Professional Documents

Culture Documents

APQP Process Flow

Uploaded by

shukumar_24Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APQP Process Flow

Uploaded by

shukumar_24Copyright:

Available Formats

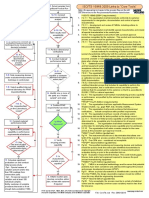

APQP PROCESS FLOW

Prepare for

APQP

Plan and Define

Program

Product Design

and

Development

Process Design

and

Development

Product and

Process

Validation

Feedback,

Assessment and

Corrective Action

APQP PROCESS FLOW

Prepare for

APQP

Plan and Define

Program

Product Design

and

Development

Process

Design and

Development

Product and

Process

Validation

Feedback,

Assessment and

Corrective Action

Organize the

Team

Define the Scope

Establish Team-toTeam

Communication

Provide Core Tools

Training

Involve Customers

and Suppliers

Implement

Simultaneous

Engineering

Develop Control

Plan Format

Decide on

Concern Resolution

Develop Product

Quality Timing Plan

APQP PROCESS FLOW

Plan and Define

Program

Product Design

and

Development

Process

Design and

Development

Product and

Process

Validation

Feedback,

Assessment and

Corrective Action

INPUT

Prepare for

APQP

Organize the

Voice of the

Team

Customer

Define the Scope

Business

Plan/Marketing

Strategy

Establish Team-toTeam

Communication

Provide Core Tools

Training

Involve Customers

and Suppliers

Implement

Simultaneous

Engineering

Product/Process

Benchmark Data

Product/Process

Assumptions

Product Reliability

Studies

Customer Inputs

Develop Control

Plan Format

Decide on

Concern Resolution

Develop Product

Quality Timing Plan

APQP PROCESS FLOW

Organize the

Voice of the

Team

Customer

Define the Scope

Business

Plan/Marketing

Strategy

Establish Team-toTeam

Communication

Provide Core Tools

Training

Involve Customers

and Suppliers

Implement

Simultaneous

Engineering

Develop Control

Plan Format

Product/Process

Benchmark Data

Product/Process

Assumptions

Product Reliability

Studies

Customer Inputs

Product Design

and

Development

Process

Design and

Development

Product and

Process

Validation

Feedback,

Assessment and

Corrective Action

OUTPUT

Plan and Define

Program

INPUT

Prepare for

APQP

Design Goals

Reliability and

Quality Goals

Preliminary Bill of

Material

Preliminary

Process Flow Chart

Preliminary Listing

of Special Product

and Process

Characteristics

Product Assurance

Plan

Management

Support

Decide on

Concern Resolution

Develop Product

Quality Timing Plan

APQP PROCESS FLOW

Organize the

Voice of the

Team

Customer

Define the Scope

Business

Plan/Marketing

Strategy

Establish Team-toTeam

Communication

Provide Core Tools

Training

Involve Customers

and Suppliers

Implement

Simultaneous

Engineering

Develop Control

Plan Format

Product/Process

Benchmark Data

Product/Process

Assumptions

Product Reliability

Studies

Customer Inputs

Design Goals

Reliability and

Quality Goals

Product and

Process

Validation

Feedback,

Assessment and

Corrective Action

Design Failure

Mode and Effects

Analysis (DFMEA)

Preliminary Bill of

Material

Design for

Manufacturability and

Assembly

Preliminary

Process Flow Chart

Design Verification

Preliminary Listing

of Special Product

and Process

Characteristics

Process

Design and

Development

OUTPUT

INPUT

Product Design

and

Development

OUTPUT

Plan and Define

Program

INPUT

Prepare for

APQP

Design Reviews

Prototype Build

Control Plan

Product Assurance

Plan

Engineering

Drawings (Including

Math Data)

Management

Support

Engineering

Specifications

Decide on

Concern Resolution

Material

Specifications

Develop Product

Quality Timing Plan

Drawing and

Specification Changes

New Equipment,

Tooling and Facilities

Requirements

Special Product and

Process

Characteristics

Gages/Testing

Equipment

Requirements

Team Feasibility

Commitment and

Management Support

APQP PROCESS FLOW

Organize the

Voice of the

Team

Customer

Define the Scope

Business

Plan/Marketing

Strategy

Establish Team-toTeam

Communication

Provide Core Tools

Training

Involve Customers

and Suppliers

Implement

Simultaneous

Engineering

Develop Control

Plan Format

Product/Process

Benchmark Data

Product/Process

Assumptions

Product Reliability

Studies

Customer Inputs

Reliability and

Quality Goals

INPUT

OUTPUT

INPUT

Design Goals

Design Failure

Packaging

Mode and Effects

Analysis (DFMEA)

