Professional Documents

Culture Documents

Manufacturing of Steam

Uploaded by

nrinithareddyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manufacturing of Steam

Uploaded by

nrinithareddyCopyright:

Available Formats

MANUFACTURING OF

STEAM TURBINE

AT

BHEL HYDERABAD

Presented

by

N. Bipin Sai

A. Lakshmipathi

N. Sree Rinitha

P. Yaswanth kumar

Contents

Introduction

Flow diagram of steam turbine

Classification of turbines

Constructional features of blade

Classification of manufacturing process

Block layout

Over speed balancing tunnel

Blade shop

Introduction

A turbine is a device that converts chemical energy into mechanical

energy, specifically when a rotor of multiple blades or vanes is driven

by the movement of a fluid or gas.

In the case of a steam turbine, the pressure and flow of newly

condensed steam rapidly turns the rotor. This movement is possible

because the water to steam conversion results in a rapidly expanding

gas.

As the turbines rotor turns, the rotating shaft can work to accomplish

numerous applications, often electricity generation.

Flow diagram of steam turbine

Classifications of Turbine

IMPULSE TURBINE

REACTION TURBINE

Constructional Features Of Blade

Profile

Converts thermal energy of steam into kinetic energy

Root

Fixes blade to turbine rotor

Damping Element

Reduces vibrations which occur in blade due to flow of steam

T-ROOT

T-ROOT

WITH SIDE

GRIP

FORK ROOT

BLADE ROOT

TYPES OF DAMPING

Material Damping

Due to inherent damping properties of material

Aerodynamic Damping

Damping of fluid which surrounds the component in

operation

Friction Damping

Due to rubbing friction between the components

CLASSIFICATION OF MANUFACTURING PROCESSES

Primary shaping process

Secondary machining process

Metal forming process

Joining process

Surface finishing process

PRIMARY SHAPING PROCESSES

Primary shaping processes are manufacturing of a product

from an amorphous material. The parts produced through these

processes may or may not require to undergo further operations.

Some of the important primary shaping processes are casting , gas

cutting, bending, forging & powder metallurgy etc.

SECONDARY MACHINING PROCESSES

Secondary processes are mainly required for achieving dimensional

accuracy and a very high degree of surface finish.

Some of the common secondary or machining processes are:

turning, facing, threading, drilling, slotting, boring, sawing etc.

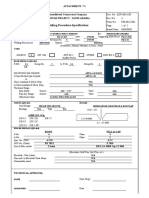

BLOCK 3 LAY-OUT

Over speed balancing tunnel

Vaccum of 2torr is created with the help

of pumps

Rotor is placed on pedestal and rotated

to 2500-4500 rpm

With help of computer, the axis of rotation of rotor is seen and is balanced by

inserting small balancing weights present in the grooves cut on the rotor

STEAM TURBINE CASING AND ROTORS IN

ASSEMBLY AREA

Blade Shop

It is an important shop of Block 3.

Blades of all the stages of turbine are made in this shop

only.

They have a variety of centre lathe and CNC machines to

perform the complete operation of blades. The designs

of the blades are sent to the shop and the Respective job

is distributed to the operators.

TYPES OF BLADES

3D Blade

TX

or cylindrical

profile blade

Twisted

profile or F

blade

Operations Performed On Blades

Milling

Blank Cutting

Grinding of both surfaces

Cutting

Root milling

MACHINING OF BLADES

Machining of blades is done with the help of Lathe

& CNC machines. Some of the machines are:

