Professional Documents

Culture Documents

Ozone Treatment For Cooling Towers and Potable Water

Uploaded by

netygen10 ratings0% found this document useful (0 votes)

38 views19 pagesOzone Treatment for Cooling Towers

Original Title

Ozone Treatment for Cooling Towers and Potable Water

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentOzone Treatment for Cooling Towers

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views19 pagesOzone Treatment For Cooling Towers and Potable Water

Uploaded by

netygen1Ozone Treatment for Cooling Towers

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 19

Ozone Treatment For

Cooling And Potable Water

Presented by:

Introduction

Cl

2

gas is used to control biological growth in

cooling tower water.

Cl

2

gas / bleaching powder is used to disinfect

drinking water.

Ozone treatment of above water is gaining

popularity as it is far more effective in

controlling biological growth & disinfection.

Its handling involves minimum hazards.

About the technology

Ozone(O

3

)is a molecule consisting of three

oxygen atoms.

It is a powerful biocide and virus de

activant.

It oxidizes many organic & inorganic

substances.

Generation

Ozone is generated by passing a high voltage

AC(6 -20 kV) across a dielectric discharge gap

through which oxygen is injected.

2 O

o

2

O + O

2

o

3

Electric

arc

O2

O

2

O2

O3

WATER

WATER

OZONISER

ALUMINIUM

ELECTRODE

6 - 20 KV AC

Concerns of drinking water

By-product of Cl

2

treated water are chloramine,

dichloroamine , which are proven carcinogens.

Disagreeable smell and taste.

Ozone is safe disinfectant , no health hazard as

only by-product is oxygen.

Maintenance concerns of

cooling towers

Biological growth

Scaling

Corrosion

Biological growth

Continuous exposure to airbourne organic

matter

Buildup of bacteria, algae, fungi and viruses

Hazardous for the tower system & health of

humans encountering the water.

Legionnaires disease caused by a legionella

bacteria thriving in cooling water environment

Biological growth

Increases risk of microbially induced

corrosion.

Certain sulphate reducing and iron

metabolising bacteria can destroy iron

pipes.

Biofilm coating on heat exchange surfaces

reduces heat transfer efficiency.

Control of biological growth

Ozone kills bacteria by rupturing

the cell walls, process to which

micro organism cannot develop

immunity.

Residual ozone concentration 0.4

mg/l results in 100% kill in 23

min for biofilm producing

bacteria.

Residual ozone conc. 0.1mg/l

removes

70-80 % biofilm in 3 hrs.

O3

Other

disinfectants

Scaling

As the water in cooling tower evaporates,

dissolved solids concentrate in a circulating water.

Biofilm acts as an adherent for these mineral

micro crystals.

Over time deposition of organic & inorganic

matters increases scale thickness.

Ozone loosens and removes the scale by

removing the biofilm.

Corrosion

Much of the corrosion in cooling towers are

microbiologically induced.

Ozone prevents corrosion by controlling

microbial population

Ozone treated cooling water rises pH to

above 8.5 providing corrosion protection.

Benefits

Energy saving

1. Less makeup water.

2. Blowdown can be reduced.

Water saving

Less water consumption.

Other benefits

Reduces chemical use

Eliminate infectious bacteria

Improve regulatory environmental

compliances.

Finally from HR perspective, reduced risk

of personnel health enhances the working

environment and makes a positive public

statement.

Limitations

Solubility

Half life

High COD

High temperature

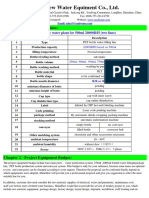

Comparison

CHLORINE TREATMENT OZONE TREATMENT

Transportation, storage and handling

is inconvenient

On sight generation

Dependent on suppliers No dependence

Excess dose will give disagreeable

smell and bitter taste

Helps in removing bad odour & colour

Most unsafe & causes cancer More safe disinfectant in comparison

of chlorine.

Operating cost comparison for cooling

water system per year

Rs. 0.0 Rs.6,00,000 Power consumption

Rs. 5,000 > 50,000

Rs. 1,50,000

Rs.4,50,000

Labour

nil Rs.10,00,000 Chemicals

Rs 11,50,000 nil Electrical operation

Ozone treatment Chemical treatment Item

Safety

Equipments

Conclusion

Through laboratory testing, field

testing and theoretical analysis, ozone

treatment of cooling water has shown to

be technically valid and economically

attractive in many applications.

