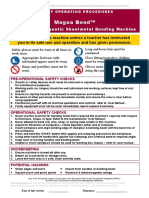

Safe Operating Procedure

GAS CUTTING & HEATING OPERATIONS

Personal Protective Equipment (PPE) Required

Safety helmet Safety Goggle Hand Gloves (Leather) Safety Shoe. Respiratory Protection Wear Aprons Risk Analysis :

Toppling of cylinders ,Fire & Explosion , Fumes, Burn injury.

Safety Instruction : 1.Shift cylinders by means of trolleys only/Cylinder carts equipped with a cylinder restraint, such as a chain or strap, should be used for all transporting of compressed gas cylinders. 2.Ensure that safety cap is in position. 3. Flash Back Arrestor must be used to prevent back flow. 4.Before connecting a regulator to a cylinder valve, the valve shall be opened slightly and closed immediately(Cracking)- to clear the valve of dust . The valve shall be opened while standing to one side of the outlet, never in front of it 5. A fuel-gas cylinder valve shall never be cracked near other welding work or near sparks, flame or other possible sources of ignition 6. Before a regulator is removed from a cylinder valve, the cylinder valve shall always be closed and the gas released from the regulator. 7. check all gas line connections for leakage by using soapy water 8. Hammer or wrench shall not be used to open cylinder valves 9. Never Interchange the hoses: Red for fuel-gas hose/ green or black for oxygen hose. oxygen inlet of the blowpipe shall be identified with the letter 0 or using a blue coloured identification Fuel gas inlet shall be marked with the following letters to indicate the particular gas for which the blowpipe has been designed: A: Acetylene, C: Coal Gas, H: Hydrogen, M: Methane , L: LPG blowpipe is designed for use with more than one fuel gas inlet shall be marked with a red colour 10.Hose shall not be crimped or kinked. Hose shall not be bent or otherwise deformed to control the pressure. 11.After connecting cutting apparatus each gas shall be allowed to flow through its respective hose separately for a few seconds so as to purge the hose. 12. Prior to start Ensure the Flammable materials are cleared & proper housekeeping operation carried out and after completion of the job ensure molten metals are not left in place. 13. Cover floor and wall openings of the work site to prevent hot sparks from entering walls or falling beneath floors or to a lower level. 14.Protect the heating burners from heat / provide heat retardant protection on the hose joint( minimum 500mm away from last burner). 15. Position the heating burner in such a way that it will not make the hose joint heated up while heating the job. 16.Open the Fuel gas slowly and ignite the gas with a spark lighter then open oxygen valve and adjust the flame. 17. On completion of work close Oxygen valve first then close the Fuel valve . 18. Display Empty or MT on used cylinders. 19. Display HOT surface dont Touch on the Job 20. Use heat retardant clothes(sleeves, aprons, Leather hand Gloves, safety shoes, safety helmet & goggles to protect from burn injury) to prevent Burn injury. 21. Ventilation of the work site, either through local or general exhaust ventilation, should be adequate for the work performed. 22.Fume extractor shall be used to avoid the inhalation of fumes . 23. Wear Fume mask to avoid the inhalation of fumes and to protect from dust. 24. Fire extinguisher shall be placed near HOT work area. 25. Do Not leave the work place while heating operation is in progress.

Training Provided : SOP training given by Lead Engineer.

Persons Authorized to Operate This Machine :

SOP NUMBER AREA Prepared by Lead Engineer : SOP- Fab/HC/1 : Fabrication Shop

Trained Gas cutters /Welders for Pre Heating activity.

First Issue Date Reviewed by EHS Officer : 04.05.2012 Revision No.: 0 Approved by Fabrication shop Manager

You might also like

- Chennai Metro Rail Project Safe Gas Cutting & Welding ProcedureDocument12 pagesChennai Metro Rail Project Safe Gas Cutting & Welding ProcedureRmr ReyesNo ratings yet

- Milling Machine SafetyDocument1 pageMilling Machine SafetyAizrul ShahNo ratings yet

- Welding and Cutting S.O.P. 3FDocument14 pagesWelding and Cutting S.O.P. 3FAlnurhakim HebatNo ratings yet

