Professional Documents

Culture Documents

QA/QC documentation summaries

Uploaded by

Anoop Chandran50%(2)50% found this document useful (2 votes)

2K views24 pagesVJ,JHVJK

Original Title

Qa Qc Dossier Index

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentVJ,JHVJK

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

50%(2)50% found this document useful (2 votes)

2K views24 pagesQA/QC documentation summaries

Uploaded by

Anoop ChandranVJ,JHVJK

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 24

QA/QC DOCUMENTATIONS

PQR

Specific codes and/or engineering

societies are often the driving force

behind the development of a

company's WPS. A WPS is supported by

a Procedure Qualification Record (PQR

or WPQR). A PQR is a record of a test

weld performed and tested (more

rigorously) to ensure that the

procedure will produce a good weld.

PWPS

A preliminary/pre-qualified welding

procedure specification (PWPS) is a

document containing required variables

of the welding procedure which needs to

be qualified in order to create the

qualified welding procedure specification

(WPS).

Based on the customer's input on type

of material, dimensions and joint

configuration, the pWPS will be prepared

WPS

A Welding Procedure Specification

(WPS) is the formal written document

describing welding procedures, which

provides direction to the welder or

welding operators for making sound

and quality production welds as per the

code requirements . ... A WPS is

supported by a Procedure Qualification

Record (PQR or WPQR).

INITIAL WELDER EVALUATION

The document which used to mention

the acceptance and rejection of a weld

joint welded by a welder

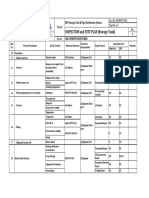

WELDER QUALIFICATION TEST ATTENDENCE REQUISITION

Welder certification, (also known as

welder qualification) is a process which

examines and documents a welder's

capability to create welds of acceptable

quality following a well defined welding

procedure.

WQTAR contains the details regarding

wqt carried out

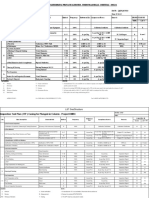

DAILY WELDING REPORT

It is report regarding the no of weld

joints completed in a day.

It contains the no of weld joints

completed by t welders including

area ,dw no, line no ,weld passes etc

FIT UP &WELD VISUAL INSPECTION REPORT

It is used to report the dimensional

details checked by the qc inspector like

root gap, bevel angle, root face and

visual inspection details

MATERIAL INSPECTION REPORT

The Material Inspection Receiving

Report provides you information about

incoming material inspection at the

shop and site. ... After the receiving

inspection, the material controller shall

prepare the Material Receiving Report.

NDE CLEARANCE

In order to determine the suitability of the

weldjoint for its intended purpose, some degree

of nondestructive examination/testing

(NDE/NDT) should be conducted as part of

sound fabrication practice and quality

assurance. For non-code fabrication, NDE may

be as simple as visual or liquid/dye penetrant

inspection. For code fabrication, certain

mandatory inspections may be required. These

NDE methods should be considered for both

intermediate inspections during multi-pass

welding, as well as for final acceptance of the

weldjoint.

NDE&HEAT TREATMENT REQUISITION FORM

Form which is used for requesting non

destructive inspection and heat

treatment process. Contains drawing

details and weld details

PRESSURE TEST REPORT

This form must be completed for each

section of newly installed section of

pipe or service line and on each service

line that is disconnected from the main

for any reason.

PUMP CHECK LIST

Chances are that your facility has

several pumps performing various

tasks. Pumps are necessary for the

smooth operation of your building

whether they are used for HVAC,

domestic water, or process. To keep

pumps running properly, it's prudent to

keep a regular maintenance schedule

using a pump maintenance checklist.

REQUEST FOR INSPECTION

There are several points during

construction where an inspection may

be required. ... When you have

completed a segment of your project

requiring that an inspection be

performed

WELDERS CONTROL SHEET BY RADIOGRAPHIC EXAMINATION

Radio graphic examination report is a

document which contains the details of

weld joints whether it can be accepted

or not ,any type of defects present in it.

TECHNICAL QUERY

Technical query is the formal process of

asking a clarification or a question from

the concerned departments involved in

the execution of the project. The

Technical query can be raised between

Owner & Contractor, between site

operations of the contractor and

engineering team of the contractor etc.

WELD REPAIR RECORD

Document which contains the details of

weld repairs with the support of ndt

report.