The technology works by virtue of the

ability of ozone to act as a disinfectant

and therefore as an alternative to

traditional chemical treatment.

You might also like

- Ozone PDFDocument4 pagesOzone PDFShesharam ChouhanNo ratings yet

- Cooling Water TreatmentDocument31 pagesCooling Water Treatmentpadmesh awasthiNo ratings yet

- Ozone Solubility ChartDocument0 pagesOzone Solubility ChartWONG TSNo ratings yet

- Shine Dew Water Equipment Co., Ltd. PET bottle water plant proposalDocument17 pagesShine Dew Water Equipment Co., Ltd. PET bottle water plant proposalardhendu1No ratings yet

- Film Tec LiteratureDocument121 pagesFilm Tec LiteraturepramodtryNo ratings yet

- Dow Membrane CleaningDocument2 pagesDow Membrane CleaningDonatas Bertasius100% (1)

- Operating Manual: Ozone Treatment SystemDocument21 pagesOperating Manual: Ozone Treatment SystemMauro Domingo'sNo ratings yet

- Rock Catchment Dam With Self-Closing WatertapDocument90 pagesRock Catchment Dam With Self-Closing WatertapGreen Action Sustainable Technology GroupNo ratings yet

- Tannin BasedDocument5 pagesTannin BasedVinod SindhavNo ratings yet

- Sewage Treatment Plant Components and ProcessDocument64 pagesSewage Treatment Plant Components and ProcessPankaj Gogoi100% (1)

- Filtration Improvements for Cooling TowersDocument5 pagesFiltration Improvements for Cooling TowerssyeddanishrasoolNo ratings yet

- Water Treatment Plant Performance Evaluations and OperationsFrom EverandWater Treatment Plant Performance Evaluations and OperationsNo ratings yet

- Ultra Filtration SystemDocument5 pagesUltra Filtration SystemAbdul SamadNo ratings yet

- Cooling Tower Descaling ProgramDocument16 pagesCooling Tower Descaling ProgramMuhammad JafarNo ratings yet

- Sustainable Production: Effluent Treatment PlantDocument12 pagesSustainable Production: Effluent Treatment PlantKush SharmaNo ratings yet

- Internship Report on PET Lines, Bulk Line and RO PlantDocument7 pagesInternship Report on PET Lines, Bulk Line and RO PlantHamza ShahidNo ratings yet

- Waste Water Treatment PlantDocument10 pagesWaste Water Treatment PlantBoiler ScrubberNo ratings yet

- Aeromatic Ltd. Fluid Bed DryerDocument13 pagesAeromatic Ltd. Fluid Bed DryerDitha ParamitaNo ratings yet

- Cooling Tower RO SystemDocument7 pagesCooling Tower RO SystemAbdul SamadNo ratings yet

- Reverse Return PipingDocument4 pagesReverse Return Pipingsurya325kiranNo ratings yet

- MSDS - ACUTHERM 3221 Boiler AntiscalantDocument4 pagesMSDS - ACUTHERM 3221 Boiler AntiscalantBopanna BolliandaNo ratings yet

- ClarifierDocument7 pagesClarifiersuleman205No ratings yet

- MSDS - Polyelectrolyte, CleartechDocument7 pagesMSDS - Polyelectrolyte, CleartechBazil BoliaNo ratings yet

- Electropure EDI Engr OEM Manual v3.5.0 (CE)Document81 pagesElectropure EDI Engr OEM Manual v3.5.0 (CE)Fábio GomesNo ratings yet

- 210928-Beierde-CO2 Water Filling PlantDocument21 pages210928-Beierde-CO2 Water Filling PlantHuong NguyenNo ratings yet

- Boiler Water Chemistry and KPI MonitoringDocument45 pagesBoiler Water Chemistry and KPI MonitoringEscobar ValderramaNo ratings yet

- Cooling Tower Side Stream FiltrationDocument5 pagesCooling Tower Side Stream FiltrationChandrakant JuikarNo ratings yet

- For Reduction of Iron/or Manganese From Water SuppliesDocument2 pagesFor Reduction of Iron/or Manganese From Water SuppliesMadalina Luca ZambreaNo ratings yet