- Metal Bandsaw: Use and Operation and Has Given PermissionDocument2 pagesMetal Bandsaw: Use and Operation and Has Given PermissionPHH9834No ratings yet

- Manual Tig Welding (RRC) - Job ProcedureDocument3 pagesManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- Sop Saw Power HacksawDocument1 pageSop Saw Power HacksawBorislav VulićNo ratings yet

- JSA for Scaffolding Erection, Dismantling and Other Construction WorksDocument9 pagesJSA for Scaffolding Erection, Dismantling and Other Construction Worksuttam mishra100% (1)

- Grinding Machine Safety Operating ProcedureDocument2 pagesGrinding Machine Safety Operating ProcedureDominic Libradilla50% (2)

- TIG Welding SOPDocument2 pagesTIG Welding SOPGnanasekaran M (TECHNICAL TRAINING/TVSTS)100% (1)

- Safe Excavation ProceduresDocument3 pagesSafe Excavation Proceduresbabu541No ratings yet

- Jsa Tank CleaningDocument5 pagesJsa Tank CleaningASLAM MULANINo ratings yet

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- Mig Welder: Safe Use and Operation and Has Given PermissionDocument1 pageMig Welder: Safe Use and Operation and Has Given PermissionBorislav Vulić0% (1)

- Safety Operating ProcedureDocument15 pagesSafety Operating ProcedureJinky L. Lavega100% (1)

- SWP Welder Gas Metal Arc AS560Document2 pagesSWP Welder Gas Metal Arc AS560Kamal ShaariNo ratings yet

- JSA for Above Ground Piping WorkDocument3 pagesJSA for Above Ground Piping WorkBhisamS SallehNo ratings yet

- Welding and Cutting Safety Procedure: PurposeDocument14 pagesWelding and Cutting Safety Procedure: PurposeadrianNo ratings yet

- Catalyst Filling & SeggregationDocument3 pagesCatalyst Filling & SeggregationMohammed MinhajNo ratings yet

- Compulsory Ppe As Needed Ppe: Safe Operating Procedures SOP 17 - Wool Press OperationDocument2 pagesCompulsory Ppe As Needed Ppe: Safe Operating Procedures SOP 17 - Wool Press OperationUlviyye ElesgerovaNo ratings yet

- JSA - Structural Steel Fabrication and Installation WorksDocument3 pagesJSA - Structural Steel Fabrication and Installation Workssakthi venkatNo ratings yet

- 19.hydro Pressure Testing.Document8 pages19.hydro Pressure Testing.Mohammad Fazal KhanNo ratings yet

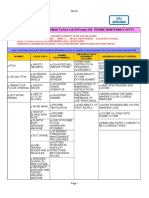

- Magna Bend SopDocument1 pageMagna Bend SopClarkKent Fabro Batucan0% (1)

- Manual metal arc welder SOPDocument1 pageManual metal arc welder SOPshalinmishraNo ratings yet

- Jsa PaintDocument2 pagesJsa PaintKhalid NaseemNo ratings yet

- Operation of CNC Machine JSA PDFDocument2 pagesOperation of CNC Machine JSA PDFashok Kumar100% (1)

- GUIDLINES FOR Contr AICDocument5 pagesGUIDLINES FOR Contr AICmadhulikaNo ratings yet

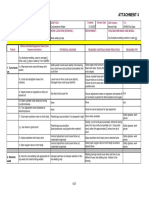

- Job Hazard Analysis Welding Operations: Attachment 4Document3 pagesJob Hazard Analysis Welding Operations: Attachment 4mujahed.ahmed4253063No ratings yet

- 3.jsa - Arc Welding-NDocument5 pages3.jsa - Arc Welding-NVivek NaikNo ratings yet

- Welding Machine Safety Operating ProcedureDocument2 pagesWelding Machine Safety Operating ProcedureDominic Libradilla100% (1)

- SOP of Pump Changing JobDocument11 pagesSOP of Pump Changing JobDwitikrushna Rout100% (1)

- SWMS Sandvik Asia Pvt Ltd Hot Work WeldingDocument14 pagesSWMS Sandvik Asia Pvt Ltd Hot Work WeldingParasNo ratings yet