Centre lathe machine

Vertical Boring machine

Vertical Milling machine

CNC lathe machine

SCHEMATIC DIAGRAM OF A CNC MACHINE

CNC MACHINE IN BLADE SHOP

THANK YOU

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- B680 BulkDocument3 pagesB680 BulkJM ArcillaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Summer15 SyllabusDocument2 pagesSummer15 SyllabusWashim WashimmachineNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 7b Packing List-The SecondDocument3 pages7b Packing List-The Secondsagar baralNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Ciclico Servioptica RepuestosDocument68 pagesCiclico Servioptica RepuestosMiguel Angel MetalcoreNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Efficient, economical Hankison HF Series Compressed Air FiltersDocument8 pagesEfficient, economical Hankison HF Series Compressed Air FiltersJuan Carlos Vazquez RosasNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Vertical Roller Mill IntroductionDocument2 pagesVertical Roller Mill Introductionemad sabriNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Accredited ApplicatorDocument9 pagesAccredited Applicatorapi-283891975No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- B02-S01 Rev 3 Mar 2014 Fabrication of Structural and Miscellaneous SteelDocument18 pagesB02-S01 Rev 3 Mar 2014 Fabrication of Structural and Miscellaneous SteelSALMANNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Stauff Sanitary Hanger BrochureDocument32 pagesStauff Sanitary Hanger BrochurekitofanecoNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Tds Kansai Conducoat 209 WBDocument2 pagesTds Kansai Conducoat 209 WBAdam FauzanNo ratings yet

- Etch Primer Is 5666Document3 pagesEtch Primer Is 5666Er Aftab ShaikhNo ratings yet

- Nissan NES M5083-1997 Rust Preventive Coating MaterialDocument7 pagesNissan NES M5083-1997 Rust Preventive Coating MaterialSumit SharmaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Quiz Water Treatment 1Document1 pageQuiz Water Treatment 1Nurin Irdina RoslanNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Data Sheet VDM Alloy 31Document15 pagesData Sheet VDM Alloy 31trinhtrungNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Payen Cylinder Head BoltsDocument2 pagesPayen Cylinder Head BoltsDamianos 980No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- AISI 1020 Low Carbon/Low Tensile Steel: Topics CoveredDocument5 pagesAISI 1020 Low Carbon/Low Tensile Steel: Topics CoveredGuntur Aji SubiaktoNo ratings yet

- K To 12 Basic Education Curriculum (Final)Document9 pagesK To 12 Basic Education Curriculum (Final)Lyn VallesNo ratings yet

- Normazione: Aluminium - and Zinc-Lamellar Base Anti-Corrosion Coating For Ferrous Material PartsDocument15 pagesNormazione: Aluminium - and Zinc-Lamellar Base Anti-Corrosion Coating For Ferrous Material Partserkin gulerNo ratings yet

- Clean crude oil storage tanksDocument2 pagesClean crude oil storage tanksOgochukwu100% (1)

- Consolidated Contractors Welding Procedure SpecificationDocument3 pagesConsolidated Contractors Welding Procedure Specificationsiva8000100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hytherm S NewDocument2 pagesHytherm S NewOliver OliverNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Sikalastomer 710Document1 pageSikalastomer 710Eliza ManNo ratings yet

- ASTM A47 A47M Spec For Ferritic Malleable Iron Castings PDFDocument5 pagesASTM A47 A47M Spec For Ferritic Malleable Iron Castings PDFMuhammad Umer DrazNo ratings yet

- Fonelos JC Me105task1Document3 pagesFonelos JC Me105task1JohnCris B. FornilosNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Fabrication of Automatic Pneumatic Ramming MachineDocument3 pagesFabrication of Automatic Pneumatic Ramming MachineRaja SelvarajNo ratings yet

- Böhler Fox EV 65 electrode for high-strength steelsDocument1 pageBöhler Fox EV 65 electrode for high-strength steelsMohamed AdelNo ratings yet

- MS HSD Bs-Vi SpecsDocument3 pagesMS HSD Bs-Vi SpecsKusunuru SandeepNo ratings yet

- Cyclone Fabrication InstructionsDocument8 pagesCyclone Fabrication InstructionsAbhijit MokashiNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- What Is Membrane FiltrationDocument7 pagesWhat Is Membrane FiltrationRobinBrittoNo ratings yet

- Citoflux R82 SR Cored Wires for Low-Temperature Welding of C-Mn and Low-Alloy SteelsDocument1 pageCitoflux R82 SR Cored Wires for Low-Temperature Welding of C-Mn and Low-Alloy SteelsbrunizzaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)