Professional Documents

Culture Documents

Dr. A. Aziz Bazoune: King Fahd University of Petroleum & Minerals

Uploaded by

Dadang Lukmanul HakimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dr. A. Aziz Bazoune: King Fahd University of Petroleum & Minerals

Uploaded by

Dadang Lukmanul HakimCopyright:

Available Formats

ME 307 Machine Design I

Dr. A. Aziz Bazoune

Mechanical Engineering Department

King Fahd University of Petroleum & Minerals

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 1

ME 307 Machine Design I

7-1 Introduction to Fatigue in Metals 306 7-2 Approach to Fatigue Failure in Analysis and Design 312 7-3 Fatigue-Life Methods 313 7-4 The Stress-Life Method 313 7-5 The Strain-Life Method 316 7-6 The Linear-Elastic Fracture Mechanics Method 319 7-7 The Endurance Limit 323 7-8 Fatigue Strength 325 7-9 Endurance Limit Modifying Factors 328 7-10 Stress Concentration and Notch Sensitivity 335 7-11 Characterizing Fluctuating Stresses 344 7-12 Fatigue Failure Criteria for Fluctuating Stress 346 7-13 Torsional Fatigue Strength under Fluctuating Stresses 360 7-14 Combinations of Loading Modes 361 7-15 Varying, Fluctuating Stresses; Cumulative Fatigue Damage 364 7-16 Surface Fatigue Strength 370 7-17 Stochastic Analysis 373

Dr. A. Aziz Bazoune Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC-21 Slide - 2

ME 307 Machine Design I

7-7 7-8 7-9

The Endurance Limit Fatigue Strength Endurance Limit Modifying Factors

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 3

ME 307 Machine Design I

7-7 The Endurance Limit

A quick method of estimating endurance limits is needed: for preliminary and prototype design for some failure analysis

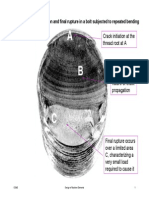

Experimental results for rotating-beam tests simple tension tests of specimens taken from the same bar are shown in Figure 7.18.

Figure 7-18 Graph of endurance limits versus tensile strengths from actual test results for a large number of wrought irons and steels.

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 4

ME 307 Machine Design I

Figure 7-18 Graph of endurance limits versus tensile strengths from actual test results for a large number of wrought irons and steels. Ratios of Se/Sut of 0.60, 0.50, and 0.40 are shown by the solid and dashed lines. Note also the horizontal dashed line for of Se=107 kpsi. Points shown having a tensile strength greater than 214 kpsi have a mean endurance limit of Se=107 kpsi and a standard deviation of 13.5 kpsi.

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 5

ME 307 Machine Design I

For steels, the relationship between the tensile strength and the endurance limit is given by

(7-8)

where

S 'e : is the minimum tensile strength. The prime mark on S 'e in this

equation refers to the rotating-beam specimen itself. The unprimed symbol S e is for the endurance limit of any particular machine element subjected to any kind of loading.

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 6

ME 307 Machine Design I

The endurance limits for various classes of cast irons, polished or machined, are given in Table A-24. Aluminum alloys do not have an endurance limit. The fatigue strengths of some aluminum alloys at 5(108 ) cycles of reversed stress are given in Table A-24.

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 7

ME 307 Machine Design I

7-7 Fatigue Strength

Region of low cycle fatigue:

The fatigue strength strength .

S f is only slightly smaller than the tensile Sut

Region of high Cycle Fatigue

The purpose of this section is to develop methods of approximation of the S-N diagram in the high-cycle region, when information may be as sparse as the results of a simple tension test. Experience has shown high-cycle fatigue data are rectified by a logarithmic transform to both stress and cycles-to-failure.

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 8

ME 307 Machine Design I

7-8 Fatigue Strength

In the region of high cycle fatigue, the equation relating the fatigue strength

S f to the number of cycles to failure N may be given by the

(7-12)

empirical curve fit equation:

where

N is the number of cycles to failure and a and b are given by

(7-13)

(7-14)

where

f is found from Figure 7-19.

Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC-21 Slide - 9

Dr. A. Aziz Bazoune

ME 307 Machine Design I

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 10

ME 307 Machine Design I

If a completely reversed stress

is given, setting

S f a in Eq. (7-12),

the number of cycles-to-failure can be expressed as

(7-15)

Low-cycle fatigue is often defined (see Fig. 7-10) as failure that occurs in a

range of

1 N 103 cycles.

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 11

ME 307 Machine Design I

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 12

ME 307 Machine Design I

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 13

ME 307 Machine Design I

Example

Given a 1050 HR steel, estimate a) The rotating-beam endurance limit at 106. b) The endurance strength of a polished rotating beam specimen corresponding to 104 cycles to failure. c) The expected life of a polished rotating-beam specimen under a completely reversed stress of 55 kpsi.

SOLUTION:

a) From Table A-20, From Eq. (7-8) b)

Sut 90 kpsi Sut 90 kpsi, f 0.86

S 'e 0.5 90 45 kpsi

From Fig. (7-19) for

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 14

ME 307 Machine Design I

Example (Cont.d)

From Eq. (7-13)

and (7-14) ==

Thus Eq. (7-12) is: for

N 104

cycles to failure, the above equation becomes

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 15

ME 307 Machine Design I

Example (Cont.d)

c) From Eq. (7-15), with

a 55 kpsi

Keep in mind that these are only estimates.

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 16

ME 307 Machine Design I

7-9

Endurance Limit Modifying Factors

The rotating-beam specimen used in the laboratory to determine endurance limits is prepared very carefully and tested under closely controlled conditions. It is unrealistic to expect the endurance limit of a mechanical or structural member to match the values obtained in the laboratory. Some differences include Material: composition, basis of failure, variability Manufacturing: method, heat treatment, fretting corrosion, surface condition, stress concentration Environment: corrosion, temperature, stress state, relaxation times Design: size, shape, life, stress state, stress concentration, speed, fretting, galling

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 17

ME 307 Machine Design I

Marins Equation

Marin identified factors that quantified the effects of surface condition, size, loading, temperature, and miscellaneous items. Marins Equations is therefore written as:

(7-17)

Se :

S 'e :

Endurance limit at the critical location of a machine part in geometry and condition of use rotary-beam test specimen endurance limit

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 18

ME 307 Machine Design I

When endurance tests of parts are not available, estimations are made by applying Marin factors to the endurance limit.

Dr. A. Aziz Bazoune Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC-21 Slide - 19

ME 307 Machine Design I

(7-18)

where

Sut

is the minimum tensile strength and

and

are to be found in

Table 7-4.

Table 7-4

Parameters for Marin surface modification factor, Eq. (7-18)

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 20

ME 307 Machine Design I

The size factor

kb

for bending and torsion may be given by:

(7-19)

For axial loading there is no size effect, so

(7-20)

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 21

ME 307 Machine Design I

QUESTION:

What to do with Eq.(7-19) if a round bar in bending is not rotating or when a

non-circular cross-section is used?

ANSWER:

Use effective dimension

d e where

(7-23)

as the effective size of a round corresponding to a non-rotating solid or hollow round. Table 7-5 provides areas of common structural shapes undergoing non-rotating bending

Dr. A. Aziz Bazoune Chapter 7: Fatigue Failure Resulting from variable Loading CH-07 LEC-21 Slide - 22

ME 307 Machine Design I

Table 7-5

Areas of common nonrotating structural shapes

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 23

ME 307 Machine Design I

Average values for the load factor are given by

(7-25)

Dr. A. Aziz Bazoune

Chapter 7: Fatigue Failure Resulting from variable Loading

CH-07

LEC-21

Slide - 24

You might also like

- Fatigue Failure Resulting From Variable Loading Fatigue Failure Resulting From Variable LoadingDocument36 pagesFatigue Failure Resulting From Variable Loading Fatigue Failure Resulting From Variable Loadingamalendu_biswas_1No ratings yet

- Dr. A. Aziz Bazoune: King Fahd University of Petroleum & MineralsDocument37 pagesDr. A. Aziz Bazoune: King Fahd University of Petroleum & MineralsJoe Jeba RajanNo ratings yet