Standards

Preliminary Bill of

Material

Design for

Manufacturability and

Assembly

Preliminary

Process Flow Chart

Design Verification

Preliminary Listing

of Special Product

and Process

Characteristics

Design Reviews

Prototype Build

Control Plan

Product Assurance

Plan

Engineering

Drawings (Including

Math Data)

Management

Support

Engineering

Specifications

Decide on

Concern Resolution

Material

Specifications

Develop Product

Quality Timing Plan

Drawing and

Specification Changes

New Equipment,

Tooling and Facilities

Requirements

Special Product and

Process

Characteristics

Product and

Process

Validation

Feedback,

Assessment and

Corrective Action

OUTPUT

Process

Design and

Development

Product Design

and

Development

OUTPUT

Plan and Define

Program

INPUT

Prepare for

APQP

Product/Process

Quality System

Review

Process Flow Chart

Floor Plan Layout

Characteristics

Matrix

Process Failure

Mode and Effects

Analysis (PFMEA)

Pre-Launch Control

Plan

Process Instructions

Measurement

Systems Analysis

Plan

Preliminary

Process Capability

Study Plan

Packaging

Specifications

Management

Support

Gages/Testing

Equipment

Requirements

Team Feasibility

Commitment and

Management Support

APQP PROCESS FLOW

Organize the

Voice of the

Team

Customer

Define the Scope

Business

Plan/Marketing

Strategy

Establish Team-toTeam

Communication

Provide Core Tools

Training

Involve Customers

and Suppliers

Implement

Simultaneous

Engineering

Develop Control

Plan Format

Product/Process

Benchmark Data

Product/Process

Assumptions

Product Reliability

Studies

Customer Inputs

Reliability and

Quality Goals

Packaging

Production Trial

Mode and Effects

Analysis (DFMEA)

Standards

Run

Product/Process

Quality System

Review

Measurement

Systems

Evaluation

Process Flow Chart

Preliminary

Process Capability

Study

Design for

Manufacturability and

Assembly

Preliminary

Process Flow Chart

Design Verification

Design Reviews

Prototype Build

Control Plan

Product Assurance

Plan

Engineering

Drawings (Including

Math Data)

Management

Support

Engineering

Specifications

Decide on

Concern Resolution

Material

Specifications

Develop Product

Quality Timing Plan

Drawing and

Specification Changes

New Equipment,

Tooling and Facilities

Requirements

Special Product and

Process

Characteristics

Floor Plan Layout

Characteristics

Matrix

Process Failure

Mode and Effects

Analysis (PFMEA)

Pre-Launch Control

Plan

Process Instructions

Measurement

Systems Analysis

Plan

Preliminary

Process Capability

Study Plan

Feedback,

Assessment and

Corrective Action

OUTPUT

Design Failure

Preliminary Bill of

Material

Preliminary Listing

of Special Product

and Process

Characteristics

Product and

Process

Validation

INPUT

INPUT

OUTPUT

INPUT

Design Goals

OUTPUT

Process

Design and

Development

Product Design

and

Development

OUTPUT

Plan and Define

Program

INPUT

Prepare for

APQP

Production Part

Approval

Production

Validation Testing

Packaging

Evaluation

Production

Control Plan

Quality Planning

Sign-Off and

Management

Support

Packaging

Specifications

Management

Support

Gages/Testing

Equipment

Requirements

Team Feasibility

Commitment and

Management Support

APQP PROCESS FLOW

Organize the

Voice of the

Team

Customer

Define the Scope

Business

Plan/Marketing

Strategy

Establish Team-toTeam

Communication

Provide Core Tools

Training

Involve Customers

and Suppliers

Implement

Simultaneous

Engineering

Develop Control

Plan Format

Product/Process

Benchmark Data

Product/Process

Assumptions

Product Reliability

Studies

Customer Inputs

Reliability and

Quality Goals

Packaging

Production Trial

Mode and Effects

Analysis (DFMEA)