- Harga Bahan KimiaDocument2 pagesHarga Bahan KimiaAndre Gazali Malik100% (1)

- Anti ScalantDocument14 pagesAnti ScalantassurendranNo ratings yet

- Wedeco UV Systems AQUADA Altima, Proxima, MaximaDocument20 pagesWedeco UV Systems AQUADA Altima, Proxima, Maximaeddysoen100% (1)

- Meghmani Organics Ltd.Document45 pagesMeghmani Organics Ltd.Vrutika PatelNo ratings yet

- How To Prevent Scale and Fouling in RO PlantsDocument14 pagesHow To Prevent Scale and Fouling in RO PlantsPeter MüllerNo ratings yet

- Drinking Water - SpecificationDocument24 pagesDrinking Water - SpecificationAmanjit SinghNo ratings yet

- OzonationDocument4 pagesOzonationKareen Jenn AmlosNo ratings yet

- Fabrication and Optimization of Cooling Tower: Abhishek KumarDocument15 pagesFabrication and Optimization of Cooling Tower: Abhishek Kumarabhishek kumarNo ratings yet

- Side Stream Filter For Cooling TowersDocument4 pagesSide Stream Filter For Cooling TowersdkmauryaNo ratings yet

- Closed System Protection Handbook PDFDocument10 pagesClosed System Protection Handbook PDFBrightwaterprocessNo ratings yet

- Understand Reverse Osmosis with our Guide to RO Process & CalculationsDocument15 pagesUnderstand Reverse Osmosis with our Guide to RO Process & CalculationsPrabhat JhaNo ratings yet

- Kristal Eng PDFDocument32 pagesKristal Eng PDFDũng Phạm AnhNo ratings yet

- Osmosis InversaDocument40 pagesOsmosis Inversashapira22No ratings yet

- Filter Press Manual for Process & PackagingDocument70 pagesFilter Press Manual for Process & PackagingNicholas Suominen100% (1)

- Heat Exchanger Descaling Chemical Condenser Descalant PDFDocument2 pagesHeat Exchanger Descaling Chemical Condenser Descalant PDFsanjay ukalkarNo ratings yet

- Water Treatment Plant Working Principles ExplainedDocument2 pagesWater Treatment Plant Working Principles ExplainedTosin Opawole100% (1)

- Exp 3Document15 pagesExp 3mjunaidNo ratings yet

- Boiler Safety Program Boiler ProgramDocument8 pagesBoiler Safety Program Boiler Programsalman akbarNo ratings yet

- Lamella Clarifier Leopold TexlerDocument4 pagesLamella Clarifier Leopold TexlerAntony ThanosNo ratings yet

- Softener Plant-2Document2 pagesSoftener Plant-2Md. Suruz Zaman100% (1)

- Where, The Temperature Ratio, Capacity Ratio, R A Value of 0.8 Is Generally Not AcceptedDocument43 pagesWhere, The Temperature Ratio, Capacity Ratio, R A Value of 0.8 Is Generally Not AcceptedAditya DeokarNo ratings yet

- Primary Settling Tank For ETP PDFDocument1 pagePrimary Settling Tank For ETP PDFZahid_DhakaNo ratings yet

- Divoflow 185 enDocument2 pagesDivoflow 185 enHau SinâuđaNo ratings yet

- Reverse Osmosis System FaridDocument30 pagesReverse Osmosis System FaridAchFaridWadjdiNo ratings yet

- Master'S Thesis: in Healthcare Management and QualityDocument81 pagesMaster'S Thesis: in Healthcare Management and QualityGhazy alshyalNo ratings yet

- MSDS Demi WaterDocument4 pagesMSDS Demi WaterjrsdveNo ratings yet

- Tube Settler Application in 40 CharactersDocument10 pagesTube Settler Application in 40 CharactersIlu SinghNo ratings yet

- Reactive Distillation Design and ControlFrom EverandReactive Distillation Design and ControlRating: 1 out of 5 stars1/5 (1)

- Ozonization: A Powerful Water Disinfection ProcessDocument21 pagesOzonization: A Powerful Water Disinfection ProcessAjay VermaNo ratings yet

- Disinfection 2023Document18 pagesDisinfection 2023Francis Mutema MahofaNo ratings yet