- Dr. A. Aziz Bazoune: King Fahd University of Petroleum & MineralsDocument37 pagesDr. A. Aziz Bazoune: King Fahd University of Petroleum & MineralsVikram BorkhediyaNo ratings yet

- Files 2 Lectures LEC 25 CH 07Document18 pagesFiles 2 Lectures LEC 25 CH 07Randerson AraújoNo ratings yet

- Fallas Por Fatiga Criterios y ProblemasDocument27 pagesFallas Por Fatiga Criterios y ProblemasTeio EstNo ratings yet

- Dr. A. Aziz Bazoune: King Fahd University of Petroleum & Minerals Mechanical Engineering DepartmentDocument14 pagesDr. A. Aziz Bazoune: King Fahd University of Petroleum & Minerals Mechanical Engineering Departmentelgheryb_choukriNo ratings yet

- LEC 31 CH-18 Shafts and AxlesDocument34 pagesLEC 31 CH-18 Shafts and AxlesJoe Hosny100% (1)

- 2-Lectures LEC 28Document15 pages2-Lectures LEC 28elgheryb_choukriNo ratings yet

- Dr. A. Aziz Bazoune: King Fahd University of Petroleum & Minerals Mechanical Engineering DepartmentDocument34 pagesDr. A. Aziz Bazoune: King Fahd University of Petroleum & Minerals Mechanical Engineering Departmentashray_111No ratings yet

- CE 3100: Structural Engineering Lab: February 4Document12 pagesCE 3100: Structural Engineering Lab: February 4Sarankumar ThathuruNo ratings yet

- Fatique Lecture NotesDocument41 pagesFatique Lecture NotesMarcel SilvaNo ratings yet

- Dr. A. Aziz Bazoune: King Fahd University of Petroleum & Minerals Mechanical Engineering DepartmentDocument14 pagesDr. A. Aziz Bazoune: King Fahd University of Petroleum & Minerals Mechanical Engineering DepartmentIsmail DoğanNo ratings yet

- RCC 06Document29 pagesRCC 06Engr SwapanNo ratings yet

- Software Verification - Plane Frame Beam Span Loads AnalysisDocument3 pagesSoftware Verification - Plane Frame Beam Span Loads AnalysisErRajivAmieNo ratings yet

- Post-Tension Flat Slab Design ExampleDocument17 pagesPost-Tension Flat Slab Design ExampleAwni Alkhteeb92% (12)

- Design of ShaftDocument5 pagesDesign of ShaftAnonymous oTrMzaNo ratings yet

- Design of Shaft PDFDocument5 pagesDesign of Shaft PDFAnonymous oTrMzaNo ratings yet

- Bolt Pressure DistributionDocument24 pagesBolt Pressure DistributionbitconceptsNo ratings yet

- Closed Loop Control of Hexagram Inverter: G.Renukadevi, K.RajambalDocument8 pagesClosed Loop Control of Hexagram Inverter: G.Renukadevi, K.Rajambalrenunila100% (1)

- Flexure in Beams: Reinforcement Ratio Limitations and GuidelinesDocument16 pagesFlexure in Beams: Reinforcement Ratio Limitations and GuidelinesEngr SwapanNo ratings yet

- Voltage Regulation Optimization of Compensated Self-Excited Induction Generator With Dynamic LoadDocument9 pagesVoltage Regulation Optimization of Compensated Self-Excited Induction Generator With Dynamic LoadKameleon TaliNo ratings yet

- Fatigue FailureDocument47 pagesFatigue FailureOmar KhanNo ratings yet

- Wind ProvisionsDocument40 pagesWind ProvisionsM Refaat FathNo ratings yet

- MachineDocument8 pagesMachineshivasapkotasNo ratings yet

- PVEfea Assembly AnalysisDocument20 pagesPVEfea Assembly AnalysisAnandh PsNo ratings yet

- ME2114E Combined Bending & Torsion - LabDocument13 pagesME2114E Combined Bending & Torsion - LabCinderella0212100% (2)

- A Novel Current Controlled Space Vector Modulation Based Control Scheme For Reducing Torque Ripple in Brushless DC DrivesDocument7 pagesA Novel Current Controlled Space Vector Modulation Based Control Scheme For Reducing Torque Ripple in Brushless DC DrivesKoukou AmkoukouNo ratings yet

