Professional Documents

Culture Documents

Airbag

Uploaded by

api-199655530 ratings0% found this document useful (0 votes)

312 views17 pagesAirbags are made of compact, plain woven fabrics, or basket woven, twill is also used sometimes. Yarns used - Nylon 6.6, Nylon 6, Nylon 4.6, and polyester Major requirements High strength on both axis High tear propagation resistance High anti-slip properties of the seams resistance against aging Defined dimensional stability fabric types Most of the driver side airbags are coated, and lower denier yarns that yield strong and lighter-weight.

Original Description:

Original Title

airbag

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAirbags are made of compact, plain woven fabrics, or basket woven, twill is also used sometimes. Yarns used - Nylon 6.6, Nylon 6, Nylon 4.6, and polyester Major requirements High strength on both axis High tear propagation resistance High anti-slip properties of the seams resistance against aging Defined dimensional stability fabric types Most of the driver side airbags are coated, and lower denier yarns that yield strong and lighter-weight.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

312 views17 pagesAirbag

Uploaded by

api-19965553Airbags are made of compact, plain woven fabrics, or basket woven, twill is also used sometimes. Yarns used - Nylon 6.6, Nylon 6, Nylon 4.6, and polyester Major requirements High strength on both axis High tear propagation resistance High anti-slip properties of the seams resistance against aging Defined dimensional stability fabric types Most of the driver side airbags are coated, and lower denier yarns that yield strong and lighter-weight.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 17

Air Bag

Chitra Siva Sankar. A

06Text07

Final Year Textile

Where it all

started???

•The key factor for

growth and

innovation – the

18th century

industrial

revolution.

•Invention of many

new technologies.

•Machine started to

do work for us.

•Mobitech – textiles

related to the

Automotives

History • John. W. Hetrick –

1952 – First Air

Cushion System

• Dr Allen. S. Breed –

the ball in tube

inertial sensor for

crash detection –

Chrysler bought it in

1967

• Eaton, Yale & Town Inc

– Autoceptor Crash

Restraint

• GM – 1970 – Air

Cushion Restraint

System

How does an Airbag

work???

• 30% safer – airbag for

frontal safety

• Airbag deployment

timing – 1/20th of a

second

Different

Airbag positions

• Airbag are made of compact,

plain woven fabrics, or Fabric types

basket woven, twill is also

used sometimes.

• Most of the driver side

• Yarns used – Nylon 6.6, Nylon

6, Nylon 4.6, and polyester airbags are coated,

• Major requirements and lower denier

• High strength on yarns that yield strong

both axis and lighter-weight

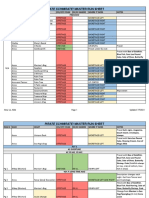

• High tear Generation

Yarn

Typical

Fabric

Thickness

Stiffness

CoatedType fabrics

Weight (g/m2(per

Construction

Size

(kgf)

(mm) ) 1stare

98

280

0.38

1.36X 986.6used.

Nylon

840d 2nd X 193

Nylon

420d

193

260

0.34

1.80 3rd X 181

6.6 1.20

Nylon

420d

181

245

0.32 6.6

propagation 10 cm)

resistance

• High anti-slip

properties of

the seams

• Resistance

against aging

• Defined

dimensional

stability

Warp Preparation

• To manufacture airbag material, the warp yarn is

supplied on a beam.

• One dip One nip process – polyacrlic coating.

• The size is adhered to the yarn by passing it between

squeeze rollers and then through series of cooling

rods.

• Encapsulating the yarn with size means that the ends

are prevented from rolling during drying and wind-

up. A gas fired dryer dries the size.

• At this stage other compounds suitable for warp

preparation can be added, like the grafting

compound designed by Reeves brothers. Grafting

compound stops excessive fabric fraying, yarn pull-

out, and distortion. The soft nature of the

compound makes the airbag pliable.