- 3 Boiler FundamentalsDocument14 pages3 Boiler Fundamentalsnetygen1No ratings yet

- Ash Handling System OverviewDocument24 pagesAsh Handling System Overviewnetygen1No ratings yet

- Cleaning NTPC's Seal Oil System PipingDocument18 pagesCleaning NTPC's Seal Oil System Pipingnetygen1No ratings yet

- A Purpose:-: Ntpc/Tstps Operation Department Operating Instruction For Management of Turbine DrainsDocument13 pagesA Purpose:-: Ntpc/Tstps Operation Department Operating Instruction For Management of Turbine Drainsnetygen175% (4)

- GT DefectsDocument17 pagesGT Defectsnetygen1No ratings yet

- Barring StallingDocument6 pagesBarring Stallingnetygen1100% (3)

- Stg-1 TDBFP Isolation NormalisationDocument4 pagesStg-1 TDBFP Isolation Normalisationnetygen1No ratings yet

- Feeder Gear Box Feeder GearDocument9 pagesFeeder Gear Box Feeder Gearnetygen1No ratings yet

- St-1 Boiler Hydrotest Checklist During Short Shutdown Location: Turbine SideDocument3 pagesSt-1 Boiler Hydrotest Checklist During Short Shutdown Location: Turbine Sidenetygen1No ratings yet

- GRID Fault Incident Unit - 1Document2 pagesGRID Fault Incident Unit - 1netygen1No ratings yet

- Airtel Digital TV Monthly Packages - DTH Packs & Prices in Delhi, Kolkata, MumbaiDocument24 pagesAirtel Digital TV Monthly Packages - DTH Packs & Prices in Delhi, Kolkata, Mumbainetygen1No ratings yet

- Air Leak in Test of Esp ProcedureDocument5 pagesAir Leak in Test of Esp Procedurenetygen1No ratings yet

- ACWSYSDocument3 pagesACWSYSnetygen1No ratings yet

- Isolating and Normalizing a Gland Steam CondenserDocument3 pagesIsolating and Normalizing a Gland Steam Condensernetygen1No ratings yet

- CMC PresentationDocument28 pagesCMC PresentationKeshav KawreNo ratings yet

- Revised Boiler Start Up Procedure For 500 MW BHEL Make UnitsDocument22 pagesRevised Boiler Start Up Procedure For 500 MW BHEL Make Unitsnetygen1No ratings yet

- MotPRO Commissioning ManualDocument45 pagesMotPRO Commissioning Manualnetygen1100% (6)

- Effect of Fast Cut Back (FCB) in A Typical Coal FiredDocument15 pagesEffect of Fast Cut Back (FCB) in A Typical Coal Firednetygen1No ratings yet

- Different Aspects To Consider Selecting FGD Type of TechnologyDocument38 pagesDifferent Aspects To Consider Selecting FGD Type of Technologynetygen1No ratings yet

- 3p3 Bus System Station - Stage-IDocument1 page3p3 Bus System Station - Stage-Inetygen1No ratings yet

- ESP OperationDocument22 pagesESP OperationVishnu Vardhan . C100% (1)

- Automatic Operation of Mill Reject System Improves PerformanceDocument26 pagesAutomatic Operation of Mill Reject System Improves Performancenetygen1100% (2)

- POWER MANAGEMENT HYDRO TURBINE GOVERNINGDocument113 pagesPOWER MANAGEMENT HYDRO TURBINE GOVERNINGnetygen1100% (1)

- CERC Tariff Regulations 2014-19 SummaryDocument80 pagesCERC Tariff Regulations 2014-19 Summarynetygen10% (1)

- PKR MillsDocument37 pagesPKR Millsnetygen1No ratings yet

- Hot Start Up 60 MWDocument11 pagesHot Start Up 60 MWnetygen1No ratings yet

- CERC Tariff Regulations 2014-19 SummaryDocument80 pagesCERC Tariff Regulations 2014-19 Summarynetygen10% (1)

- Mill Burner ControlDocument54 pagesMill Burner Controlnetygen1No ratings yet

- Paper4 Mill RejectDocument39 pagesPaper4 Mill Rejectnetygen1No ratings yet

- Lis 773 Layton Collection Development ProposalDocument14 pagesLis 773 Layton Collection Development Proposalapi-599263295No ratings yet