- An Efficient Approach For Cogging Torque Analysis of Motors With Three-Dimensional Flux DistributionDocument3 pagesAn Efficient Approach For Cogging Torque Analysis of Motors With Three-Dimensional Flux DistributionDeni Shidqi KhaerudiniNo ratings yet

- Winches System Design - Thesis Paper Incl Calculations PT2Document17 pagesWinches System Design - Thesis Paper Incl Calculations PT2heddichead100% (1)

- Software Verification: Example 1 Plane Frame With Beam Span Loads - Static Gravity Load Analysis Problem DescriptionDocument3 pagesSoftware Verification: Example 1 Plane Frame With Beam Span Loads - Static Gravity Load Analysis Problem DescriptionRyu Rey RogerNo ratings yet

- RCC 10Document17 pagesRCC 10Engr SwapanNo ratings yet

- AISC 360-05 Example 002Document6 pagesAISC 360-05 Example 002Anitha Hassan Kabeer100% (1)

- Wrap Around Gusset PDFDocument25 pagesWrap Around Gusset PDFmuralihare100% (1)

- Failure Analysis and Redesign of The BucDocument13 pagesFailure Analysis and Redesign of The BuckaustavNo ratings yet

- Manufacturing Remaining Stresses in Truck Frame Rail's Fatigue Life PredictionDocument10 pagesManufacturing Remaining Stresses in Truck Frame Rail's Fatigue Life Predictionklomps_jrNo ratings yet

- Ejemplo Diseño de Muro SW PDFDocument24 pagesEjemplo Diseño de Muro SW PDFAstrid JustinianiNo ratings yet

- 31 PDFDocument24 pages31 PDFRafael Severo da SilvaNo ratings yet

- BAEK Et Al. Fatigue Life Prediction Based On The Rainflow Cycle Counting Method For The End Beam of A Freight Car BogieDocument7 pagesBAEK Et Al. Fatigue Life Prediction Based On The Rainflow Cycle Counting Method For The End Beam of A Freight Car BogiePPNNo ratings yet

- Design of Beam-ColumnsDocument37 pagesDesign of Beam-Columnssalahaddinsharif100% (1)

- Two Way Slab ExampleDocument14 pagesTwo Way Slab ExampleKryle Dayle VillanuevaNo ratings yet

- Mechanical Engineeering Machine ElementsDocument48 pagesMechanical Engineeering Machine ElementsHüseyinYılmazNo ratings yet

- Spandrel Flexural Design: Technical NoteDocument10 pagesSpandrel Flexural Design: Technical Notetomxxx34No ratings yet

- AASHTO Segmental BridgeDocument96 pagesAASHTO Segmental BridgeDeraman Abdullah100% (1)

- FatigueLife FEA PDFDocument43 pagesFatigueLife FEA PDFAbigail SommersetNo ratings yet

- AISC 360-05 Example 002Document6 pagesAISC 360-05 Example 002Bùi Văn HợpNo ratings yet

- Pushover Analysis of RC Frame Structure Using ETABS 9.7.1Document9 pagesPushover Analysis of RC Frame Structure Using ETABS 9.7.1Skerdi MucoNo ratings yet

- unit 3Document100 pagesunit 3dagimawgchew777No ratings yet

- Stress Analysis On CrankshaftDocument5 pagesStress Analysis On CrankshaftChanduReddyNo ratings yet

- Chap06 Fatigue PDFDocument30 pagesChap06 Fatigue PDFAlex IskandarNo ratings yet

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Advanced Multilevel Converters and Applications in Grid IntegrationFrom EverandAdvanced Multilevel Converters and Applications in Grid IntegrationAli Iftekhar MaswoodNo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- 6 Speed RWD Technician's GuideDocument159 pages6 Speed RWD Technician's GuideMalissa Cole100% (34)

- GM Tech Info 6t70 6l80Document72 pagesGM Tech Info 6t70 6l80matechbta100% (7)

- Automatic Transmission CR-V 2007Document470 pagesAutomatic Transmission CR-V 2007mrosalvo100% (13)