Weaving Process and

• All 3 Modern shuttle-

less technologies Finishing

• The fabric’ tensile

strength and the

elongation are

strongly influenced

at the weaving

stage

• Weaver’

Responsibility –

engineering Thickness

Properties

Mass

Stiffness

(kgf)

(GSM) (mm) 01280

Current

840d

.38

4 420d

01265

.34

8Neoprene

420d

01246

.32

2 Products

New

420d

0200

.28

7 Silicone

Products

uniform air

permeability across

the whole fabric

• Double rapier with

double shedding

Design parameters for

Sley race instead of supporting teeth rapier loom

§ Full width temple

§

§ Selvedge rollers

§ Knot stop motion

§ Controlled weft yarn break

§ Take up roller with rubber coating

§ Warp used in this need not twisted or sized but

intermingled

•

•

Y-Axis :Air permeability in L/min/100cm2

X-Axis : Fabric width in cm

Design parameters for

projectile loom

§ Robust design

§ Cam motion

§ Filament equipment

§ Electronically controlled warp let-off

§ Warp tensioner

§ Projectiles D12 with large clamping surface

§ Full width temple

Y-Axis :Air permeability in L/min/100cm2

X-Axis : Fabric width in cm

Post Chemical Finishing

processes

• Post finishing – It is cut into • A variety of folds are suitable

panels, which are then including the

sewn together – Accordion fold

• Laser cutting is done - fast – Reversed accordion fold

and accurate – It fuses the – Pleated accordion fold

edges of the fabrics to – Overlapped folds

prevent fraying, and • Packing should allow for tethers

reduces costs by joined to the bag to control its

eliminating cutting protrusion into the car during

• Airbags are sewn with nylon deployment.

6.6, polyester, and Kevlar • Cover can be fitted over the bag

aramid yarns, the sewing to protect it from abrasion –

patterns and stitch DuPont made jacket Tyvek AC

densities being chose spun-bonded polyethylene for

carefully to maximise this purpose – It tears to

performance release the airbag when it

• After sewing – Folded inside inflates.

Performance Tests &

Standards

• To maintain the quality of airbags, there

are more than 50 different types

• Cost of validation is very high

• The full certification of a complete airbag

module costs approximately $100,000.

• There are many testing standards ASTM,

SAE, and Automotive Occupant Restrains

Councils.

• Different related ASTM standards – ASTM

D1423, ASTM D1422, ASTM S 3786,

ASTM D3787, ASTM D5034…

Performance Tests &

Standards ( cont …)

• ASTM D1423 – Yarn from package – amount and

• direction of twist

•• ASTM D1422 – Yarn from airbag fabric

• Fiber identification – double beam spectrophotometer

• Size on the fabric – extraction using any suitable

solvent

• Mass per unit area – a full width sample is taken with

selvedges

• ASTM – air permeability testing using calibrated

orifice method

• ASTM D3786, 87 – Bursting strength

• ASTM D5034 – Fabric breaking force

Fatalities & Damages

• Airbag can injure or kill

• Condition is more sever

when seat belts are not

worn

• Injuries such as abrasion

of the skin, hearing •3 . 3 m illio n a ir b a g d e p lo ym e n ts, 6 , 3 7 7

live s sa ve d a n d co u n tle ss in ju rie s

damage from the sa ve d .

extremely loud 165-175•S a fe ty p re ca u tio n s

dB deployment •R e a r m o st co m fo rta b le se a tin g

explosion, head injuries, •S lig h tly re clin e th e b a ck o f yo u r

se a t ( 1 0 in ch e s fro m th e

eye damage, and

ste e rin g )

broken nose, fingers, •Po in t th e a irb a g to w a rd yo u r

hands or arms, burns ch e st

due to heat can occur •C h ild re n 1 2 a n d u n d e r – R e a r

S e a tin g fo r ch ild re n ( n e ve r in

Scope – The Future

• Different applications – aircraft seating to motorcycle helmets,

wearable airbags

• Prospects

– More economical

– Lighter weight

• Improved sensors – ‘Smart’ – Size and weight of the occupant,

presence…

• Side impact airbags – door panels – head protection – head/knee

bolsters (energy absorbing pads) – complement airbags

• Rear seat airbags – consumer demand is not expected to be high

• Hybrid inflator – combination of inert gases and heat from

propellant to significantly expand the gas – techno-economic

Thank You one and all

Your Thoughts!

and

Queries?