Standards

Run

Product/Process

Quality System

Review

Measurement

Systems

Evaluation

Process Flow Chart

Preliminary

Process Capability

Study

Design for

Manufacturability and

Assembly

Preliminary

Process Flow Chart

Design Verification

Design Reviews

Prototype Build

Control Plan

Product Assurance

Plan

Engineering

Drawings (Including

Math Data)

Management

Support

Engineering

Specifications

Decide on

Concern Resolution

Material

Specifications

Develop Product

Quality Timing Plan

Drawing and

Specification Changes

New Equipment,

Tooling and Facilities

Requirements

Special Product and

Process

Characteristics

Floor Plan Layout

Characteristics

Matrix

Process Failure

Mode and Effects

Analysis (PFMEA)

Pre-Launch Control

Plan

Process Instructions

Measurement

Systems Analysis

Plan

Preliminary

Process Capability

Study Plan

OUTPUT

INPUT

OUTPUT

Design Failure

Preliminary Bill of

Material

Preliminary Listing

of Special Product

and Process

Characteristics

Feedback,

Assessment and

Corrective Action

Product and

Process

Validation

INPUT

INPUT

OUTPUT

INPUT

Design Goals

OUTPUT

Process

Design and

Development

Product Design

and

Development

OUTPUT

Plan and Define

Program

INPUT

Prepare for

APQP

Reduced Variation

Customer

Satisfaction

Delivery and

Service

Production Part

Approval

Production

Validation Testing

Packaging

Evaluation

Production

Control Plan

Quality Planning

Sign-Off and

Management

Support

Packaging

Specifications

Management

Support

Gages/Testing

Equipment

Requirements

Team Feasibility

Commitment and

Management Support

APQP PROCESS FLOW

Organize the

Voice of the

Team

Customer

Define the Scope

Business

Plan/Marketing

Strategy

Establish Team-toTeam

Communication

Provide Core Tools

Training

Involve Customers

and Suppliers

Implement

Simultaneous

Engineering

Develop Control

Plan Format

Reliability and

Quality Goals

Product/Process

Assumptions

Product Reliability

Studies

Customer Inputs

Production Trial

Standards

Run

Product/Process

Quality System

Review

Measurement

Systems

Evaluation

Process Flow Chart

Preliminary

Process Capability

Study

Preliminary

Process Flow Chart

Design Verification

Design Reviews

Prototype Build

Control Plan

Product Assurance

Plan

Engineering

Drawings (Including

Math Data)

Management

Support

Engineering

Specifications

Decide on

Concern Resolution

Material

Specifications

Develop Product

Quality Timing Plan

Drawing and

Specification Changes

New Equipment,

Tooling and Facilities

Requirements

Special Product and

Process

Characteristics

Floor Plan Layout

Characteristics

Matrix

Process Failure

Mode and Effects

Analysis (PFMEA)

Pre-Launch Control

Plan

Process Instructions

Measurement

Systems Analysis

Plan

Preliminary

Process Capability

Study Plan

OUTPUT

INPUT

OUTPUT

INPUT

Packaging

Mode and Effects

Analysis (DFMEA)

Design for

Manufacturability and

Assembly

FMEA

Feedback,

Assessment and

Corrective Action

Product and

Process

Validation

Design Failure

Preliminary Bill of

Material

Preliminary Listing

of Special Product

and Process

Characteristics

OUTPUT

INPUT

OUTPUT

INPUT

Design Goals

Product/Process

Benchmark Data

Process

Design and

Development

Product Design

and

Development

OUTPUT

Plan and Define

Program

INPUT

Prepare for

APQP

Reduced Variation

Customer

Satisfaction

Delivery and

Service

Production Part

Approval

Production

Validation Testing

Packaging

Evaluation

Production

Control Plan

Quality Planning

Sign-Off and

Management

Support

Packaging

Specifications

Management

Support

Gages/Testing

Equipment

Requirements

Team Feasibility

Commitment and

Management Support

APQP PROCESS FLOW

Organize the

Voice of the

Team

Customer

Define the Scope

Business

Plan/Marketing

Strategy

Establish Team-toTeam

Communication

Provide Core Tools

Training

Involve Customers

and Suppliers

Implement

Simultaneous

Engineering

Develop Control

Plan Format

Reliability and

Quality Goals

Product/Process

Assumptions

Product Reliability

Studies

Customer Inputs

Production Trial

Standards

Run

Product/Process

Quality System

Review

Measurement

Systems

Evaluation

Process Flow Chart

Preliminary

Process Capability

Study

Preliminary

Process Flow Chart

Design Verification

Design Reviews

Prototype Build

Control Plan

Product Assurance

Plan

Engineering

Drawings (Including

Math Data)