- Img 001Document1 pageImg 001Dadang Lukmanul HakimNo ratings yet

- Listening To 2018-2019Document3 pagesListening To 2018-2019Dadang Lukmanul HakimNo ratings yet

- 01 06 PDFDocument2 pages01 06 PDFDadang Lukmanul HakimNo ratings yet

- ITS Undergraduate 10358 PaperDocument12 pagesITS Undergraduate 10358 PaperDadang Lukmanul HakimNo ratings yet

- 1992-1993 Automatic Transmission Service ManualDocument292 pages1992-1993 Automatic Transmission Service Manualpatrick_boza100% (1)

- MK SRS SystemDocument96 pagesMK SRS SystemDadang Lukmanul HakimNo ratings yet

- Toyota Technician Handbook Chapter on Suspension, Steering and Handling SystemsDocument20 pagesToyota Technician Handbook Chapter on Suspension, Steering and Handling SystemsDadang Lukmanul Hakim100% (1)

- System Allocation: ABS Warning Lamp Right Brake LampDocument5 pagesSystem Allocation: ABS Warning Lamp Right Brake LampDadang Lukmanul HakimNo ratings yet

- Katalog Engine StandDocument21 pagesKatalog Engine StandDadang Lukmanul HakimNo ratings yet

- Tugas EngineDocument2 pagesTugas EngineDadang Lukmanul HakimNo ratings yet

- Mitsubishi Triton 4d56 4m4Document52 pagesMitsubishi Triton 4d56 4m4Ricardo Diaz100% (3)

- Mitsubishi Galant PDFDocument180 pagesMitsubishi Galant PDFDadang Lukmanul HakimNo ratings yet

- Active Reading Strategies: Improving ComprehensionDocument29 pagesActive Reading Strategies: Improving ComprehensionDadang Lukmanul HakimNo ratings yet

- CHGDocument22 pagesCHGDadang Lukmanul Hakim100% (1)

- BPR Supra X 125 PGM-FIDocument88 pagesBPR Supra X 125 PGM-FITorres Nicola100% (11)

- Diesel Engine Operation and Diagnosis: Automotive Technology, Fourth EditionDocument216 pagesDiesel Engine Operation and Diagnosis: Automotive Technology, Fourth EditionDadang Lukmanul HakimNo ratings yet

- Organisasi ManajemenDocument22 pagesOrganisasi ManajemenDadang Lukmanul HakimNo ratings yet

- Accelerator Pedal Release Learning GRAND LIVINADocument1 pageAccelerator Pedal Release Learning GRAND LIVINADadang Lukmanul HakimNo ratings yet

- Toyota 14Document76 pagesToyota 14Dadang Lukmanul HakimNo ratings yet

- Mitsibushi Galant 96 02 Workshop ManualDocument1,218 pagesMitsibushi Galant 96 02 Workshop ManualTaurus Sun Eria89% (9)

- Bosch Diesel Emissions InformationDocument28 pagesBosch Diesel Emissions InformationBarcanescu ConstantinNo ratings yet

- Os6 1Document4 pagesOs6 1Dadang Lukmanul HakimNo ratings yet

- Civil 3D TutorialsDocument840 pagesCivil 3D TutorialsRebecca ZodinpuiiNo ratings yet

- Pemeriksaan: Pro Technician ALTERNATOR OVERHAULDocument7 pagesPemeriksaan: Pro Technician ALTERNATOR OVERHAULDadang Lukmanul HakimNo ratings yet

- Stering AligmentDocument90 pagesStering AligmentDadang Lukmanul HakimNo ratings yet

- Enginesystems Dieselengineanalyst Parte2 130115174627 Phpapp02Document30 pagesEnginesystems Dieselengineanalyst Parte2 130115174627 Phpapp02Dadang Lukmanul Hakim100% (2)

- Sony SCPH-90010 Play Station 2 Slim PS2Document3 pagesSony SCPH-90010 Play Station 2 Slim PS2Ernesto Pereira100% (1)

- Helical Springs and Shear and Moment DiagramDocument25 pagesHelical Springs and Shear and Moment DiagramPoncelito KachupoyNo ratings yet