You might also like

- Presentation On: Different Parts of Ring FrameDocument15 pagesPresentation On: Different Parts of Ring FrameTowfic Aziz Kanon100% (3)

- Yarn Tension and Balloon Geometry in Ring SpinningDocument18 pagesYarn Tension and Balloon Geometry in Ring Spinningapi-1996555380% (5)

- Tsukihi Phoenix Final ChapterDocument346 pagesTsukihi Phoenix Final ChapterLuxioNo ratings yet

- TootsieDocument133 pagesTootsieMartha Lyroni100% (1)

- A2 Final TestDocument5 pagesA2 Final TestMiljana100% (2)

- WeatherforecastDocument2 pagesWeatherforecastEmily Doreen0% (1)

- L-Mesh Composite Mesh Brochure 20may17Document2 pagesL-Mesh Composite Mesh Brochure 20may17atharmediciveNo ratings yet

- Showa: General PurposeDocument2 pagesShowa: General PurposeMohamed AliNo ratings yet

- Endurance Dyform 18 PiDocument1 pageEndurance Dyform 18 PicarlosorizabaNo ratings yet

- Kemco V Sepa enDocument2 pagesKemco V Sepa enDanilaGAdNo ratings yet

- HARTL Publication CRDDocument16 pagesHARTL Publication CRDeaglego00No ratings yet

- Datacard Soric XFDocument1 pageDatacard Soric XFRazaq PayapoNo ratings yet

- Synthetics Brochure PDFDocument4 pagesSynthetics Brochure PDFSujai BalasubramaniamNo ratings yet

- Access Tank Cover Circular Cover Type LKDCDocument3 pagesAccess Tank Cover Circular Cover Type LKDCMartha WidjayaNo ratings yet

- Lab Report (7) : Title: TasksDocument6 pagesLab Report (7) : Title: TasksAsad Jamil RanaNo ratings yet

- 84cc0dcb-e317-4878-b6b7-9f018442e3e7Document1 page84cc0dcb-e317-4878-b6b7-9f018442e3e7mehdi HKNo ratings yet

- Affordability & Productivity: BasicDocument2 pagesAffordability & Productivity: BasicChandra NurikoNo ratings yet

- SF M18 144 565W 580W Topcon enDocument2 pagesSF M18 144 565W 580W Topcon enlorymarcus8No ratings yet

- Glands: Comet Single Compression Type Heavy Duty Cable Gland (Sibg)Document2 pagesGlands: Comet Single Compression Type Heavy Duty Cable Gland (Sibg)dip461No ratings yet

- Automobile Carpet Moulding ProcessDocument26 pagesAutomobile Carpet Moulding ProcessEr Kaushik PatelNo ratings yet

- Paver BlockDocument16 pagesPaver BlockRavinder Singh100% (1)

- Nepal Rubber & Engineering PVT - LTD: Material Property Test ReportDocument5 pagesNepal Rubber & Engineering PVT - LTD: Material Property Test ReportAankil SharmaNo ratings yet

- Fiber Optic CablesDocument24 pagesFiber Optic CablesARCC2030No ratings yet

- Sun Micron Mesh BagsDocument1 pageSun Micron Mesh BagsOmar Escalante RomeroNo ratings yet

- Fuse CarrierDocument4 pagesFuse CarrierThang Pham DucNo ratings yet

- Cement BoardDocument5 pagesCement BoardYsabella May Sarthou CervantesNo ratings yet

- Irjet V6i1057Document4 pagesIrjet V6i1057Vijayanidhi SivakumarNo ratings yet

- Alfa Laval Access Tank Cover Circular Cover Type LKDC Product LeafletDocument2 pagesAlfa Laval Access Tank Cover Circular Cover Type LKDC Product LeaflettitieNo ratings yet

- Adhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Document4 pagesAdhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Reza AbdolahiNo ratings yet

- Compacted-Non Rotating Wire Rope Specification - Anbao CorpDocument2 pagesCompacted-Non Rotating Wire Rope Specification - Anbao CorpUntung AjiTiaNo ratings yet

- D5 N8-121727C8 - 80% Wool + 20% Nylon FloatDocument1 pageD5 N8-121727C8 - 80% Wool + 20% Nylon FloatsdhrtwrNo ratings yet

- Data Sheet C25.30 4D 8060 PDFDocument1 pageData Sheet C25.30 4D 8060 PDFNavneet NarayanNo ratings yet

- Quality Management System in TextilesDocument62 pagesQuality Management System in TextilesShivam AgnihotriNo ratings yet

- BOPP - SI 總和目錄Document12 pagesBOPP - SI 總和目錄Gibson leeNo ratings yet

- Installation Instructions: AI-GC01-E Rev.4Document21 pagesInstallation Instructions: AI-GC01-E Rev.4kiranNo ratings yet