Management

Support

Engineering

Specifications

Decide on

Concern Resolution

Material

Specifications

Develop Product

Quality Timing Plan

Drawing and

Specification Changes

New Equipment,

Tooling and Facilities

Requirements

Special Product and

Process

Characteristics

Floor Plan Layout

Characteristics

Matrix

Process Failure

Mode and Effects

Analysis (PFMEA)

Pre-Launch Control

Plan

Process Instructions

Measurement

Systems Analysis

Plan

Preliminary

Process Capability

Study Plan

OUTPUT

INPUT

OUTPUT

INPUT

Packaging

Mode and Effects

Analysis (DFMEA)

Design for

Manufacturability and

Assembly

FMEA

Feedback,

Assessment and

Corrective Action

Product and

Process

Validation

Design Failure

Preliminary Bill of

Material

Preliminary Listing

of Special Product

and Process

Characteristics

OUTPUT

INPUT

OUTPUT

INPUT

Design Goals

Product/Process

Benchmark Data

Process

Design and

Development

Product Design

and

Development

OUTPUT

Plan and Define

Program

INPUT

Prepare for

APQP

Reduced Variation

Customer

Satisfaction

Delivery and

Service

Production Part

Approval

Production

Validation Testing

Packaging

Evaluation

Production

Control Plan

Quality Planning

Sign-Off and

Management

Support

Packaging

Specifications

Management

Support

Gages/Testing

Equipment

Requirements

Team Feasibility

Commitment and

Management Support

APQP

10

APQP PROCESS FLOW

Organize the

Voice of the

Team

Customer

Define the Scope

Business

Plan/Marketing

Strategy

Establish Team-toTeam

Communication

Provide Core Tools

Training

Involve Customers

and Suppliers

Implement

Simultaneous

Engineering

Develop Control

Plan Format

Reliability and

Quality Goals

Product/Process

Assumptions

Product Reliability

Studies

Customer Inputs

Production Trial

Standards

Run

Product/Process

Quality System

Review

Measurement

Systems

Evaluation

Process Flow Chart

Preliminary

Process Capability

Study

Preliminary

Process Flow Chart

Design Verification

Design Reviews

Prototype Build

Control Plan

Product Assurance

Plan

Engineering

Drawings (Including

Math Data)

Management

Support

Engineering

Specifications

Decide on

Concern Resolution

Material

Specifications

Develop Product

Quality Timing Plan

Drawing and

Specification Changes

New Equipment,

Tooling and Facilities

Requirements

Special Product and

Process

Characteristics

Floor Plan Layout

Characteristics

Matrix

Process Failure

Mode and Effects

Analysis (PFMEA)

Pre-Launch Control

Plan

Process Instructions

Measurement

Systems Analysis

Plan

Preliminary

Process Capability

Study Plan

Reduced Variation

Customer

Satisfaction

Delivery and

Service

Production Part

Approval

Production

Validation Testing

Packaging

Evaluation

Production

Control Plan

Quality Planning

Sign-Off and

Management

Support

Packaging

Specifications

Management

Support

Gages/Testing

Equipment

Requirements

Team Feasibility

Commitment and

Management Support

OUTPUT

INPUT

OUTPUT

INPUT

Packaging

Mode and Effects

Analysis (DFMEA)