BLAST/PAINT RELEASE FORM

Document or release form which used

to hand over the work to the paint/blast

department for further action

PAINT INSPECTION REPORT

Inspection report which contains all the

find outs regarding a painting

FIELD INSPECTION REPORT

It is final inspection report otherwise

known as final punch/check list.it

contains the unfinished or balance work

which has to be done before handover

FLANGE MANAGEMENT CERTIFICATE

Punch list or check list regarding a

flange.

HAND OVER CERTIFICATE

Certificate which used to hand over the

work done by the contractor to the

client.

THANKS

You might also like

- Works Instruction For Piping Welding InspectionDocument5 pagesWorks Instruction For Piping Welding InspectionAbg SepulNo ratings yet

- QapDocument9 pagesQaprenjithv_4No ratings yet

- Itp 001 PipelineDocument2 pagesItp 001 PipelineMohd Effiezool YaserNo ratings yet

- Al-Uqlah Central Processing Facility Water Level & Settlement TableDocument12 pagesAl-Uqlah Central Processing Facility Water Level & Settlement TableSantosh Kumar BogelaNo ratings yet

- Piping Replacement Carbon Steel InspectionDocument3 pagesPiping Replacement Carbon Steel Inspectionmohd as shahiddin jafriNo ratings yet

- Rotating Itp 1Document4 pagesRotating Itp 1abdul aziz100% (1)

- Leak Test Procedure for Atmospheric VesselDocument9 pagesLeak Test Procedure for Atmospheric VesselRicardo NapitupuluNo ratings yet

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTDocument5 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTVKT TiwariNo ratings yet

- Engineering & Construction: Magnetic Particle Test ProcedureDocument13 pagesEngineering & Construction: Magnetic Particle Test Proceduresoledense5470100% (1)

- 24.tank Oil Chalk TestDocument3 pages24.tank Oil Chalk TestShubham ShuklaNo ratings yet

- Test Pack SampleDocument12 pagesTest Pack SampleGomathyselviNo ratings yet

- DPT ProcedureDocument4 pagesDPT ProcedureRohit Attri100% (1)

- Basic Fabrication Process FlowchartDocument2 pagesBasic Fabrication Process FlowchartGodwin A.udo-akan100% (1)

- Itp Piping PDFDocument4 pagesItp Piping PDFdashNo ratings yet

- Material Receiving Inspection Report: Project TitleDocument2 pagesMaterial Receiving Inspection Report: Project TitleGomathyselviNo ratings yet

- Visual Inspection ReportDocument2 pagesVisual Inspection ReportAlfian ImaduddinNo ratings yet

- Report-1683-1 B1 25mm 14 10 2020Document7 pagesReport-1683-1 B1 25mm 14 10 2020sakthi velNo ratings yet

- Itp Internal CoatingDocument4 pagesItp Internal CoatingkamlNo ratings yet

- 5111FA-Assessment Report-Shell & Roof Rev.1Document14 pages5111FA-Assessment Report-Shell & Roof Rev.1Hosam AhmedNo ratings yet

- Alignment Survey ReportDocument1 pageAlignment Survey ReporttreyNo ratings yet

- Asnt Level Ii - NDT In: Application For The Post Of: QC PIPING INSPECTORDocument34 pagesAsnt Level Ii - NDT In: Application For The Post Of: QC PIPING INSPECTORJAMHSED KHANNo ratings yet

- Roundness Shell #1 - 1-Tank -012 BEFORE WELDDocument2 pagesRoundness Shell #1 - 1-Tank -012 BEFORE WELDyuwantoniNo ratings yet

- Bolt Tightening ReportDocument2 pagesBolt Tightening Reportmujahed_muhammedNo ratings yet

- Spark Holiday Test Report SummaryDocument3 pagesSpark Holiday Test Report SummaryPat Lim100% (1)

- TANK ERECTION PROCEDURESDocument5 pagesTANK ERECTION PROCEDURESkushar_geoNo ratings yet

- Nig VT Spec QB S2 - Level IiDocument12 pagesNig VT Spec QB S2 - Level Iikingston100% (1)

- Chemical Resistance (LLDPE) PDFDocument24 pagesChemical Resistance (LLDPE) PDFrubyshreeNo ratings yet

- Weld Defects and Imperfections GuideDocument43 pagesWeld Defects and Imperfections Guideraju100% (1)

- Storage Tank Hydrostatic Test Quality Control and Inspection Report FormDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report FormsugiantobarusNo ratings yet

- Storage Tank Foundation Settlement Quality Control and Inspection Report FormDocument1 pageStorage Tank Foundation Settlement Quality Control and Inspection Report FormKhepa BabaNo ratings yet