- Fibreprop PDFDocument45 pagesFibreprop PDFvaraduNo ratings yet

- ScanRope Marine KatalogDocument16 pagesScanRope Marine KatalogMasterPie1950No ratings yet

- Kathrein RRU 4570 Reader Unit DatasheetDocument4 pagesKathrein RRU 4570 Reader Unit DatasheetBackups SantafeNo ratings yet

- Pet Resin Bopet FilmsDocument12 pagesPet Resin Bopet FilmsParam JothiNo ratings yet

- Ceat 18 00-25 Port XL Plus 4.5Document3 pagesCeat 18 00-25 Port XL Plus 4.5Jay TailorNo ratings yet

- Folder NoCut 2017 EN SpanSetDocument6 pagesFolder NoCut 2017 EN SpanSetRenato VieiraNo ratings yet

- Computer Imprintable Polyester Label MaterialDocument4 pagesComputer Imprintable Polyester Label MaterialyoganandvNo ratings yet

- P924 (Tds-Eng)Document1 pageP924 (Tds-Eng)s_d_sudhirrajNo ratings yet

- 4core Aluminium PVC ArmouredDocument4 pages4core Aluminium PVC ArmouredMdNo ratings yet

- 316H Direct Roving Technical Data SheetDocument3 pages316H Direct Roving Technical Data SheetHuber Abad Alvarado CoronelNo ratings yet

- Sika Loadflex Polyurea Product Data 322187Document2 pagesSika Loadflex Polyurea Product Data 322187quaeNo ratings yet

- InAir ADSS 192 Ultra 8.13kN Dry 0.748 (IAL)Document3 pagesInAir ADSS 192 Ultra 8.13kN Dry 0.748 (IAL)Tony Daniel Aguilar AlvarezNo ratings yet

- X2543 enUS 2543 FlexLagRubber 021621Document2 pagesX2543 enUS 2543 FlexLagRubber 021621German RestrepoNo ratings yet

- Advanced Textiles Increase Tyre PerformanceDocument4 pagesAdvanced Textiles Increase Tyre Performancemyuvaraj91No ratings yet

- Technical Details: Vee Pack SetsDocument2 pagesTechnical Details: Vee Pack SetsJosé HurtadoNo ratings yet

- T 13 PG 35-36 PDFDocument2 pagesT 13 PG 35-36 PDFJossimar PerezNo ratings yet

- Spec bảo ôn lạnh dạng tấmDocument5 pagesSpec bảo ôn lạnh dạng tấmTruong Ngoc SonNo ratings yet

- Hilti RE 500 CatalogDocument1 pageHilti RE 500 CatalogChing EddieNo ratings yet

- Brochure-Filter Press.-TORODocument12 pagesBrochure-Filter Press.-TOROSebastian Gomez BetancourtNo ratings yet

- Bored Pile BBS (8m) - Jan 30, 2019Document2 pagesBored Pile BBS (8m) - Jan 30, 2019Jimmy PimentelNo ratings yet

- Bored Pile BBS (8m) - Jan 30, 2019Document2 pagesBored Pile BBS (8m) - Jan 30, 2019Jimmy PimentelNo ratings yet

- Strux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet ApplicationsDocument2 pagesStrux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet ApplicationsneilNo ratings yet

- Designs and Purposes For Coated Abrasive Belt Joints - Norton AbrasivesDocument3 pagesDesigns and Purposes For Coated Abrasive Belt Joints - Norton Abrasivesneuzainamine48No ratings yet

- Unlimited & G+12 DM Exam-Revision-03_230901_154530Document19 pagesUnlimited & G+12 DM Exam-Revision-03_230901_154530Ali403No ratings yet

- Unlimited & G+12 DM Exam-Revision-03Document19 pagesUnlimited & G+12 DM Exam-Revision-03Ali403No ratings yet

- Sika® Carbodur® S: Product Data SheetDocument4 pagesSika® Carbodur® S: Product Data SheetMohammed FarhanNo ratings yet

- Coating, Laminating and Testing CapabilitiesDocument28 pagesCoating, Laminating and Testing CapabilitiesrabiulfNo ratings yet

- LTL BOPP Film Properties & ApplicationsDocument2 pagesLTL BOPP Film Properties & ApplicationsQUALITY CONTROLNo ratings yet