Design for

Manufacturability and

Assembly

FMEA

Feedback,

Assessment and

Corrective Action

Product and

Process

Validation

Design Failure

Preliminary Bill of

Material

Preliminary Listing

of Special Product

and Process

Characteristics

OUTPUT

INPUT

OUTPUT

INPUT

Design Goals

Product/Process

Benchmark Data

Process

Design and

Development

Product Design

and

Development

OUTPUT

Plan and Define

Program

INPUT

Prepare for

APQP

APQP

SPC

11

APQP PROCESS FLOW

Organize the

Voice of the

Team

Customer

Define the Scope

Business

Plan/Marketing

Strategy

Establish Team-toTeam

Communication

Provide Core Tools

Training

Involve Customers

and Suppliers

Implement

Simultaneous

Engineering

Develop Control

Plan Format

Reliability and

Quality Goals

Product/Process

Assumptions

Product Reliability

Studies

Customer Inputs

Production Trial

Standards

Run

Product/Process

Quality System

Review

Measurement

Systems

Evaluation

Process Flow Chart

Preliminary

Process Capability

Study

Preliminary

Process Flow Chart

Design Verification

Design Reviews

Prototype Build

Control Plan

Product Assurance

Plan

Engineering

Drawings (Including

Math Data)

Management

Support

Engineering

Specifications

Decide on

Concern Resolution

Material

Specifications

Develop Product

Quality Timing Plan

Drawing and

Specification Changes

New Equipment,

Tooling and Facilities

Requirements

Special Product and

Process

Characteristics

Floor Plan Layout

Characteristics

Matrix

Process Failure

Mode and Effects

Analysis (PFMEA)

Pre-Launch Control

Plan

Process Instructions

Measurement

Systems Analysis

Plan

Preliminary

Process Capability

Study Plan

Production

Validation Testing

Reduced Variation

Customer

Satisfaction

Delivery and

Service

MSA

Packaging

Evaluation

Production

Control Plan

Quality Planning

Sign-Off and

Management

Support

Packaging

Specifications

Management

Support

Gages/Testing

Equipment

Requirements

Team Feasibility

Commitment and

Management Support

Production Part

Approval

OUTPUT

INPUT

OUTPUT

INPUT

Packaging

Mode and Effects

Analysis (DFMEA)

Design for

Manufacturability and

Assembly

FMEA

Feedback,

Assessment and

Corrective Action

Product and

Process

Validation

Design Failure

Preliminary Bill of

Material

Preliminary Listing

of Special Product

and Process

Characteristics

OUTPUT

INPUT

OUTPUT

INPUT

Design Goals

Product/Process

Benchmark Data

Process

Design and

Development

Product Design

and

Development

OUTPUT

Plan and Define

Program

INPUT

Prepare for

APQP

APQP

SPC

12

APQP PROCESS FLOW

Organize the

Voice of the

Team

Customer

Define the Scope

Business

Plan/Marketing

Strategy

Establish Team-toTeam

Communication

Provide Core Tools

Training

Involve Customers

and Suppliers

Implement

Simultaneous

Engineering

Develop Control

Plan Format

Design Goals

Reliability and

Quality Goals

Product/Process

Benchmark Data

Product/Process

Assumptions

Product Reliability

Studies

Customer Inputs

Production Trial

Standards

Run

Product/Process

Quality System

Review

Measurement

Systems

Evaluation

Process Flow Chart

Preliminary

Process Capability

Study

Preliminary

Process Flow Chart

Design Verification

Design Reviews

Prototype Build

Control Plan

Product Assurance

Plan

Engineering

Drawings (Including

Math Data)

Management

Support

Engineering

Specifications

Decide on

Concern Resolution

Material

Specifications

Develop Product

Quality Timing Plan

Drawing and

Specification Changes

New Equipment,

Tooling and Facilities

Requirements

Special Product and

Process

Characteristics

Floor Plan Layout

Characteristics

Matrix

Process Failure

Mode and Effects

Analysis (PFMEA)

Pre-Launch Control

Plan

Process Instructions

Measurement

Systems Analysis

Plan

Preliminary

Process Capability

Study Plan

Production

Validation Testing

Reduced Variation

Customer

Satisfaction

Delivery and

Service

MSA

Packaging

Evaluation

Production

Control Plan

Quality Planning

Sign-Off and

Management

Support

PPAP

Packaging

Specifications

Management

Support

Gages/Testing

Equipment

Requirements

Team Feasibility

Commitment and

Management Support

Production Part

Approval

OUTPUT

INPUT

OUTPUT

INPUT

Packaging

Mode and Effects

Analysis (DFMEA)