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocument19 pagesHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdNo ratings yet

- Magnetic Particle Testing ReporDocument2 pagesMagnetic Particle Testing ReporGabriela MotaNo ratings yet

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- Remote Visual Inspection ProcedureDocument10 pagesRemote Visual Inspection ProcedureThinh Nguyen100% (1)

- OCS Engineering & Construction Visual Inspection ReportDocument1 pageOCS Engineering & Construction Visual Inspection ReportvinothNo ratings yet

- Equipment Inspection and Testing ProcessesDocument13 pagesEquipment Inspection and Testing ProcessesDevid Peri Sonefel100% (1)

- L&T GeoStructure casing inspection planDocument2 pagesL&T GeoStructure casing inspection plansanil50% (2)

- Inspection Checklist For: Pipework InsulationDocument2 pagesInspection Checklist For: Pipework InsulationMuquequ@100% (1)

- RT ReportDocument4 pagesRT ReportWeldcast Ndt100% (1)

- Procedure For Vacuum Box TestingDocument3 pagesProcedure For Vacuum Box TestingZakirUllahNo ratings yet

- Inspection and Test Plan For Storage TankDocument8 pagesInspection and Test Plan For Storage TankAndreas AlexanderNo ratings yet

- 003 ITP UG PipingDocument4 pages003 ITP UG Pipingrvsingh70100% (1)

- Inspection RoleDocument18 pagesInspection Rolesribd9128No ratings yet

- QA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsDocument1 pageQA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsvinothNo ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- Fire Protection Pipes Method Statement PDFDocument16 pagesFire Protection Pipes Method Statement PDFفاعل خيرNo ratings yet

- Test Certificate 01Document1 pageTest Certificate 01Anoop RaghuNo ratings yet

- Russindo Group Vacuum Box Test ProcedureDocument5 pagesRussindo Group Vacuum Box Test ProcedureIkhsan Dalimunthe100% (2)

- Final Inspection Report for Venturi Pin LinersDocument1 pageFinal Inspection Report for Venturi Pin LinersSenthil KumarNo ratings yet

- 3D 301 Header AnalysisDocument19 pages3D 301 Header AnalysisMahmoud GaberNo ratings yet

- 8 Material ControlDocument8 pages8 Material ControlPrakash RajNo ratings yet

- Inspection & Test Plan TankDocument3 pagesInspection & Test Plan TankJOSHUA SULLEGUE100% (1)

- Visual Welding Inspector Course TopicsDocument40 pagesVisual Welding Inspector Course TopicsJohn Dare100% (2)

- Safe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallDocument1 pageSafe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallHarun AkkayaNo ratings yet

- RT API 650 12th - 2013Document1 pageRT API 650 12th - 2013Đỗ Thị HuyềnNo ratings yet

- Roundness Check Record of 1St Shell CourseDocument1 pageRoundness Check Record of 1St Shell CourseRhannie GarciaNo ratings yet

- CV of Welding InspectorDocument4 pagesCV of Welding Inspectorramesh77c100% (2)

- 01-Visual Inspection & Welding InspectorsDocument7 pages01-Visual Inspection & Welding InspectorsSaif UllahNo ratings yet

- Validation Commissioning DocumentsDocument4 pagesValidation Commissioning DocumentsPrashansa ShresthaNo ratings yet

- Armstech Training Division Brochure NewDocument12 pagesArmstech Training Division Brochure NewAnoop ChandranNo ratings yet

- June 2022 Batch Training ScheduleDocument47 pagesJune 2022 Batch Training ScheduleAnoop ChandranNo ratings yet

- 12th First TermDocument11 pages12th First TermAnoop ChandranNo ratings yet

- June 2022 Batch Training ScheduleDocument47 pagesJune 2022 Batch Training ScheduleAnoop ChandranNo ratings yet

- June 2022 Batch Training ScheduleDocument47 pagesJune 2022 Batch Training ScheduleAnoop ChandranNo ratings yet

- Playboy 2Document12 pagesPlayboy 2theraphimNo ratings yet

- Mechanical Engineering 4 Year PlanDocument2 pagesMechanical Engineering 4 Year PlanMark OsborneNo ratings yet

- Cell Phone Safety in SchoolsDocument2 pagesCell Phone Safety in SchoolsYvez Vyanka CastilloNo ratings yet

- NLP - The Satanic Warlock - NLP and The Science of SeductionDocument18 pagesNLP - The Satanic Warlock - NLP and The Science of SeductionnegreanNo ratings yet