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- Amit Enterprises: Safety Mass MeetingDocument3 pagesAmit Enterprises: Safety Mass MeetingSandeep Kumar0% (1)

- Safety Plan HSDDocument110 pagesSafety Plan HSDvijayNo ratings yet

- 02-070302 JSA For Relocation of Monkey Ladder For Construction of Phase-I Tranformer Bay in Brown Zone.Document4 pages02-070302 JSA For Relocation of Monkey Ladder For Construction of Phase-I Tranformer Bay in Brown Zone.Mohammed MinhajNo ratings yet

- Scaffold CampaignDocument9 pagesScaffold CampaignAdel SukerNo ratings yet

- Hand DrillDocument1 pageHand DrillDth InfraNo ratings yet

- Gas Welder SOPDocument1 pageGas Welder SOPKamal ShaariNo ratings yet

- JSA Installation of GearboxDocument2 pagesJSA Installation of Gearboxprasong100% (1)

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument5 pagesThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarNo ratings yet

- SS - GEN-25-work Permit SystemDocument5 pagesSS - GEN-25-work Permit SystemmadhulikaNo ratings yet

- R1937-JSA-004 Job Safety Analysis For Pipe PullDocument3 pagesR1937-JSA-004 Job Safety Analysis For Pipe PullVineet AgrawalNo ratings yet

- 3 SPS Sop RCC FullDocument14 pages3 SPS Sop RCC FullDwitikrushna RoutNo ratings yet

- Fixed Air Compressor: Do NotDocument1 pageFixed Air Compressor: Do NothainguyenbkvhvNo ratings yet

- JSA #19 Grinding, Welding, Gas CuttingDocument2 pagesJSA #19 Grinding, Welding, Gas CuttingSubham Sohal100% (1)

- DRL - Project Check List For Metal Cutting Machine: .RPM .RPMDocument1 pageDRL - Project Check List For Metal Cutting Machine: .RPM .RPMSachin Hse Rohtak100% (1)

- JSA - Main Turbine Lub Oil Pumps - OHDocument2 pagesJSA - Main Turbine Lub Oil Pumps - OHShubham Gupta0% (1)

- 4-JSA - Unloading Under Inert - F9030 B NewDocument6 pages4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNo ratings yet

- Air Compressor Operation SafetyDocument10 pagesAir Compressor Operation SafetyKelvin TanNo ratings yet

- Risk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelDocument3 pagesRisk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelMohamed ElnagdyNo ratings yet

- 008 JSA - Manual BoringDocument3 pages008 JSA - Manual BoringMohammed MinhajNo ratings yet

- SOP of Angle GrindingDocument6 pagesSOP of Angle GrindingINFNo ratings yet

- Ultratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSADocument5 pagesUltratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSATFattah100% (1)

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- JSA For Coating and Raping Activity in TankDocument7 pagesJSA For Coating and Raping Activity in TankEslam lotfy- Eslam elsadatNo ratings yet

- Method Statement For Hot WorkDocument1 pageMethod Statement For Hot WorkDark FantasyNo ratings yet

- Cutting Torch SafetyDocument1 pageCutting Torch SafetyDocholosoNo ratings yet

- Safety in Work Place Safety in WeldingDocument25 pagesSafety in Work Place Safety in WeldingRahul SiwakotiNo ratings yet

- 091-0541 CobraTig 150XM 254-151 LoResDocument32 pages091-0541 CobraTig 150XM 254-151 LoResAmenAllahRaoudhaBoukerNo ratings yet

- Osha Outreach Training General Industry Safety Standards Compressed Gases & Gas Cylinders OSHA 29 CFR 1910.101Document10 pagesOsha Outreach Training General Industry Safety Standards Compressed Gases & Gas Cylinders OSHA 29 CFR 1910.101jhoniNo ratings yet

- Ie Rules-1956Document191 pagesIe Rules-1956Murali MohanNo ratings yet

- Standard Codes Followed in LPG IndustriesDocument41 pagesStandard Codes Followed in LPG Industriesaarunsnair100% (2)

- 91 322 EecDocument4 pages91 322 EecaarunsnairNo ratings yet

- Lighting RequirementDocument3 pagesLighting RequirementaarunsnairNo ratings yet