Design for

Manufacturability and

Assembly

FMEA

OUTPUT

Design Failure

Preliminary Bill of

Material

Preliminary Listing

of Special Product

and Process

Characteristics

Feedback,

Assessment and

Corrective Action

Product and

Process

Validation

Process Design

and

Development

INPUT

OUTPUT

INPUT

Product Design

and

Development

OUTPUT

Plan and Define

Program

INPUT

Prepare for

APQP

APQP

SPC

13

You might also like

- Apqp & PpapDocument63 pagesApqp & Ppapjd4u100% (1)

- AS9145 Aerospace Standard APQP and PPAP GuidanceDocument20 pagesAS9145 Aerospace Standard APQP and PPAP Guidance44abcNo ratings yet

- APQP Workbook TrainingDocument31 pagesAPQP Workbook TrainingFranciscoNo ratings yet

- Advanced Product Quality Planning (APQP)Document22 pagesAdvanced Product Quality Planning (APQP)mjapmgNo ratings yet

- APQP Process Flow GuideDocument13 pagesAPQP Process Flow Guidejohnoo70% (1)

- Advanced Product Quality PlanningDocument35 pagesAdvanced Product Quality Planninggerry3854100% (2)

- APQP Phases ActivitiesDocument1 pageAPQP Phases Activitiesaorto3919No ratings yet

- Procedure APQPDocument9 pagesProcedure APQPAzmul Fadhli80% (10)

- Manual - APQP 20121017 PDFDocument135 pagesManual - APQP 20121017 PDFBerk NoyanNo ratings yet

- Apqp PpapDocument50 pagesApqp PpapEvandro Ribeiro50% (2)

- Volvo ApqpDocument30 pagesVolvo ApqpAmolPagdalNo ratings yet

- APQP Process AssessmentDocument3 pagesAPQP Process AssessmentSergio ArellanoNo ratings yet

- APQPDocument25 pagesAPQPHeera Singh100% (3)

- Software ReliabilityDocument211 pagesSoftware Reliabilityapi-3775463100% (1)

- APQP ENG SiemensDocument12 pagesAPQP ENG SiemensVikash KumarNo ratings yet

- APQPDocument2 pagesAPQPjitenderbawalia0% (1)

- Apqp Workflow - EXAMPLEDocument1 pageApqp Workflow - EXAMPLEMiguel NetoNo ratings yet

- APQP FormsDocument23 pagesAPQP FormsJOECOOL670% (1)

- APQP GoodDocument70 pagesAPQP Goodtrung100% (1)

- CSR Matrix For RefDocument6 pagesCSR Matrix For RefBard Z8No ratings yet

- Spec Characteristics GdlnesDocument2 pagesSpec Characteristics Gdlnessathyabalaraman0% (1)

- APQP Manual VolvoDocument30 pagesAPQP Manual VolvoVictor Hugo50% (2)

- Core Tools Forms V5dDocument119 pagesCore Tools Forms V5dIng. Alberto AguilarNo ratings yet

- Core Tools PDFDocument1 pageCore Tools PDFsentrakerjaan100% (3)

- Ii. Structure Analysis Iii. Function Analysis: Company NameDocument6 pagesIi. Structure Analysis Iii. Function Analysis: Company NameJohn OoNo ratings yet

- IATF 16949 ClientsDocument126 pagesIATF 16949 ClientsKumaravel100% (1)

- MSR-Columns hidden or deletedDocument2 pagesMSR-Columns hidden or deleted57641100% (1)

- Apqp - DR SHFTDocument60 pagesApqp - DR SHFTrajesh5000100% (2)

- Format No-Blank/Dir: Detail Inspection ReportDocument18 pagesFormat No-Blank/Dir: Detail Inspection ReportRock RockyNo ratings yet

- APQP OverviewDocument86 pagesAPQP OverviewLuis Lujano100% (1)

- Register Forum Home Page Post Attachment Files All Help Lost PasswordDocument3 pagesRegister Forum Home Page Post Attachment Files All Help Lost PasswordKirthivasanNo ratings yet

- Process Control PlanDocument10 pagesProcess Control Planapi-3701688No ratings yet

- PFMEA ExampleDocument14 pagesPFMEA Examplekalebasveggie100% (1)