- Tilak Highschool Exam Activity Sheet for English SubjectDocument8 pagesTilak Highschool Exam Activity Sheet for English SubjectJay Bhatia0% (1)

- Assignment I Topics: LevellingDocument2 pagesAssignment I Topics: LevellingsagarNo ratings yet

- Prospectus 2023-24Document11 pagesProspectus 2023-24Niranjan SahooNo ratings yet

- PHP Jeremy Djakoure BEDJEDocument6 pagesPHP Jeremy Djakoure BEDJEjbedjeNo ratings yet

- Arithmetic SequencesDocument3 pagesArithmetic SequencestuvvacNo ratings yet

- I+ME ACTIA SAE J2534 Support Release NotesDocument4 pagesI+ME ACTIA SAE J2534 Support Release NotesJose AGNo ratings yet

- TOK Essay - Does Language Play Roles of Equal Importance in Different Areas of KnowledgeDocument3 pagesTOK Essay - Does Language Play Roles of Equal Importance in Different Areas of KnowledgeTenisha Castillo100% (2)

- Bresnen M. and Marshall N. 2000a Building Partnerships Case Studies of Client Contractor Collaboration in The UK Construction Industry'Document14 pagesBresnen M. and Marshall N. 2000a Building Partnerships Case Studies of Client Contractor Collaboration in The UK Construction Industry'VivianeLeuchtenbergPEspositoNo ratings yet

- Cyril Acott - Occultism - An Alternative To Scientific HumanismDocument20 pagesCyril Acott - Occultism - An Alternative To Scientific Humanismparadigmshifter6360100% (2)

- Journal No.1:: My Personal TimelineDocument5 pagesJournal No.1:: My Personal TimelineSheena ChanNo ratings yet

- Business Plan GEMO 1.0Document13 pagesBusiness Plan GEMO 1.0KrzysztofWitkowski-SoroczanNo ratings yet

- Thesis Statement For AladdinDocument8 pagesThesis Statement For Aladdindianaturnerspringfield100% (2)

- Purcell 10.2: Solutions To Problem Set 12Document5 pagesPurcell 10.2: Solutions To Problem Set 12Eugene YiNo ratings yet

- Detection of Structural Damage in Building Using Changes in Modal Damping Mechanism (2012) - Paper PDFDocument6 pagesDetection of Structural Damage in Building Using Changes in Modal Damping Mechanism (2012) - Paper PDFJulio Humberto Díaz RondánNo ratings yet

- Recruitment Needs Are of Three Types: PlannedDocument7 pagesRecruitment Needs Are of Three Types: PlannedShraddha MomayaNo ratings yet

- The Real Case For Aushwitz - Carlo Mattogno PDFDocument692 pagesThe Real Case For Aushwitz - Carlo Mattogno PDFJordan100% (3)

- C What HappensDocument192 pagesC What Happenschopsticks_phc100% (2)

- Journal Final For WEBDocument84 pagesJournal Final For WEBnormanwillowNo ratings yet

- Early Journal Content On JSTOR, Free To Anyone in The WorldDocument5 pagesEarly Journal Content On JSTOR, Free To Anyone in The WorldLAURLOTUSNo ratings yet

- Logitech Z 5500Document23 pagesLogitech Z 5500Raul Flores HNo ratings yet

- (Nijhoff International Philosophy Series) Stanislaw Lesniewski - S. J. Surma Et Al. (Eds.) - Collected Works. 1, 2-Springer (1991)Document408 pages(Nijhoff International Philosophy Series) Stanislaw Lesniewski - S. J. Surma Et Al. (Eds.) - Collected Works. 1, 2-Springer (1991)Aldana Fontana100% (4)

- Manuel V. Gallego Foundation Colleges, Inc. Cabanatuan City, PhilippinesDocument12 pagesManuel V. Gallego Foundation Colleges, Inc. Cabanatuan City, PhilippinesEdelmar BenosaNo ratings yet

- LocationDocument12 pagesLocationPavithra GowthamNo ratings yet

- Human Factors Risk Assessment and Management - Process Safety in EngineeringDocument16 pagesHuman Factors Risk Assessment and Management - Process Safety in EngineeringAndrés VegaNo ratings yet

- Lecturio The 40 Day Study Schedule USMLE Step 1Document20 pagesLecturio The 40 Day Study Schedule USMLE Step 1Kimberly Kanemitsu50% (2)

- Computer QuizDocument31 pagesComputer QuizYOGESH CHHAGANRAO MULEYNo ratings yet