- Teaching quadratic equationsDocument19 pagesTeaching quadratic equationsSaurabh SharmaNo ratings yet

- Chapter 5.Document44 pagesChapter 5.cabir hacinNo ratings yet

- 20 QTR SupplementDocument38 pages20 QTR SupplementsebastienNo ratings yet

- An Introduction To Conveyor FundamentalsDocument18 pagesAn Introduction To Conveyor Fundamentalscakendri100% (2)

- Intrapartum Assessment LectureDocument9 pagesIntrapartum Assessment LectureErald PaderangaNo ratings yet

- 16th Sep - Pure MathematicsDocument133 pages16th Sep - Pure Mathematicssalem05alnuaimiNo ratings yet

- B737 3 ATA 27 L3 eDocument296 pagesB737 3 ATA 27 L3 eAnonymous afPplXbc100% (2)

- Understanding Vibration Orders and HarmonicsDocument7 pagesUnderstanding Vibration Orders and HarmonicsSantiago MolinaNo ratings yet

- 1st Research ArticleDocument14 pages1st Research ArticleMuhammad RomanNo ratings yet

- Generalised Model For Hydrocyclone Classifiers PDFDocument1 pageGeneralised Model For Hydrocyclone Classifiers PDFMatthew Lowrey100% (1)

- LFS Tutorial 29-01-2010Document53 pagesLFS Tutorial 29-01-2010สุดจัดปลัดบอก.100% (1)

- Determination of Electron AffinitiesDocument35 pagesDetermination of Electron Affinitiesnena100% (1)

- Instruction Manual Fisher 249 Caged Displacer Sensors en 134918Document20 pagesInstruction Manual Fisher 249 Caged Displacer Sensors en 134918Senthil KumarNo ratings yet

- PWD SR Rate of Belagavi 2015-16 PDFDocument483 pagesPWD SR Rate of Belagavi 2015-16 PDFRavindra67% (3)

- R2G Conversation QuestionsDocument4 pagesR2G Conversation QuestionsMileta SandićNo ratings yet

- 2004 Legacy Service Manual Quick Reference Index Transmission SectionDocument64 pages2004 Legacy Service Manual Quick Reference Index Transmission SectionMauricio Exequiel ChavezNo ratings yet

- RCT Appraisal Sheets 2005 EnglishDocument4 pagesRCT Appraisal Sheets 2005 EnglishAmanda SoebadiNo ratings yet

- Homework #19 (Phy 112) SolutionsDocument9 pagesHomework #19 (Phy 112) SolutionsKvn4N6No ratings yet

- Math8 Quarter 2 Module 7Document27 pagesMath8 Quarter 2 Module 7maxene jadeNo ratings yet

- Philips IE33 XMatrix Ecocardiography System Ultrasound MachineDocument16 pagesPhilips IE33 XMatrix Ecocardiography System Ultrasound MachineHAITHM MURSHEDNo ratings yet

- Multipurpose Mechanical Machine Project ReportDocument41 pagesMultipurpose Mechanical Machine Project ReportAbhishek Sharma78% (9)

- Data Management - Exer1Document2 pagesData Management - Exer1ron barceloNo ratings yet

- Stratified Sampling LessonDocument15 pagesStratified Sampling LessonDebbie GriffinNo ratings yet

- Characteristics of Copper Tailings in Direct Simple Shearing - A Critical State ApproachDocument17 pagesCharacteristics of Copper Tailings in Direct Simple Shearing - A Critical State Approachgabriela.p.alfaro.aNo ratings yet

- Spring Security Saml ReferenceDocument36 pagesSpring Security Saml ReferenceebazzanaNo ratings yet

- PROPER MAINTENANCE OF CRUCIBLE FURNACESDocument3 pagesPROPER MAINTENANCE OF CRUCIBLE FURNACEScarrialdiNo ratings yet

- Mod 3 Exam Jun 2015Document1 pageMod 3 Exam Jun 2015PrathameshSagareNo ratings yet

- Re-Usable Big Data Tools & Some Factory Use CasesDocument17 pagesRe-Usable Big Data Tools & Some Factory Use CasesSaikat ChatterjeeNo ratings yet