- IATF 16949:2016 IntroductionDocument20 pagesIATF 16949:2016 IntroductionDisha Shah100% (4)

- Process Flow Chart (Pre-Launch / Production)Document1 pageProcess Flow Chart (Pre-Launch / Production)kumar0% (1)

- Ppap - Aiag ManualDocument102 pagesPpap - Aiag Manualquintozh100% (1)

- Sr. No. Requirements: Ppap Check ListDocument3 pagesSr. No. Requirements: Ppap Check Listkamlesh kuchekarNo ratings yet

- IATF 16949 - 2016: Presented by - Kuldeep TanwarDocument193 pagesIATF 16949 - 2016: Presented by - Kuldeep Tanwarsololips100% (2)

- PPAP ManualDocument102 pagesPPAP Manualsuresh196950% (2)

- APQP TrainingDocument22 pagesAPQP TrainingSandeep Malik100% (1)

- Supplier Apqp Gated ReviewDocument1 pageSupplier Apqp Gated Reviewtanto_deep_15No ratings yet

- Ppap Master TabsDocument37 pagesPpap Master TabsRaju.PalNo ratings yet

- Core ToolsDocument15 pagesCore ToolsUn-peu de-toutNo ratings yet

- PPAP Check List FormDocument5 pagesPPAP Check List FormRaju.PalNo ratings yet

- IATF 16949:2016 Process Audit TrainingDocument4 pagesIATF 16949:2016 Process Audit TrainingisolongNo ratings yet

- Control Plan Training GuideDocument20 pagesControl Plan Training GuidelittlekheongNo ratings yet

- 1 - APQP Process FlowDocument13 pages1 - APQP Process FlowGONZALEZNIETONo ratings yet

- APQP PresentationDocument13 pagesAPQP PresentationShailesh KulkarniNo ratings yet

- Qms (Quality Management System)Document16 pagesQms (Quality Management System)Sundaramoorthy ArumugamNo ratings yet

- Apqp (Concept Explanation)Document6 pagesApqp (Concept Explanation)mierulsNo ratings yet

- Ford Full ApqpDocument169 pagesFord Full ApqpCésar Meza83% (6)

- PPAP TRGDocument102 pagesPPAP TRGArivazhagan Art100% (1)

- Supplier APQP Process Training (In-Depth)Document142 pagesSupplier APQP Process Training (In-Depth)A MNo ratings yet

- Advanced Product Quality Planning APQP GuideDocument142 pagesAdvanced Product Quality Planning APQP GuideVijayNo ratings yet

- APQP Process Training (In-Depth)Document142 pagesAPQP Process Training (In-Depth)Sunil67% (3)

- Eaton ApqpDocument142 pagesEaton ApqpAmolPagdalNo ratings yet

- APQP Training MaterialDocument13 pagesAPQP Training Materialsuresh kumar100% (1)

- Basics of Internal AuditDocument19 pagesBasics of Internal Auditshukumar_24No ratings yet

- New Seven Q.C. Tools Problem Solving TechniquesDocument70 pagesNew Seven Q.C. Tools Problem Solving Techniquesshukumar_24100% (1)

- Basics of Internal AuditDocument19 pagesBasics of Internal Auditshukumar_24No ratings yet

- Basics of Internal AuditDocument19 pagesBasics of Internal Auditshukumar_24No ratings yet

- GD&TDocument81 pagesGD&Tshukumar_24No ratings yet

- Problem Solving Basic 7 QC ToolsDocument53 pagesProblem Solving Basic 7 QC Toolsshukumar_24100% (4)

- Basics of Internal AuditDocument19 pagesBasics of Internal Auditshukumar_24No ratings yet

- GD&TDocument81 pagesGD&Tshukumar_24No ratings yet

- Measurement System Analysis (MSA) GuideDocument30 pagesMeasurement System Analysis (MSA) Guideshukumar_24No ratings yet

- TPM GuideDocument40 pagesTPM Guideshukumar_24No ratings yet

- Measurement System Analysis (MSA) GuideDocument30 pagesMeasurement System Analysis (MSA) Guideshukumar_24No ratings yet

- Perancangan Business Digital Platform Dalam Mendukung Keberlanjutan IKM Dengan Pendekatan Quality Function DeploymentDocument13 pagesPerancangan Business Digital Platform Dalam Mendukung Keberlanjutan IKM Dengan Pendekatan Quality Function DeploymentFajar IndraNo ratings yet