- Sheltor CostDocument1 pageSheltor CostBalajiYachawadNo ratings yet

- Defence Textiles Final PresentationDocument15 pagesDefence Textiles Final Presentationapi-19965553No ratings yet

- Enhancement of Clothing Comfort Using Phase Changing MaterialsDocument12 pagesEnhancement of Clothing Comfort Using Phase Changing Materialsapi-19965553No ratings yet

- Outlooks and Prospects For Non Woven Industry in IndiaDocument16 pagesOutlooks and Prospects For Non Woven Industry in Indiaapi-19965553No ratings yet

- DKTES' Ecolabeling Chitra Siva SankarDocument14 pagesDKTES' Ecolabeling Chitra Siva Sankarapi-19965553No ratings yet

- JIS B 0203 - Taper ThreadsDocument4 pagesJIS B 0203 - Taper Threadslokesh38No ratings yet

- THULE Crossover KatalógusDocument6 pagesTHULE Crossover KatalógusTHULE Partner - BudaörsNo ratings yet

- Classes I To VIII.: This Is To Inform You That Tomorrow Wednesday I.E (26/02/2020) Will Be A Preparatory Leave ForDocument22 pagesClasses I To VIII.: This Is To Inform You That Tomorrow Wednesday I.E (26/02/2020) Will Be A Preparatory Leave ForVish PatilNo ratings yet

- Offshore Ladders for Escape to Sea GuideDocument7 pagesOffshore Ladders for Escape to Sea GuidemrudhulrajNo ratings yet

- PEZ 2015 CatalogDocument32 pagesPEZ 2015 CatalogRoxanne PeñaNo ratings yet

- Ruined InnocenceDocument648 pagesRuined Innocencesnonyawo2No ratings yet

- Economics of The Madhouse (Chris Harman)Document109 pagesEconomics of The Madhouse (Chris Harman)Sinsia Van KalkerenNo ratings yet

- Chap 8Document13 pagesChap 8anshumanNo ratings yet

- Henry's HolidayDocument8 pagesHenry's HolidayPei Hwee Tan100% (2)

- Industrial Sewing Machine Clutch Motor SpecsDocument15 pagesIndustrial Sewing Machine Clutch Motor SpecsArja'un TeaNo ratings yet

- NHÓM CHUYÊN ĐỀ 4 BÀI TẬP TUẦN 5Document17 pagesNHÓM CHUYÊN ĐỀ 4 BÀI TẬP TUẦN 5Xờm Bé NhỏNo ratings yet

- Buwan NG Wika Activities EvaluationDocument2 pagesBuwan NG Wika Activities EvaluationDashuria Ime100% (2)

- Master Run SheetDocument8 pagesMaster Run Sheetapi-538676793No ratings yet

- World Textile Fibers: Freedonia Industry Study #1525Document16 pagesWorld Textile Fibers: Freedonia Industry Study #1525NGUYEN MINH HUYNo ratings yet

- Freelang English Swedish and Swedish English DictionaryDocument353 pagesFreelang English Swedish and Swedish English DictionaryAnna Bella100% (1)

- Meile ManualDocument80 pagesMeile ManuallionnnNo ratings yet

- Boarlander Silverback - TS JoyceDocument237 pagesBoarlander Silverback - TS JoyceMariana MedeirosNo ratings yet

- Beluga Instructions. IIDocument4 pagesBeluga Instructions. IIjimNo ratings yet

- Spoken Phrases For ComplimentDocument4 pagesSpoken Phrases For ComplimentAbdallaNo ratings yet

- Alle V-Infos EnglischDocument43 pagesAlle V-Infos EnglischMohamed Rashed50% (2)

- Dress Code19sepDocument36 pagesDress Code19sepapi-100323454No ratings yet

- Sample Instructions Ladder WernerDocument6 pagesSample Instructions Ladder WernerYume HendraNo ratings yet

- Cotton, Polyester & Cotton Polyester BlendDocument4 pagesCotton, Polyester & Cotton Polyester BlendTanaji Santra100% (1)

- Site Storage PlanDocument28 pagesSite Storage PlanSimamora Samuel Hansen100% (1)

- Marco Polo 2 ManualDocument12 pagesMarco Polo 2 ManualluisricardosantosNo ratings yet

- Crash (Film Script)Document52 pagesCrash (Film Script)Maite GuelermanNo ratings yet