- Ministry of Petrolemum & Natural Gas NotificationDocument5 pagesMinistry of Petrolemum & Natural Gas NotificationApoorv KumarNo ratings yet

- 20&604 WDSeriesDocument2 pages20&604 WDSeriesbiteme99No ratings yet

- Lab 02 - Boundary Layer-2Document21 pagesLab 02 - Boundary Layer-2Walid El AhnafNo ratings yet

- Physics 110A: Electromagnetism: 1 Introduction and OverviewDocument4 pagesPhysics 110A: Electromagnetism: 1 Introduction and OverviewJoshua LinNo ratings yet

- 12 ElectrostaticsDocument24 pages12 ElectrostaticsTanvi ShahNo ratings yet

- DTH Drilling MachineDocument8 pagesDTH Drilling MachineREL PromoNo ratings yet

- Monarch Industrial Products (I) Pvt. Ltd. Decorative Floor Toppings Supply Order Price ListDocument1 pageMonarch Industrial Products (I) Pvt. Ltd. Decorative Floor Toppings Supply Order Price ListgangadevimgmNo ratings yet

- Design DocumentDocument10 pagesDesign DocumentLiza WoodsNo ratings yet

- Strain Gage-WhatDocument16 pagesStrain Gage-WhatAshok JoshiNo ratings yet

- Ce1a3q E1a3qDocument5 pagesCe1a3q E1a3qapi-239041842No ratings yet

- Cutting Guide: Integrated Seat Post (ISP)Document4 pagesCutting Guide: Integrated Seat Post (ISP)Anand sNo ratings yet

- Materials System SpecificationDocument8 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- Emergency Braking SystemDocument4 pagesEmergency Braking Systemieee4mybusinessonlyNo ratings yet

- Laminated Composite Stiffened Panels Application and BehaviourDocument46 pagesLaminated Composite Stiffened Panels Application and BehaviourHemendra Jain100% (1)

- Desmodure-Rfe-Tds CROSSLİNKİNG AGENTDocument2 pagesDesmodure-Rfe-Tds CROSSLİNKİNG AGENTGİZEM DEMİRNo ratings yet

- Radiography 2 ProcedureDocument9 pagesRadiography 2 ProceduresheikmoinNo ratings yet

- Dell Operation ManagementDocument13 pagesDell Operation ManagementIsha GosainNo ratings yet

- Carbon Compounds: Standard/ Class/ Grade - 10 SSC, CBSE - 8 ICSEDocument53 pagesCarbon Compounds: Standard/ Class/ Grade - 10 SSC, CBSE - 8 ICSEsaintEmNo ratings yet

- FUJI FRONTIER 340E - PartslistDocument172 pagesFUJI FRONTIER 340E - Partslistvitprint22No ratings yet

- SailPointCustomConnectors PDFDocument17 pagesSailPointCustomConnectors PDFprudhvi reddy0% (1)

- Ccsviiid1 2029-3Document2 pagesCcsviiid1 2029-3DieguitoOmarMoralesNo ratings yet

- An Introduction To Orgone Matrix Material (Jon Logan)Document42 pagesAn Introduction To Orgone Matrix Material (Jon Logan)Jose CiprianiNo ratings yet

- OMEGA AIR Alternative Filter Elements English PDFDocument56 pagesOMEGA AIR Alternative Filter Elements English PDFbinhleduc36No ratings yet

- Unit One: Wind LoadsDocument67 pagesUnit One: Wind Loadsabdu yimerNo ratings yet

- Laboratory Design GuideDocument110 pagesLaboratory Design Guidejuly lang100% (5)

- SyllabusDocument2 pagesSyllabusjackychen101No ratings yet

- BS3974 Pipe SupportsDocument20 pagesBS3974 Pipe SupportsTony100% (1)

- Math TaskDocument2 pagesMath TaskAsher MananganNo ratings yet

- LHR IndstryDocument84 pagesLHR Indstryabubakar09ect50% (2)

- Lecture 04 Critical Path Method (CPM) PDFDocument25 pagesLecture 04 Critical Path Method (CPM) PDFAmira HachemNo ratings yet

- Lecture - Force MethodDocument73 pagesLecture - Force MethodF FNo ratings yet