- Store Design and Visual MerchandisingDocument32 pagesStore Design and Visual MerchandisingBusiness Expert Press86% (14)

- Tourism MarketingDocument60 pagesTourism MarketingGuruKPO100% (7)

- Marketing RedefinedDocument2 pagesMarketing RedefinedCarlos Comino GonzálezNo ratings yet

- Innovation Management Case StudyDocument3 pagesInnovation Management Case StudySujit ShahNo ratings yet

- World Assembly of Public Relations Associations (1978)Document18 pagesWorld Assembly of Public Relations Associations (1978)Chris TuckerNo ratings yet

- RMKV FinalDocument16 pagesRMKV Finall_krish07100% (2)

- 411 Product Management-1Document110 pages411 Product Management-1Awadhesh YadavNo ratings yet

- Developing and Managing Market Insights A Study On Akij Food and Beverage LimitedDocument36 pagesDeveloping and Managing Market Insights A Study On Akij Food and Beverage LimitedNafees Hasan ChowdhuryNo ratings yet

- Director Financial Planning Analysis in Boston MA Resume Melissa SalernoDocument2 pagesDirector Financial Planning Analysis in Boston MA Resume Melissa SalernoMelissaSalernoNo ratings yet

- Chapters 1 3. Revision. CalmaDocument66 pagesChapters 1 3. Revision. CalmaJulie Basbas-CruzNo ratings yet

- Customer Persona Worksheet.: Created byDocument7 pagesCustomer Persona Worksheet.: Created byImi FeketeNo ratings yet

- Trans MGT SYLLABUSDocument15 pagesTrans MGT SYLLABUSgemma adovoNo ratings yet

- Fresh Fruits & Veg Marketing Constraints & OpportunitiesDocument53 pagesFresh Fruits & Veg Marketing Constraints & OpportunitiesNgan TuyNo ratings yet

- Cisco ST>RT Catalog Provides Overview of Security-Focused Networking Solutions for Asia Pacific SMBsDocument32 pagesCisco ST>RT Catalog Provides Overview of Security-Focused Networking Solutions for Asia Pacific SMBsAndreas B KresnawanNo ratings yet

- Article 8 Reflective Paper 2Document11 pagesArticle 8 Reflective Paper 2Nur Amira NadiaNo ratings yet

- Application of Demand and SupplyDocument25 pagesApplication of Demand and SupplyThriztan Andrei BaluyutNo ratings yet

- Case 10-Trimo: Institutional Affiliation Student's Name Instructor's Name Course Name DateDocument4 pagesCase 10-Trimo: Institutional Affiliation Student's Name Instructor's Name Course Name Datesteve OduyaNo ratings yet

- Four Market StructureDocument20 pagesFour Market StructureadithyaNo ratings yet

- Service ScapeDocument17 pagesService ScapeKiran Peravali100% (1)

- Copetitor Analysis (Cola Next)Document6 pagesCopetitor Analysis (Cola Next)farwa100% (1)

- Chapter 8 - SellingDocument17 pagesChapter 8 - SellingKPRobinNo ratings yet

- MedNet AM Case SolutionDocument6 pagesMedNet AM Case Solutionsourobhdas.007100% (2)

- A CASE STUDY OF THE FASHION SHOW CURATORIALDocument2 pagesA CASE STUDY OF THE FASHION SHOW CURATORIALShankar ChapagainNo ratings yet

- Chapter 2 MIS MCQDocument8 pagesChapter 2 MIS MCQRana SabryNo ratings yet

- Gamification 101Document14 pagesGamification 101willwnetNo ratings yet

- IntroDocument20 pagesIntroAnam Lalwani-VastaniNo ratings yet

- Vertical Integration and Global Operations Drive Luxottica SuccessDocument5 pagesVertical Integration and Global Operations Drive Luxottica SuccessMohit MotwaniNo ratings yet

- CV1 Ayushi Mowar 61920572Document1 pageCV1 Ayushi Mowar 61920572Harmandeep singhNo ratings yet

- Creating A Marketing PlanDocument5 pagesCreating A Marketing PlanjhanelNo ratings yet