- Thermo1 - Module 4 - v2Document36 pagesThermo1 - Module 4 - v2lukeNo ratings yet

- Project SynopsisDocument6 pagesProject Synopsislive userNo ratings yet

- Ce6401 PDFDocument143 pagesCe6401 PDFPrithiv D CruzzNo ratings yet

- 9th Class Chemistry Notes.Document3 pages9th Class Chemistry Notes.Faheem RajpootNo ratings yet

- Introduction To Heat TransferDocument15 pagesIntroduction To Heat TransferRishabh KumarNo ratings yet

- A CLPE Booklist: Information BooksDocument13 pagesA CLPE Booklist: Information BooksChong Beng LimNo ratings yet

- Sy 2022 2023 - 2Q - GP1 - Set Ab ExamDocument9 pagesSy 2022 2023 - 2Q - GP1 - Set Ab ExamLucaney Sectel HannahNo ratings yet

- Physics 2.2 Mechanics 2-181 To 2-190Document8 pagesPhysics 2.2 Mechanics 2-181 To 2-190siddiqueNo ratings yet

- Activity 9.1: OIL Eeming With IFEDocument16 pagesActivity 9.1: OIL Eeming With IFEAlisha ChopraNo ratings yet

- BuildingstoneDocument20 pagesBuildingstoneAlexander AsonkeyNo ratings yet

- Geography Final Objective Life TimeDocument109 pagesGeography Final Objective Life Timegowrishankar nayanaNo ratings yet

- Advanced Ceramic Processing and TechnologyDocument421 pagesAdvanced Ceramic Processing and TechnologyJuan Pablo Cano Mejia100% (2)

- Environmental Impact of Cement ProductionDocument2 pagesEnvironmental Impact of Cement ProductionRahul SainiNo ratings yet

- Engineering Geology: IntroductionDocument14 pagesEngineering Geology: IntroductionLyn GarciaNo ratings yet

- Soil Physics Silabus: Fisika TanahDocument25 pagesSoil Physics Silabus: Fisika TanahLand RoamNo ratings yet

- Mod 2-Introduction To Kiln ProcessesDocument644 pagesMod 2-Introduction To Kiln Processeslovjnx100% (1)

- Ped QuestionsDocument11 pagesPed QuestionsYashPatel100% (1)

- Impact of climate change on soilDocument11 pagesImpact of climate change on soilasdfgNo ratings yet

- Determining Soil Texture by FeelDocument4 pagesDetermining Soil Texture by FeelKy TaNo ratings yet

- Heat Transfer From Fin SurfacesDocument25 pagesHeat Transfer From Fin SurfacesAizaz HabibNo ratings yet

- Computational Pollutant of So2/no2 in The Environment Using Aermod in Semi-Urban Area, Studi Case in Tuban, East JavaDocument6 pagesComputational Pollutant of So2/no2 in The Environment Using Aermod in Semi-Urban Area, Studi Case in Tuban, East JavaIJAR JOURNALNo ratings yet

- Chapter - 17 Static ElectricityDocument54 pagesChapter - 17 Static ElectricityNayeem HakimNo ratings yet

- Indian Energy ScenarioDocument19 pagesIndian Energy ScenarioVishal RamakrishnanNo ratings yet

- Solar RadiationtransDocument51 pagesSolar RadiationtransmrizqynugrahaNo ratings yet

- Thermal KineticsDocument37 pagesThermal KineticsgowthamiNo ratings yet

- The Modern Periodic Table Chemistry PresentationDocument15 pagesThe Modern Periodic Table Chemistry PresentationShee YingNo ratings yet

- Freezing and Refrigerated Storage in Fisheries - 8. Calculation of Cold Store Refrigeraion Load PDFDocument3 pagesFreezing and Refrigerated Storage in Fisheries - 8. Calculation of Cold Store Refrigeraion Load PDFPrateekNo ratings yet

- Mechanical Properties of Mortar Containing Waste PDocument10 pagesMechanical Properties of Mortar Containing Waste Pنوالدين محمد الطويرNo ratings yet

- Solar Powered Cathodic ProtectionDocument2 pagesSolar Powered Cathodic ProtectionncharalaNo ratings yet